The Su-9 interceptor, created in the second half of the 50s, became the first Soviet aircraft with a delta wing. The fighter was the first in the world designed to carry out comprehensive interception of air targets. The vehicle was intended to combat high-altitude reconnaissance aircraft, which were actively used by NATO countries in those years.

Despite the fact that the Su-9 aircraft has won several records for speed and flight altitude, it has proven to be difficult to operate. There were especially many complaints about the power plant. Because of this, its life was short-lived - already in the mid-70s, the aircraft was supplanted by more modern MiG-23 and Su-15 aircraft.

History of creation

In the early 50s of the last century, the Mikoyan Design Bureau became the locomotive of fighter aviation in the USSR, the developments of which were produced or prepared for production at several aircraft factories. Therefore, the appointment in the spring of 1953 of P.O. Sukhoi to the position of head of the OKB-1 design bureau was perceived by many as an ordinary personnel reshuffle.

However, the new chief designer systematically sought permission to begin work on new aircraft, and already at the end of the year he received at his disposal the premises previously belonging to the Mikoyan Design Bureau, located on the outskirts of Khodynskoe Field.

It was there that work began on a new fighter-interceptor under the designation T-3 (or “product 81”), equipped with a delta wing. The project included the installation of an AL-7F engine and an onboard radar installed in the forward fuselage.

A prototype of the aircraft was assembled by the end of 1955.

Flight tests lasted a year and a half and showed the correctness of the chosen concept, although it was not possible to achieve all the requirements of the technical specifications. At the same time, a backup aircraft was built under the designation PT-7, on which some errors were corrected.

In the series, the aircraft received the designation PT-8, but in mid-1956 a decree of the USSR Government was issued, according to which it was necessary to create an interceptor with a service ceiling of 21,000 m, capable of fighting U-2 reconnaissance vehicles.

To achieve the required parameters, it was planned to use a forced version of the AL-7F-1 engine, which had increased dimensions.

A modified version of the aircraft, built on the basis of the PT-8, received the designation T-43. It featured a symmetrical nose air intake with an adjustment cone. The car was built in the summer of 1957, but it stood for several months waiting for an engine.

The very first flights showed that the interceptor met the mission requirements in terms of speed and flight altitude.

Further work began to be carried out in order to determine the installation location of the on-board radar. At this stage, the T-47 project appears, equipped with an enlarged cone. But at the same time, a new radar TsD-30 appeared, the dimensions of which made it possible to get by with a standard cone from the T-43.

In the spring of 1958, another decree was issued on the creation of an air defense complex, which included an interceptor that worked in conjunction with ground guidance and control stations. The vehicle, modified to meet new requirements, entered state tests, which began at the end of the year and continued until the spring of 1960. During testing, the design of the interceptor continues to change, for example, the working stroke of the adjusting cone is increased and an electromechanical drive of the unit is introduced.

During testing, one of the experimental aircraft crashes; the causes of the disaster could not be determined. In general, the tests are considered successful, and the vehicle is designated Su-9, and the entire air defense complex is designated Su-9-51. In July 1961, the new interceptor was shown during the air parade in Tushino.

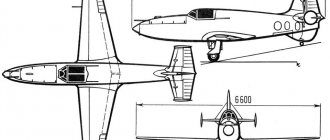

Characteristics of the Su-9 aircraft

Below are the characteristics of the Su-9 fighter:

- wingspan - 8.54 m;

- fuselage length – 18.06 m;

- height – 4.82 m;

- wing area – 34 sq. m;

- weight max. take-off – 12512;

- fuel mass – 3100-3720 kg

- engine - TRDF AL-7F-1–100U;

- engine thrust in afterburner – 9600 kgf;

- Max. speed – 2120 km/h;

- practical range - 1800 km;

- Max. rate of climb – 12000 m/min;

- practical ceiling – 20,000;

- crew – 1 person.

Design

The fuselage of the Su-9 interceptor is built according to a semi-monocoque design based on a power set of frames connected to each other by stringers. The design uses various aluminum alloys, some of the elements are made of high-strength steels. Along the length, the fuselage section changes in shape and size. Structurally, the assembly was divided into two sections - tail and bow (or head).

A special bolted connector was used for the connection. The forward part of the fuselage contained the forward compartment of the airborne radar, behind which there was a pressurized cabin for the pilot. Behind the cab is a rear compartment designed to install the engine, equipment and part of the fuel tanks.

In the front part of the nose section of the Su-9 there is an annular air intake with a channel symmetrical relative to the axis. A controlled cone is installed in the center, and four additional adjustable flaps are installed, which reduce the likelihood of power plant surge. When flying at subsonic speeds, the cone is in the maximum retracted position.

After the interceptor accelerates to the speed of sound and above, a smooth adjustment of the position of the unit begins, which smoothes out pressure surges in the air intake channel.

The actuators of the air intake mechanisms of the Su-9 interceptor are electrically and hydraulically controlled. The pressurized cabin installed on the bow section divides the air channel into two symmetrical parts, which are connected behind it into a common pipeline.

The Su-9 interceptor's turbojet engine is installed in the rear fuselage. The tail section contains an extension channel for the afterburner of the power plant. Additionally, a titanium partition is installed, which serves as a fire barrier. The third tank of the aircraft's fuselage fuel system is installed along the lower edge and there is a cavity for stowing a braking parachute (model PT-7 or PTZ-7B). Four hydraulic brake flaps are installed on the outer surface.

At the end of the tail section there is a power frame for mounting vertical and horizontal tails. The tail unit is equipped with a working skin made of aluminum sheets. At the tip of the fin of the Su-9 interceptor there is a fiberglass insert with an on-board radio antenna.

The rudder is made in the form of a single part and is equipped with a weight balancer. The horizontal tail is swept along the leading edge, the elevators are equipped with special weights that reduce the likelihood of vibrations in flight (flutter).

The Su-9 pilot's cockpit is covered with a canopy equipped with a bullet-resistant windshield made of silicate-based material. The rear part of the lamp is sliding, made of heat-resistant organic glass. The instrument panels are backlit with red lamps; early cars used ultraviolet lighting.

The flight equipment of the Su-9 interceptor included a gyrocompass (on later machines - a heading system), an attitude indicator, an altimeter, speed and turn indicators, as well as additional equipment. To communicate with the ground and other aircraft, a VHF radio station and a high-altitude communication system were used. In addition, there was a radio compass on board, a blind landing system based on radar data, an aircraft identification system and other equipment.

The cabin of the Su-9 interceptor has an air conditioning and heating system powered by air taken from the turbojet engine compressor. An oxygen device is installed in the cockpit to ensure the pilot’s performance when flying at high altitudes. Additionally, the pilot wore a high-altitude suit equipped with a pressure helmet.

The aircraft controls are equipped with boosters with an irreversible operating pattern. Rigid rods and cables are used in the drives to the controlled planes. Additionally, spring aerodynamic loading simulators are installed. The Su-9 flaps are equipped with hydraulic cylinders; in later series they were changed to pneumatic actuators.

For emergency escape from the cabin of the Su-9 interceptor, an ejection seat is used. Early and late aircraft used different models, differing in the maximum speed at which ejection was possible.

The Su-9 interceptor uses a delta wing with a constant sweep along the leading edge at an angle of 60⁰. The wing's load-bearing frame consists of two spars and three beams, fastened with ribs and stringers. Each wing is divided into five compartments. In the front compartment there is a fuel tank, which in early production of the Su-9 was used to mount cannon weapons. Another fuel tank was located in a compartment along the trailing edge of the wing.

The wing structure had niches for the main landing gear, located between the beams. On the outer surface there was mechanization, which included a flap and aileron, equipped with an aerodynamic and weight compensator. On the lower plane of the wing there were points for mounting two pylons, which served as supports for missile weapons or additional tanks.

The Su-9 interceptor uses a three-legged chassis with a forward-mounted steering column. The rack is installed on the bow section under the pressurized cockpit; the unit is retracted forward during flight. The strut design has a special damper that eliminates the wobbling effect at high speed, as well as a special headlight to illuminate the runway.

Additional lighting was provided by retractable headlights installed in the wing consoles. The main struts located on the wings are retracted towards the fuselage. The design of the struts uses a lever suspension with a double-acting hydropneumatic shock absorber.

The nose wheel of early Su-9 aircraft is not equipped with a braking mechanism; the aircraft is slowed down during landing by the wheels of the main landing gear. Later, a chamber brake was introduced on the front strut and disc brake mechanisms with hydraulic and pneumatic (reserve) control on the main struts. The brake discs are made of a composite material based on ceramics and metal. To reduce the interceptor's range, a braking parachute is used.

The power plant is a turbojet engine of the AL-7F1 series, equipped with an afterburner. Depending on the time of manufacture of the Su-9 interceptor, engines with different overhaul times were installed. The turbine was started by a separate small-sized turbine running on gasoline.

Control of engine systems in nominal mode is cable, activation of the afterburner is electric. The engine of the Su-9 interceptor is equipped with heat-insulating shields and a special fire extinguisher equipped with a spray manifold connected to fire hazardous points of the power plant. Information about a fire is sent to the instrument panel in the pilot's cabin using special sensors.

Aviation kerosene is used as engine fuel. The fuel supply on board the early production aircraft was 3060 liters. After the introduction of two additional wing tanks, the volume of kerosene reached 3780 liters. Additionally, the Su-9 interceptor could carry two tanks under the wings, which could hold 1200 liters of fuel.

The onboard hydraulic system of the Su-9 interceptor included three lines - the main, booster and reserve (to power the amplifiers).

Each system is connected to an individual pump installed on the aircraft engine. The backup system has an additional electrically driven pump.

Working pressure in systems is 210 ks/cm². A pneumatic system is installed on board the aircraft, divided into the main and reserve lines. A pneumatic drive is used to seal the canopy and emergency release of the landing gear. The Su-9 uses nitrogen under a pressure of 150 ks/cm² in three cylinders as the working gas.

Renewal of the nitrogen supply is possible only from the airfield network.

The turbine of the Su-9 aircraft is equipped with direct and alternating current generators. An additional source of electricity was a battery. The interceptor's electrical system contains voltage converters that generate single-phase and three-phase current with a stabilized frequency.

The early version of the Su-9 interceptor was armed with four RS-2US air-to-air missiles, guided by a radio signal. Later, R-55 missiles equipped with thermal homing heads were introduced into the armament. There have been cases of the use of K-5MS missiles. An airborne radar station was used to detect targets; there was a movie camera on board that recorded the results of missile launches. The weapons control system allowed for single or salvo fire.

There was no cannon armament on production aircraft, but in the early 70s, tests were carried out on the UPK-23-250 container installed under the wing instead of an external tank. The second tank was also dismantled. The container contained a double-barreled 23-mm GSh-23 cannon and an ammunition load of 250 shells.

The tests were successful, but the installation on the Su-9 interceptor was not widely used due to the reduction in flight range. A comparison of the technical characteristics of the Su-9 with foreign analogues shows that the domestic machine was distinguished by its minimal weight and wingspan. At the same time, the range of action is minimal for the Su-9.

| Take-off weight, kg | 12515 | 18915 | 14187 |

| Flight speed, km/h | 2230 | 2415 | 1387 |

| Ceiling, m | 20000 | 18915 | 16093 |

| Radius, km | 450 | 600 | 1048 |

The English interceptor was equipped with two Rolls-Royce turbojet engines and had onboard cannon armament, but only two missile hardpoints. The American plane was not equipped with small arms, carried up to six missiles, but developed a low flight speed.

Modifications

The base vehicle was the Su-9 interceptor (NATO code Fishpot), produced in quantities of more than 1,100 copies. All built aircraft entered service with the aviation units of the USSR; no deliveries were made to the Warsaw Pact countries. The cars were produced in series, which had minor differences among themselves.

Assembly was carried out at aircraft factories in Moscow and Novosibirsk. Early production vehicles that had differences were either written off by 1961 or modified to a later version.

Based on the serial interceptor, the Su-9U two-seat training aircraft was produced in small batches, retaining the layout of the Su-9. On board the vehicle, weapons, guidance and launch equipment were stored at two workstations.

The aircraft was fully suitable for combat operations, the instructor's cabin was located in a special extension insert in the fuselage, and the fuel supply on board was not changed. According to NATO classification, the training interceptor was designated Maiden. A total of 50 copies of the Su-9U were assembled.

In the second half of the 60s, tests were carried out on a bomber version of the aircraft, which received the semi-official designation Su-9B. Two high-explosive bombs weighing 250 kg each were suspended on pylons instead of a pair of missiles. The vehicles retained the suspension of two fuel tanks and two RS-2US missiles. Conversion could be carried out in the field.

One step away from the fifth generation: young heirs of the Su-27

Since 1984, when serial production of the “twenty-seventh” began, about 1,500 aircraft of this type, including its modifications, have been produced. On its basis, such machines as the multifunctional two-seat fighter Su-30MK, the ship-based Su-33 aircraft, the two-seat attack aircraft Su-34, and the multifunctional single-seat fighter Su-35S were created.

These machines are one step away from the fifth generation of fighters and belong to the so-called “4+” generation. First of all, this is a breakthrough in the field of super-maneuverability. It began in the mid-1990s, when dryers began to be equipped with engines with thrust vector control. New engines, combined with a new control system, have significantly simplified the aircraft's piloting and increased its safety. The problems of “spin” and stalling were overcome.

Su-30SM aircraft

The multirole fighter Su-30MK fully possesses these qualities. The aircraft was originally designed for the Indian Air Force; mass production of these aircraft began in 2000. Based on the basic version, several new modifications were created: Su-30MKM for the Malaysian Air Force, Su-30MKI(A) for the Algerian Air Force. The Su-30SM (serial, modernized) is currently being actively supplied to the Russian Aerospace Forces. In 2016, the Russian Knights switched to these fighters.

The youngest successors of the Su-27 - the multirole fighter Su-35 and the fighter-bomber Su-34 - in their characteristics practically correspond to the fifth generation of aviation. The Su-35 is equipped with the latest Irbis radar and AL-41F1S engines, which are more powerful than those on the Su-30SM.

The Su-34 bomber can attack targets in any weather conditions, and also effectively conduct electronic warfare. These machines are distinguished by a cockpit that is unusual for a dryer. To increase crew comfort during long-distance flights, it was decided to seat the pilots nearby.

Service and combat use

The first deliveries of Su-9 interceptors began back in 1959, when 150 vehicles were delivered to units located in the border regions of the USSR. Among them were Baranovichi, Krasnovodsk, Kilpyavr and a number of other settlements.

The vehicles were delivered to the location under their own power. At first, the operation of the machines was difficult due to the short life of the power plant, which did not exceed 50 hours. There were also complaints about the launch system, which did not work satisfactorily at low air temperatures.

The identified deficiencies were promptly eliminated, the saturation of flight units proceeded at a rapid pace, and by the mid-60s, Su-9 interceptors were available in several dozen air defense regiments. But the number of accidents remained high. The reason was problems with the power plant and violations of the rules of operation and maintenance of equipment.

In the early 60s, Su-9 interceptors were used to combat American Lockheed U-2 reconnaissance aircraft. One of the episodes was an attempt to ram Francis Powers' car. There was also a case of interception in the late 60s of a pair of Iranian fighters violating the airspace of the Soviet Union.

The attack by Soviet aircraft ended in vain. Later, interceptors were used to combat balloons carrying automatic reconnaissance stations. Enemy aircraft flew at an altitude of 24-26 km, inaccessible to aircraft. For destruction, missiles launched while flying at the maximum ceiling were used. Su-9 interceptors were used until the mid-60s to patrol the Baikonur Cosmodrome.

Production of Su-9 vehicles ceased already in 1962 due to the start of assembly of an improved version under the designation Su-11. And 10 years later, the displacement of vehicles from combat lists began, which proceeded at the same rapid pace as the introduction. Decommissioned vehicles were transported to storage depots, where they gradually deteriorated and were dismantled for scrap. Some of the planes were used as targets and training aids.

As a result, only two Su-9 interceptors have survived to this day in museum condition. A dozen more cars have been preserved in the form of monuments installed in different cities of the former USSR.

Before the MiG-25 entered service, the Su-9 aircraft remained the fastest Soviet interceptors. The opinions of pilots and aviation historians about this aircraft are extremely contradictory. The reason for the negative reviews was the numerous flight accidents and disasters that accompanied the interceptor throughout its service life.

Other pilots remember the Su-9 fondly, considering it much better to fly and operate than the MiG-19S. In any case, the Sukhoi Design Bureau aircraft became a pioneer in many areas of the military aviation industry and the ancestor of modern Russian interceptors.

Links[edit]

- [1]

- MIchael Holm, https://www.ww2.dk/new/air%20force/regiment/iap/894iap.htm, accessed December 2012.

- ↑

Antonov, Vladimir;

Gordon, Efim; Gordyukov Nikolay; Yakovlev, Vladimir; Zenkin, Vyacheslav; Carruth, Lenox; Miller, Jay (1996). Sukhoi Design Bureau: history of the design bureau and its aircraft

(1st ed.). Earl Shilton: Midland Publishing. pp. 110–128. ISBN 9781857800128. - www.3ebra.com, Zebra IT Bureau -. "Sukhoi Company (JSC) - Aircraft - Museum - Su-9, 11, 13 - Technical characteristics". www.sukhoi.org

. Archived from the original on 2017-09-25. Retrieved September 25, 2022.