The history of the F-86 began in the fall of 1944 with the North American project NA-134, which was intended for carrier-based fleet aviation. The war was coming to an end, and the sailors wanted to have several types of jet fighters at their disposal. They were to gain air superiority during the invasion of Japan, planned for May 1946. The NA-134 had a straight, low wing and a short, barrel-shaped fuselage. The TG-180 turbojet engine with a thrust of 1820 kg provided a fighter weighing 6532 kg with a maximum flight speed of 872 km/h. In addition, the “134” had a rate of climb at sea level of 23.8 m/s, and its service ceiling reached 14,500 m. With such characteristics, the machine became a very formidable opponent for Japanese aircraft. Even one of the best American fighters of that time, the P-51D Mustang, was inferior to it in all characteristics. The maximum speed of the Mustang was 703 km/h, the ceiling was slightly more than 12,700 m, and the rate of climb of this piston machine barely reached 18 m/s. In the spring of 1945, the Navy ordered 100 production NA-134 jets under the designation FJ-1 Fury.

F-86F in flight

Almost simultaneously with the start of design of the NA-134, the Air Force issued requirements for a day fighter that could be used as an escort fighter or a dive bomber. The requirements stated that it must reach a speed of at least 965 km/h. This value was determined from the desire to surpass the similar indicators of the P-80A and XP-84 aircraft, whose speed was 898 and 945 km/h, respectively, and to get closer to the world record of that time - 975.67 km/h of the British Meteor fighter (see “ NiT" No. 3 and No. 4 for 2006).

North American almost immediately offered the military the NA-140 project with the required technical characteristics. In reality, it was the XFJ-1 fighter with some modifications. The explanatory note submitted on November 22, 1944 indicated that specialists examined 1,265 different schemes and, based on this analysis, the engineers managed to achieve the required results.

Impressed by the depth of study of the issue, on May 18, 1945, the Air Force ordered three experimental models of the NA-140 from the company. The aircraft were given the designation XP-86. The construction of the model was soon completed, which was approved on June 20, 1945.

The main differences between the NA-134 and the NA-140 were the shape of the fuselage, which received a more elongated shape, and the wing profile. The shape of the frontal air intake has changed slightly. The tail was carried over to the new model without external changes. However, the project was distinguished by several features that had not previously been used in American fighters: a pressurized cabin and boosters in the pitch and roll control channels. Regarding weapons, we can say that the designers paid more attention to shooting accuracy than to the power of on-board weapons. Six M-3 heavy machine guns with 267 rounds of ammunition per barrel were considered sufficient, but an A-1B universal sight was installed in the cockpit, working in conjunction with the AN/APG-5 radar rangefinder. Eight unguided rockets or grenade launchers could be hung under the wing.

The detailed development of the project raised many questions for the engineers. The main one was the question of achieving a given speed. Despite the fact that by changing the wing profile and reducing its thickness relative to the chord, it was possible to slightly push back the critical Mach number, the maximum speed of the XP-86 was estimated by aerodynamicists at only 923.6 km/h at sea level and 936.4 km/h h at an altitude of 3048 m. The threat of closure hangs over the project.

Two experimental aircraft XF-86A and XB-45A in a joint flight

At this time, the Americans were intensively collecting military-technical information on the territory of defeated Germany. Special teams consisting of military personnel and representatives of interested companies “combed” German factories, research organizations and testing grounds. Aeronautical advances were carried out by the US Army Scientific Advisory Group, headed by the famous aerodynamicist Theodore von Kármán. All found documents and equipment were exported to America. German sympathizers helped the Americans in this. There was so much documentation that we simply didn’t have time to translate it. It was Karman's group that discovered documents on the use of swept wings to combat the effect of air compressibility and to increase the speed of advanced aircraft. These papers were immediately used by several aviation companies. Among them were such authorities as Boeing, Vought and, of course, North American.

The results of these “discoveries” were not long in coming, and in August 1945, aerodynamicist Raymond Rice proposed to blow the XP-86 model with a new swept wing. The purges, which began in September, immediately showed a decrease in drag and an increase in maximum flight speed. The problem with aircraft stability at low speeds was solved by installing slats. In October, the company reported to the military that all difficulties had been overcome and showed them the new aircraft. On November 1, 1945, the Air Force approved the prototype and its 35° swept wing with an aspect ratio of 6. Additional stability studies carried out in early 1946 forced the latter figure to be reduced to 4.97.

The transition to a swept wing delayed the construction of the XP-86 prototype. When the deck-based XFI-1 had already taken off, its “land brother” had not yet left the prototyping stage. Drawings of the new aircraft were sent to the plant in August 1946.

Just at this time, tests began on the Republic XP-84 fighter, which demonstrated excellent speed characteristics, although it had a traditional straight wing. On September 7, the XP-84 sets a speed record for the United States - 977.6 km/h. The Air Force command showed great interest in the speedy construction of the XP-86 aircraft for comparison with its competitor, because it was necessary to decide on the number of aircraft to be purchased, and no one wanted to spend money on an obviously inferior aircraft. Moreover, Congress was not going to give much money. The war ended long ago, military programs began to be cut, and in order to support aviation companies in difficult times, they decided to buy “a little bit” from everyone. Only nuclear weapons carriers were considered priority programs.

On December 20, 1946, North American received an official letter with an order for 33 production aircraft. The first fighter (s/n 45-59507) rolled out of the assembly shop at the Inglewood plant on August 8, 1947. It was powered by a J35-C-3 turbojet engine with a thrust of 1820 kg. No weapons have been installed on it yet. After taxiing tests, the vehicle was dismantled and transported to Muroc airbase. The FJ-1 had been flying there for seven months. Now he looked more like a grandfather than a brother, but sailors with their tiny aircraft carrier decks could only dream of swept wings for now. The first carrier-based aircraft with swept wings, the F7U, has already been drawn up, but it will only be built in a year.

Training TF-86

On October 1, 1947, test pilot George Welch took the XP-86 into the air. The flight was going well until it was time to land. The front landing gear did not come out completely. For forty minutes the pilot tried to put the strut into the extended position using overloads, but to no avail. The fuel was running out, and Welch decided to land the faulty car. The impact of the main landing gear on the runway caused the nose gear to lock, and the flight ended safely. In this flight, the fighter accelerated to 1046 km/h. Excellent visibility from the teardrop-shaped canopy and low noise level left a favorable impression, but the thrust of the J35 engine did not allow achieving the required rate of climb. However, the designers were not worried about this, planning to use the new J47 engines with higher thrust on production aircraft.

On October 16, 1947, the Air Force signed a contract for the production of 33 R-86A and 190-R-86B aircraft with increased wheel tire sizes for deployment at unprepared airfields.

After the landing gear malfunction was eliminated, flight tests continued. During several high-speed dives, Welch reported that he encountered unusual vibrations in the airspeed and altitude indicator needles. Experts suggested that the plane exceeded the speed of sound, but there was no complete certainty about this. The instruments were not designed for such a speed, and no special measurements were taken from the ground. After Chuck Yeager's famous supersonic flight in the X-1 experimental aircraft, rumors of this secret achievement reached North American test pilots and they persuaded the NACA people to monitor the flight of the XP-86 using their ground equipment. On October 19, 1947, five days after the X-1 flight, the NACA ground tracking station reported that George Welch was flying at Mach 1.02. On the twenty-first, the result of the record-breaking flight of the XP-86 was repeated.

It was only in May 1948 that the achievements of the XP-86 were made public. The official report referred to George Welch's record-breaking flight on April 26, 1948, when he exceeded the speed of sound in a dive. In fact, there was a British pilot in the cockpit of the XP-86, who inadvertently reported over an open radio channel about exceeding the speed of M=1. Indeed, the XP-86 could exceed the speed of sound in a dive, showing quite satisfactory controllability at high altitudes with a slight tendency to pitch up. However, at an altitude below 7620 m, the aircraft sought to enter into rotation relative to the longitudinal axis and the speed had to be reduced. On production aircraft, for reasons of flight safety, below this altitude the speed was limited to M = 0.95.

Laying cartridge strips in boxes. In the foreground is a cart with an M117 bomb.

On November 30, 1948, a prototype of the new fighter was presented to the US Air Force command. Five months earlier, the Air Force abandoned the letter “P” in the designation of fighters, moving to a new one - “F”, thus, the military became acquainted with the machine - the XF-86.

Soon the second and third prototypes (s/n 45-59598 and 45-59599) joined the flight test program. They were distinguished by the presence of a warning system for impending stall, fully equipped radio navigation systems and hydraulic drives for the slat release system. Both vehicles lacked a ventral aerodynamic brake, which was replaced by two plates on the sides of the fuselage.

The third aircraft had fully automatic slats, released at a speed of 217.2 km/h, and built-in small arms. Six M3 heavy machine guns with a rate of fire of 1,100 rounds per minute and with ammunition of 300 rounds each were located on the sides of the forward fuselage.

To improve aerodynamics, the machine gun ports were closed with rectangular covers, which automatically opened after pressing the trigger. Aiming was carried out using a Mk.18 gyroscopic sight, with manual corrections. The cartridge boxes were located in the lower part of the fuselage, and the flap to access them was used by the pilots as a footrest when boarding the cockpit. Two 938.7 liter fuel tanks, a pair of 454 kg bombs, or four unguided HVAR missiles could be suspended under the wings.

These two prototypes flew until the spring of 1953, and the first copy crashed in September 1952, having flown 241 hours.

History of the development of the F-86 Saber fighter

At the end of 1944, by order of the US Navy, under the leadership of R. Rice, the development of a jet fighter for the needs of the army and navy began under the designations NA-134 and NA-140, respectively.

On January 1, 1945, the company received an order from the Navy for 3 prototypes NA-134 under the designation XFJ-1, and on May 18 of the same year - for the construction of three prototypes according to the “army” project NA-140, under the designation FJ-1 (XP-86 ) , with an agreement to pre-order hundreds of new aircraft at once, if successful.

Both versions of the XP-86 - both naval and army - had almost the same design and were designed for the same engine: the General Electric J36 turbojet. The differences were mainly that the former NA-134 had a thicker wing profile, while the former NA-140 had a longer fuselage.

On June 20, 1945, a mock-up commission on the XP-86 was held, with the model of the aircraft being purged in a wind tunnel. The result was depressing - the plane never managed to get close to the cherished speed of 960 km/h, declared by the designers.

The American advanced jet fighter project was under threat of closure, but unexpected help arrived in time. Having studied documents on promising combat aircraft exported from Germany (in particular, the Me-262 ), experts decided to change the design of the future Saber.

The NA-140 prototype was urgently converted to a swept wing, and on November 1, 1945, it began a series of wind tunnel tests designed to clarify the parameters of the new wing.

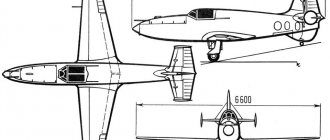

Drawing of the F-86 Saber fighter

Only two years later, on October 1, 1947, the XP-86 aircraft took to the skies for the first time (test pilot J. Wilch), and on October 16, the US Air Force ordered 33 P-86A aircraft and made a preliminary request for another 190 P-86B.

The first production Sabers were assembled at the Inglewood plant in May 1948, and in June 1948 the aircraft received a new designation - F-86 . The fighter was put into service in 1949, and at the same time received its own name: F-86 “Sabre” (“Saber”, “Sabre”). It was the F-86 Saber that became the first full-fledged jet fighter adopted by the United States.

Like its main opponent, the Soviet MiG-15 fighter , the Saber had a long way to go, being repeatedly modernized and improved. The first fighter of the “Western world” to break the sound barrier, the F-86 had quite a few titles and achievements during its career, including several speed records of its time.

The aircraft was manufactured in the USA in Inglewood and Columbus. The F-86 was also produced under license in Australia, Canada, Japan and Italy, becoming the main instrument of air warfare for the United States and its allies for a long time. A total of 9,860 F-86 Saber fighters were produced.

F-86 Saber and MiG-15

RF-86A

The Korean War showed the need to have a high-speed photo reconnaissance aircraft at the disposal of the Air Force command. The RB-45C and RF-80A used for these purposes could not operate in the MiG Alley area without fighter cover. The first to take the initiative were several pilots of the 67th Tactical Reconnaissance Wing, stationed at Kimpo Air Base. They asked permission to convert several F-86A fighters into reconnaissance aircraft. The pilots' proposal received the support of the command. The project was called Honey bucket - Sweet deception. For the conversion, the Air Force command allocated two F-86A (s/n 48-187 and 48-217), which were transported to Tachikawa Air Base in Japan.

The engineers faced a difficult task. There was practically no free space in the fuselage of the fighter to accommodate cameras. We had to remove the lower pair of machine guns from the left side of the aircraft. This made it possible to place the K-25 camera from the RB-26C reconnaissance aircraft. The camera was installed horizontally, but thanks to a system of mirrors, it was possible to shoot vertically through a window that opened in flight.

F-86F against the background of a B-29 bomber

The first improvised F-86A reconnaissance aircraft were transported to Kimpo Air Base in October 1951. The aircraft made their first combat missions at the end of the month. For insurance, they were accompanied in the air by four F-86A fighters.

At the end of 1951, six more F-86As were converted into reconnaissance aircraft. This program was called Ash-tray - Ashtray. The photographic equipment compartment was enlarged to accommodate one K-11 camera and two K-24 cameras. To improve the operating conditions of photographic equipment, the compartment was equipped with an air conditioning and heating system. This reconnaissance version of the Saber has already received the official designation RF-86A. It differed from the fighter by the presence of two convex fairings for the photographic equipment compartment. On some RF-86A, another additional K-14 camera was installed on top of the nose compartment in place of the radar. Most RF-86As had their weapons completely removed. Five RF-86A aircraft became part of the 15th Squadron of the 67th Airlift Wing.

F-86 making a turn

When performing combat missions, the new reconnaissance aircraft was able to evade combat with MiGs and carry out reconnaissance in the most dangerous areas in which the use of other aircraft was risky. True, the quality of the photographs obtained from the RF-86A was considered low (due to unusually high flight speeds and vibrations of the reflecting mirrors, the photographs were blurry). By changing the installation of mirrors and replacing cameras with faster K-14 ones, we managed to achieve the required quality of pictures. In total, 11 F-86A fighters were converted into reconnaissance aircraft.

Service and use of the F-86 Saber fighter

The F-86 Saber's record of combat victories was opened on December 17, 1950, when it was shot down by a Chinese MiG-15 over Korean territory. And on December 22, 1950, the account of defeats was opened - this time the MiG overtook the Saber. In the fights of this pair - MiG-Saber, the score was always approximately equal (adjusted for the higher quality of training of American pilots, compared to the Chinese and Korean ones). In just a few years of war on the Korean Peninsula, both sides brought the tally of victories and losses to hundreds of aircraft.

The Korean War became the main one for the F-86 Saber. After its completion, the F-86 began to be massively exported and sold to third countries - by this time the United States was adopting much more advanced vehicles (since 1958, Sabers began to be gradually withdrawn from the Air Force). However, they served in the US National Guard until September 1970, and in the hands of US allies they took part in a whole galaxy of military conflicts in different parts of the planet (including the Sino-Thai military conflict of 1958, the war between Honduras and El Salvador in 1969, Indo-Pakistani war of 1971).

The F-86 Saber remained in service with the Bolivian Air Force for the longest time - the last aircraft there was decommissioned in 1993.

Over the years, in various modifications, Sabers were exported to: Australia, Argentina, Bangladesh, Belgium, Bolivia, Great Britain, Venezuela, Holland, Honduras, Greece, Denmark, Indonesia, Iraq, Spain, Italy, Canada, Malaya, Norway, Pakistan, Peru, Portugal, Saudi Arabia, Thailand, Taiwan, Tunisia, Turkey, Philippines, France, Germany, Ethiopia, South Africa, Yugoslavia, South Korea, Japan.

F-86E

The next production version of the Saber fighter was the F-86E modification. Work on this version of the aircraft began on November 15, 1949. The fighter received the corporate designation NA-170. The contract for the construction of 111 new vehicles, under the designation P-86E, was completed on January 17, 1950.

The F-86E featured an all-moving stabilizer, unlike the adjustable stabilizer on the F-86A. The new stabilizer improved the aircraft's pitch control at transonic flight speeds. On the F-86A, the stabilizer was repositioned electrically. A hydraulic stabilizer rotation system was installed on the F-86E, and the power cylinder of the mechanism was covered with a characteristic elongated convex fairing.

The aircraft's equipment has also undergone changes. The combination of the A-1SM sight with the AN/APG-Z0 radar, which appeared on 24 F-86A-5 aircraft, has now become standard for the F-86E. In addition, the thrust of the J47-GE-13 engine installed on the aircraft was increased to 2474.3 kg.

The first F-86E (s/n 50-0579) took flight on September 23, 1950. The flights showed that installing an all-moving stabilizer on the aircraft made it possible to steadily recover the aircraft from a dive at high speeds, which subsequently saved the lives of many pilots. The first of 60 F-86E-1s rolled out of the assembly shop in February 1951. In the spring of 1951, the 33rd Fighter Wing, stationed at Otis Air Force Base, Massachusetts, received new aircraft.

In July of the same year, a batch of F-86Es was delivered to Korea and transferred to staff units of the 4th Fighter Wing, which suffered significant losses during battles with MiGs. The F-86A of the first series, which were damaged in air battles, were also subject to replacement. True, the replacement of the F-86A was slow, and the last of them was removed from the front only in July 1952. From Korea, F-86As, after repairs, were sent to staff units of the National Guard.

A total of 369 F-86Es were produced.

Characteristics of the F-86 Saber

A country:USAType:FighterYear of issue:1948Crew:1 personEngine:1x J47-GE-27 thrust 2683 kgfMaximum speed:1112 km/h (at altitude), 958 km/h (at ground level)Practical ceiling:14640 mRange of flight:2120 km (fertilization, practical - about 750 km).Empty weight:4945 kgMaximum take-off weight:9300 kg (normal takeoff - 6900 kg)Wingspan:11.32 mLength:11.45 mHeight:4.5 mWing area:26.78 sq.m.Weapons:6x 13.7 mm machine guns or 4x 20 mm cannons, up to 900 kg bomb load on two external nodes

Characteristics are given for the F-86F-30 Saber model

F-86F

The main production version of the Saber is considered to be the F-86F modification. The main difference between the aircraft and previous versions was the installation of a new J47-GE-27 engine with a capacity of 2683.1 kg.

North American began designing a new aircraft on July 31, 1950. According to the company's designation system, the car was designated NA-172. Serial production of the aircraft was planned to begin in October 1950, but the deadlines were not met due to delays in the supply of J47-GE-27 engines. For this reason, the first 132 aircraft of the NA-172 project had to be equipped with less powerful GE-13 engines. These vehicles were designated F-86E-10 and were produced from September 1951 to April 1952. The F-86E-10 differed from the original version in its flat armored windshield, which replaced the convex armored glass found on the F-86A and F-86E.

In the spring of 1952, deliveries of J47-GE-27 engines resumed, and on March 19, the first of 78 F-86F-1s (s/n51-2850) rolled out of the assembly shop. By July 1952, F-86F-1s were already in service with the 84th Squadron and began arriving at the 51st Fighter Wing based in Korea. The 4th Wing received the first F-86F-1s in September.

F-86s arrived in Japan aboard an aircraft carrier

Having the same weight as the F-86E-10 but having a more powerful engine, the new modification of the aircraft was significantly different in its better characteristics. The maximum speed of the F-86F increased to 1107.0 km/h at sea level, and to 965.4 km/h at an altitude of 10668 m. The service ceiling was 15849.6 m. The better efficiency of the J7-GE-27 engine made it possible to increase the range fighter up to 692 km. With the entry into battle of the new modification of the Saber, the advantage of the MiG-15 in the practical flight ceiling was eliminated.

In June 1952, a new series was released - the F-86F-5. The model was distinguished by the installation of pylons of greater carrying capacity under the wing. This allowed the use of external fuel tanks with a capacity of up to 757 liters, which increased the radius by 53 km. A total of 16 F-86F-5 fighters were produced.

The next series was the F-86F-10. Its only difference was the installation of a new A-4 automatic sight. The previously used A-1SM sight was characterized by low reliability and difficulty in maintenance.

The design of the F-86 Saber fighter

The American jet fighter F-86 Saber is built according to the aerodynamic design of a cantilever low-wing aircraft with a swept wing (35° along the leading edge). The fuselage structure is all-metal.

The pilot's cabin is sealed, pressurized by the engine compressor. The cockpit is equipped with a North American T-14E ejection seat. The pilot's protection consists of an armored windshield, an armored backrest with an armored headrest made of heterogeneous steel. From the front, the pilot is protected by two armored parts made of duralumin.

The aircraft had a retractable, tricycle landing gear with a nose gear. The on-board equipment included a radar sight, a radio compass, and a “friend or foe” identification system.

The composition of the weapons varied depending on the modification. The aircraft was armed with 12.7 mm machine guns, 20 mm cannons, unguided missiles, and bombs (including tactical nuclear ones). To increase the flight range, up to 4 external fuel tanks could be suspended.

F-86 Saber fighter

Modifications of the F-86 Saber fighter

- XP-86 (NA-140, XF-86) - a prototype without weapons, with a Chevrolet J35-C-3 engine with a thrust of 1816 kgf. First flight October 1, 1947. On April 26, 1948, the sound barrier was broken for the first time in a shallow dive. 3 aircraft were produced.

- XFJ-2 (NA-179) - prototype carrier-based fighter without weapons. It was distinguished by a landing hook, attachments to the catapult, and an extended nose landing gear. There were no weapons. In 1951, 2 aircraft were manufactured.

- XFJ-2B (NA-181) - prototype with 4x 20 mm Colt Mk.12 cannons. In 1951, 1 aircraft was manufactured.

- YF-86D (NA-164, YF-95A) - prototype of the F-86D. It was distinguished by a canopy similar to the F-86A and the lack of weapons. In 1949, 2 aircraft were manufactured. First flight December 27, 1949.

- YF-86K (NA-205) - prototype of the F-86K. In the spring of 1953, 2 aircraft were manufactured. First flight July 15, 1954.

- P-86A (NA-151, F-86A ) - serial fighter. The armament consisted of 6x 12.7 mm machine guns. First flight May 20, 1948. F-86A-1-NA - first series. It was distinguished by a General Electric J47-GE-1 (GE-3, GE-7) engine with a thrust of 2360 kgf, a convex windshield canopy, and automatically closing machine gun ports. In 1948-1949, 33 aircraft were manufactured. All were used for various tests and combat units were not hit.

- F-86A-5-NA - with J47-GE-7 engine. It featured a new canopy, a heating system for the machine gun compartment, and the ability to hang bombs on underwing pylons. Produced in February-September 1949.

- F-86A-5-NA (NA-161) - with a J47-GE-13 engine with a thrust of 2360 kgf. Produced from October 1949 to December 1950.

- F-86A-6-NA - with A-1CM radar sight. 24 aircraft were produced.

- F-86A-7-NA - with the A-1CM sight installed in the troops. Previously produced F-86A-5s were converted.

F-86 Saber

- F-86C (XF-93) - long-range escort fighter (experienced).

- F-86D (NA-165, F-95) - all-weather interceptor with J47-GE-17 engine with afterburner (2270/3020 kgf thrust), AN/APG-36 airborne radar, Hughes E-4 fire control system, all-moving stabilizer, enlarged keel, tilting rear canopy. The armament consisted of 24x 70-mm Mighty Mouse missiles. Produced from spring 1951 to September 1955. Exported to Greece, Denmark, Taiwan, Turkey, Philippines, Yugoslavia, South Korea, Japan. F-86D-1-NA - the first production version. It featured the Hughes E-3 fire control system. In March 1951 - October 1952, 153 aircraft were manufactured.

- F-86D-5-NA - with E-4 fire control system. In the summer of 1952, 26 aircraft were manufactured.

- F-86D-10-NA - with booster control without trimmers. 36 aircraft were manufactured.

- F-86D-15-NA - with single-point fueling system. 54 aircraft were produced.

- F-86D-20-NA (NA-177) - with heated filters in the fuel system. 188 aircraft were manufactured.

- F-86D-25-NA - with external fuel tanks. 88 aircraft were manufactured.

- F-86D-30-NA - with manual rudder and trim tab. 200 aircraft were manufactured.

- F-86D-35-NA (NA-173) - with a radio range finder. Some aircraft were equipped with an afterburner with a ceramic coating. 350 aircraft were produced.

- F-86D-40-NA (NA-190) - with a J47-GE-17B engine with a thrust of 2463/2950 kgf. 300 aircraft were manufactured.

- F-86D-45-NA - with a braking parachute. Later production aircraft were equipped with a J47-GE-33 engine with a thrust of 2500/3473 kgf. In April-July 1954, 309 aircraft were manufactured.

- F-86D-50-NA - modified. 301 aircraft were produced.

- F-86D-55-NA, F-86D-60-NA (NA-201) - the last production version. 624 aircraft were manufactured.

- F-86E-1-NA - the first production version. Produced since February 1951. 60 aircraft were manufactured.

- F-86F-1-NA - the first production version. In March-June 1952, 78 aircraft were manufactured.

- F-86H-1-NH - the first production version. The armament consisted of 4 12.7 mm machine guns. Between September 1953 and May 1954, 112 aircraft were manufactured at the Columbus plant.

F-86G "Saber" - very different from previous models in appearance

- QF-86H - radio-controlled target. The F-86Hs that had served their service life were re-equipped.

- The RF-86A is a photo reconnaissance aircraft based on the F-86A. In October 1951, 5 F-86A-5s were converted.

- RF-86F Haymaker is a photo reconnaissance aircraft based on the F-86F. Equipped with 2 cameras K-22 and 1 K-17. The lower pair of machine guns was missing. In 1953, several F-86F-30s were converted. 7 aircraft were transferred to Taiwan. Another 18 aircraft were converted in Japan in 1961-1962.

- TF-86F (NA-204) - training. It featured an extended fuselage and a two-seat cabin with dual controls. There were no weapons. 2 aircraft were manufactured. First flight December 14, 1953.

- FJ-2 Fury (NA-181) is a carrier-based fighter. It was distinguished by a J47-GE-2 engine with a thrust of 2724 kgf, folding wingtips, a landing hook, attachments to the catapult, an extended nose landing gear, and cockpit equipment. From November 1952 to September 1954, 200 aircraft were manufactured at the Columbus plant.

- The CA-26 is an Australian fighter prototype. It was distinguished by a Rolls-Royce Avon RA7 engine with a thrust of 3405 kgf and fuselage design. The armament consisted of 2 30-mm Aden cannons. First flight August 3, 1953.

- CA-27 "Saber" Mk.30 - the first production aircraft assembled in Australia. It was distinguished by the Avon Mk.20 engine, cabin equipment, engine starting system, and increased fuel reserve. In 1954, 22 aircraft were manufactured.

- CA-27 "Saber" Mk.31 - with a wing similar to the F-86F-30. 32 aircraft were manufactured.

- CA-27 "Saber" Mk.32 - with an Avon Mk.26 engine, additional underwing pylons and fuel tanks in the leading edge of the wing. Could carry Sidewinder missiles. 69 aircraft were manufactured. Delivered to Malaya and Indonesia.

- CL-13 Mk.1 - Canadian variant of the F-86A. Manufactured at the Canadair plant in Carteville in one copy. First flight August 9, 1950.

- CL-13 Mk.2 ( F-86E-6-CAN , "Saber" Mk.F.2) - Canadian version of the F-86E. 60 aircraft were delivered to the USA, 3 to the UK.

- CL-13 Mk.3 - experimental with the Orenda Mk.3 engine with a thrust of 2724 kgf. It differed in the design of the fuselage.

- CL-13 Mk.4 (“Saber” Mk.F.4) - with a new cabin pressurization system. Equipped with a J47-GE-13 engine. 438 aircraft were manufactured. Most of them are supplied to the UK.

- CL-13A Mk.5 - serial with the Orenda Mk.10 engine with a thrust of 2885 kgf. It featured a wing similar to the F-86F-30. 370 aircraft were manufactured. Delivered to Germany.

- CL-13B Mk.6 - with the Orenda Mk.14 engine with a thrust of 3303 kgf. In 1954-1958, 655 aircraft were manufactured. Delivered to Colombia, Pakistan, Germany, South Africa.

- CL-13C - with afterburner (project).

- CL-13D - with an Armstrong-Sidley rocket engine (project).

- CL-13E - experimental with a fuselage modified according to the area rule. Converted 1 Mk.5.

- CL-13G - educational (project). It featured a two-seater cabin.

- CL-13H - all-weather interceptor (project). The onboard radar was different.

- CL-13J - with Bristol afterburner (project).

• Aviation Directory • Aircraft of the same period • American fighters •

Source: compilation based on publicly available information on the Internet, including the book US Fighters. - Part 3. - M.: TsAGI, 2001.

Tested in the USSR. North American F-86 Saber fighter and chronicle of the birth of OKB-1

Home » Real story » Controversial history of the recent past » Tested in the USSR. North American F-86 Saber fighter and chronicle of the birth of OKB-1

Controversial history of the recent past

byakin 06/25/2013 1495

2

in Favoritesin Favoritesfrom Favorites 0

The history of Soviet aviation contains many interesting pages, one of which is the attempt to copy the American F-86 Saber fighter, undertaken in the USSR in the period 1952-53. Veterans of the Sukhoi Design Bureau helped the author to restore the actual course of events on the basis of archival materials and personal memories: E.G. Adler , PM Drigo, A.Yu. Ongo, N.S. Ponomarev, as well as L.E. Krylov. I express my sincere gratitude to all of them.

To provide air defense to North Korea, in November 1950, the 64th IAK was formed as part of the USSR Air Force, whose aircraft from the end of that year took a direct part in repelling American air raids on North Korean targets. On our side, MiG-15 and MiG-15bis took part in the battles. Their main opponent was the latest US Air Force fighter F-86 “Saber” modifications A, E and F.

The inevitable question arose about comparing the characteristics of these machines (interestingly, the debate about the advantages and disadvantages of the MiG-15 and F-86 has not subsided to this day). The best way to find out the truth would be to flight test a real aircraft. Attempts to capture the MiG-15 by the Americans were unsuccessful - our pilots were strictly ordered not to fly south of the conditional demarcation line, which ran along the 38th parallel. The Americans solved this problem after the end of hostilities in Korea. On September 20, 1953, North Korean Air Force lieutenant Kim Sum No flew on a MiG-15bis aircraft (serial number 2015337) to the territory of the Republic of Korea and surrendered. The vehicle was transported to the United States to Wright-Peterson Air Force Base. During 1954, US Air Force pilot Tom Collins completed a comparative flight test program on this aircraft, which made it possible to identify the actual level of performance of the main fighter of the USSR Air Force. American experts gave him a very high rating.

The Soviet Union also showed interest in the possibility of studying new enemy technology “live.” In April 1951, by order of the Air Force Commander-in-Chief, a special group of GNIKI test pilots, led by Lieutenant Colonel Dzyubenko, was even sent to Korea, who was given the task of “capturing” the F-86 and forcing it to land at its airfield. Then this plan could not be implemented, but later, during an air battle on October 6, 1951, one of the downed Sabers made an emergency landing on the coast of North Korea. The pilot was picked up by the US Air Force search and rescue service, and the plane, after a long epic transportation, was delivered to Moscow for study at the end of 1951.

downed F-86A

Initially, the F-86 was located at the Air Force State Research Institute, but was soon transferred to TsAGI for a more detailed study and preparation of a detailed report. A preliminary inspection showed that the aircraft was not suitable for flight testing - the damage it received during landing and transportation was too great (the nose of the fuselage was severely crushed, and the skin and power kit in its lower part were damaged; in addition, there were numerous holes ). We decided to limit ourselves to studying the aerodynamic characteristics of an exact (based on the existing sample) model of the Saber in the TsAGI wind tunnels, to check the strength of the aircraft in static tests, to carefully study its design features, and to reproduce in its natural form only the individual, most interesting units and systems. There were no disagreements with the Air Force on this issue, and a joint letter with the text of the draft relevant Resolution, signed by Marshal of the Soviet Union AM Vasilevsky, Commander-in-Chief of the Air Force, Colonel General of Aviation P.F. Zhigarev and Minister of Aviation Industry M.V. Khrunichev in mid-January 1952 was sent to the USSR Council of Ministers.

Government decree No. 478-152, issued on January 26 of the same year, confirmed the proposed plan and set a completion date for the work - April. TsAGI was involved in the work - to study the aerodynamic layout, CIAM - the engine, VIAM - the materials used, NIAT - on aircraft and engine manufacturing technology, OKB-155 (A.I. Mikoyan) - to study the control system. A little earlier, at the end of December 1951, a separate government decree TsKB-589 of the Ministry of Armament and NII-17 MAP instructed to copy the automatic sight A-S1 and the associated AN/APG-30 radio rangefinder installed on the Sabre. The corresponding domestic devices received the code designations “Snow” and “Grad”.

By early May 1952, the study of the captured F-86 was completed. The summary report was approved by the leadership of MAP and the Air Force in the middle of the month and sent to the Council of Ministers of the USSR on May 23. The assessment given by TsAGI specialists is of particular interest:

“The F-86A aircraft has generally satisfactory aerodynamic characteristics in all flight modes up to Mach numbers = 0.93-0.94. Tests of its models ... show that starting from M = 0.8, the F-86A aircraft experiences a sharp dive, and at M > 0.9 there is a sharp decrease in the effectiveness of the elevator. ... Satisfactory flight performance of the aircraft at high flight speeds (M > 0.8) is achieved with the help of a stabilizer controlled in flight, and at high angles of attack - with the help of slats distributed over the entire wing span.

The aircraft has large ailerons, providing good lateral control at both low and high flight speeds...

The aircraft is equipped with large brake flaps that increase the aircraft's drag by approximately three times without changing the longitudinal stability characteristics.

Boosters are used in the aileron and elevator control system, which provides acceptable handling characteristics without the use of specially developed aerodynamic compensation.

A special feature of the F-86A aircraft layout is the use of the old design with a low wing, which made it possible to achieve satisfactory lateral stability characteristics with a small relative area of the vertical tail. In addition, this scheme made it possible to separate the horizontal tail from the vertical one and place it on the fuselage. However, with such an aerodynamic configuration on the F-86A aircraft, it was not possible to eliminate the sharp dive into the dive and this required the use of a stabilizer controlled in flight.

... At numbers M=0.93-0.94 there is a loss of efficiency of the elevators and ailerons... Therefore, the number M=0.94 is the maximum permissible... for normal operation...

A comparison of the aerodynamic characteristics of the F-86A and MiG-15 bis models shows that their drag and lift coefficients in the range of angles of attack up to α = 14° are practically the same. The F-86A aircraft has larger dimensions, higher flight weight and an engine with lower thrust compared to the MiG-15bis aircraft. As a result, according to the calculation data, it follows that the F-86A aircraft is somewhat inferior to the MiG-15bis aircraft in terms of maximum speed at low altitudes and is significantly inferior in terms of vertical speeds and rate of climb at all altitudes. The steady dive speeds of the F-86A and MiG-15bis aircraft with open brake flaps are almost the same, however, in horizontal flight the braking of the F-86A aircraft occurs more intensely than that of the MiG-15bis aircraft.

The calculated breaking load... is approximately equal to 12... which coincides with the calculated overloads established for this class of aircraft by our strength standards. ..."

The conclusion read:

“As a result of the ... research ... it was established that the design and aerodynamic configuration of the aircraft are not of particular interest, except for the use of:

a) ailerons with large relative chord and span; b) brake flaps with a large relative area; c) effective landing mechanization in the form of a slotted flap; d) slat; e) booster control of ailerons and elevator.”

Similar conclusions were made by other specialists who took part in the study of the aircraft's systems. For example, the use of duplicated cable wiring in the aircraft control system, an in-flight adjustable stabilizer and the use of high pressure in the aircraft’s hydraulic system (up to 211 kg/cm², while on the MiG-15bis - no more than 150 kg/cm²) were noted. Materials scientists drew attention to the high cobalt content in heat-resistant alloys (noting that the domestic industry has developed new heat-resistant alloys that do not contain cobalt, which is scarce in our country, and which are superior to American alloys with cobalt), as well as the use of a special sealing material based on thiokol, which vulcanizes without heating. CIAM specialists who studied the J47-GE-13 engine noted the use of a protective grille at the engine inlet, high elongation steel blades in the compressor rotor, the simplicity and reliability of the combustion chamber and the compressor disk mounting system. The use of JP-3 type fuel, which is a wide-fraction mixture with a high yield from oil compared to kerosene, made it possible to increase the engine start altitude and improve its operation at low temperatures.

A few caveats need to be made here. Judging by the data given in the text, it is unclear what modification - A or E - the plane that came to us was. Judging by the serial number, from which the first five digits of 49-131X are known, it follows that it was an F-86A-5, because “Sabers” of modification E, according to all reference books, belonged to the order of 1950 and their numbers began with the number “50”. But if you trust American sources, then some of the mentioned design features of the aircraft (such as a controlled stabilizer or the J47-GE-13 engine) were introduced only starting with modification E, while the F-86A appears throughout the text of the report. As for the “controlled stabilizer,” there is obviously just terminological confusion: our designers had in mind the so-called “adjustable” stabilizer, which was not directly included in the longitudinal control channel and was used only for balancing and trimming. Such a stabilizer was installed on aircraft like the F-86A along with the elevators, in contrast to the F-86E, which had a stick-controlled stabilizer that deflected together with the elevators. But the engine, apparently, did not have to be chosen in the field, and the aircraft was equipped with what was at hand at the moment. The seats ensured complete interchangeability of engines of all modifications. And most importantly: it is not entirely correct to draw an unambiguous conclusion about the advantages or disadvantages of a particular machine only on the basis of calculations. It is very easy to make a mistake here - the calculation results and the actual flight data of the aircraft may vary. This is confirmed by the testimony of Soviet and American pilots who participated in the battles about the Saber’s better maneuverability in the horizontal plane due to the installation of slats, which ensured that it could turn at high angles of attack and that it did not have such strict restrictions as on the MiG-15. speed due to the installation of an adjustable stabilizer and boosters in the longitudinal channel). This allowed the Americans to effectively evade the attacks of our pilots, using a sharp dive into the “dive” from a coup. It was difficult to repeat such a maneuver on the MiG-15bis due to the rapid increase in speed, because the plane became poorly controllable already at M > 0.92. The Americans managed to delay this border to large values of the M number.

The recommendations of the report, in fact, provided for the development by domestic industry and the use of individual units, components and materials in the designs of new aircraft. They did not even hint at the possibility of copying and building the F-86A in the USSR. Such a formulation of the question should be considered justified. It was impractical to copy the Saber in 1952 with the aim of launching it into series when there were domestic MiG-15bis/17 type aircraft in production (despite all their shortcomings). The leaders of MAP and the Air Force were unanimous in this opinion. In addition, some innovations with the F-86A (radio range finder coupled with an optical sight, brake flaps of increased area, boosters in the missile control system and others), on the recommendation of the military, taking into account the experience of the Korean War, have already either been tested as prototypes, or were introduced into series on MiG-15bis and MiG-17 aircraft. It was assumed that this direction would be reflected in the government's decision.

F-86A brake flaps

It should be noted, however, that not all senior army leaders were of the opinion about the advantages of the MiG-15. Thus, the commander of fighter aviation (IA) air defense, aviation lieutenant general E.Ya. Savitsky, who traveled to a unit of the 64th IAK, based on the results of these trips, repeatedly expressed his concern to the country's top officials about the state and prospects for the development of aviation of the air defense forces. At least twice - in February 1952 and in April 1953 - he addressed the Council of Ministers with letters in which, based on an analysis of the experience of the IA units that were part of the 64th IAK, he raised the question that MiG-type aircraft The -15 cannot effectively fight F-80 and F-84 fighters at low altitudes and is inferior to the F-86A and F-86E in maneuverability at low and medium altitudes. He proposed to create in the USSR a special fighter for medium and low altitudes, more effective than the existing MiG-15. Perhaps his opinion subsequently played a role.

Meanwhile, things took an unexpected turn. In May 1952, with a letter addressed to I.V. Stalin was contacted by a certain V.V. Kondratyev, TsAGI employee who proposed

“to build the F-86A Saber aircraft in mass production, maintaining its complete similarity with the original”

, and in the future -

“to critically learn the methods of the American school by working to improve this aircraft with a view to modifying it.”

He motivated this proposal with considerations about the better maneuverability of the Saber compared to the MiG-15bis, and at the end of the letter he made a “modest” proposal - to use himself as the chief designer.

Here we need to make some digression for clarification. At the beginning of 1952, Kondratiev worked at TsAGI as a team leader in the 3rd department (strength) and was directly responsible for testing the F-86A design. It is no longer possible to find out how he came up with the idea of copying the Saber. In those days, a person who declared himself in such a way knew (he could not help but know!) how his initiative would turn out in case of failure. But the fact remains that Kondratiev himself came up with such a proposal to the leadership and, as we will see below, despite the desperate resistance of the department, he managed to receive official support. There were rumors that the leader of the idea of copying Saber in the highest echelons of power was N.A. Bulganin, and that Kondratiev was his distant relative. But this is just a version. I will only note that at that time Bulganin held the post of Deputy Chairman of the Council of Ministers of the USSR and oversaw the work of the defense industries. Most of the documents on the construction of the Saber, found in the archives of the MAP, relate specifically to the correspondence of the leadership of the ministry with the secretariat of Bulganin.

Within the framework of the existing administrative-command system, Kondratiev’s proposal could have the most unpredictable consequences and the MAP leadership was forced to take retaliatory measures. A letter from the minister was sent to Bulganin, in which Khrunichev quite objectively expressed doubt about the need to copy the F-86 and launch it into series. But it was too late: by this time I.V. became personally interested in the issue. Stalin. We learned how further events developed from the story of E.G. Adler (according to V.V. Kondratiev himself).

In June 1952 G.M. Malenkov, who oversaw the work of the MAP in the Central Committee, summoned a group of chief designers - A.N. - to report to Stalin. Tupolev, A.I. Mikoyan, A.S. Yakovlev and the “hero of the occasion” V.V. Kondratyev, accompanied by Deputy Minister S.N. Shishkina. The leader was ill and only Malenkov himself went to see him. The rest of the guests were waiting in the reception area. After some time, Malenkov came out and turned to Shishkin:

“Iosif Vissarionovich said that you underestimated Saber.

It is not difficult to imagine what the deputy minister might have felt after such a statement. But no conclusions were drawn, and after a pause Malenkov, turning to the designers, said:

“It was decided to copy the plane. Which one of you will take on this job?

Tupolev, obviously mindful of the recent epic with the B-29, refused immediately, Mikoyan also did not show much enthusiasm, and only Yakovlev immediately and unconditionally agreed with the proposal. The situation in the reception area calmed down somewhat. Malenkov went back to Stalin, and all those present were already congratulating their colleague on his new “successful” task. But Malenkov, who had again left the office, reported Stalin’s final resolution:

“To copy the Saber, organize a special OKB-1, whose chief designer will be Kondratiev.”

Orders, as you know, are not discussed, but accepted for execution. This time it was impossible to make a mistake: the instructions of Comrade. Stalin had to be followed to the point, but there was the possibility of interpreting the instructions themselves. Apparently, the management of MAP did not change its attitude towards the idea of copying the Saber, as evidenced by the subsequent course of events. In the draft resolution prepared by the ministry, obviously not without intention, it was decided to locate OKB-1 in Kuibyshev at plant No. 1. On the one hand, Stalin’s order on the formation of the design bureau was carried out, since the organization of experimental design bureaus at serial plants in those days became widespread practice, and on the other hand, a “time bomb” was placed under the work - the design bureau was deprived of its own production base, and its location in isolation from the main industry organizations of MAP greatly hampered communications, staffing with qualified personnel and reduced the efficiency of work.

Resolution of the Council of Ministers of the USSR No. 2804-1057, entitled “On the F-86A Saber aircraft,” was issued on June 18, 1952. Its essence was that at plant No. 1 in Kuibyshev an experimental design bureau was organized for (directly according to Kondratiev ) copying, construction and further development of the F-86A aircraft, and V.V. was appointed chief designer of this OKB-1. Kondratiev. The copied aircraft was to be built in three copies: two for flight tests and one for static tests and equipped with the domestic VK-1 engine. The deadline was set very strictly: exactly one year later, that is, in June 1953, the aircraft was to be handed over for flight testing.

As expected, the government decree was supported by departmental order No. 706 dated June 20 of the same year, which, in particular, provided for the temporary location of OKB-1 in Moscow on the territory of the TsAGI branch to speed up work on the production of drawings. The branch in this case meant the BNI (Bureau of New Information), located on the “old” territory of TsAGI on Radio Street.

The recruitment of specialists took place according to a long-established scheme - people were sent according to orders issued “from above” from adjacent factories and design bureaus. The backbone of the new team consisted of BNI employees and former employees of Kondratiev at TsAGI, and E.G. became the head of the assembly team. Adler, who came to Kondratiev from A.S. Yakovleva. By the beginning of September, OKB-1 in Moscow had reached its full staff. The situation was worse with the formation of the design bureau at the plant in Kuibyshev - there were no necessary specialists on site, and no one wanted to move there from the capital. As a result, to replenish the OKB staff, Plant No. 1 itself sent its draftsmen to Moscow, and work on introducing the aircraft into production was transferred from the non-existent OKB-1 branch to the plant.

During the work, from the very beginning, the question arose about replacing the engine, since the domestic VK-1 with a centrifugal compressor specified in the resolution had large transverse dimensions and, when installed in the fuselage of the Saber, designed for an engine with an axial compressor, “knocked out” almost the entire reserve fuel. In addition, most of the organizations that participated in the study of the Saber subsequently “forgot” to return the studied samples of instruments and assemblies to it, as a result of which the OKB-1 designers were essentially left with an “empty tin can.”

On May 13, 1952, in an area controlled by the North Koreans, another Saber made an emergency belly landing, hit by anti-aircraft artillery fire. The pilot (he was the commander of the 51st Fighter Wing of the US Air Force, one of the aces of World War II - Walker Mahurin) was unlucky - he was captured. And the plane (this time F-86E) was delivered to the Air Force Research Institute by July 1952. Kondratyev, who learned about this on July 7, in a letter addressed to the minister, proposed to transfer the aircraft to OKB-1 for the purpose of using its engine, components and instruments, and also undertakes to exceed the previously established plan, reduce the construction period to 8 months and build four aircraft instead of three. Of these, one, as expected, is for statistical testing, and the other three are flight tests: one with a J47 engine, and the other two with A.I. engines. Mikulina AM-5 with afterburner. The replacement of engines was motivated in a letter

“...from the point of view of providing the aircraft with the necessary flight properties, which was not clarified earlier, before the preliminary study of this issue...”

The leadership of the MAP “supported” Kondratiev, approaching Bulganin with a proposal to partially change the assignment: it was proposed to build only 2 flight vehicles: the first with the J47 installed on it, and the second, as before, with the VK-1. The proposal to install the AM-5 engine on aircraft was considered inappropriate. By agreement with Bulganin, a compromise decision was made to continue work on the F-86A

“using on this aircraft the most modern components and assemblies from the F-86E aircraft”,

which Kondratiev especially insisted on. But CIAM, which initially gave some residual life to the J47-GE-13 engine, soon refused to guarantee anything. The situation has reached a dead end.

By mid-November, a mock-up of the aircraft was made and a commission appointed by order of the minister examined it at its meeting (unlike the usual procedure, when holding a mock-up commission was the prerogative of the customer, the Air Force, this aircraft was initially created for research purposes and the composition of the commission was determined by the ministry) . Obviously, it was here that the designers’ concerns about the engine were finally expressed and soon, on November 25, the minister’s order No. 1344 was issued, which proposed considering the possibility of installing the Mikulin AM-5 on the aircraft, along with the original J47. Specific instructions were also given to ensure the completion of the task to all related workers. At the same time, it was proposed to install the J47 engine on the restored aircraft, and on the copied (that is, newly built) aircraft - domestic AM-5 engines “with afterburning”. The equipment on all aircraft was supposed to be domestic (similar to the MiG-15), with the exception of weapons (American Colt-Browning machine guns available in the USSR were installed).

It seemed that the situation had calmed down. The OKB received the opportunity to calmly finalize the technical documentation, and the production of airframe parts began at the plant in Kuibyshev. But new circumstances intervened: in December 1952, by government decree, Plant No. 1 was reoriented to serial production of the Il-28 instead of the MiG-15, and its director V.Ya. Litvinov approached management with a request to remove the task of building the F-86A from the plant. As a result, it was decided that part of the order (production of wings, center section and empennage) would be transferred to plant No. 292 in Saratov, and the plant in Kuibyshev would only be left with the production of the fuselage with a pressurized cabin and general assembly.

Be in V.V.’s place. Kondratyev, a person more prepared for such work, and most importantly, a person more acceptable to the leadership of MAP, perhaps a “Soviet Saber” would have been born. But the deadlines were getting closer and closer, and things were still not going well with the construction of a “living” machine in Kuibyshev. Under the circumstances, the chief designer needed to somehow demonstrate his activity. There was only one path - to receive the task of building a new aircraft. By January 1953, the design department of the OKB, headed by E. G. Adler, had prepared a proposal to create a now fundamentally new “high-speed fighter.” The aircraft was a mid-wing aircraft with a normal design with delta wings and a two-fin vertical tail, placed in the form of washers on the ends of the stabilizer. Two turbojet engines designed by A.I. Mikulin had a common nose air intake and were located vertically in the rear fuselage, one above the other. The design data for this aircraft were (the values of quantities according to TsAGI expertise are given through fractions):

- Maximum speed - 1940/1650 km/h,

- Practical ceiling - 18700/18000 m,

- Maximum range - 2100/1500 km.

The new project did not cause any particular opposition, TsAGI specialist V.V. Struminsky even wrote a quite favorable review. The MAP leadership, forced to respond to this proposal, in a letter addressed to Bulganin, gave an evasive answer, the essence of which was that Kondratiev was not the first to propose the creation of such a promising machine:

“... the declared flight performance data of the new fighter proposed by Comrade Kondratyev are not confirmed by TsAGI calculations and turned out to be lower compared to the data of front-line fighters proposed by the chief designers of Comrade Comrade. Mikoyan and Yakovlev...", and "as for the new design of the aircraft (with a delta wing), as you were reported earlier, a similar proposal to create a new aircraft with a delta wing was made by the chief designer Comrade Antonov with higher flight characteristics...".

In conversations with Kondratiev himself, officials referred to the fact that to build such an aircraft, a strong production base was needed, which OKB-1 did not have. According to the existing order, strong production was created only for the fulfillment of a specific government task. It turned out to be a vicious circle. The time bomb has finally worked. All that remained was to wait for erroneous steps on the part of the inexperienced chief designer.

The calculation turned out to be correct. Kondratiev could not sit still, and new projects were soon baked like pancakes - every month: on February 16, he came up with a proposal to create

“a supersonic fighter aircraft with a maximum speed of 2000-2200 km/h and a flight altitude of 21 km with two new engines with a thrust of 5000 kg each designed by Comrade Mikulin (AM-11F)”,

and on March 17 - with a new project

“a high-altitude fighter-interceptor with a maximum speed of 3000-4000 km/h and a flight altitude of 30 km, using ... a gas turbine engine operating on a new principle (MD engine designed by B.G. Shpitalny).”

And if in relation to the first of them the MAP’s response was still evasive, then by the time the second was released, the political situation in the country had seriously changed. After Stalin's death, as a result of personnel changes N.A. Bulganin moved to the chair of the Minister of Defense and lost the opportunity to directly influence the course of events; the post of Chairman of the Council of Ministers was taken by G.M. Malenkov, and the Ministry of Aviation Industry for some time (from April to August 1953) ceased to exist altogether, as it was merged with the Ministry of Armaments into one common Ministry of Defense Industry (MOP), of which D.F. was appointed minister. Ustinov (formerly the Minister of Armaments). M.V. was appointed his deputy. Khrunicheva.

These events could not but affect the fate of OKB-1 and its chief designer. In April 1953, Ustinov appointed a representative commission to consider the joint proposal of the chief designers Kondratiev (OKB-1) and Shpitalny (OKB-15) to create

"High-altitude fighter-interceptor with molecular engine MD-53."

The commission's findings were discouraging:

“The declared ... characteristics of the engine and aircraft are technically unfounded and unrealistic. ...The proposal can only be considered as a technical adventurism, and not as a serious engineering proposal. ... The proposal ... is essentially an attempt to mislead the Government.”

It is now difficult to say what caused the harsh tone of the conclusions. Perhaps, in the changed situation, industry leaders decided to get even with Kondratiev for past grievances. A successful opportunity turned up - the MD-53 engine project, developed by the “non-professional” Shpitalny, was utopian, which was the main focus of the commission experts, which included A.I. Mikulin, S.K. Tumansky and AM Lyulka. No such clear conclusions were made regarding the aircraft. Moreover, it was said that to work out the issues of flight at such high speeds, extensive and deep research work is required, that is, the obvious lag of fundamental research from the demands of practical science was recognized. However, this fact did not prevent the bureaucratic machine from running. All that remained was to wait for the results.

By the beginning of May 1953, the question of the very existence of OKB-1 was already being discussed. Now almost no one remembered what it was once created for. Career V.V. Kondratiev’s position as chief designer ended with the issuance of Ministerial Order No. 233 of May 14, 1953. The document literally says the following:

“Due to the fact that the Chief Designer of OKB-1, Comrade Kondratyev, is not able to ensure the creation of new prototype aircraft, does not have sufficient experience in this area and, according to the conclusion of the expert commission, has taken the path of technical adventurism, I order:

1. Comrade Kondratiev is relieved of his duties as chief designer of OKB-1; 2. appoint P.O. Sukhoi as the chief designer of OKB-1.”

Thus ended the short history of copying the Saber fighter in the Soviet Union. New chief designer P.O. Sukhoi, apparently, by agreement with the leadership of the Ministry of Aviation Industry, was no longer engaged in work in this area. He began developing fundamentally new machines, later embodied in metal under the names S-1 and T-3. The corresponding government decree, which legitimized the work of OKB-1 on this topic, was issued in August 1953, and at the end of the year the design bureau finally received its own production base - a branch of OKB-155 on the territory of the former plant No. 51 in one of the corners of Khodynskoye Pole . Hence the new name: OKB-51. It should be noted that the initial versions of the configurations of aircraft of the T-1 and T-3 types were largely based on those proposals that were developed by E.G. Adler at OKB-1 under Kondratiev, and some technological innovations from the Saber were very successfully introduced into their design.

The appearance of the F-86 in the USSR in the early 50s was not in vain for Soviet aviation; it made it possible to directly become familiar with the equipment of the opposing side. Among direct borrowings, we can note, for example, the ASP-4N optical sight (Snow) and the SRD-3 radio rangefinder (Grad), which are copies of the A-1C sight and AN/APG-30 radio rangefinder installed on the Saber. In 1953, they were tested on a specially equipped MiG-17/SG, and later the ASP-4N was even installed on MiG-17 type aircraft. In addition to studying and copying some new devices and units, new technological processes were introduced into production, such as, for example, machining on special milling machines to produce wing skin sheets of variable section thickness, widespread use of roller and spot welding of steel and light alloys, more widespread use of hot-stamped and cast assemblies, explosive rivets, ramrod sealing of the canopy triplex, and the like.

Another consequence of the Saber study was the work carried out in the USSR on the creation and use of new types of fuel and hydraulic fluid. Thus, in particular, according to Government Decree No. 1691-621 of April 7, 1952, work began at VNIINP of the Ministry of the Oil Industry to create kerosene of an expanded fractional composition - types T-2 and T-4. In collaboration with MAP and the Ministry of Defense, this work continued until the end of the 50s, and the requirement to be able to operate on these types of kerosene was an indispensable condition for all newly developed types of aircraft and engines. The end result of the work on hydraulic fluid was the appearance of the AMG-10 - the main type of hydraulic fluid in USSR aviation. But that's a completely different story.

In conclusion, it only remains to note that formally the work on the Saber was closed by Decree of the Council of Ministers of the USSR No. 2460-1017 of September 19, 1953, expenses were written off, and the backlog at the factories in Kuibyshev and Saratov was destroyed.

V.V. After May 1953, Kondratiev repeatedly tried to protest the label of “technical adventurer” attached to him, and appealed to the MAP, the CPSU Central Committee and the USSR Council of Ministers with requests to reconsider his case. In September 1953, the minister replaced the wording of the dismissal order with a neutral one:

"due to a change in assignment."

Kondratiev was offered the position of deputy chief designer at plant No. 918, where he worked for several years. Both here and later - in OKB-256 / Tsybina / he repeatedly went to the Central Committee and the Council of Ministers with proposals for the creation of new promising aircraft - a strategic bomber, a supersonic strategic reconnaissance aircraft and similar machines, but he never received support from high levels of leadership, because in response to a request to the MAP about the substance of these proposals in April 1958, the CPSU Central Committee received the following answer:

“...he (Kondratiev - author's note) due to his knowledge, practical experience and organizational abilities will not be able to provide leadership to any independent experimental design bureau or scientific department because Comrade Kondratiev is completely unprepared to conduct leadership work in the field of experimental aircraft construction...”

source: Pavel PLUNSKY “CHRONICLE OF THE BIRTH OF OKB-1” // “Planes of the World” 1.2/1997