Steel armor for the Red Army soldier: the mass-produced CH-42 and its competitors

Began back in 1937–1938. Work on the development of individual armor to protect Red Army soldiers from bullets and shrapnel progressed with difficulty, but by the summer of 1942 several samples appeared that were tested at the front and received positive reviews. The Main Artillery Directorate of the Red Army and the State Defense Committee were faced with the task of deciding on the best model and accepting it for supply. As a result, the CH-42, the most famous breastplate of the Red Army, went into full production.

Works of the Moscow Institute of Steel

On March 23, 1942, by order of the acting head of the 5th Department of the GAU Artillery Committee A.R. Yemets, the first samples of chest shields developed by the Moscow Institute of Steel were tested by firing from a German submachine gun. Five pilot batch bibs, made of cold-rolled sheet steel 50 with various heat treatment options, were submitted for testing. The shelling was carried out from a distance of 10 meters, and through holes were found on all five shields. After this, the shelling was carried out from a distance of 15 and 20 meters, and in this case there were through holes in the breastplates. At this point the tests were completed.

The conclusions based on the results of testing the first MIS chest shields were made unequivocal: the product does not meet the main tactical and technical requirements of the AK GAU - protecting a fighter from bullets from a German submachine gun at a distance of 10 meters. The shields were returned to the Moscow Steel Institute for modification. It should be noted that the first samples of CH-42 were not tested in this way.

From the end of March to the end of June 1942, work was carried out to improve the bullet resistance of the armor from which the MIS breastplate was made. At the same time, the educational activities of the institute were not interrupted; the teaching staff was also engaged in teaching students (some of the students and teachers were evacuated or went into the people’s militia). The workshops of the institute produced mortars and mines for them, as well as PPSh-41 submachine guns. By the end of June, the optimal temperature regime for hardening armor with a thickness of 1.8–2 mm was selected.

Steel breastplates from the Moscow Institute of Steel, found in the battle zone of the 5th Army of the Western Front

By July 21, 1942, the first experimental batch of 50 MIS bibs was manufactured; Professor V. S. Emelyanov supervised their creation. When developing the shape of the bib, we proceeded from the wishes received in the reports of the 5th Army and took into account the tactical techniques developed in the 34th Army. With a thickness of 1.8–2 mm, the weight of the bib was 3.4–3.5 kg. On the reverse side it had a folding bipod, which could be used for carrying and at the same time served as a stop-limiter for the abdominal section when the bib was installed as a shield. The bib was made from hot-rolled sheets of steel grade 35ХГС.

On July 25, the shields were sent to the 5th Army of the Western Front for testing in combat conditions. The covering letter, signed by the GAU leadership, to the army commander, Lieutenant General I. I. Fedyuninsky, contained a request to send them to the same units that had previously tested the first batch of CH-42.

Activities of Research Institute No. 48

In parallel with Research Institute No. 13 and MIS, Research Institute No. 48 of the People's Commissariat of Tank Industry (TsNII No. 48 NKTP) carried out their work, and this work was not authorized by the GAU. On March 14, 1942, bullet resistance tests were carried out on 19 armor plates with a thickness of 1.5–2.3 mm made of steel 30 KhGSA and 35 KhGSA using various hardening and tempering methods, manufactured at the Verkh-Isetsky plant in Sverdlovsk. The shelling was carried out along the normal line from a distance of 50 meters from the PPSh using ordinary cartridges available at the infantry school located next door. The tests made it possible to establish that 1.8 mm thick plates “... reliably protect against damage from PPSh from a distance of 50 meters... The heat treatment mode does not have a noticeable effect when testing PPSh armor plates from a distance of 50 meters... Bring the test results to the attention of higher military organizations"

.

Vest Research Institute No. 48 (TsAMO)

The conclusion of the 5th Department of the GAU Artillery Committee on these tests was given in early July 1942. It emphasized that steel breastplates had already been developed, and the armored shields offered by Research Institute No. 48 could not be recommended for production and supply to the Red Army.

Nevertheless, Research Institute No. 48, on its own initiative, nevertheless developed and proposed its own version to protect soldiers from bullets and shrapnel, and this product can rightfully be considered the first body armor in the USSR. It consisted of armor plates made of steel 30ХГС or 35ХГС with a thickness of 1.8 mm, sewn into a fabric vest. Two versions were made - the first provided protection only from the front, the second also had inserts that covered the back (the weight was 2 kg and 3 kg, respectively).

Testing of an experienced CH-42 in the Airborne Forces

In mid-July 1942, experimental CH-42s were transferred to the experimental testing ground of the Airborne Forces to determine their suitability for use in the airborne forces. The tests were completed by August 5. The paratroopers creatively approached the task, conducting shelling tests according to their own program - they fired from everything they encountered at the front: the domestic Mosin rifle and the German Mauser 98K, PPSh submachine guns and one of the German PP (modification not specified), as well as pistols TT, Luger P.08 and Mauser C96.

CH-42 of the first series on a Red Army soldier from the Airborne Forces (TsAMO)

The results of the attacks differed from the results of the Small Arms Research Range, showing the following:

- The “three-ruler” with a regular bullet pierces the breastplate at a distance of up to 400 meters, from 450 meters its bullet leaves deep depressions with cracks, getting stuck in the depression, from 500 meters it leaves a deep depression and cracks. At an angle, the penetration distance is reduced. The German rifle hits harder: bullets get stuck from a distance of 550 meters, there is no penetration at a distance of over 600 meters. When firing at an angle to the normal, the penetration distance is reduced.

- The PPSh does not penetrate the breastplate when fired at point-blank range (only cracks remain). A point-blank burst of four bullets in one place broke out a piece with an area of 13 sq.cm. There are no cracks when shooting at an angle. German PP is much weaker than PPSh, it leaves dents without cracks.

- Shooting from all pistols leaves smaller dents than a German PP. The breastplate springs back when hit by a bullet, increasing the protective properties of the armor. There should not be a tight fit to the body.

General view of the experimental CH-42 at the Airborne Forces training ground and CH-42, converted at the pilot plant of the Air Force Research Institute (TsAMO)

Tactical tests were carried out to determine how much the breastplates restrict the movements of fighters on the march, when digging in, running, and whether the time spent on one or another maneuver increases. For these purposes, the commander of the 8th Airborne Corps assigned a rifle platoon. These tests yielded interesting results showing:

- For standard techniques with a bib, the time spent increased slightly;

- It was noted that if the bib is removed and installed as a shield, then when changing position there is no time to put it on, and you have to carry the bib by the straps, covering yourself with it in front. During these actions, the breastplate is unstable and provides little protection. It is impossible to put your hand under the straps (like a shield), because the bib in this position is completely unstable;

- When shooting from a prone position with a breastplate installed in front (in the form of a shield), you cannot shoot from a rifle - the breastplate falls from the recoil after the shot;

- When carrying the breastplate by the suspension straps of the lower part, shooting on the move from a rifle is impossible. You can shoot from the PPSh by placing the barrel on the neck of the breastplate, but the shooting accuracy is very poor;

- Before an attack, the breastplate has to be either thrown away or fastened on both hooks, which leads to a loss of time, because straps get tangled;

- The right shoulder strap easily slips off the waist strap and gets lost. Of the 30 bibs used in field testing, 26 had lost straps;

- Covert actions in reconnaissance, at night, etc. are impossible, because bibs rattle and restrict movement;

- In bayonet combat, the breastplate does not restrict action and provides good protection, allowing you to shoot and throw grenades with normal accuracy.

Using a modified CH-42 for prone shooting (TsAMO)

Based on the results of tests at the pilot plant of the Air Force Research Institute, a small modification of one armored breastplate was made:

- The straps were removed, the left shoulder pad was lengthened, a hook was attached at the height of the waist belt on the right side, adjustable in height, now the bib was held on the shoulder pad and on the waist hook.

- A canvas loop was riveted to the left side of the armored breastplate, through which one could pass the left arm up to the elbow, and a steel handle was riveted on the right side of the breastplate - this made it possible to carry the breastplate in front of oneself on the left hand.

- A number of changes have also been made to ensure stable shooting from a rifle with the breastplate mounted in front of you. To eliminate the ringing that occurs when parts of the bib hit each other, the lower edge of the upper part was lined with dermantine.

However, these changes did not eliminate the shortcomings, but only replaced one with another - only the change made for prone shooting turned out to be successful. The parachute jumps with the bib on were successful and did not reveal any difficulties.

Shooting while standing and moving with the modernized CH-42 (TsAMO)

In general, the testers from the airborne troops liked the bibs; they only needed to eliminate the indicated shortcomings. It was noted that the bib is more adapted to actions of an offensive nature, but it is necessary to adapt it to defensive actions: make loops and handles for carrying, hooks and stops for stable installation in front of you, adapt the bib for silent actions. At the end of the report there was the phrase “... we can agree to temporarily receive bibs without the desired design improvements”

.

Difficult choice

The direct management of the enterprises, the relevant people's commissariats and supervising departments were aware of all these works - moreover, in the end, JV Stalin personally showed interest in them and demanded a report. On August 7, 1942, in a report to Stalin signed by L.P. Beria (Deputy Chairman of the Council of People's Commissars, member of the State Defense Committee), N.D. Yakovleva (Head of the GAU), I.F. Tevosyan (People's Commissar of the NKChM) three types of defense were reported fighters developed by Research Institute No. 13, MIS and Research Institute No. 48. The report emphasized that the steel necessary for their production has been mastered by NKChM in gross production.

On August 8, by a resolution of the State Defense Committee (GKO) signed by Stalin, a decision was made to release a pilot batch of each of the samples and to comparatively test them among the troops:

- NKChM (Tevosyan, People's Commissariat of Ferrous Metallurgy) produces 500 bibs of the model of Scientific Research Institute No. 13 NKV at plant No. 700 (LMZ, Lysva) and supplies them to the State Autonomous Institution by 08/10/1942;

- NKSM (Akopov, People's Commissariat of Medium Engineering) produces 500 bibs of the MIS model at the Stalin plant (ZiS, Moscow) and supplies them to the GAU by 08/12/1942;

- NKTP (Zaltsman, People's Commissariat of Tank Industry) produces 500 vests of the NII model No. 48 at Uralmashzavod (UZTM) and supplies them to the GAU by 08/12/1942;

- The People's Commissariat of Textiles must provide all enterprises with cotton fabric for lining, in quantities and terms according to their requests;

- At ZIS, the local industry department of the Moscow City Executive Committee (Selivanov) manufactures and supplies fittings and plating for MIS type bibs, NKChM ensures the supply of metal;

- The GAU must send the received samples to the active army, carry out their comprehensive testing, and by 08/25/1942 provide considerations on the best sample of armored breastplates for acceptance into general production.

In fact, the resolution was formal, since the first technical specifications and drawings for the “classic” CH-42 appeared on July 27, 1942, and the final version was approved by the scientific and technical journal of the GAU Artillery Committee No. 0173 dated August 7, 1942. The GAU index also appeared there to designate the bib “56-F-002”.

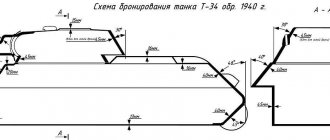

Drawing of the final version of the SN-42 (GAU index “56-F-002”), approved on July 27, 1942 (TsAMO)

According to the technical specifications dated July 27, 1942, three options for the chest device were provided:

- made of two layers of cotton fabric, with a layer of cotton wool, tow or felt sewn at the collar;

- made of cloth with a layer of cotton wool, tow or felt sewn at the collar;

- made of felt padding with one side covered with cotton fabric.

The lining was made in two sizes (the first size was used for bibs of height 1–2, and the second for bibs of height 3), secured with cotter pins, and the straps were made of “milz” braid or four layers of khaki cotton fabric.

Thus, the CH-42 acquired the form in which it is known to most of those interested in the history of the Second World War: a braid loop for carrying, a hinge for attaching the abdominal part to the chest (for installation in the form of a shield), slots for attaching the hooks of the straps, covering the lower part with cotton fabric ( to prevent the sound of the plates hitting each other). The wishes of the troops were taken into account as much as possible in the final design.

Soldiers wearing CH-42 breastplates of gross production

A little later, on August 7, 1942, the technical conditions were clarified:

- material for the bib – steel 36SG, thickness 1.8–2.2 mm;

- lining according to options No. 1 and No. 3 from the technical specifications dated July 27, 1942;

- belts made of 35 mm wide braid or four layers of cotton fabric.

Of greatest interest is the discussed acceptance process:

- For shelling testing, six parts are selected from a batch of 200 pieces, separately upper and lower;

- shelling is carried out after testing the hardness of heat-treated parts from a distance of 10 meters normal from a German MP-40 submachine gun, one bullet each in the upper and lower parts of the breastplate;

- in case of holes or cracks in at least one part (upper or lower), an additional 9 parts are selected from this batch for testing;

- in case of unsatisfactory results, the entire batch is returned for repeated heat treatment, after which it is tested as newly presented;

- repeated heat treatment of the same batch is allowed no more than two times;

- the results of the shelling are activated.

CH-42 installed as a shooting shield

It was planned to produce 250,000–300,000 CH-42s by January 1, 1943. The detailed development of the technical conditions for the CH-42 and the assignment of an index to it proves that the GAU made its choice before the start of testing in accordance with the decree of the State Defense Committee of August 8, but the GAU could not ignore Stalin’s order.

ZIS and LMZ were more or less able to meet the strict deadlines set by the State Defense Committee, but UZTM did not make it on time. For this reason, the troops of the 5th Army received the MIS and NII No. 13 bibs for testing, and the NII No. 48 vest got there much later, in October.

The MIS bibs of the second batch were manufactured at the ZIS plant from 30KhGSA steel with a thickness of 1.9 mm, produced at. The third batch of CH-42s were made according to technical specifications and drawings from the scientific and technical journal of the GAU Artillery Committee No. 0173.

MIS breastplate mounted as a shield for prone shooting

The results of comparative tests were recorded in a report from the headquarters of the 5th Army dated September 5, 1942 addressed to the head of the GAU; copies were sent to the directors of Research Institute No. 13 and MIS. The bibs were tested in the 1st Guards Rifle Division and the 3rd Guards Motorized Rifle Division. In terms of bullet resistance, the SN-42 bib turned out to be the best; in terms of shape, I liked the MIS bib better. At the end of the report, the CH-42 was recommended for adoption, but “with an extension to cover the lower abdomen according to the MIS model”

and a wish was expressed

“to have armored breastplates in mass quantities in the near future

.

Remains of the Research Institute No. 48 vest, found in the battle zone of the 5th Army (provided by a forum participant ww2.ru/forum with the nickname “Pechkin”)

However, they were in no hurry to accept the CH-42 for supply, but decided to wait until the end of testing of the NII No. 48 vest. At the beginning of October, the vests were manufactured, arrived at the front and were distributed to the 108th and 353rd Rifle Divisions, as well as to the 3rd Guards Motorized Rifle Division, 100 pieces each. Another 200 vests remained at the artillery supply warehouse in Mozhaisk. The results were disappointing: the NII No. 48 vest was not liked by the troops due to the fact that the protection area was smaller than that of the MIS and SN-42.

Moreover, during military tests, one of the vests of Research Institute No. 48 was captured and studied by soldiers of the German 35th division, and reports about it were sent to higher command.

Drawing of the Research Institute No. 48 vest from a German report (NARA)

The general conclusions after military tests were as follows:

- The MIS sample is structurally no different from the NII sample No. 13, but has less bullet resistance;

- The MIS sample is better in shape than the NII sample No. 13;

- Research Institute sample No. 48 provides insufficient protection of the abdominal cavity;

- The MIS and NII samples No. 13 have straps that break where they are fastened with rivets to the breastplate;

- Recommend for acceptance for supply sample NII No. 13, SN-42.

Thus, by November 1942, the GAU KA finally decided on the model and accepted the SN-42 breastplate under the symbol “56-F-002” for supply to the Red Army, and plant No. 700 (LMZ) began their bulk production. Breastplates began to be supplied to the troops en masse. The production order called for 100,000 units to be produced by January 1, 1943.

Differences in the first gross CH-42 - changes occurred during the production process. Samples found by search engines

The first gross CH-42 had a number of differences from the approved drawing: the introduction of a hinge for fastening when folded and a braid loop for carrying did not happen immediately, but gradually, with the manufacture of dies and equipment.

MIS employees were discouraged by this outcome of military tests and conducted their own investigation into the reasons for the low bullet resistance of their sample. It turned out that the steel supplied had significant surface decarburization (up to 0.2 mm), and the carbon and chromium content in the melt was at the lower limit and slightly below it, respectively. This was the reason for the unsatisfactory results.

General view of the NII No. 48 vest with additional belly protection (TsAMO)

Modernized vest of Research Institute No. 48 (TsAMO)

In turn, employees of Research Institute No. 48 developed and proposed a modernized version of their vest. The new model had additional plates sewn in to protect the fighter’s abdominal cavity.

But all these reasons and improvements were identified and made later, the CH-42 defeated its competitors. A memo on their use was issued to the command of the troops that received the CH-42. It summarized all previous experience accumulated since 1937, and indicated how and by whom the steel breastplate should be used:

- scouts searching;

- sappers during reconnaissance, making passages in the wire, when clearing mine barriers under enemy fire;

- infantry groups conducting force reconnaissance (reconnaissance in force);

- machine gunners infiltrating enemy battle formations in tank landings, and groups of machine gunners in ambush;

- assault groups capturing bunkers;

- signalmen checking or correcting cables under enemy fire;

- by decision of the commander, whenever the situation allows us to count on the successful use of bibs.

Three use cases were envisaged:

- the bib is attached to the body with straps and covers the chest and abdominal cavity during movement;

- when crawling, the bib is used as an embrasure;

- the bib is used as a shell, covering individual parts of the body (right side, left side, head).

The competitor to the mass-produced CH-42, developed in besieged Leningrad and also making its way into the army, will be discussed in the next article.

THE USSR. Steel breastplate

A steel bib (SN) is an individual protective device such as a cuirass, the simplest body armor used by the Red Army during the Great Patriotic War. The breastplate belongs to the rare, rather exotic equipment of the Red Army soldiers and, although it was mass-produced, the quantity produced was only a few tens of thousands. It is noteworthy that the history of its creation is much more interesting than the very use of the breastplate in the army.

The idea of a protective breastplate came from the First World War, where it was used to a limited extent in the armies of Great Britain, Germany and France. After the war, in the 20-30s, steel cuirasses were in service with the Polish police. And the Imperial Japanese Army used them during the fighting in China. In the Red Army, attention began to be paid to the problem of protecting soldiers from bullets and shrapnel from the early 30s, simultaneously with the beginning of the development of the domestic steel helmet, or as civilians say, helmets. The task set before the scientists was twofold: to create a steel capable of combining good bullet resistance and ductility; determine the optimal shape of a helmet, which, together with protective shells and armored shields, could provide the infantryman with protection on the battlefield. By the end of 1935, the necessary alloy was found, the hardening technology was developed, and in November the first samples of a steel helmet, designated SSh-36, were born. While the helmet was being finalized and perfected, the Red Army's Supply Department (UOVS) began to receive all sorts of proposals to protect the soldier's body.

The most interesting was the project of the head of the technical conditions bureau of design bureau No. 2 of the Izhora plant, engineer I.M. Weinblat, received in April 1937. This project is noteworthy in that it attracted the attention of NGO management to the problem of individual protection of fighters and gave impetus to further work in this direction. Weinblat proposed an “armored breastplate” for protection against a 7.62 mm rifle bullet, consisting of two parts. The breastplate itself was supposed to protect the entire chest and shoulders from bullets, as well as bayonet and saber strikes. The belly protection was supposed to be attached to it from below with straps. The breastplate was intended for assault troops, motorized infantry and cavalry.

Sketch of the “Armored Breastplate” by engineer I.M. Weinblat.

Two versions of the breastplate were offered - with 2-mm and 3-mm thick plates made of IZ-2 armor steel. For the 2-mm version, protection was provided against damage from a normal bullet at a distance of 850 m, while 3-mm plates withstood hits at a distance of 350–400 meters. In addition, the breastplate protected against bayonet and saber strikes.

Already on September 13, 1937, the first test samples were manufactured, which showed good results and gave suggestions for improving the product. At the end of 1937, the deputy of the NKO, A. Egorov, prepared a document to authorize the order of an experimental batch of 1000 pieces of bibs. However, Egorov was removed from office and subsequently shot. Therefore, they returned to the bib only in August 1938. The author of the project was summoned to the UOVS, where he presented a modified version of the bib, but upon returning to the Izhora plant, Weinblat was arrested by the NKVD. At the same time, a state order was established for the production of bibs.

In October 1938, the People's Commissar of Heavy Industry M. Kaganovich, without waiting for documentation from UOVS and NPOs, gave instructions to develop and produce at LMZ (Lysva Metallurgical Plant) by January 1, 1939 a pilot batch of steel bibs: 250 pieces weighing 4–5 kg and 250 lightweight pieces weighing 2–2.5 kg. At the plant, without waiting for the technical specifications and forms of the bib from UOVS (formulated on the basis of Weinblat’s work), they developed three of their own options. All these LMZ bibs received the index SN-38, although in fact they were products of different design. On November 9, 1938, the plant received tactical and technical requirements for bibs and the procedure for accepting a pilot batch. The TTT specified bullet resistance (the distance at which it is guaranteed not to penetrate) for each type of bib: 350 meters for a bib weighing 4–5 kg and 700 meters for a bib weighing 2–2.5 kg.

Engineer Weinblat was convicted and ended up in the “sharashka” - the Special Technical Bureau of the NKVD of the Leningrad Region. There he tried to resume work on his bib by writing a letter to the UOVS in June 1939, but it was too late - the work was already being carried out by another plant and research institute.

In January 1939, a pilot batch of four types of bibs was made: 1. Heavy type of three parts - 107 pcs. 2. Heavy type of two parts – 115 pcs. 3. Lightweight type of two parts – 260 pcs. 4. Light type of two parts – 9 pcs.

Since the breastplates differed from each other not only in steel, but also in the under-body device, there were actually nine varieties of CH-38.

CH-38 heavy type in three parts (left) and heavy type in two parts (right).

Two lightweight two-piece samples of CH-38.

CH-38 heavy type of three parts with a first type under-body device.

Reconstruction of one of the types of the CH-38 bib.

In February 1939, NPOs of the USSR organized field tests of the bib, noted shortcomings and proposals for improvement. But for unknown reasons, the product was not put into production. Until August 1939, there was a break in work on steel breastplates. The further direction of work involved the division into bibs SN-39 and bibs-shields SNShch-39, which were to be carried by soldiers.

Front and back sides of the steel bib CH-39.

Trial operation of the CH-38 revealed certain shortcomings in the design of the bib that needed to be removed. The tactical and technical requirements for the product were also finally formulated. So, the weight should be in the range of 2–2.5 and 4–5 kg for a lightweight and heavy type steel bib, respectively. It should consist of two parts - the upper one to protect the chest and the lower one to protect the abdominal cavity. The design should provide for a loose fit to the body and the ability to use the breastplate when shooting from all positions (standing, sitting, kneeling, prone). The upper part should have a hinge for the left shoulder, a cutout for the rifle butt on the right, allowing good control of the rifle when shooting from all positions, without interfering with the use of camping equipment. The flange of the neck part should provide free tilt of the head and protection from lead splashes when hit by bullets. The lower part should provide easy access to cartridge pouches and normal carrying of the rifle on a belt. The fastening system should be simple, ensuring independent putting on and removal of the breastplate from all positions with full combat gear. The chestplate must withstand the impact of a light bullet weighing 9.6 grams at any point when hitting normal 700 and 350 meters for the light and heavy types, respectively. The additional chest plate in the heart area was abandoned, as was the ability to install the chest plate when folded as a shield. The breastplate was now fastened to the fighter’s body using two braid belts – horizontal and vertical. A horizontal belt with an adjustable sliding buckle on one side was firmly attached to the cutout in the bib, and on the side opposite the cutout a special half-ring was attached to the bib. The belt was fastened with a carbine that clung to the half ring. There was only one vertical strap (there were two on the CH-38), the upper side was firmly attached to the cutout on the left shoulder of the bib, and the lower one had a loop through which a horizontal belt was threaded.

Breastplate-shield SNShch-39 from the back side. Nickname: “heart of steel.”

The reasons that prompted the creation of the SNShch-39 breastplate are not reflected in the documents, but one can see the desire of the UOVS to combine the advantages of a rifle shield and a breastplate in one product. In any case, the following tactical and technical requirements were put forward to him. The shield must provide protection for the fighter from rifle and machine gun fire: from direct hits - at a distance of 200–225 m and from hits at an angle of 25°–30° - at a distance of 120–150 m. The weight of the shield should not exceed 4 kg, the surface of the shield should cover the fighter when shooting prone and have approximate dimensions of 300x400 mm. The shield must have:

a) a slot for firing a rifle, closed with a bolt; b) a device for installation in a combat position at an angle of 25°–30°; c) a handle for using the shield when crawling; d) cover in the form of a cover, providing dampening of lead splashes; e) a device for wearing on straps and behind a belt to protect the fighter’s abdominal cavity in a combat position.

On September 21, 1939, both products were launched into pilot production in a batch of 256 pieces. By December 1939, field tests were completed and the bibs were sent to the Soviet-Finnish War, to the 7th Army on the Karelian Isthmus. Since the tests in a combat situation took place without representatives of Research Institute No. 13 and UOVS, and also because they were treated without due attention (the troops did not receive instructions and recommendations), contradictory results were obtained. Therefore, on the report on the combat use of bibs, a resolution appeared: “The tests of the bibs were crumpled, no conclusions can be drawn.” Due to the ambiguity of combat tests, the decision to produce an additional batch was suspended, and work on improving the breastplates and breastplates continued.

The new model received the designation CH-40. When creating it, they relied on the tactical and technical requirements of the UOVS of August 5, 1939, but deviated somewhat from them in terms of size: according to the largest measurement, the length of the new type of shield was 420 mm - instead of 400 mm, voiced in the requirements. The breastplate was a shield with a sliding embrasure for firing. Hinges for a folding stop and a loop were riveted to it, allowing it to be carried. On one side of the loop there was a hook needed to hang the shield from a special braid strap that the soldier wore, and on the other side of the loop there was a special hook for the waist belt, which reduced the amplitude of the shield's swinging during movement when it was worn on the soldier. The loop could also serve to carry the CH-40, worn on the left hand like a knight's shield. When using the shield in a prone position, the shield was installed obliquely at an angle of 60° to the horizontal on a folding stop, the rifle was inserted into the loophole and covered from above with an embrasure bolt for additional head protection. When running short distances, the fighter put the loop on his left hand (like a shield), removing the rifle from the loophole, and when moving over long distances and using the shield as a breastplate, he hung it on a strap on his chest, while the loophole was closed with a latch. Seven prototypes were manufactured and tested by normal firing with a cartridge with a reduced charge in the plant's shooting range. Five copies of the CH-40, which remained intact after the shelling, were sent on March 15, 1940, along with an explanatory note, in the form of samples to the UOVS of the Red Army for further study.

Work on upgrading the CH-40 at LMZ continued even after the prototypes had been sent. On May 4, 1940, the chief engineer of the plant, Filippov, sent an explanatory note to the UOVS containing a description of the modernized CH-40 designed by A. Filin. Without waiting for an answer, Filippov wrote a second letter a month later. July 6, 1940, Lieutenant General A.V. Khrulev. With his resolution, he put a bold end to the CH-40: “...I believe that it is inappropriate to introduce steel breastplates into service for the following main reasons:

- Steel breastplates of the CH-40 type, weighing 4.5 kg, are pierced by a direct bullet impact at short distances (below 350 meters).

- The introduction of steel bibs will require additional transportation.

- Steel breastplates will dramatically reduce a fighter's mobility.

Based on this, I report that this is an unnecessary undertaking for the Red Army that will not bring any benefit.”

One of the reviews about the use of bibs.

However, work was carried out not only in Lysva at the LMZ - in parallel, research work was continued at Research Institute No. 13 in Leningrad. In accordance with feedback from the 7th Army, in which the SN-39 and SNShch-39 were tested during the Soviet-Finnish War, Research Institute No. 13 carried out work aimed at increasing the bullet resistance of breastplates in order to provide reliable protection at close combat distances. It was decided to take a simple path - to increase the thickness of the bib without changing the design. The new bib of Research Institute No. 13 received the index CH-40A. Thus, it was a further development of the CH-39 with some changes: the thickness of the metal was increased and the shape of the bib was slightly changed, and the slot for the waist strap was shifted down. Also, to prevent rotation around the axis and the associated difficulty in fastening the waist strap, the metal loop on the left, holding the half-ring for snapping the strap's carabiner, began to be riveted on one side from the outside of the chest section, and the other from the inside (going around the edge of the bib).

Drawing of the CH-40A bib.

It was decided to produce a serial batch of CH-40A in two versions, from sheets with a thickness of 4.2 and 5.2 mm, which provided protection from rifle and machine gun fire along the normal distance: “heavy” - 150 meters, “light” - 300 m; at an angle of 30°: “heavy” - any distance, “light” - 175 m. In addition, the bibs were produced in three different sizes. A total of 123 “heavy” and 104 “light” breastplates were produced. Factory tests were completed on July 26, 1941.

In August 1941, 200 CH-40A “light” and “heavy” types were sent to the Western Front, where S. K. Timoshenko got acquainted with them. He did not like the significant weight of the bibs (from 5.5 to 9.3 kg). On August 23, on behalf of Tymoshenko, the head of artillery supply of the Western Front, Major General of the Quartermaster Service A. Volkov, wrote a letter with the following resolution: “...Steel breastplates cannot be used by a fighter who is already overloaded. The Marshal considers it advisable to make a marching embrasure instead of a breastplate, from behind which a fighter could fire.” Apparently, Marshal Timoshenko was not aware of the work of the previous few years... An experimental embrasure was made at the Moscow plant named after Stalin and shown to Tymoshenko, after which he personally made adjustments to the design of the shield. On September 6, 1941, the marshal demanded that a batch of 20 pieces be urgently produced and sent for testing to the military council of the Western Front. It is not known whether these products received any index, but two batches of “embrasures designed by Timoshenko” were manufactured with a total of 25 pieces. Both series did not withstand factory shelling tests and were safely forgotten.

According to the Decree of the State Defense Committee of the USSR No. 2160ss dated August 8, 1942, 15 thousand CH-40A were manufactured. The Leningrad Front received 1,000 pieces, the Donskoy Front received 5,000 pieces, the South-Western Front received 5,000 pieces, the Volkhov Front received 1,000 pieces, and the Stalingrad Front received 3,000 pieces. The release of the bibs was intended for widespread testing among the troops in a combat situation.

Imitation of a gun crew when testing the CH-42 breastplate with mortar fire.

Military tests of the CH-42 by anti-tank artillery crews.

Since February 1942, all developments on shields and breastplates were officially transferred to Research Institute No. 13 of the People's Commissariat of Armaments. And already in March, new products were presented for testing. The bibs received the index SN-42, and the shields - SShchN-42. The technical conditions for their production were approved on August 7, 1942. At the same time, by Stalin’s personal order, the products were sent to the front for testing. Only in November 1942 was the bib sample finally approved and an order for its production in the amount of 100 thousand pieces was approved. A guide to their use has been developed. It summarized all previous experience accumulated since 1937, and indicated how and by whom the steel breastplate should be used:

— scouts performing a search;

- sappers during reconnaissance, making passages in the wire, when clearing mine barriers under enemy fire;

- infantry groups conducting force reconnaissance (reconnaissance in force);

- submachine gunners infiltrating enemy battle formations in tank landings, and groups of submachine gunners in ambush;

- assault groups capturing bunkers;

— signalmen checking or correcting cables under enemy fire;

- by decision of the commander, whenever the situation allows us to count on the successful use of bibs.

The front side of the steel bib CH-42 with the top loop.

The back of the bib with a second shoulder strap.

Three options for use were provided: the bib is attached to the body with straps and covers the chest and abdominal cavity during movement; when crawling, the bib is used as an embrasure; the bib is used as a shell, covering individual parts of the body (right side, left side, head).

Reenactor wearing a steel bib CH-42.

CH-42 was made of 2-mm steel 36SGN, within tolerances of 1.8 -2.2 mm, the weight of the bib was 3.3 - 3.5 kg. Protection area 0.2 sq. m. By modern standards, it approximately corresponds to class 2 body armor - both in weight and in protective qualities. The breastplate protected against a bullet fired from a submachine gun or pistol from a distance of over 50 m. Light rifle bullets were safe from a distance exceeding 600 m. Machine gun bullets and heavy rifle bullets pierced the breastplate from almost any combat flight distance of the bullet. Soldiers usually put this “shell” on a padded jacket with the sleeves torn off, which served as an additional shock absorber, despite the fact that the breastplate had a special lining on the inside. The presence of clothing under the body armor reduced not only post-concussion injury from a bullet, but also the impact of the shock wave from the explosion of shells or mines. The breastplate had a second vertical shoulder strap, which made it easier to carry on the “march” and the ability to use it when folded as armor protection from two sheets.

Using the CH-42 for prone shooting.

SN-42 breastplate, captured from soldiers of the 171st Infantry Division. Demyansk boiler. 1942

In besieged Leningrad, due to limited human and medical resources, the task of protecting soldiers from bullets and shrapnel was more urgent than on the “mainland.” But the city was supplied primarily with weapons, ammunition, fuel and food; the rest of the equipment was supplied on a residual basis. The provision of Lenfront with CH-42 bibs is eloquently stated in the report of I.V. Stalin dated May 7, 1943, according to which, out of 85 thousand bibs produced by that time at the Lysvensky Metallurgical Plant, only 1000 pieces were sent to Leningrad. And since Research Institute No. 13, the developer of steel helmets and CH-42, operated on the territory of Leningrad, the local leadership set the task of creating their own version of protecting soldiers. This is how the PZ-ZIF-20 protective shell was born, which began to be produced at the Frunze plant (hence the abbreviation ZIF). The problem was the choice of armor steel for making the breastplate: in the besieged city there was nowhere to get it from. Therefore, local metallurgists had to work hard before they achieved the required steel composition and hardening technology.

Leningrad protective armor PZ-ZIF-20.

In terms of its characteristics, it was better than the CH-42, but even today there is a contrary opinion in the literature due to an inaccurate report sent to Moscow. Thus, the Leningrad armor protected against a machine gun bullet fired from a distance of 10 m, while the SN-42 protected only from 50 m. The armor was produced in 1943 in several batches of three sizes. The thickness of the armored plates was in the range of 2.5-2.6 mm, the weight reached 4.8-5 kg. In August 1943, 5 thousand CH-42 breastplates were delivered to Leningrad, which somewhat improved the supply of infantrymen. However, the production of shells continued until the end of the blockade. In total, about 10 thousand products were produced.

The breastplate consisted of five steel plates connected by leather or braid straps riveted to a fabric sleeveless jacket. It was intended to protect the chest and abdominal cavity of soldiers of infantry units. Sometimes PZ-ZIF-20 is confused with CH-38 or CH-39 due to its external similarity, but they have little in common.

In addition to the PZ-ZIF-20 shell, armor protection for sailors, or “marine armor protection from the Frunze plant”, was developed in Leningrad under the designation MPZ-ZIF-22. It was created to protect the chest and abdominal cavity of the gun crews of naval and coastal artillery installations of the Navy from shrapnel and bullet wounds, and could be used by enlisted personnel and officers located on the upper decks of ships during battle. The main difference from other bibs was the presence of back protection.

The protection consisted of three armor plates with a thickness of 2.2–2.6 mm: a breastplate, a hanging shield and a back. The structure was connected together with straps placed over holster buttons. Such a device ensured almost instantaneous dropping of the shell (a requirement of sailors who did not want to swim in the shell if they got overboard) while ensuring the necessary freedom of movement when working with weapons and mechanisms. The assembled kit weighed 9 kg and was identical in bullet resistance to PZ-ZIF-20. The design has not become widespread, but there are references to the use of such shells by torpedo boat crews in the literature.

Soldiers wearing CH-42 breastplates.

In conclusion, let us look at the surviving examples of the use of steel breastplates in combat conditions. It was most often used in engineering assault brigades, which appeared already during the battles with Stalingrad. Later they were officially called assault engineer reserve brigades (SHISBr). They were widely used in urban battles in Europe and the Far East. The fighters of such brigades were called “panzer infantry”.

A Soviet soldier wearing a steel CH-42 breastplate during street fighting.

Three quarters of the brigade's sappers had steel breastplates. Usually bibs were worn over padded jackets or padded jackets. Soldiers willingly used them in battles for cities, but tried not to wear them in field operations, where most of the work and movement was done while lying down. The breastplate saved soldiers during close and hand-to-hand combat, and often protected them from fragments of small mines and enemy hand grenades.

Storming of the building by soldiers of the 1st ShISBr. Central Front, September 1943

When assessing the effectiveness of using steel breastplates during the war, some important points should be noted.

Firstly. The development, testing and production of products took a criminally long time. Extreme bureaucracy and paperwork ate up an enormous amount of time. The command's lack of understanding of the importance of individual protection for soldiers was the result of red tape with the introduction of bibs. Zhukov’s expression of not sparing the soldiers - women are still giving birth is clearly the root cause of this attitude of the high command to protection. Not a single weapon or equipment in the USSR was developed for as long as the steel breastplate. For delaying the fulfillment of a defense order by several days, they were shot within a few minutes. And here... Secondly. Initially, the developers of the bibs were given the wrong task - protection from a submachine gun bullet. “Smart” rear commanders considered it the main weapon of the Wehrmacht. At a time when this was a rifle, and a submachine gun was used as a weapon of self-defense in certain branches of the military, but not by infantry. Hence the high penetration of a rifle bullet. Third. The lack of interest of the high command in the production of breastplates led to the fact that the development of the composition of the armor was carried out by enthusiasts rather than by special institutes under strict control. Steel compositions were used as armor according to the recipe “what God sent,” and the issues of replacing steel with other materials were not considered at all. As a result, the armor turned out to be heavy, and the bulletproof protection was very weak. Fourthly, a one-sided approach to the means of protection - everyone saw it only in the form of a breastplate - killed promising developments of body armor in the bud. Fifthly. The idea of individual protection on the battlefield in the USSR was 30-40 years ahead of the actual demand for it. Although already at that time the US police widely used body armor that protected against pistol and revolver bullets, as well as bladed weapons. It was only during the war in Afghanistan that body armor became the everyday equipment of an infantryman.

Considering that the number of steel breastplates produced during the war was scanty, there are no statistics on the effectiveness of their use. The remaining front-line memories are mixed. However, the very fact that the soldiers wore them speaks volumes – there was some benefit. At the same time, the lack of protection for the back, not to mention the sides, made the breastplates in many cases a useless piece of iron. Hence, the bib should not be considered as a universal means of protection, such as today’s body armor, but exclusively for the purpose described in the instructions for its use. In this framework, if the bibs did not save from bullets and shrapnel, then at least they significantly reduced the number of deaths. And this is already the effectiveness of protection.

Based on materials from the sites: https://ru.wikipedia.org;

https://smolbattle.ru; https://warbook.info; https://warspot.ru; https://www.russianarms.ru; https://www.drive2.ru; https://cold.refepic.ru; https://warfor.me; https://web.archive.org. Share to:

The article is devoted to several samples of steel bibs CH-40, CH-40A, CH-42 (CH-2). The article may contain inaccurate information due to the unpopularity of some samples of steel breastplates, differences in the thickness of armor plates, as well as their visual similarity. I hope that everything in the review article describing these body armor is accurate.

The CH-40, CH-40A, CH-42 series became a continuation of the first Soviet body armor CH-38 and CH-39 .

CH-39 and CH-38 (PZ-ZIF-20) were first seen in real combat in the Winter War of 1939-1940 with the Finns, where the advantages and disadvantages of the steel breastplate were found. The armor protection was not enough, since the body armor was penetrated by Finnish machine guns and rifles, they discovered that the Finns used weighted bullets and armor-piercing bullets B-30 and B-32, which were obtained from downed Soviet aircraft). Even by modern standards, protection against heavy bullets requires the latest class of armor protection, and this is already the 6th class of protection, as a result of which the CH-40 was created, which had two movable shields made of 2-mm steel, and also a reinforced version of the CH-40A appeared, made from 5.2 mm steel grade 36SGN with a tolerance of 0.3 mm. Testing of Steel Breastplates took place at the Red Army Small Arms Research Site (NIPSVO KA). As a result of the tests, it was discovered that the SN-40 steel breastplate provides protection when fired from a rifle at a range of 100-150 meters and protection from F-1 and RGD-33 grenade fragments even with a close explosion. According to the Decree of the State Defense Committee of the USSR No. 2160ss dated 08/08/1942, 15,000 CH-40A were manufactured and delivered to the Leningrad Front - 1000 pieces, the Don Front - 5000 pieces, the South-Western Front - 5000 pieces, the Volkhov Front - 1000 pieces and the Stalingrad Front - 3000 pieces.

According to the modern protection class, the steel bib CH-42 (SN-2) and CH-40A can be classified as body armor of the second class of protection according to GOST

The CH-40A was put on a soldier using several belts; under the body armor, the soldiers preferred to wear a cut-off quilted sweatshirt in the summer season, a “sweatshirt”, and in the winter they wore a robe on top of their clothes, if possible. The presence of clothing under the body armor reduced not only post-concussion injury from a bullet, but also the impact of a shock wave from the explosion of shells or mines. The steel breastplate consisted of two armored shields connected by metal belts and canvas belts. The design of two armored shields made it comfortable to wear, since you could sit down with it in a vehicle, in this position the lower shield would rise. Also, the design of two shields provided the largest possible area of body protection.

A further continuation of the CH-40A was the CH-42 (CH-2), for the manufacture of which they used lighter and more vicious steel grade 34Х2ГС2 in 2 mm with a tolerance of 0.2 mm, which made it possible to reduce weight, the steel bib also received a second metal loop, which provided easier carrying on the “march” and the ability to use it when folded as armor protection from two sheets (see figure). The first CH-42 (steel breastplates) were ordered by the State Defense Committee No. GOKO-2442ss at plant No. 700 of the People's Commissariat of Ferrous Metals. The CH-42 had slightly worse armor protection properties in comparison, since it could already penetrate 200-300 meters with rifle bullets.

Steel bibs proved to be excellent during the Second World War, saving thousands of lives, and sometimes several times. The disadvantage of steel breastplates was their weight, since when marching they were often thrown away so as not to bear the weight.