Today, spoiled by a wide variety of semi-automatic smoothbore weapons, even Russian hunters of the old formation have begun to forget that once upon a time most of them had a longed-for dream - the Tula self-loading gun MTs 21-12. Today, this single-barreled gun, despite the fact that it continues to be produced by TOZ, is considered bad and outdated in all respects. Especially for young hunters, for whom hunting is just a tribute to fashion or a type of business corporate event. In such circles, a gun is not a tool, but an indicator of the social status of its owner. In this article we will not praise the honored veteran of the Soviet arms industry. And we won’t throw mud at it by listing all the shortcomings. The purpose of the article is to look at the MTs 21-12 hunting weapon from the position of a modern fisherman who has fully experienced the variety of both imported and domestic “self-loading” guns.

History of weapons

Probably, only the lazy have not written about the MTs 21-12 gun over its more than fifty-year history, so in this article we will simply recall the most important events in the life of this weapon and also briefly dwell on its technical characteristics and design features. This “self-loading” is truly iconic for many hunters and commercial hunters of the past, so even this tired information may be useful to someone, or at least theoretically interesting. So, the MTs 21-12 shotgun (photo above) was created by designer V.A. Nikolaev. It is a self-loading single-barreled weapon for commercial and amateur hunting. Initially, from 1956 to 1964, this model was manufactured at TsKIB SOO. In addition, until 1965, the MTs 21 was also produced in 16 and 20 calibers. At the Leipzig Fair, held in 1965, this model was awarded a Gold Medal. In the same year, the production of the gun was transferred to TOZ. Until today, MTs 21-12 was produced only in twelve gauge.

History of appearance

The development of the MTs 21 shotgun was carried out in the late 1950s at the Central Design and Research Bureau of Sports and Hunting Weapons (TsKIB SOO) in Tula. This project was carried out under the leadership of designer V.A. Nikolaev. Some design solutions were copied from the Italian Breda Antares weapons.

The new gun was initially intended to be chambered for 12, 16 and 20 caliber cartridges in a 65 mm long paper sleeve. The passport of this weapon stated: “The MTs 21 shotgun is a self-loading single-barreled weapon for commercial and amateur hunting.” From 1958 to 1964, the model was actually manufactured piece by piece and only at the TsKIB SOO.

In 1965, the Soviet MTs 21 shotgun received recognition outside the USSR: it was awarded a gold medal at the Leipzig Fair. In the same year, serial production of these weapons began at the Tula Arms Plant (TOZ), but the model range was limited only to 12-gauge guns. The new weapon was able to achieve a serious increase in popularity and recognition among hunters with the start of production of charges with plastic sleeves.

It should be noted that the serial production of MTs 21-12 hunting rifles at TOZ significantly reduced the cost of their production, but sometimes there were complaints about the quality of the products. This especially affected specimens manufactured after the 1990s, when new economic conditions in the country forced some technological processes. However, according to the Tula Arms Plant, over the entire period of serial production it produced over 300 thousand copies of MTs 21-12 hunting rifles.

The modification of the MTs 21-12R shotgun resulted in its equipping with a rubber shock absorber on the butt plate. The version of the MTs 21-12M carbine differs from the basic one in the presence of replaceable choke tubes. There is also a modification MTs 21-12MR, which provides a combination of the previous options.

The “Soviet” version of the MTs 21-12, despite all the primitiveness of the “equipment”, is considered to be of very high quality

Description of components and mechanisms

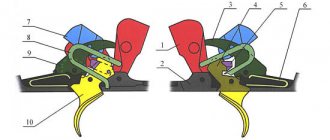

The automatic weapon is based on the recoil principle of a spring-loaded movable barrel and a bolt mechanism sliding longitudinally along the Browning system of the 1905 model. Reloading is carried out as a result of using a rather long stroke of the barrel at the moment it moves to the rear and then to the front position. The removable barrel, 750 mm long, has a ventilated rib. Chamber – 70 mm. The trigger parts, muzzle channel and bolt are chrome-plated, this greatly facilitates the maintenance of the weapon and also increases its durability.

The barrel is locked using a longitudinally sliding bolt. Its combat stop is fixed by the hole in the shank. The progenitor of this model, the Auto-5 produced by Browning, has a rectangular stop. So, in one of the issues of the magazine “Hunting and Hunting. Economy" Tsarkov V. (honorary member of MOOR), describing the delay characteristic of the MTs 21-12 gun - non-disconnection of the bolt and barrel when fired, focused on the round shape of the stop as the cause of this defect. Of course, there is truth in the words of the old hunter, but it should be understood that changing the shape of the combat rest, so to speak, simplifying the design, is explained by the need to circumvent the patent rights of Browning’s design. In addition, the time of release of the gun should also be taken into account; in the fifties, no one would have allowed an unfinished model into production. The causes of problems with weapons, provided design flaws are excluded, usually lie in the quality of assembly and manufacturing. Also, we should not forget about the quality of ammunition.

The MTs 21-12 hunting rifle has a trigger-type trigger assembly assembled on a separate base. Extraction of the cartridges is carried out at the moment the barrel moves to the forward position. If the channel is unlocked, a shot is impossible.

General conclusion

Both hunting rifles deserve a worthy place in the arsenal of every hunter. MP-155 and MC-21-12 have approximately the same cost, so which gun to choose is an individual choice, based on personal preferences. One thing is certain that both of the guns reviewed will last quite a long time.

What do you think is better - MP-155 or MTs-21-12?

Video of firing from MP-155 and MTs-21-12

Previous post Spring hunting for game birds

Next post Beretta 686 Silver Pigeon1 or Benelli 828U Black: who is better?

Short description

The MTs 21-12 shotgun (the photos given in this article will help the reader form their opinion about this weapon) has an under-barrel tubular magazine with a capacity of four rounds. The body serves as a guide for the movement of the barrel. The cartridges from the clip are fed by the bolt as it moves to the forward position. The magazine is filled one ammunition at a time, through a window in the lower part of the receiver. If necessary, the shooter can block the supply of cartridges from the clip by turning on the cut-off device mounted on the left side of the box. A non-automatic flag-type safety locks the trigger. An interesting feature is the ability to move the checkbox to the left side. MC 21-12 pistol buttstock. The stock is removable and is secured with a spring-loaded nut on the magazine body.

Disadvantages of MTs-21-12:

- In the butt, in a humid environment, condensation collects.

- The gun has a mass of about 3.7 kg, which many people think is too much, especially if it is used as a gun for running hunting.

- Iron sleeves must not be used. Prohibited by the manufacturer.

- The MTs-21-12 shotgun requires careful care, otherwise malfunctions in the operation of the automation and trigger mechanism may occur.

- The gun is not intended for shooting light ammunition; when shooting cartridges with loads of 28 grams or less, there may be problems with reloading.

- The gun is quite heavy, the balance of the gun leaves much to be desired, and it is difficult to shoot short-handedly.

Performance characteristics

The weight of the weapon is 3.2-3.4 kg. Overall dimensions -1285x65x200. Trigger force - 1.5-2.5 kg. Sometimes the literature indicates no more than 3.7 kg. When compared with modern self-loading shotguns based on aluminum alloys, this is quite a lot. However, MTs 21-12 is entirely made of high-quality Tula steel; it has a large margin of safety. The manufacturer provides a guarantee for 6500 shots. If the reader doubts whether this is a lot or a little, then as an example we can cite the Izhevsk Saiga, the guarantee for which is only 2000 shots.

However, let's return to our gun. The safety margin of this weapon is so large that with proper care it can serve for a very long time. Breakdowns even after ten thousand shots are very rare. Here is such a reliable model - MTs 21-12. The characteristics of this gun speak for themselves. Try to fire 10,000 shots from an imported “self-loading” basic configuration, it is unlikely that you will succeed. Owners of this gun should take into account one feature - only ammunition with plastic casings can be used. The manufacturer strictly prohibits the use of metal and paper cartridges.

Specifications

Cartridges and caliber

For shooting, 12-gauge cartridges with a non-metallic sleeve 70 mm long are used. It is optimal to use only plastic cartridges in a gun. The use of metal is prohibited by the manufacturer, and the metal back of folder (paper) sleeves often comes off.

For the MTs 21 shotgun, it is preferable to use powerful hunting ammunition. Although adjustment of the barrel stroke is provided for small and large charges, under-recoil of the barrel with weak cartridges occurs more often. It is strictly forbidden to shoot sports cartridges for clay pigeon shooting: such ammunition, intended for shotguns with short barrels, develops a pressure in the long barrel higher than the maximum permissible for the MTs 21 shotgun.

Dimensions, weight, length

| Options | Values |

| Overall body length | 1 120 mm |

| Barrel length | 625 mm |

| Weapon height | 202 mm |

| Weapon thickness | 57 mm |

| Weight | 3.89 kg |

Working resource reserve

The working life reserve declared by the manufacturer of the MTs 21-12 is 6.5 thousand shots. For comparison: this figure of only 2 thousand shots is set for the Saiga, the civilian version of the Kalashnikov assault rifle, which is considered the world standard for reliability. The durability of the MTs 21-12 carbine is facilitated by chrome plating of its chamber and bore.

Firing range and lethal force

The MTs 21-12 shotgun is considered quite long-range for hunting purposes. This is due to the fact that, in comparison with gas-operated guns, the MC 21 uses the entire power of the charge per shot. In addition, a relatively large choke (choke) of 1 mm contributes to less dispersion of shot when shooting at long distances. Thus, even without the use of attachments, a shot at a bird is effective at a distance of up to 70 meters.

You won't be nice to everyone

Let's look at another unique side of the MC 21-12 model. Reviews and diversity of opinions about it are probably inferior in the severity of discussions between opponents and supporters of Saiga. In fact, this applies to any gun. After all, we are all different. Gender, age, type of higher nervous activity, social status and income level, experience with weapons and hunting, presence or absence of desire/ability to do something with your own hands, etc. All of these factors will inevitably influence the perception of phenomena and objects , making them special for each individual. Well, if you take into account the bright individuality of any weapon model that is not made on the production lines of CNC machines, then it becomes clear: you cannot expect a consensus from such a diverse hunting community about the very controversial MTs 21-12 gun.

Advice from experienced hunters will help you understand the main problems of this weapon. They are known to many, and all of them are curable in a home workshop. Simply put, any hunter whose hands grow from the right place, with a couple of free evenings and a minimal set of tools, can make his semi-automatic machine absolutely reliable and trouble-free to use.

What to do: buy a foreign car or support a domestic manufacturer?

For those who do not want to think and do mechanics, it is easier to purchase an imported “self-loading”. Such single-barreled hunting rifles are beautiful, lightweight and almost trouble-free. There is one small drawback: the price of such weapons can be several times, or even an order of magnitude, higher than the cost of our MTs 21. There are also so-called budget models, but their quality cannot be compared even with our “handicraft” production; this is money thrown away .

Today, the whole world is again gripped by an economic crisis; the cost of imports is steadily rising, as a result of which their supplies are declining. Domestic gunsmiths have an excellent chance to occupy the emerging niche of this market not only in Russia and the CIS countries, but also in Europe. Agree that it is better to purchase inexpensive equipment from Russian gunsmiths and, if necessary, modify it slightly, than to be left without your hobby at all. Turkish consumer goods do not solve the problems - their self-loading single-barreled shotguns are more expensive than domestic ones, and they have similar problems with quality, although commercials say the opposite.

MC 21 was valued by experienced hunters in the past, and now it is bought by those who cannot afford expensive weapons, or by experienced connoisseurs. Of course, this gun has modern competitors, such as the legendary Murka MP-153, TOZ-87 and Bekas-auto. “Bekas” and “Murka” are also very controversial representatives of semi-automatic hunting rifles, but the TOZ-87, if it were manufactured at a higher quality level, could become the best domestic self-loading rifle. The MP-153 rightfully occupies the title of “national”, but its cost is one and a half times higher than the MTs 21-12, and in comparison with it this model is often inferior in the quality of the barrel, has a narrow, inconvenient sighting bar, and is also characterized by misalignment of the muzzle nozzles The guns of Tula gunsmiths are traditionally distinguished by excellent barrels and remarkable action. Many hunters purchasing MC 21 today make their choice precisely because of these qualities.

Characteristics of the MP-155 shotgun

The Izhevsk smoothbore semi-automatic shotgun MP-155 is much “younger” than the MTs-21-12, since it appeared only in 2014. year. The MP-155 shotgun itself is an improved version of the MP-153 semi-automatic weapon, which has long been discontinued. The automation of the MP-155 smooth-bore self-loading shotgun is based on the use of the energy of powder gases. When fired, the gases push the piston, which is rigidly coupled to the bolt, which leads to reloading of the gun. The MP-155 automation itself has automatic adjustment, that is, when using a regular 70 mm. cartridge, part of the powder gases is released through special valves.

The MP-155 is produced in 12 gauge, with a chamber length of 76 mm, that is, for a reinforced cartridge. The barrel length, depending on the modification, can be 540 mm, 610 mm, 640 mm, 710 mm. and 750 mm. The capacity of the under-barrel magazine is 4 rounds, plus an additional one in the barrel. The butt and fore-end of the MP-155 hunting rifle are made of birch (for the ordinary version), beech or walnut (for export or piece version).

MP-155 - owner reviews

The undoubted advantages of the MP-155 include the simplicity and reliability of the automation: with proper care and timely maintenance, this gun can last for several decades. The accuracy and accuracy of the shot of this gun is very high: a target with a diameter of 50 cm is confidently and accurately hit from a distance of 50 meters, while the spread of the shot is minimal, which guarantees a successful and accurate shot during the hunt.

We recommend reading: a comparative review of the technical characteristics of the Tula MTs-21-12 and Stoeger-2000 from the Turkish manufacturer

The MP-155 has a ventilated rear sight and a clearly visible front sight, which makes aiming easier. Moreover, the gun is equipped with a dovetail rail, which makes it possible to install an optical or collimator sight, which makes shooting much more effective.

The MP-155 has many modifications, so choosing the appropriate option will not be difficult. The Izhevsk semi-automatic machine has incorporated all the technical innovations.

Since 2017, an updated and improved version of this hunting rifle began to be produced

Among the shortcomings, it can be noted that the build quality, especially in ordinary models, is not very good. There are unnecessary gaps, the wooden parts do not fit well with the metal ones. When using non-factory-made ammunition, it will inevitably lead to jamming of the gun, which will be very difficult to eliminate.

Debugging and fine-tuning according to A. Azarov’s method: automation system

In one of the issues of the magazine “Hunting and hunting. Economy" an article by A. Azarov was published, in which he gives recommendations for debugging the MTs 21-12 gun. Below we will look at what the author advises.

The recoil system plays a huge role in the operation of automation. Sometimes guns go on sale whose barrels do not have a chamfer in the brake clamp ring. In such copies, a pair of buffer rings are placed on the magazine. The author of the article recommends that owners make small chamfers on the rings themselves, otherwise the mechanisms will begin to scratch each other with sharp edges, and shavings will literally be removed. In addition, scuff marks on the clip will interfere with the functioning of the recoil system.

The process of locking the barrel also plays a decisive role in the performance of the automation. The bolt lug, being in the forward position, rises up and enters the barrel shank window. Its cylindrical part may fit unequally tightly to the walls of the window. It is necessary to look when the gun is assembled with the box cover removed; there should be a tight fit only in the rear part. If it is not there, then when fired, the stop will produce hardening on the cutout of the shank. On some specimens, such a gap can reach one millimeter - this is unacceptable. Now in gun stores you can purchase spare parts for the MC 21-12 model, so to speak, for all occasions. Thus, combat lugs are produced with diameters of the cylindrical part from 10.7 to 11.9 mm. It is necessary to eliminate this deficiency through selection. Strong tension and poor polishing in this part are also unacceptable, since the bolt and barrel will not disengage.

Possible malfunctions, debugging and fine-tuning of the bolt mechanism

At the top of the bolt end there is a latch on the left, and an ejector on the right. It is necessary to check the quality of grinding visually and by touch; if there are burrs, carefully remove them with velvet sandpaper. If the insert on the shutter is plastic, it is better to replace it with metal to avoid chipping. In addition, it is necessary to check the tightness of the mechanisms. Large transverse play of the shutter in the grooves of the box is not allowed. If you rock it from side to side, it should not slosh, otherwise this may lead to the breaking of the mechanisms. You should also check the feed tray. It should be level with the magazine window (displacement is unacceptable), there should be no burrs on it, since the cartridges will be slowed down as they slide along the tray. All mechanisms must be polished, otherwise the ammunition will cling to uneven surfaces when fed. Cartridges for MTs 21-12 should also have no defects on the outer surfaces of the cartridge cases.

In the assembled state, the lower right protrusion of the bolt must press the right stop to avoid delays in the release of ammunition from the clip to the limiter. Sometimes it slips through in poorly tuned weapons. In this case, the right stop is not recessed into the groove on the box. This results in the cartridge getting stuck in the clip. The same can happen after intensive use of the gun, when the barrel and the end of the forearm shock absorber break. As a result, the shutter will begin to move forward further than it should. In this case, the repair comes down to moving it back and fixing the forearm shock absorber. You can glue a specially machined ring under it.

If the bolt is pulled back a little, the right stop should fix the ammunition in the clip, resting against the flange of its cartridge case. If this does not happen (dirt in the groove or the spring is broken), then the cartridge falls to the ground. This happens when the bolt, moving forward, sends the next ammunition into the chamber with the tray raised, and the next one falls under it. This can also occur when the diameter of the liner flange is too low. If the feeder latch is held in the groove at the moment of moving back, then the tray rises up, and the barrel, moving forward, pushes the left stop and releases the cartridge, which as a result falls to the ground.

Debugging and fine-tuning of the receiver

As a result of the fact that the end of the lid protrudes above the box, the forend of the gun does not fit tightly into its proper place, and the clamps in this case may not fit into the ends of the grooves. As a result, the stock rotates on the holder. In this case, it is necessary to adjust the box lid. Sometimes you come across specimens in which the end clip can be screwed to the fore-end with a bias, as a result of which the barrel will be slowed down when it rolls back against the internal walls. In this case, you should clean the wooden surface in these places. If this does not help, then you need to reinstall the clip.

It is also necessary to pay attention to how the mainspring is installed in the trigger. Does the right wall interfere with her work? In the assembled position, remove the cover and check whether the shutter pushers are pinching the trigger. You should make sure that the stock support (front) washer is not displaced relative to the hole, otherwise it may damage the threads on the end of the cage and will loosen its fastening.

General debugging

There are specimens in which the case flange is severely deformed after firing. This occurs as a result of poor fit of the locking mechanism. This defect can only be detected after shooting.

Before operating the gun, it is necessary to determine the smaller diameter coil of the brake spring. Use this ring to put it on the magazine tube. You should also use a velvet file to smooth out the sharp parts on the last turn of the spring. In this case, the ferrule tube will not be scratched.

When jerking the shutter, you need to make sure that the rod and spring do not jam in the shank of the box. If something bothers them, the cause should be eliminated. In addition, you need to check the operation of the ammunition cutter. If you turn the flag counterclockwise, the cartridge should stop at the cutoff when the bolt is pulled back. And in the future do not reach the left stop.

Shotgun MTs 21-12: price

Due to the fact that this weapon has already been discontinued, it is difficult to find it on the shelves of gun stores. However, there is no need to despair, they are still in stock, and if desired, they can be ordered, although you will have to wait a while. The disadvantage of such a purchase is that you will not have the opportunity to choose the best among several copies. So it’s better to find a store that still has this weapon in stock. So, you have decided to buy a shotgun MTs 21-12. The price of such a “self-loading” will be approximately 15 thousand rubles, but if you wish, you can also purchase weapons on the secondary market. In this case, its cost will be much lower.

Advantages of MTs-21-12:

- The gun has a good service life; with proper care and consideration, it will serve the hunter for many years.

- The gun is fairly easy to care for. The gun is easy to disassemble, easy to clean and easy to assemble.

- Compared to other semi-automatic shotguns, the MTs-21-12 reloads well, even when using fairly powerful cartridges.

- Due to reloading by moving the barrel, as well as its large mass, the MTs-21-12 gun has a very comfortable recoil.

- The MTs-21-12 shotgun, like many other domestic shotguns, can always be modified and changed to suit your needs.

- Low price of the gun.

Summary

Many young hunters are frightened by the automatic principle in this gun - the recoil of the barrel. However, we should not forget that this scheme was the only one that worked until the end of the 80s of the last century. The first mass-produced semi-automatic shotguns with a gas-operated system appeared only in 1990. A little more than twenty years have passed - and on the shelves of gun stores you can see orderly rows of gas-operated “self-loading”, and the system with a recoil barrel is represented only by the MTs 21-12 model. Reviews from Arctic hunters about this gun are clear. It turns out that in these difficult weather conditions there has never been and still is no alternative to this weapon. The well-functioning MC 21-12 proved to be an accurate and reliable assistant at autumn temperatures down to twenty degrees below zero. Until now, in the north it is used both for hunting deer and for hunting geese, because a very sharp and close fight allows you to hit a bird at distances of up to seventy meters.

Today, the MTs 21-12 shotgun is still in demand by hunters. Often a new copy works flawlessly, refuting evil slander, right out of the box. True, the opposite situations also happen when the gun does not want to work at all. However, in this case, it is enough to spend an hour or two of time, armed with a file, for it to work like a clock. Given the attractive price, the gun is purchased by both experienced hunters and beginners. Soviet-built specimens are especially prized. Despite their advanced age, they still delight their owners.

So we won’t rush to write off the MTs 21-12 gun, despite its shortcomings, from the arsenal of domestic hunters for now...