Chapter IV OPERATION OF PISTOL PARTS AND MECHANISMS

Chapter IV

OPERATION OF PISTOL PARTS AND MECHANISMS

Position of pistol parts and mechanisms before loading

34. The parts and mechanisms of the pistol are in the following position before loading.

The shutter under the action of the return spring is in the extreme forward position; the bolt cup rests against the breech section of the barrel, as a result of which the barrel is locked with a free bolt. The longitudinal protrusions of the shutter fit into the grooves located in the rear of the frame. The bolt and frame are locked with a safety rib.

The trigger , under the action of the wide feather of the mainspring, is lowered and rests with its front plane against the fuse protrusion so that it cannot move forward.

The sear is raised upward by the shelf of the ledge on the safety axis and is held in this position so that there is a small gap between the safety cocking of the hammer and the nose of the sear.

The trigger rod with the cocking lever is moved to the rearmost position under the action of the narrow mainspring; The cocking lever is recessed into the frame and its self-cocking protrusion is engaged with the trigger's self-cocking tooth so that when the tail of the trigger is pressed, the hammer is not cocked, but has some free movement back.

The magazine is inserted into the base of the handle. The feed is at the top and rests against the ridge of the bolt. The feed tooth presses on the bolt stop.

The fuse box is in the “safety” position. In this case, the fuse protrusion is lowered down and comes into contact with the front plane of the trigger; the ledge shelf on the fuse axis, by acting on the sear tooth, lifts the sear up and holds it in this position; the safety hook enters the trigger recess and, resting against its protrusion, locks the trigger in the “safety” position so that it cannot be cocked; the fuse rib extends beyond the left protrusion of the frame and locks the bolt with the frame.

Operation of pistol parts and mechanisms during loading

35. To load the pistol you need:

— equip the magazine with cartridges;

— insert the magazine into the base of the handle;

— turn off the fuse (turn the flag down);

- move the shutter to the rearmost position and release it sharply.

When loading the magazine, the cartridges are placed on the feeder one on top of the other in one row, compressing the feeder spring; As the magazine is filled with cartridges, the feeder spring compresses and, pressing the feeder from below, lifts the cartridges upward. The upper cartridge is held by the curved edges of the side walls of the magazine body.

When a loaded magazine is inserted into the base of the handle, the magazine latch slides over the protrusion on the wall of the magazine and holds the magazine in the base of the handle. The upper cartridge rests against the ridge of the bolt. The feeder is located at the bottom; its tooth does not act on the bolt stop.

When the safety is turned off (the flag is turned down), the safety protrusion rises and releases the trigger. When turning the safety, its hook, coming out of the trigger recess, releases the trigger protrusion, which ensures free retraction of the trigger. The shelf of the ledge on the safety axis releases the sear, which falls slightly down under the action of its spring, and the nose of the sear becomes in front of the safety cocking of the trigger (the trigger is on the safety cocking). When you turn the safety, its edge comes out from behind the left protrusion of the frame and separates the bolt from the frame. In this case, the shutter can be pulled back by hand.

When the shutter is pulled back, the following happens.

The shutter, moving along the longitudinal grooves of the frame, turns the trigger. The sear, under the action of a spring, jumps its nose behind the cocking cock. The rearward movement of the shutter is limited by the ridge of the trigger guard. The return spring is under maximum compression.

When the trigger is turned by the front part of the annular recess, it shifts the trigger rod with the cocking lever forward and slightly upward, due to which part of the free play of the trigger is selected. When the cocking lever is lifted up, its cutout approaches the protrusion of the sear.

The magazine feeder, under the action of the feeder spring, lifts the cartridges up so that the upper cartridge becomes in front of the bolt rammer.

When the bolt is released, the return spring sends the bolt forward. Moving along the longitudinal grooves of the frame, the bolt rammer moves the upper cartridge into the chamber. The cartridge, sliding along the curved edges of the side walls of the magazine body and along the bevel on the tide of the barrel and in the lower part of the chamber, enters the chamber and rests with the front cut of the sleeve against the chamber ledge; The barrel bore is locked with a blowback bolt. The second cartridge, under the action of the feeder spring, is lifted up by the feeder until it stops against the bolt ridge.

Rice. 46.

Position of parts and mechanisms of the pistol before firing:

1

- shutter;

2

- ejector;

3

— return spring;

4

— trigger;

5

— trigger rod;

6

- store;

7

— mainspring;

8

— sear with a spring;

9

— cocking lever;

10

- trigger

When the bolt reaches its extreme forward position and sends the cartridge into the chamber, the ejector hook slides into the annular groove of the sleeve.

The trigger is cocked.

The pistol is ready to fire (Fig. 46).

Operation of parts and mechanisms of a loaded pistol when the safety is turned on

36. If it is not necessary to fire a shot, then, without releasing the trigger, you should turn on the safety by turning its flag up all the way so that the red circle is covered by the safety flag.

When the flag is turned, the fuse protrusion lowers and before the sear begins to rise, it stands in the path of the trigger movement; the fuse axis raises the sear with the shelf of the ledge, as a result of which the sear rotates and releases the trigger; the trigger, under the action of the wide feather of the mainspring, turns and strikes the fuse protrusion; The fuse rib, turning, extends beyond the left protrusion of the frame and locks the bolt with the frame. The safety hook, lowering, enters the hammer recess and locks it so that it is impossible to cock the hammer.

If you turn off the safety in this position, the trigger automatically becomes safety cocked thanks to the release. In this case, the pistol is ready to immediately open fire by self-cocking. The safety of handling the pistol in case of accidental impacts is ensured by automatically setting the trigger to the safety cock.

If the trigger is released not by the safety catch, but manually, that is, by pressing the tail of the trigger with the index finger of the right hand while holding the head of the trigger with the thumb of the same hand, then the trigger, after releasing the trigger, also automatically (thanks to the “release”) goes to safety platoon.

Operation of pistol parts and mechanisms when fired

37. To fire a shot, you must turn off the safety, cock the hammer and press the tail of the trigger with your finger.

When the safety is turned off and the hammer is cocked, the parts and mechanisms of the pistol operate as described in Art. 35.

When you press the tail of the trigger with your finger , the trigger rod moves forward, and the cocking lever, connected to the rear end of the trigger rod, rotates on the rear trunnion of the trigger rod and rises until it rests against its own. cutout into the sear protrusion; then the cocking lever lifts the sear and disengages it from the cocking hammer. The release protrusion of the cocking lever fits into the bolt recess.

The trigger is released from the sear and, under the action of the wide feather of the mainspring, sharply turns forward on the trunnions and hits the firing pin.

The firing pin moves forward energetically and breaks the cartridge primer with its striker; a shot occurs.

The pressure of the resulting gases forces the bullet out of the barrel; at the same time, the gases press on the walls and bottom of the sleeve. The cartridge case expands and is pressed tightly against the walls of the chamber. The gas pressure at the bottom of the cartridge case is transferred to the bolt, causing it to move backward.

Operation of pistol parts and mechanisms after a shot

38. The bolt moves back along with the cartridge due to the pressure of the powder gases on the bottom of the cartridge case. At the beginning of the backward movement (at a length of 3–5 mm), the bolt with its protrusion displaces the release protrusion of the cocking lever to the right, thereby disengaging it from the sear (disconnection occurs).

The released sear is pressed against the trigger under the action of a spring; when the trigger turns back all the way, the nose of the sear jumps behind the cocking of the trigger and holds it until the next shot.

With further movement of the bolt back, the release protrusion of the cocking lever slides along the groove of the bolt; The cartridge case, held by the ejector in the bolt cup, hits the reflector and is thrown out through a window in the bolt wall.

The feeder delivers the next cartridge and places it in front of the bolt rammer.

The bolt, having reached the rearmost position, returns to the forward position under the action of the return spring; The bolt rammer pushes the next cartridge out of the magazine and sends it into the chamber. When the bolt reaches its extreme forward position and sends the cartridge into the chamber, the ejector hook slides into the annular groove of the sleeve.

The cocking lever rests on the sear (on the side), and its release protrusion is located opposite the recess on the bolt. The pistol is ready for the next shot.

39. To fire the next shot, you must release the tail of the trigger and press it again.

When the tail of the trigger is released, the trigger rod with the cocking lever moves back under the action of the narrow feather of the mainspring, at the same time the cocking lever moves down and with its cutout goes under the protrusion of the sear.

When you press the tail of the trigger, the cocking lever raises the sear and again releases the hammer from the sear. The next shot occurs.

If the bolt does not reach the extreme forward position (the cartridge is dented), then the release protrusion of the cocking lever will not fit into the recess on the bolt, as a result of which the cocking lever will not engage with the sear and, when the trigger is pressed again, will not turn the sear and will not release the hammer . This eliminates the possibility of a shot if the cartridge is not completely chambered.

Operation of pistol parts and mechanisms when firing by self-cocking

40. If shooting is carried out without first cocking the hammer, then when you press the tail of the trigger, the hammer is cocked automatically (Fig. 47). In this case, the cocking lever, having engaged its self-cocking protrusion with the self-cocking tooth of the hammer, cocks the hammer. The trigger, without being cocked (since the sear at the moment of release is raised to the upper position by the protrusion of the cocking lever), breaks away from the self-cocking protrusion of the cocking lever and hits the firing pin; a shot occurs.

Rice. 47.

The position of the parts and mechanisms of the pistol before firing a self-cocking shot:

1

- shutter;

2

- ejector;

3

— return spring;

4

— trigger;

5

— trigger rod;

6

- store;

7

— mainspring;

8

— sear with a spring;

9

— cocking lever;

10

- trigger

The operation of pistol parts and mechanisms when cartridges are consumed from the magazine

41. When all the cartridges from the magazine are used up, the magazine feeder lifts the front end of the bolt stop up with its tooth. The bolt, resting its tooth against the protrusion of the bolt stop, stops in the rear position.

The trigger is cocked.

The feeder spring has the least compression. The bolt remains in the rear position even after the magazine is removed from the base of the pistol grip, held by the bolt stop.

42. The bolt is released from the slide stop (with the magazine removed or inserted) by pressing the slide stop button with your finger.

Delays when firing a pistol and how to eliminate them

43. A pistol, when handled correctly, carefully maintained and preserved, is a reliable and trouble-free weapon.

However, during prolonged operation due to wear of parts and mechanisms, and more often due to careless handling and inattentive maintenance, delays in shooting may occur.

44. To prevent delays when firing a pistol and ensure trouble-free operation of the pistol, you must:

- properly prepare the pistol for shooting;

— inspect, clean and lubricate the gun in a timely manner and in compliance with all rules; Take special care to ensure that the rubbing parts of the gun are clean and lubricated;

- repair the pistol in a timely manner;

— before shooting, inspect the cartridges; Do not use faulty, rusty or dirty cartridges for shooting;

- during shooting and when moving, protect the pistol from contamination and impacts;

- if the pistol was in severe frost for a long time before firing, then before loading it, vigorously retract the bolt by hand several times and release it, and after each retraction and release of the bolt, release the trigger by pressing the tail of the trigger,

45. If a delay occurs during shooting, then it must be eliminated by reloading the pistol. If reloading does not eliminate the delay, then it is necessary to find out the cause of the delay and eliminate it, as indicated below.

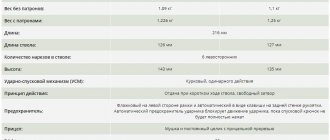

| Delays | Reasons for delays | Ways to eliminate delays |

| 1. Misfire. The bolt is in the forward position, the trigger is pulled, but the shot does not fire. | 1. The cartridge primer is faulty. | 1. Reload the pistol and continue shooting. |

| 2. Thickening of the lubricant or contamination of the channel under the firing pin. | 2. Inspect and clean the gun. | |

| 3. The handle screw is not fully screwed in (in pistols without a mainspring bolt). | 3. Screw in the handle screw until it stops. | |

| 4. The output of the striker or nick on the striker is small. | 4. Send the gun to the workshop. | |

| 2. Failure to cover the cartridge with the bolt. The shutter stopped before reaching the extreme forward position; the trigger cannot be pulled. | 1. Contamination of the chamber, frame grooves and bolt cup. | Push the bolt forward with a hand push and continue shooting. Inspect and clean the gun. |

| 2. Difficult movement of the ejector due to contamination of the ejector spring or pressure. | ||

| 3. Failure to feed or advance the cartridge from the magazine into the chamber. The bolt is in the forward position, but there is no cartridge in the chamber; the shutter stopped in the middle position along with the cartridge, without sending it into the chamber. | 1. Contamination of the magazine and moving parts of the gun. | 1. Reload the pistol and continue shooting. Clean the gun and magazine. |

| 2. Bent upper edges of the magazine body. | 2. Replace the faulty magazine. | |

| 4. Seizing (pinching) of the cartridge case by the bolt. The cartridge case was not thrown out through the window in the bolt and became wedged between the bolt and the breech end of the barrel. | 1. Contamination of the moving parts of the gun. | 1. Throw away the stuck cartridge case and continue shooting. |

| 2. Malfunction of the ejector, its spring or reflector. | 2. If the ejector with a spring or reflector malfunctions, send the gun to a workshop. | |

| 5. Automatic shooting. | 1. Thickening of the lubricant or contamination of parts of the trigger mechanism. | 1. Inspect and clean the gun. |

| 2. Wear of the hammer cocking or sear nose. | 2. Send the gun to the workshop. | |

| 3. The sear spring is weakened or broken. | Same. | |

| 4. Touching the shelf of the fuse ledge of the sear tooth. | Same. |

Trigger in a hunting rifle.

Other people’s thoughts: “My little dog, where are you, my little dog, my kind little dog, hashi-masi-moni-noni, Zhulenka, my little dog, my sweet little dog, where are you?

Doggy, don’t go, doggy! The front door slammed - the window glass trembled and ached. The refrigerator clanged in the kitchen. “Girl, and grandma, why did the dog run away?” My son-in-law looked out onto the balcony. “He took the skim milk, the sour cream hasn’t been delivered yet, but They threw out the bananas at the vegetable store. “I want ba-na-ny!”

Of course, there is no need to “put pressure” on the child, there is no need to pull back at every step. So, the baby saw a dog and shouted to it: “av - av!”; without correcting him, just say correctly: “Dog, beautiful dog.”

It’s like this: like in the summer with a sore throat, two hours on a packed train, everything is dry to the guts, like in a toaster, and mom whispers: “Be patient, dear, we’ll get there, there’s a dog, there’s a girl, Sanna, there’s a fruit drink.” strawberries-just-be patient!” And you still have to wait an hour at a small bus station, where there is nowhere to sit and you can only lean against the wall, but there is a hole dug out on it “The Girl Sanna and Her Dog” - only the tail remains to be dug out, but the whitewash is packed and it hurts under the nail, and mom mutters: “You’re not-lucky-to-have-a-sick-boy’s-mother-this-distance-but-if-they-had-a-phone-you understand?” And you are already swimming in a lake, in which instead of water there is strawberry juice.

They were indignant at his desire: “What kind of white dog can there be at night!” But we looked around and it turned out that it was really “night time”, and the cabbage and pasta were closed, but the white dog?

Three policemen rode out on white horses, followed by a tiny white dog of the same type - yapping at the horses and at the policemen; they looked into the distance, at the horizon line - everything was so bare and deserted, and if it weren’t for the indoor white dog on the bank of the frozen river, it would have been completely scary.

When the dog reached its allotted dog age and threw back its white paws, it was solemnly, but not without hidden gloating, buried in a hatbox in the park near the Theater, and Prima got a new dog, a puppy, a white dwarf Spitz, who grew up and, what Surprisingly, he also became angry.

When the doll asks: “Who lives in the little house?”, the dog replies: “It’s me, the dog, come live with me.”

My husband joked about this with rough army humor: “A small dog is always a puppy!” And in the men's room he said a different word, laughing uproariously.

When the pawl passes through the end of the tooth and the spring is activated, the pawl will hit the wheel and begin to bounce.