PT-SAU “Yagdtiger” Sd.Kfz.186 – “Hunting Tiger”

The giant car retained the same Maybach HL 230 P30 engine with 690 hp. s., which was used on the Panther tank, although the Jagdtiger was 60% heavier. Theoretically capable of 21 miles per hour, the "moving bunker" settled on a practical figure of 9 miles per hour over rough terrain, and its fuel consumption characteristics were limited to a range of fifty to seventy-five miles. The engine simply didn't have enough power and, as expected, broke down with alarming frequency.

Abandoned Jagdtiger - local landmark

The 128mm Pak 44 gun had only 10 degrees of traverse on each side. Its 27 kg projectiles flew at a speed of 950 meters per second, with a range of up to 24 km when used for indirect fire. Forty two-piece ammunition had to be supplied by two loaders, and the gun had to be constantly leveled after firing. The Jagdtiger also had a hull-mounted machine gun and sometimes a second anti-aircraft machine gun at the rear of the engine.

Tiger specialist tank ace Otto Carius (he owned more than 150 tanks and self-propelled guns) was not enthusiastic about this “secret weapon that could still save Germany,” as stated in his autobiography “Tigers in the Mud”:

KV-2 legendary Soviet heavy assault tank

“Any significant movement of the gun required moving the entire vehicle. Because of this, the gearbox and steering differentials soon failed. … We also needed a better idea for the airlock of our Hunting Tiger's eight-meter cannon. It had to be removed from the outside when colliding with the enemy. Of course, it was necessary to lock the barrel while traveling on the road. Otherwise, the mountain brackets would wear out too quickly and accurate aiming would be impossible. ... We found that the gun, due to its enormous length, suffered greatly even as a result of short movement on the road, and when aimed it no longer coincided with the position of the optics.”

The Jagdtiger was intended to “shoot” enemy tanks from a distance of 3-4 km, at which point it remained invulnerable to return fire. It was a great concept - Germany already had the Pak 43, a 71 caliber anti-tank gun that could penetrate the heaviest Allied tanks (such as the Churchill VII and IS-2). It had already worked successfully on the Jagdpanther, a 50-ton tank destroyer with excellent mobility and still formidable armor protection.

The Pak 44 had about the same maximum penetration as the Pak 43. Although admittedly its heavier projectiles retained more energy for longer shots. However, even standard German 75mm guns were very effective against numerous types of Allied tanks - the American M4 Sherman, the Soviet T-34. Despite its individual advantages, the Pak 44 was a classic overpowered weapon.

Jagdtiger self-propelled gun hulls in the workshop

Between February 1944 and May 1945, the Nibelungenwerk plant in St. Valentin, Austria produced only 80-88 Jagdtiger hulls. Most had nine-wheel suspension systems, although 11 had the cheaper but less robust eight-wheel configuration developed by Porsche. Due to a shortage of 128mm cannons, four Jagdtigers were reportedly equipped with Pak 43s.

Lame-footed "Jagdtiger"

The German self-propelled gun "Jagdtiger" was produced in two versions, with chassis and "Henschel", and the first was considered unsuccessful and was soon discontinued in favor of the second. This fact is cited in all publications about the history of the Jagdtiger, but until now it has received undeservedly little attention. We will not limit ourselves to brief descriptions with dubious assessments and conclusions - first, let’s talk about the development of the chassis of German tanks at the end of the war and analyze the design of the Porsche suspension, and then move on to the history of the chassis of the Jagdtiger, putting it in the appropriate context. The story will be based on an analysis of structures, and not on a compilation of retellings of the opinions of different authors.

Development of chassis

One of the important problems faced by German tank designers was the insufficient survivability of rubber bands. Trying to increase their service life, they switched to running gears with a staggered arrangement of large-diameter road wheels. However, new tanks became increasingly heavier, and this approach also exhausted itself. On the 57-ton Tiger, some of the road wheels had to be made removable in order to fit into the railway gauge during transportation, while the service life of the rubber tires still left much to be desired. Meanwhile, the weight of the future Tiger 2 during the design process exceeded 65 tons.

Drawing of the Tiger 2 chassis with road wheels with internal shock absorption

Then the Germans turned to road wheels with internal shock absorption. In such rollers, the steel rim is clamped by discs through rubber rings. Conventional rubber-coated rollers are better at shock absorption, but at any given moment only a small part of the rubber is compressed, so due to heavy loads it overheats and wears out quickly. In track rollers with internal shock absorption, the entire volume of rubber works simultaneously, so they can withstand much greater loads and wear out less.

During the creation of “Panther 2” and “Tiger 2”, the Germans carried out work to unify their chassis. Track rollers with internal shock absorption with a diameter of 800 mm were developed. Now the twin rollers were arranged in two rows with overlap, so at least the dismantling of the outer row of rollers took place without difficulty. In addition, compared to the Panther and Tiger, the number of road wheels was reduced, and now they did not extend beyond the railway gauge.

However, another problem arose. Originally designed for rubber rollers, the existing tracks themselves showed insufficient survivability with the new rollers, since their guide ridges often broke. Therefore, for use with internally cushioned road wheels, the designers developed tracks with alternating two types of tracks - also called two-piece, double or twin in some descriptions.

Testing new tracks and road wheels on the first Panther prototype, summer 1943

The main track with two guide ridges and developed lugs was made by casting, and the connecting track, as the name suggests, only connected the main tracks; there were no ridges or lugs on it. The connecting track consisted of several forged parts, between which there was space for the teeth of the drive wheel.

Panther 2 tracks made from Gg 24/660/300 tracks with a width of 660 mm were also used to transport Tiger 2 by rail. The connecting tracks were assembled from two parts, large and small. In the combat tracks of the "Tiger 2" from Gg 24/800/300 tracks with a width of 800 mm, the connecting tracks were assembled from four parts, one large and three small. By introducing tracks with alternating tracks, the Germans achieved the following. The Panther 2 tracks were used as transport tracks on the Tiger 2, in addition, the connecting tracks for the 660 and 800 mm wide tracks were assembled from the same parts. Both tracks consisted of interchangeable tracks, while early Tigers had different tracks for the left and right tracks.

Finally, the connecting tracks weighed much less than the main ones, which made the tracks lighter. To test tracks with alternating tracks and road wheels with internal shock absorption, MAN redesigned the first Panther prototype.

Diagram of the composition of the combat and transport tracks of the “Tiger 2” and “Jagdtiger”: at the top there is a wide combat track Gg 24/800/300, at the bottom there is a narrow transport track Gg 24/660/300

In addition to the Panther 2 and Tiger 2, tracks with alternating tracks were used on the Schwerer Wehrmachtschlepper half-track tractor, as well as the super-heavy Maus and E 100 tanks. Another German hobby in the second half of the war was the transition to single road wheels instead of double ones. All E-series tanks, except the E 100, were designed with single road wheels with internal shock absorption. The final version of the Maus also received a chassis with single road wheels. The Porsche chassis for the Jagdtiger was designed using the same principles.

Porsche suspension with longitudinal torsion bars

A unique feature of wartime tanks was the locked suspension with longitudinal torsion bars. In some publications it is characterized as compact, easy to repair and highly efficient. True, it wouldn’t hurt to explain what is meant by high efficiency, especially considering the fact that after the war no one ever used it. Other authors, on the contrary, criticize the Porsche suspension as complex and unreliable, since the short torsion bars were allegedly prone to frequent breakdowns. We will not thoughtlessly make such assessments, but instead we will analyze the structure of the suspension unit and explain the principle of its operation.

Cross section of Porsche suspension

The Porsche suspension assembly consists of a balancer, a housing, a torsion bar, a rubber cushion (damper) and a cam drive for twisting the torsion bar. The balancer is hinged to the tank body. One end of the balancer is rigidly connected to the axis of the first roller (the designations of the rollers are, of course, arbitrary), and a rubber cushion is attached to the other end.

A swinging housing is installed on the axis of the first roller, at the opposite end of which there is an axis of the second roller. Inside the crankcase there is a torsion bar and a cam drive for twisting it. On the side of the second roller, the torsion shaft is secured in the crankcase with a spline connection; on the side of the first roller, in a pipe that rotates on bearings relative to the crankcase. A fist is attached to the pipe, which rests against a fist that is fixedly mounted on the axis of the first roller.

Drawings of the suspension unit. Photo from the collection of Harold Biondo

The suspension works as follows. When the tank hits an uneven surface, the support roller makes a move, which is accompanied by swinging of the crankcase. The pipe fist rests against a stationary fist on the axis of the first roller, so the pipe begins to rotate relative to the swinging crankcase, twisting the torsion bar. On the side of the second roller, the crankcase rests against the balancer through a rubber cushion, which serves as a travel limiter. After the rubber is compressed to the limit, the suspension unit will work hard, transferring all the impacts to the tank body. There is a protrusion on the crankcase with a rubber pad that limits its swing in the opposite direction.

Let us note the following features of the suspension: for every two rollers there is only one balancer, the axes of the road wheels are always at the same distance from each other, and the torsion bar twists when the angle between the crankcase and the balancer changes. By analogy with bending the knee, in English this is called knee-action. The Porsche suspension is very compact and easy to install; it does not take up space inside the body, but is covered by the road wheels.

Drawing of the first version of a trolley with a slide. Photo from the collection of Harold Biondo

The Porsche suspension also has serious drawbacks. The travel of the roller, accompanied by the twist of the short torsion bar, is relatively small, the suspension as a whole is rigid and is not suitable for high-speed equipment. The support roller can make a significant move only if the paired roller makes a similar move in the opposite direction. In addition, the sprung weight of the tank is transmitted only to 6-8 compact cam drives, which requires the use of expensive alloy steels. But the relative complexity of the suspension unit can hardly be considered a disadvantage, since it is more than compensated by the smaller number of units and the ease of their installation. As for the reliability of the short torsion bars, there were no anomalies here, since rubber cushions protected them from excessive load.

A promising alternative

Now, taking into account all of the above, we can understand the history of the Jagdtiger. It was planned to launch production of the new self-propelled gun at . In his workshops they assembled the Porsche Tiger, Ferdinand and Pz.Kpfw.IV - that is, combat vehicles with external suspensions and a traditional arrangement of road wheels without overlap. The Jagdtiger required a different technology. In the suspension, the torsion bar bearings directly rested on the side armor plates, so many holes had to be drilled and milled with high precision. This process was expensive and time-consuming in itself, and due to inevitable tolerances and welding distortions, it could not be alleviated before the hull was assembled by pre-drilling holes in the lower side plates.

The British drawing shows the first version of the undercarriage with skids supporting the top of the track. It was tested on chassis #305001. Photo from the collection of Harold Biondo

In January 1944, Ferdinand Porsche convinced Hitler to use a simplified chassis with a suspension similar to his version of the Tiger with longitudinal torsion bars on the Jagdtiger. It made it possible to reduce weight by 2680 kg (according to other sources, by 1200 kg) and reduce the processing time of the hull and suspension components by 450 hours, and the cost of machine tools by 404,000 Reichsmarks, or almost twice. In addition, repairs were greatly simplified, since the bogie with a longitudinal torsion bar could be replaced in the field without any problems.

Note that claims about the benefits of this suspension should be treated with caution, since we can hardly say to what extent they were implemented in practice. For example, the armored hull of the Jagdtiger underwent minimal changes, so the freed up armored space was not rationally used. It was impossible to simply reduce the height of the body and increase the ground clearance along the lines of the Tiger from Porsche, since the air duct from the transmission, engine mount, and so on would have to be redone.

Photo of factory tests of the Jagdtiger chassis No. 305001. Later, a gun was installed on it and sent for comparison with the Henschel chassis. The skids of the first trolley are clearly visible

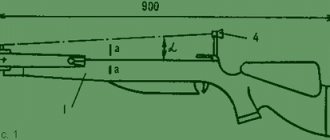

The proposal was accepted, and a new chassis was designed with four bogies and eight road wheels on board. The length of the torsion bars was 1075 mm - for comparison, for the Henschel chassis it was 1960 mm. Single track rollers with internal shock absorption with a diameter of 700 mm for Porsche (double rollers for Henschel had a diameter of 800 mm) were installed in two rows with overlap, with a row of guide ridges running between them.

The width of the steel rim was greater than that of the Henschel - 88 mm versus 75 mm. The full stroke of the roller was 165 mm (static 73 mm, dynamic 92 mm), which corresponded to a torsion bar twist of approximately 13°. This chassis was reminiscent of the E 75 project and corresponded to the latest trends in German tank building: external suspension arrangement, single road wheels with internal shock absorption instead of double ones, and tracks made of alternating tracks with one row of ridges.

Sloth type "Henschel", photo of chassis No. 305001

In February 1944, he built the first two Jagdtigers - No. 305001 with a Porsche chassis and No. 305002 with a Henschel chassis. Both self-propelled guns were unique. The Jagdtiger No. 305001 used carts with sleds that supported the upper branch of the caterpillar, but they were later abandoned. The sloth was borrowed from the Henschel chassis, which did not allow us to abandon the second row of guide ridges. The fact is that the Henschel chassis included two rows of ridges corresponding to two rows of road wheels.

In the Porsche chassis, an outer row of ridges ran between the single road wheels, but the inner one was not needed. However, the Henschel sloth disks covered just the inner row, since the last road wheel was located in the outer row. Therefore, the Jagdtiger No. 305001 had tracks with two rows of ridges, and the inner one was partially cut off. Subsequently, another sloth with discs covering the outer row of ridges was used on the Porsche chassis, while the inner row was almost completely cut off.

The Porsche-type sloth was installed starting with chassis No. 305003

"Jagdtiger" No. 305002 was also one of a kind. Although it was assembled with the Henschel chassis, its side armor plates were originally prepared for mounting the Porsche suspension. The Porsche chassis has already gone into production, and self-propelled gun No. 305002 was intended for comparison of designs.

A series of problems

On May 5, 1944, comparative tests of Jagdtigers No. 305001 and No. 305002 began. The Jagdtiger with a Porsche chassis exhibited excessive shaking. At first, suspicion fell on a new type of tracks made from alternating tracks Gg 24/800/300. Then the Jagdtiger No. 305003 was equipped with tracks from the Ferdinand, assembled from Kgs 62/640/130 tracks, and a new type of sloth for single-ridge tracks. However, during the tests, strong shaking was again observed, which, however, subsided when the self-propelled gun accelerated on a flat road to 14–15 km/h.

"Jagdtiger" No. 305003 with Ferdinand-type tracks and Porsche-type sloths. Unfortunately, replacing the tracks did not help get rid of the vibration

As a result, it was decided to switch to the production of Jagdtigers with the Henschel chassis. It is often said that the breakdown of the cart, known from a series of photographs, also played a role, but the author has not seen direct evidence of this. The mentioned breakdown occurred on the Jagdtiger No. 305004, and problems with the chassis were revealed already on self-propelled guns No. 305001 and No. 305003. In addition, the flange broke, and not any parts specific to the Porsche design, such as the torsion bar drive.

The decision to switch to the Henschel chassis turned out to be correct, which was confirmed by military operation. In the 653rd heavy tank destroyer battalion, which received seven Jagdtigers with Porsche chassis, the following problems were identified:

- The shaking from the tracks with alternating tracks confused the adjustment of the guns. The suspension turned out to be too stiff.

- Single road wheels loaded the tracks extremely unevenly, which caused the tracks to bend and pins to break on rough terrain.

- The presence of different types of chassis with incompatible components and assemblies made maintenance and repair difficult.

In February 1945, the head of the design bureau, Erwin Aders, prepared a note on the progress of the design of the Tiger 2, which was carried out under his leadership. According to Aders, the chassis with alternating compound tracks and two rows of dual road wheels was initially questionable. The rollers transferred the load to the tracks extremely unevenly, but compared to the Tiger, the tracks became even wider.

Gg 26/800/300 trucks close up, photo from the Panzer Fakten group (https://www.facebook.com/groups/PanzerFacts)

In addition, tracks with composite connecting tracks were characterized by low rigidity, so problems with broken tracks and pins were expected from the very beginning. Finally, when using them, increased wear of every second tooth of the drive wheels was observed. All of the above concerned the 68-ton Tiger 2 with nine dual road wheels on board. Needless to say, on the 74-ton Jagdtiger with eight single road wheels on board, these problems became even more pronounced.

In September 1944, after assembling 11 Jagdtigers with Porsche chassis, he switched to Henschel chassis. At that time it had already been redone. To increase the rigidity of the tracks, new one-piece cast connecting tracks Gg 26/800/300 were created instead of four-piece ones.

Yes, the tracks became significantly stronger, but it was impossible to make holes for the teeth in these tracks. As a result, it was necessary to switch to drive wheels with nine teeth instead of 18. In July 1944, deliveries of Gg 26/800/300 tracks began, and every second tooth was cut off on the old drive wheels. As for the Jagdtigers, the introduction of new tracks and drive wheels took place in September simultaneously with the re-equipment of production.

By introducing new tracks, the Germans solved one problem, but immediately created another. On such heavy equipment, the load on the rings with only nine teeth was too great. The very idea of tracks with alternating tracks led the Germans to a dead end; a different design was required. Since March 1945, the Tiger 2 began to be equipped with new tracks from conventional Kgs 73/800/152 tracks, which made it possible to return to drive wheels with 18 teeth.

The second prototype of "Tiger 2" with Kgs 73/800/152 tracks. They can be easily distinguished from Gg 24 and Gg 26 by the guide ridges on each track, and not through one

However, they never had time to use them on the Jagdtigers. Finally, Erwin Aders noted ongoing problems with internally damped road wheels, the bearings of which easily moved and warped - and this despite the fact that, compared to the Tiger, the permissible displacement of the road wheels relative to the guide ridges has decreased.

Summing up

An assessment of a Jagdtiger with a Porsche chassis usually comes down to two typical opinions. According to the first of them, in general, the Porsche chassis was a reasonable alternative, but its mass production was canceled due to the protracted conflict between Ferdinand Porsche and the Armaments Directorate, in addition, the bogie broke during testing.

Chassis of the Jagdtiger No. 305004 from the collection of the Museum in Bovington

Another point of view is that the Porsche suspension was initially unsuccessful and prone to torsion bar failures - this was already revealed on the Porsche Tiger, and the fact that the Germans again used a similar suspension on the Jagdtiger suggests that history the Tigers' comparative tests taught them nothing. Note that in both cases, problems with tracks and drive wheels are usually not mentioned at all.

The above facts force us to reject both common points of view. On the one hand, the Porsche chassis for the Jagdtiger really turned out to be unsuccessful, but the transition to the Henschel chassis was correct. On the other hand, what was unsuccessful was not some individual technical solution, such as a locked suspension with longitudinal torsion bars, but the entire complex of solutions as a whole. Narrow single track rollers transferred the load extremely unevenly to the wide tracks, which was aggravated by their placement in two overlapping rows, and tracks with composite connecting tracks had low bending strength.

Suspension, road wheels and tracks of the Mouse. The track design of alternating tracks is clearly visible

Separately, these technical solutions could well work. The Mouse had a chassis with single road wheels and tracks with composite connecting tracks, but the single rollers were arranged in four rows and distributed the load fairly evenly. The Ferdinand self-propelled gun had a suspension with longitudinal torsion bars, but coupled with conventional tracks and double road wheels with wide steel bands (84 mm versus 75 mm for the Henschel), it generally performed much better. In the case of the Jagdtiger, some problems were aggravated by others.

The failure with the Porsche chassis for the Jagdtiger cannot be attributed solely to the activities of the design bureau of Ferdinand Porsche. It was Department No. 6 of the Armament Directorate, under the leadership of Heinrich Kniepkamp, that promoted the ideas of using single road wheels in two rows with overlap and tracks with composite connecting tracks. A similar chassis with eight single road wheels in two rows and four bogies on board was planned for the E 75 tank, and in the self-propelled gun version the load on the roller was close to that of the Jagdtiger (4160 kg versus 4100 kg). It turns out that I actually tested this approach and clearly showed that although the E 50 and E 75 projects have not yet been completed even on paper, they already need to be redone. Erwin Aders from Henschel also spoke directly about the influence of the Armaments Directorate.

Processing of Jagdtiger hulls at . There, the Henschel chassis, which was difficult to install, was accepted without much enthusiasm (https://yuripasholok.livejournal.com)

By setting up the assembly of the Jagdtigers with the Henschel chassis instead of the Porsche, the Germans actually replaced a completely bad design with a simply bad one. In a report dated January 16, 1945, Oberst-Lieutenant Johannis noted that he apparently considered the Henschel chassis alien and disgusting. It should be noted that, despite all the changes in the design, the Germans were never able to bring the chassis of the Tiger 2 and Jagdtiger to perfection - and this despite the fact that the chassis of the later Jagdtigers was almost completely redesigned relative to the earlier ones.

When writing this article, we used archival materials published by Harold Biondo (USA)

Sources and literature:

- Thomas L. Jentz, Hilary L. Doyle. Germany's Tiger Tanks. VK45.02 to Tiger II: Design, Production & Modifications - Schiffer Publishing, 1997

- Thomas L. Jentz, Hilary L. Doyle. Panzerkampfwagen Panther II and Panther Ausfuehrung F (Panzer Tracts Nr. 5–4) - Panzer Tracts, 2006

- Walter J. Spielberger, Hilary L. Doyle, Thomas L. Jentz. Heavy Jagdpanzer: Development, Production, Operations - Schiffer Publishing, 2007

- Suspension Unit for Tanks Type E 50/75 – Combined Intelligence Objectives Sub-Committee, 1945

- The War Time Activities of Dr.Ing HCF Porsche, KG – Combined Intelligence Objectives Sub-Committee, 1945

- P.M. Volkov, N.V. Shchudrov. Tanks. Atlas of chassis drawings - M.: Academy of BTiMV, 1949

- Vasily Chobitok. Chassis of tanks. Suspension (https://armor.kiev.ua)

The 653rd was late for the Battle of the Bulge

By the end of World War II, the morale of German forces was undermined by limited fuel supplies, rapid loss of territory, and deteriorating supply lines. In this unfavorable situation, the Jagdtiger required a lot of fuel and parts, and often broke down when trying to move short distances.

It was difficult to tow - reportedly requiring a recovery Bergepanther (armored recovery vehicle) and two pioneer Sd.Kfz.9s (half-track armored tractor). As a result, there were several recovery vehicles for every Jagdtiger destroyed by enemy fire, abandoned, or blown up by its own crew due to engine failure, low fuel, or minor battle damage.

The 653rd Heavy Tank Battalion, which previously fielded the oversized Elefant anti-tank guns (StuK 43 Sfl L/71 Panzerjäger Tiger), began receiving its first Jagdtigers in September 1944. Although the Jagdtiger would have been a good counter to the Soviet IS-2 heavy tanks, Hitler personally assigned tank destroyers to fight the Western Allies in the Ardennes Offensive, believing they would be more likely to succeed there. However, although some American units mistakenly claimed to have encountered the Jagdtigers at the Battle of the Bulge, in reality winter weather and mechanical problems prevented them from even reaching the front lines.

A platoon of three Jagdtigers actually took part in Operation Nordwind and the subsequent offensive aimed at Strasbourg, France. Its combat debut on January 4, 1945 was unsuccessful: while observing from a slope near the French city of Rimling, Jagdtiger 134 was hit in the vulnerable side armor by a grenade launcher or M36 self-propelled gun, causing an explosion of ammunition and the death of the crew. The two accompanying Jagdtiger disappeared. Later in the month, the heavy tank hunters had more success destroying several newly occupied Maginot Line bunkers and a pair of Shermans.

Destroyed and abandoned self-propelled gun Jagdtiger

By 23 January, the 653rd had finally reached its full strength of forty-two Jagdtigers, supported by six Möbelwagen and Wirbelwind anti-aircraft tanks. However, a week later, after a 200-kilometer road march, due to breakdowns, only twenty-two Jagdtigers remained in working order. The unit used its guns as makeshift artillery in February, and on March 14 entered into a series of intense battles, beginning with the destruction of a Sherman tank column. The next day, the battalion launched a counterattack, but five tanks were quickly knocked out by P-47 Thunderbolt fighter-bombers and artillery fire.

| World War II: behind-the-scenes secrets |

On 22 March, three Jagdtigers took up positions near Neustadt and ambushed a column of Shermans and M10 Wolverine fighters. The Jagdtiger unit destroyed the leading and rear vehicles of the column. It was then stated that another 23 armored vehicles had been destroyed. On the same day, a platoon of Jagdtigers at Böhl destroyed nine tanks and two half-tracks, but one of the huge tanks broke down and the other was destroyed by artillery.

The 653rd Tank Battalion could not boast of its successes. In a series of battles in Schwetzingen, Kirchen and Klingenberg, several Jagdtigers were knocked out by French and American tanks, and ten were abandoned and destroyed by their own crews during the retreat. One of the tanks exploded when maintenance personnel released compressed oxygen into the wrong pipeline. Another was lost when the Mangfall Bridge in Kolbermoor, Austria, collapsed under its weight. The last four Jagdtigers were detached to fight in the final battle alongside the First SS Panzer Division, but eventually surrendered to Soviet forces on May 5 at Amstetten, Austria.

Birth of a Monster

I should note that the creation of heavy self-propelled guns in the Third Reich started at the very beginning of the 40s; Several prototypes were created - subsequently two of them were used during the assault on Stalingrad, where they were captured by the Red Army. In the fall of 1942, Hitler ordered the continuation of work on the creation of a promising super-heavy self-propelled gun, but the workload of all available production capacities was the reason that not a single company dared to take on this project.

Only in 1943, with the joint efforts of Henschel, design work began, which by the fall was embodied in a model, and by the Fuhrer’s penultimate birthday - in a prototype embodied in metal, which, as you probably guess, became the most desired gift for the hero of the day.

The vehicle had an engine compartment in the rear, a transmission in front, and a fighting compartment in the center of the resulting very spacious hull. The latter differed from the tank only in its length - 300 millimeters were added due to the need to install a massive conning tower.

Its dimensions, in turn, were determined by the need to install and maintain a 128-mm gun with separate loading, which became the reason for the inclusion of a second loader in the crew. This made it possible to maintain a fairly high rate of fire for a “ship” gun – up to 5 rounds per minute.

The Jagdtiger had the following characteristics:

- Dimensions - 10.65 (with gun)/3.63/2.95 m.

- Weight - 75.2 tons.

- Reservation - inclined and vertical: 80-150 mm; cutting edge: 250 mm; horizontal: 45 mm.

- Engine - 1×HL 230 P45, 700 hp. With.

- Speed - 42 km/h.

- Cruising range - 170 km.

- Armament - 1×Pak 44 L/55, 128 mm; 1×MG-34, 7.92 mm.

- Crew - 6 people.

A total of 79 self-propelled guns were manufactured.

Combat use of self-propelled guns

There are only a few known cases of Jagdtigers participating in battles: in mid-March, when the 45th battalion staffed by them tried to cover the withdrawal of German troops, retreating with rearguard battles from Hagenau to Salzburg. I should note that at the same time he did not achieve any special results, only losing people and equipment as a result of air attacks to no avail. In the end, the remnants of this unit surrendered to the Americans near Strangberg in the first ten days of May.

In addition, at the end of March, two companies armed with these self-propelled guns clashed with American armored vehicles in battles for crossing the Rhine near the towns of Remagen and Siegen. The first company quite successfully repulsed all attacks, the second, due to the obvious cowardice of the commander who decided to abandon his position, began a retreat to the city of Unna, where from what was left of both companies, the “Ernst battle group” was formed. This is the name given to the combined tank detachment, consisting of several Jagdtigers, as well as Stugas and Pzs “collected from around the world.” IV.

Jagdtiger in Germany

The vehicles took up defensive positions on the heights dominating the terrain and, when the Americans approached, they met them with concentrated fire - new self-propelled guns destroyed what was further away, Stugas and tanks what was closer. As a result, the Yankees lost 11 tanks and about fifty units of other equipment. Our own losses amounted to 7 self-propelled guns: one was shot down by the enemy, the rest as a result of breakdowns and friendly fire.

I think it would be appropriate to note here that the preparation, as well as the morale of the German “Panzerniks” by the spring of 1945 were nowhere lower. When in April the Americans closed a “ring” around the most important industrial region of Germany, the remnants of the Ernst group surrendered to the Americans, without even destroying what remained in their ranks.

In contrast to them, two platoons that fought against the Red Army in Austria and had four Jagdtigers in service on May 9, 1945, went for a breakthrough to the west - their crews somehow did not want to clear away the ruins of Soviet cities. During the clash that took place, two heavy and two medium Soviet tanks were destroyed, but only a couple of self-propelled guns were able to crawl towards the Americans.

Jagdtiger at the Bovington Tank Museum