Valve assembly for air rifle vpo 512 ppsh m

Brass screws in the side planes serve for precise positioning of the valve in the box and elimination of transverse bolts.

For precise vertical positioning of the valve, pins Ø 1-2 mm can be installed in its lower planes if necessary.

The result of the modification is complete alignment of the bypass with the breech, the absence of shanks, and, as a consequence, a slight increase in the NS of the explosive ball.

Sealing of the interface between the valve and the rear plane of the magazine and partial sealing of the ball supply shaft, increasing the throughput.

1. The bypass hole of the expansion chamber and the channel in the silumin “body” of the valve are deployed to 3.5 mm; Using a milling cutter in the machine, the channel hole is turned to a depth of 6 mm, and an elastic seal is installed in the resulting socket. 2. On the axis of the magazine lock there is a shaped folding plate made of high-carbon steel, which is pressed against the front plane of the magazine (including the neck of the disk), and thereby reduces the “siphon” from the shaft into the atmosphere when fired.

The thread of the seal is shortened, which slightly increases the volume of the expansion chamber.

Instead of the standard plastic one, a steel feeder was made; for ease of loading, it is fixed in a groove machined in the side plane of the magazine (according to the MP-654/656 principle). The small L-shaped part in photo 3 rests with its heel on the spring fixation pin, and serves to prevent the spring from bending towards the groove when pulling the feeder down, and as a result prevents the feeder from wedging in the shaft. Note: photo 3 is old, later the feeder was replaced with another one - with a hardened pusher insert in the upper part, which does not rivet upon contact with the explosive ball.

Barrel replacement and barrel sealing

The PPSh-M of the latest releases is equipped with a standard PPSh-41 mortar-type barrel, which, when converted into a CO2 version, is lined with a fecal barrel stub. 4.5 mm. and no more than 60 mm long. To increase the NS of the explosive ball, this stub was pressed out, and the “mortar” was lined with a 4.5 mm barrel. full length (externally turned barrel for Drozd from the manufacturer Pyotr). In the breech of the liner, a fitting was made for a trapezoidal polyurethane gasket (see figure), which seals the gas line at the “magazine-barrel” interface. Boring for the gasket, due to the refusal of familiar craftsmen to sharpen the cutters specifically for this work, was carried out in the chuck of a rigidly fixed drill: with an appropriately sharpened needle file. The gasket is made from MP-512 cuff using 2 die cutters and a drill.

The PPSh-M barrel—the original PPSh-41 “mortar” with a short liner inside—is installed in the radiator casing differently than the combat source barrel, i.e. “incorrectly.” It is moved back by approx. by 15 mm., and rotated along the longitudinal axis by 90C. Accordingly, it is not fixed in the casing according to the standard pattern:

- that is, not with a transverse collapsible axis of the hinge in a semicircular groove - but permanently - with a blind new-made pin:

To do this, near the breech of the barrel, “Molot” mills a flat area with a large tolerance for this pin:

And since the standard “mortar” is a cone, tapering towards the front edge, the Molotov displacement of the barrel back causes its front end to bulge in the casing diaphragm. On my copy, the new-made pin has been removed, the remaining hole in the casing is riveted with a steel pin:

The barrel is rotated to the correct position, and moved forward to its original position in the diaphragm. The barrel is fixed with a hinge axis according to the standard PPSh-41 scheme, through 1 of 2 standard grooves:

The result is a simple “entourage” dismantling of the barrel, no looseness of its front end in the diaphragm, and I realized the opportunity to lengthen the liner by approx. by 15 mm., pushing it out of the “mortar” back by the same amount of mm. as it was shifted forward by me.

Modification of the shutter and installation of anti-stall

To make the PPSh-M as similar as possible to the combat source, the standard shutter “stub” was replaced with the so-called MMG shutter PPSh-41. This is a real factory bolt from the 1940s, which had its firing pin ground off for deactivation purposes. In order for the MMG shutter to “fit” into the scheme and the trigger of the valve mechanism not to interfere with its installation, the front part of the shutter was milled from the bottom, and the height of the trigger was reduced by about 3 mm. In the non-working position, the bolt, like that of the combat source, is in the forward position, and, not allowing the trigger to rise when the trigger is pressed, in addition to a purely decorative function, it performs another function: it serves as an additional fuse. In order to fire a shot, the bolt must be pulled to the rearmost position and its latch must be secured in the groove of the casing cover.

Shpagin submachine gun (PPSh-41)

7.62 mm submachine gun model 1941 Shpagin system (PPSh) - Soviet submachine gun, developed in 1940 by designer G. S. Shpagin chambered for 7.62 × 25 mm TT and adopted by the Red Army on December 21, 1940 year[1]. The PPSh, along with the PPS-43, was the main submachine gun of the Soviet Armed Forces in the Great Patriotic War.

After the end of the war, by the mid-1960s, the PPSh was removed from service with the Soviet Army and gradually replaced by the Kalashnikov assault rifle; somewhat longer it remained in service with rear and auxiliary units, units of internal troops and railway troops, until the collapse of the USSR in 1991.[ source not specified 1258 days] It is still in service with paramilitary security units and the Ministry of Internal Affairs of a number of CIS countries.

Also, in the post-war period, PPSh was supplied in huge quantities to countries friendly to the USSR, was in service with the armies of various states for a long time, was used by irregular forces and was used in armed conflicts around the world throughout the 20th century.

At the moment, it is sold to civilians as a hunting carbine for amateur shooting with minor modifications (the fire selector is welded in the position for single shots, a 10-round limiter is installed in the magazine, the muzzle and bolt cup in the firing pin area can be punched).

The history of the creation of the Shpagin submachine gun (PPSh-41)

In 1940, the People's Commissariat of Armaments gave technical instructions to gunsmiths to create a submachine gun, similar or superior in tactical and technical characteristics to the PPD-34/40 submachine gun, but more technologically advanced and adapted for mass production (including at non-specialized machine-building enterprises)[ 2][3][4].

The main task in developing the PPSh was to create a sample that was close to the PPD or superior to it in terms of performance characteristics, but at the same time cheap and suitable for mass production, including at non-core enterprises. In 1940, the People's Commissariat of Armaments issued a request to gunsmiths to create a submachine gun, parts of which could be manufactured with minimal machining (which practically meant the need to use stamped parts). By the fall of 1940, the designs of submachine guns by G. S. Shpagin and B. G. Shpitalny were submitted for consideration.

Shpitalny submachine gun, a competitor to the PPSh-41 at field tests in 1940

Field tests and technological assessment of the samples presented for consideration at the end of November 1940 showed that, with similar combat qualities of both projects, the Shpagin submachine gun was much more technologically advanced in production. To produce the required 87 parts, 5.6 machine hours were required, at the same time, the production of the necessary 95 parts of B. G. Shpitalny's software required 25.3 machine hours, that is, almost five times more.

Georgy Semyonovich Shpagin

The first PPSh was manufactured on August 26, 1940, and a test batch of 25 pieces was manufactured in October 1940[5].

At the end of November 1940, based on the results of field tests and technological assessment of the PPSh samples presented for consideration, it was recommended for adoption.

“The survivability of the sample designed by Shpagin was tested with 30,000 rounds, after which the PP showed satisfactory accuracy of fire and good condition of the parts. The reliability of the automation was tested by shooting at elevation and declination angles of 85°, with the mechanism artificially dusted, in the complete absence of lubrication (all parts were washed with kerosene and wiped dry with a rag), and by shooting 5,000 rounds of ammunition without cleaning the weapon. All this allows us to judge the exceptional reliability and reliability of the weapon, along with high combat qualities.”

— D. N. Bolotin. "History of Soviet small arms."

On December 21, 1940, the Shpagin system submachine gun model 1941 was adopted by the Red Army. By the end of 1941, more than 90,000 pieces were manufactured. In 1942, the front received 1.5 million submachine guns.

Design and principles of operation of the Shpagin submachine gun (PPSh-41)

PPSh is an automatic hand-held firearm designed to fire in bursts and single shots.

Automation works according to the scheme of using recoil with a free shutter. The fire is fired from the rear sear (the bolt is in the rearmost position before firing, after release it goes forward, chambers the cartridge, the primer is pierced at the moment chambering is completed), the bolt is not fixed at the moment of firing.

A similar scheme is often used in the development of submachine guns. Despite its simplicity, such a solution requires the use of a massive bolt, which increases the total weight of the weapon. In addition, a weapon using such a reloading scheme can fire as a result of a strong impact (for example, when falling), if the impact causes the bolt to roll back along the guides from the extreme forward (non-fixed) position further than the magazine's cartridge feed window, or from the extreme rear one to break off. stopper

The trigger mechanism allows firing in bursts and single shots from an open bolt. The firing pin is placed motionless in the shutter mirror. The translator is located inside the trigger guard, in front of the trigger. The safety is a slider located on the bolt cocking handle. When the safety is on, it locks the bolt in the forward or rear position.

Like the PPD, the PPSh has a receiver fused with the barrel casing, a bolt with a safety on the cocking handle, a fire selector in the trigger guard in front of the trigger, a reversible sight and a wooden stock[8]. But at the same time, the PPSh is significantly more technologically advanced: only the barrel requires precise machining, the bolt was made on a lathe followed by rough milling, and almost all other metal parts can be made by stamping.

The muzzle brake-compensator is a part of the barrel casing protruding forward beyond the muzzle (a beveled plate with a hole for the passage of a bullet, on the sides of which there are through windows in the casing). Due to the reactive action of powder gases when fired, the muzzle brake-compensator significantly reduces recoil and “lifting” of the barrel upward.

The stock was made of wood, mainly birch. PPSh-41 was first equipped with drum magazines from the PPD-40 with a capacity of 71 rounds. But since drum magazines in combat conditions proved to be unreliable, excessively heavy and expensive to manufacture, and also required manual individual adjustment for each specific submachine gun, they were replaced by sector magazines developed in 1942 with a capacity of 35 rounds.

Sights initially consisted of a sector sight (with a range of 50 to 500 m and a pitch of 50 m) and a fixed front sight. Later, a flip-over L-shaped rear sight was introduced for shooting at 100 and 200 meters. Since the sighting range is an exclusively conditional, subjective characteristic, the PPSh of early production, like most pre-war submachine guns, had a sector sight marked up to 500 meters, but subsequently a simplified version was produced with a sight up to 200 meters - while the characteristics of the weapon itself were de - in fact remained the same, but the new sight was much easier to manufacture and was fully consistent with the real combat use of this weapon.

In general, upon closer inspection, the rough execution, the ubiquitous sloppiness of the joints and the carelessness of sealing the seams caught the eye. When shaking, the knocking of parts could be heard through large tolerances on the dimensions of the parts. A significant drawback of the design was the fire translator, as well as the magazine receiver - a thin groove at the end of the receiver required the fighter’s dexterity and skills when replacing the magazine, which was especially aggravated in winter, when it was necessary to remove the mittens.

Trigger

The trigger mechanism is modular and removable, mounted in the trigger box together with the trigger guard and has a fire mode translator - single shots and bursts of arbitrary length (the rate of fire is about 1000 rounds/min.)

Impact mechanism

Typical for mass-produced submachine guns, a simple hammer mechanism with a recoil spring, the firing pin is rigidly fixed in the bolt, and the cocking mechanism is located on the bolt.

A slide-type fuse is located on the bolt cocking handle and ensures its locking in the cutouts of the receiver in the forward position, which prevents the bolt from being retracted, and when cocked.

Characteristics of the Shpagin submachine gun (PPSh-41)

With an aiming range of 500 m (in the early version), the actual firing range in bursts is about 200 m, an indicator that significantly exceeds the average level of weapons of this class. In addition, thanks to the use of the 7.62x25 mm TT cartridge, in contrast to the 9x19 mm Parabellum or .45 ACP (used in foreign SMGs), as well as the relatively long barrel, a significantly higher muzzle velocity of the bullet was achieved (500 m/ s versus 380 m/s for the MP-40 and 280–290 m/s for the Thompson submachine gun), which gave better trajectory flatness, which made it possible to confidently hit a target with single fire at distances of up to 200–250 m, as well as fire at greater distances - up to 300 meters or more - distance, compensating for the decrease in accuracy with a higher rate of fire or concentrated fire from several shooters. The high rate of fire, on the one hand, led to a high consumption of ammunition (for which the PP received the nickname “cartridge eater”) and rapid overheating of the barrel, on the other hand, it provided a high density of fire, which gave an advantage in close combat.

comparison of PPSh (left) and PPS (right) stores.

The survivability of PPSh, especially with a box magazine, is very high. A clean and lubricated PPSh is a reliable weapon. A fixed firing pin causes delays in firing when the bolt cup becomes contaminated with soot or dust gets on the thickened lubricant: according to the recollections of veterans of the Great Patriotic War, when traveling in open cars or armored vehicles on dirty roads, the PPSh was almost always hidden under a raincoat.

The disadvantages include the relatively large size and weight, the difficulty of replacing and equipping the drum magazine, an insufficiently reliable fuse, as well as the possibility of spontaneous discharge when falling on a hard surface (which is generally typical for weapons with a blowback), which often led to accidents; The fiber shock absorber, which softens the impact of the bolt on the receiver in the rear position, had low survivability; after the shock absorber wore out, the bolt broke the rear part of the receiver.

The advantages of the PPSh also include the larger capacity of the drum magazine (71 rounds) compared to the MP-40 (32 rounds), but a larger number of cartridges significantly increased the weight and dimensions of the weapon, and the reliability of the drum magazine was relatively low. The box magazine was lighter and more reliable, but equipping it with cartridges was more difficult due to the rearrangement of cartridges at the exit from two rows into one: the next cartridge had to be placed under the jaws in a downward-backward motion.

On the other hand, for example, the Schmeisser system magazine, used in German and English submachine guns, also had cartridges rearranged from two rows to one. To make it easier to equip PPSh box magazines, there was a special device. Due to the presence of a muzzle brake-compensator, a neighboring shooter who finds himself at a distance of up to 2-3 m to the side of the muzzle can suffer barotrauma or rupture of the eardrum. PPSh-41 is easy to identify by its high rate of fire, similar to the whirring of a sewing machine, and in the dark by three tongues of muzzle flame escaping from the top and side holes of the casing.

TTX (tactical and technical characteristics) of the Shpagin submachine gun (PPSh-41)

- Weight, kg 3.6 (without cartridges)

5.3 (with equipped drum magazine)4.15 (with equipped sector magazine)

- Length, mm 843

- Barrel length, mm 269

- Cartridge 7.62×25 mm TT

- Caliber, mm 7.62

- Operating principles of a blowback shutter

- Rate of fire, rounds/min 1000

- Initial bullet speed, m/s 500

- Sighting range, m 200—300

- Maximum range, m 400-600

- Type of ammunition store:

sectoral for 35 rounds,drum for 71 rounds

- The sight is non-adjustable, open, at 100 m, with a folding stand at 200 m

Combat accuracy and fire efficiency of the Shpagin submachine gun (PPSh-41)

To defeat a single enemy fighter (a tall target) when firing in short bursts from a weapon brought to normal combat, 1 cartridge was needed at a distance of up to 100 m, 2 - at a distance of 150 m, 3 - at a distance of 200-250 m, and 4 cartridge at a distance of 300 m.

Performance characteristics of the Shpagin submachine gun cartridge (PPSh-41)

- 7.62×25 mm TT

- Country of origin: USSR

- Caliber, mm 7.62×25

- Bullet weight, g 5.52

- Cartridge weight, g 10.2—11

- Type of weapon using the PPSh-41 cartridge

- Sleeve length, mm 25.1

- Chuck length, mm 35

- Initial bullet speed, m/s 424—455

- Bullet energy, J 508—576

- Powder charge weight, g 0.48—0.52

Production of the Shpagin submachine gun (PPSh-41) in the USSR

The PPD, due to its technological features, turned out to be unsuitable for production in large series; moreover, its production was very expensive: one PPD with a set of spare parts cost 900 rubles in 1939 prices - despite the fact that a DP light machine gun with spare parts cost 1,150 rubles. PPSh was initially designed for the possibility of production at any industrial enterprise with low-power pressing equipment, which turned out to be very useful during the Great Patriotic War. The production of PPSh in July 1941 began at the NKV USSR plant in the town of Zagorsk near Moscow. This plant was initially preparing for the production of PPD. However, soon, as German troops approached Moscow, the plant was evacuated to the city of Vyatskie Polyany, Kirov Region. Drum magazines for PPSh were produced in the village of Lopasnya near Moscow. This plant was also evacuated there.

In 1938, a bobbin factory was opened in the village of Vyatskie Polyany to serve the needs of the textile industry, and the village received the status of a working village. With the beginning of the Great Patriotic War, in the fall of 1941, a machine-building plant was evacuated to Vyatskie Polyany from Zagorsk near Moscow. His equipment for the production of the PPSh submachine gun was installed on the territory of the bobbin-reel factory. The first submachine guns were sent to the front at the end of November 1941. In 1942, 1.5 million units were produced. The design bureau of the plant was headed by the creator of the submachine gun, Georgy Semenovich Shpagin. This year the workers' settlement received city status. During the war years, the team of the Vyatsko-Polyansky Machine-Building Plant produced more than 2.5 million PPSh submachine guns. In addition to the Vyatsko-Polyansky Machine-Building Plant, PPSh was also mass-produced at other enterprises such as the Degtyarev Plant, the S. M. Kirov Diesel Plant (Tokmak), the S. M. Kirov Machine-Building Plant (Alma-Ata), and the First State Bearing Plant. (GPZ-1), Electromechanical and others.

Most of the PPSh parts were made by stamping on low-power pressing equipment available at almost any industrial enterprise, and the rest, except for the barrel (unified along the channel with a three-line rifle) - mainly by turning or rough milling.

Its production took half as much time as the production of its predecessor, the Degtyarev PP, and the metal consumption was significantly reduced, while its combat qualities increased. (compared to PPD-40, consisting of 95 parts, PPSh could be produced in 7.3 hours, which was much faster than PPD, which was produced in 13.7 hours.) The cost of PPSh in 1941, that is, by at the earliest stage of its development in production, was 500 rubles, which was already comparable in order to the cost of a rifle of the 1891/30 model. in the same period - 163 rubles, and significantly lower than the price of the SVT self-loading rifle, which, according to pre-war plans, was supposed to become the main small arms in the Red Army by 1942 - 713 rubles for 1940, although with a planned reduction to 508 rubles in the future. In addition, its production did not require any materials that were in critical shortage in wartime, such as high-strength alloy steels necessary to ensure the strength of parts of automatic rifles chambered for powerful cartridges.

Moreover, as more and more mass production was deployed and changes were made to the design, the cost of PPSh decreased further, so that by 1943 it was already 142 rubles. As a result, during the war years, about 6 million copies of this PP were produced, and the more “niche”, intended primarily for the crews of armored vehicles, the Sudaev PP, which was distinguished by even greater manufacturability, was about half a million.

Operation and combat use of the Shpagin submachine gun (PPSh-41)

The deployment of increasingly mass production, along with high combat qualities for a submachine gun - a single fire from a PPSh was effective up to 300-350 m, and in short bursts up to 200, predetermined the leading role of this submachine gun in the light weapons system of the Red Army during the war period, starting from second year of the war.

They supplied entire companies and battalions of machine gunners that appeared in the Red Army by the end of 1942[11]. By the end of the war, about 55% of the Red Army soldiers were armed with these weapons, and they became an integral part of the image of the Soviet soldier during the war.

The widespread use of PP during the war had a significant impact on the formation of infantry combat tactics and the weapons system of the Soviet army in the post-war period, when great importance began to be attached to the conduct of dense automatic fire along the entire front, to the detriment of shooting accuracy, and the Kalashnikov assault rifle replaced the more accurate, but less Simonov's rapid-fire carbine, while in the West, especially in the USA, for a long time (until the mid-late 60s) the ideology of precision self-loading weapons with powerful cartridges continued to develop, sometimes with the ability to fire in bursts at a critical moment combat similar to the Soviet pre-war developments - ABC and SVT.

During the Great Patriotic War

USSR - PPSh was the most popular submachine gun of the Red Army during the Great Patriotic War. It was also supplied to Soviet partisans, allies and entered into service with foreign military formations on the territory of the USSR. PPSh were armed by units of the NKVD troops.

NKVD soldiers with PPSh

Czechoslovakia - the 1st separate Czechoslovak infantry battalion under the command of L. Svoboda received PPSh in October 1942, and later they were received by other units of the Czechoslovak Army Corps.

Poland - in 1943, the PPSh was received by the 1st Polish Infantry Division named after T. Kosciuszko, and later by other Polish units;

Socialist Republic of Romania Socialist Republic of Romania - in 1944-1945. a number of PPSh were transferred to the 1st Romanian Infantry Division. Tudor Vladimirescu, after the end of the war, additional quantities were received from the USSR for the Romanian army. Used under the name PM Md. 1952.

Yugoslavia - in 1944, the PPSh was received by units of the People's Liberation Army of Yugoslavia; after the war, the PPSh remained in service with the Yugoslav People's Army.

Hungarian People's Republic - the first Hungarian unit to receive PPSh in February 1945 was a company of Hungarian volunteers attached to the 144th battalion of the 83rd separate marine brigade of the Red Army. After the war, the PPSh remained in service with the Hungarian People's Army under the name 48M.

Third Reich - captured PPSh under the name Maschinenpistole 717(r) entered service with the Wehrmacht, SS and other paramilitary forces of Nazi Germany and its satellites.

Finland - captured PPSh were used in the Finnish army, there were also “alterations” for 9 mm.

Bulgaria - in the period after September 9, 1944, the USSR transferred a batch of PPSh to the Bulgarian army, which were used during the hostilities of 1944-1945.[17]

After the end of the Great Patriotic War.

PPSh-41 after the war

After the war, significant quantities of PPSh were supplied abroad, mainly to the Warsaw Pact countries and other states friendly to the USSR. A significant amount was supplied to China.

PPSh armed teams to protect particularly important objects of the militarized security of the USSR Ministry of Railways[18].

PPSh was sometimes used in conflicts in the second half of the 20th century and even at the beginning of the 21st century:

Albania - in 1945, the first PPSh were received by the Albanian National Liberation Army; they remained in service with the Albanian armed forces until at least 1994.

GDR - a certain number was transferred to the people's police and army of the GDR, received the name MPi 41

DPRK - in 1950-1953, Soviet, Chinese and North Korean versions of the PPSh were in service with the Korean People's Army and were intensively used during the Korean War.

Cuba - in the early 1960s, a number of PPSh were received by the Cuban government; in April 1961, they were used to repel the landing of the “2506 Brigade” in the Bay of Pigs.

In the early 1960s, PPSh were in service with the Vietnamese People's Army; they were used in the initial period of the Vietnam War. Subsequently, during the war, they were gradually withdrawn from the arsenal of regular army units and transferred to the arsenal of territorial defense forces.

Angola - As of November 1966, a number of PPSh were in service with MPLA guerrillas in Angola.

Jordan - as of 1968, a number of PPSh were in service with Palestinian paramilitary forces in Jordan, and were used by fighters of local self-defense units in the Battle of Karam.

Afghanistan signed an agreement with the USSR on the acquisition of a batch of Soviet small arms in August 1956, the first PPSh were received from the USSR in October 1956[25], later the PPSh was in service with army units at least until 1980[26], and then, in the 1980s, it was used by units of the DRA people's militia.

Also, a significant number of PPSh were in service with student “detachments for the defense of the revolution,” people’s militias and territorial self-defense units that fought against the “dushmans” in 1981[28][29] and even in 1986[30].

In Nicaragua, a number of PPShs were in service with the territorial detachments of the Sandinista People's Militia (milicianos) at least until mid-1985. At least until the 1980s, PPShs were used by military and paramilitary units in some African countries.

Ukraine - as of July 14, 2005, there were 350,000 PPSh in the storage of the Ministry of Defense of Ukraine; as of August 15, 2011, 300,000 pieces of PPSh remained in the storage of the Ministry of Defense of Ukraine;

Republic of Belarus - withdrawn from service in December 2005;

Croatia - used the Yugoslav version of the Zastava M49 PPSh;

Options and modifications of the Shpagin submachine gun (PPSh-41)

USSR - PPSh model 1941, with a drum magazine for 71 rounds and a sector sight with ten divisions for shooting at a distance from 50 to 500 m. Production of the first batch of 400 pieces. at plant No. 367 began in November 1940, even before the official adoption of the submachine gun for service.

USSR - PPSh model 1942, with a box magazine for 35 rounds, a sight in the form of a rotating rear sight for shooting at 100 and 200 m, a more reliable magazine latch, a chrome-plated surface of the barrel bore. The production of sector magazines began on February 12, 1942, the first batches were made of sheet steel with a thickness of 0.5 mm, but operational experience in the army revealed their insufficient mechanical strength and subsequently the magazines were made of sheet steel with a thickness of 1 mm [36].

USSR - handicraft and semi-handicraft variants of wartime PPSh:

“Product No. 86” - submachine guns manufactured at plant No. 310 in Kandalaksha. The sample was the PPSh arr. 1941, the first submachine gun was manufactured on January 25, 1941, a total of 100 units were produced. (due to the lack of drawings, the parts of the submachine guns were adjusted manually and were not interchangeable). After receiving technical documentation, the plant produced another 5,650 serial PPSh.

in the summer of 1942, one PPSh submachine gun was hand-made by master P.V. Chigrinov in the weapons workshop of the “Razgrom” partisan brigade, which operated in the Minsk region of the BSSR; Another submachine gun was restored from parts of the PPSh mod. 1941 by partisan E. A. Martynyuk in the detachment named after. S. G. Lazo (as part of the partisan brigade named after V. M. Molotov, operating in the Pinsk region of Belarus) - the barrel, bolt and magazine were taken from a standard serial PPSh mod. 1941, and the barrel casing, receiver, trigger guard and wooden stock were made by hand;

Homemade PPSh of partisan gunsmiths

In the village of Zaozerye, in the weapons workshop of the Chekist partisan brigade operating in the Mogilev region of Belarus, engineers L.N. Nikolaev and P.I. Scheslavsky produced ten PPSh from March 30 to July 3, 1943, in total until July 1944 here 122 PPSh were manufactured. In their production, parts of weapons that could not be restored were used (for example, the barrel of “partisan PPSh” was made from part of a rifle barrel), the missing parts were made of structural steel.

There were also rare, experimental modifications with a curved barrel, presumably developed in 1943-43.

Third Reich - MP.41(r), a modification of the PPSh chambered for the 9x19 mm "Parabellum" cartridge, in which the barrel and magazine receiver were replaced to use standard box magazines from the MP 38/40. The conversion began in 1944 and was carried out in the weapons workshops of the Dachau concentration camp; a total of about 10 thousand units were produced.

Wehrmacht soldier with PPSh

Iran - since 1942, it was produced for the USSR at the Tehran Machine Gun Factory (under the name “model 22”)[41], in total several tens of thousands of units were produced[42], of which, by the end of 1944, 9586 units were actually delivered to the USSR.[ 43]. A distinctive feature is the brand in the form of a crown.

Socialist Republic of Romania Socialist Republic of Romania - produced under the name PM PPȘ Md. 1952.

Hungarian People's Republic - in 1949-1955 it was produced under the name “7.62mm Géppisztoly 48.Minta”.

China - after the end of World War II, it was produced under the name “Type 50”. Minor changes were made to the design and production technology in connection with adaptation to the characteristics of Chinese industry.

DPRK - after the end of World War II, it was produced under the name “model 49”.

DPRK soldiers with model 49

Yugoslavia - in 1949-1992, the M49 submachine gun was produced, which had some design differences from the PPSh. Variants of this submachine gun were also produced - M49/56 and M49/57.

Vietnam - during the Vietnam War of 1964-1973, a modification of the PPSh was made - the K-50 submachine gun.

Croatia-Jelen is a hand-made Croatian submachine gun, assembled in Turopol at the Jelen factory of the same name. Actively used during the war in Croatia and Bosnia. Based on PPSh.

Conversion samples of the Shpagin submachine gun (PPSh-41)

- PPS-50 is a self-loading version chambered for the .22 LR small-caliber cartridge, produced by .

- SR-41 Semi-Auto Rifle - a self-loading version, produced since 2000 chambered for 7.62x25 mm[45] and 9x19 mm. Features an elongated barrel.

- SKL-41 is a self-loading version chambered for 9x19 mm cartridge. Produced since 2008.

- PPSH 41 SemiAuto is a self-loading version chambered for 7.62×25 mm, with a barrel extended to 16 inches (completely covered by a barrel casing) and design changes (firing is carried out from a closed bolt). Produced (USA).

- VPO-135 is a self-loading carbine chambered for 7.62x25 mm, developed in 2013 by the Vyatsko-Polyansky Armory.

- PPSh-O is a self-loading carbine chambered for 7.62×25 mm, developed in 2013 by the Kovrov plant named after. V. A. Degtyareva.

- PPSh-Luger is a self-loading carbine chambered for the 9×19 mm Luger cartridge, developed in 2014 by the Kovrov plant named after. V. A. Degtyareva. The barrel was replaced with a new one chambered for the 9×19 mm cartridge. Visually it differs from PPSh-O and VPO-135 in that it has a slightly longer barrel that fits into the front cutouts of the casing, forming a compensator.

- VPO-512 PPSh-M “Daddy” is a 4.5-mm air gas rifle, manufactured using the main parts of PPSh submachine guns (while maintaining all technical marks). Developed in 2007, produced since 2008 by the Vyatsko-Polyansky Armory

- MP-562K "PPSh" - 4.5 mm pneumatic gas rifle with the ability to fire in bursts, produced by the Izhevsk Mechanical Plant

Disassembling the Shpagin submachine gun (PPSh-41)

Complete disassembly is carried out only in case of severe contamination or repair (during repairs, all detachable connections can be disassembled, down to the rolled axles).

Assembly is carried out in the reverse order, and when placing the barrel in the casing, it is necessary to pay attention to the coincidence of the marks on the end of the barrel with the mark on the end of the casing liner, to ensure the correct position of the semicircular fixing recess of the barrel for the connecting axis, since the barrel may have two semicircular recesses for passage of the connecting axis of the receiver and bolt boxes (main and repair).

The procedure for partial disassembly of the Shpagin submachine gun (PPSh-41)

1 – separate the magazine by pressing its latch (forward) and unload it

2 – by pressing the latch (button) on the back of the magazine, turn the lid latch 90°

3 – remove the cover,

4 – overcoming the resistance of the spring, turn the drum slightly counterclockwise and pour the cartridges onto the mat,

5 – firmly holding the drum and the magazine body, press the latch (button) on the back of the magazine and, holding the drum, smoothly unload the wound spring, allowing it to rotate clockwise until the feeder exits the magazine receiver

6 – by pressing the receiver latch, open the receiver

7 – lower the muzzle of the receiver down

8 – pull the bolt back slightly and move it upwards and to the right, remove it from the receiver,

9 – move backwards to separate the return mechanism with the shutter buffer

General view of the PPSh with incomplete disassembly

The procedure for complete disassembly for cleaning the Shpagin submachine gun (PPSh-41)

10 – use a punch to knock out the split pin and remove the connecting axis,

11 – separate the receiver with the barrel,

12 – use a large-diameter drift to knock the barrel out of the receiver casing, being careful not to damage the muzzle of the barrel,

13 – remove the barrel from the casing,

14 – unscrew the tail screw connecting the stock with the bolt box,

15 – move the trigger mechanism down and back,

16 – move down and back to separate the stock from the bolt box

General view of the PPSh when completely disassembled:

1 – receiver with sight; 2 – trunk; 3 – shutter; 4 – return mechanism with textolite buffer; 5 – connecting axis and split pin; 6 – bolt box; 7 – tail rotor; 8 – box; 9 – trigger mechanism; 10 – magazine and its cover

Disassembling PPSh (video, 3D)

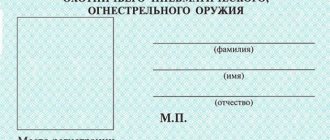

VPO-512 (PPSh-M) (Valve mechanism with magazine)

You can choose the order delivery method, depending on your personal preferences:

You can indicate all your wishes regarding the product or delivery conditions when placing your order in the “Additional information” window.

To receive your product as quickly as possible, please check your details for errors before submitting your order.

If the item you need is not in stock, please contact us and we may be able to help you.

If you have any questions, just contact us by phone or E-mail.

Delivery is convenient for sending light, small-sized cargo.

The goods will be delivered to the nearest post office.

A notification will be sent to the address you specified when ordering.

To receive the goods at the post office, you must present your passport and notification.

100% prepayment for order delivery.

Pros: low delivery costs for light, small-sized cargo, a large number of post offices throughout the country;

Cons: no targeted delivery to the door, long time for delivery of goods and notifications, there are restrictions on sending (air rifles, pistols, etc.)

Delivery is carried out by road and rail.

After the goods arrive at the warehouse, the recipient receives a phone call about delivery (the method of receiving the goods is determined - receipt at the terminal or targeted delivery)

You must present your passport to receive it.

Payment for delivery can be made both when sending the order and upon receipt.

Pros: low cost for sending large and heavy cargo to the nearest company terminal, prompt delivery, targeted delivery to the door;

Cons: limited number of terminals throughout the country, high cost of delivery to the specified address;

You can find out all the details on delivery by transport companies using the links below:

When purchasing a product in our store, you receive a full manufacturer's warranty.

Exceptions include cases of mishandling, misuse of products or devices, as well as repairs or attempts to repair (disassemble) in unauthorized service centers and workshops.

Source

Model of the PPSh VPO-512 Papasha rifle (PPSh-M, without valve mechanism)

The promotion is valid for order amounts over RUB 6,500. More details in the delivery section!

- Pickup: Moscow, Oktyabrskoye Pole metro station, st. Marshala Biryuzova, 30, from 9-00 to 21-00. St. Petersburg, metro Technological Institute-1, st. Angular Lane, 3A, from 9-00 to 21-00.

- By courier: We deliver most orders on the day of order ! Delivery cost within the Moscow Ring Road (KAD) from 0 rub. Delivery cost outside the Moscow Ring Road (KAD) from 400 rubles.

- Russian Post: Delivery cost from 0 rub. Delivery exclusively by national mail (not Air). It is possible to pay upon receipt - Cash on delivery.

- Transport company:

Energy, PEC, Business lines, etc. - Boxberry: Courier service. Delivery cost from 0 rub. It is possible to pay upon receipt - Cash on delivery.

- SDEK: Courier service. Delivery cost from 350 rub.

- DPD: Courier service. Delivery cost from 350 rub.

The promotion is valid for order amounts over RUB 6,500. More details in the payment section!

- Pickup: Free. (In Moscow and St. Petersburg)

- By courier: Delivery cost from 0 rub. (Moscow, Moscow Region, St. Petersburg and Leningrad Region)

- Russian Post: Cash on delivery (All Russia).

- Boxberry : Courier service. Payment upon receipt (All Russia)

- SDEK : Courier service. Cash on delivery (All Russia)

- Bank card Visa/MasterCard, etc.

- By bank receipt

- Yandex money

- QIWI

- Payment to bank account

- Payment in cash upon receipt!

- Delivery in Moscow and St. Petersburg on the day of order!

- Free delivery throughout Russia!*

- 12 month warranty on all products!

- Exchange/return goods within 14 days!

- We work seven days a week from 9.00 to 21.00!

- All products undergo pre-sale inspection!

Description of the model of the PPSh VPO-512 Papasha rifle (PPSh-M, without valve mechanism)

As you know, G.S. Shpagin developed a model of the PPSh submachine gun in 1940. By 1941, the weapon entered service and replaced the Degtyarev PPD-40 submachine gun. The Shpagin submachine gun or, as the Red Army soldiers called it, “Daddy,” played a significant role in the victory over Nazi Germany. At the same time, it is believed that the weapon’s combat qualities were superior even to the German MP-40 submachine gun. The target range of the PPSh was 200-300 m/s, while for the Wehrmacht submachine gun this figure was 100-120 m/s. At the same time, the weapon fired at a speed of 1000 rounds per minute. The PPSh was also effective during hand-to-hand combat thanks to its massive handle and butt. Interestingly, during the war, the Germans also began to use captured PPSh and at the same time remade the weapon, changing the barrel, from the original 7.62x25 mm TT caliber to the familiar 9x19 mm Parabellum caliber. Moreover, the Germans supplied the weapon with an adapter for the MP-40 magazine.

The weapon was used in the Soviet army until the 60s, at the same time PPSh were supplied to friendly Soviet countries. Today the PPSh is being converted into a carbine for hunters with a 10-round magazine. The pneumatic model VPO-512 PPSh-M is also popular.

Here is a model of the mass-sized rifle PPSh VPO-512, which is also called “Daddy” (PPSh-M, which is supplied from the manufacturer without a valve mechanism). As the name of such a specimen suggests, at the Molot Arms plant the weapon was deprived of the valve mechanism in order to make it impossible to convert such a PPSh into a combat model. Thus, we received a collectible model of the Shpagin submachine gun. Those who want to add to their collection of popular Soviet weapons should buy a model of the mass-dimensional type of the PPSh pneumatic rifle VPO-512 Papasha (available for sale without a valve mechanism, also going under the name PPSh-M) through the website “Get into Ten.ru”.

What distinguishes such pneumatic submachine guns is that such models are made from parts of rare combat PPSh. Some of these machine guns were used during the 2nd World War.

At the same time, the price of a model of the MMG PPSh VPO-512 “Papasha” rifle (or PPSh-M, which is sold without a valve mechanism) is noticeably lower than the pneumatic model of this weapon. If such a rifle is needed as an exhibition or collector's item for aesthetic or educational purposes, and there is no need to shoot from a machine gun, then this option will come in handy.

Models of the PPSh VPO-512 Papasha rifles, converted from pneumatics, (or PPSh-M, with bolts without a valve mechanism) weigh 3 kg . Such a PPSh consists of a butt and fore-end, made in Soviet times from wood with a barrel and bolt made of weapons-grade alloy. The length of the weapon is 840 mm. We sell a weapon with a mock-up disk magazine chambered for 7.62×25 mm cartridge. At the same time, a box-shaped in-line magazine is also suitable here.

"Symbol of Victory"

During the Great Patriotic War, almost 6 million Shpagin submachine guns were produced. This is the most popular weapon of this class not only in the USSR, but also among other countries participating in the war. PPSh-41 went through the entire war and took part in all the key battles. Mikhail Egorov and Meliton Kantaria with PPSh-41 at the ready in May 1945 hoisted the Victory Banner over the Reichstag in Berlin.

The weapon created by Georgy Shpagin, along with the T-34 and IS-2 tanks, La-7 and Il-2 aircraft, became a real symbol of Victory.

PPShs were in service with the Soviet Army until the mid-1960s, until they were replaced by Mikhail Kalashnikov’s assault rifle. Shpagin's brainchild was manufactured in dozens of countries in Europe, Asia and Africa and is still in service in some places.

© From the Victory Museum fund

Fragment of the exhibition Feat of the People - arms factory producing PPSh-1_From the collection of the Victory Museum.

Characteristics of the model of the PPSh VPO-512 Papasha rifle (PPSh-M, without valve mechanism)

| Housing material | metal |

| Base material | metal, wood |

| Equipment | , store layout, passport ]»>Rifle VPO-512 “PAPASHA” (PPSh-M) , store layout, passport |

| Number of charges | 1 PC |

| Manufacturer | (RF) ]»>IZHMASH (RF) |

| Combat prototype | Rifle VPO-512 "PAPASH" (PPSh-M) |

| Length (mm) | 840 |

| Type of ammunition | 4.5mm cartridge mockups |

Video review on MMG

Model of the PPSh VPO-512 Papasha rifle (PPSh-M, without valve mechanism) buy in the Popadiv10 online store. Model of the PPSh VPO-512 Papasha rifle (PPSh-M, without valve mechanism) at a low price of 14,990 rubles. You can pay for your order by mail upon receipt in any part of the Russian Federation. Before placing an order, be sure to check the price and contents of the product by phone (during business hours) or by e-mail and feedback system (at any time convenient for you).

Source

Air pistol IZH-53m (MR-53m) – classic PPP

Once again let's return to our air pistols.

Mostly gas-cylinder models were described here, and then I remembered our native air pistol IZH-53M. We will devote some time today to this development of the Izhevsk Mechanical Plant. IZH-53 has become one of the most famous air pistols in Russia, its low price (about 2000 rubles) made it almost a pistol within walking distance (if you don’t have it, then your neighbors have it). Of course, it is far from ideal, and now it has been well replaced on the market by foreign models in this niche, but still, I consider this pistol to be a classic; we used to shoot with such a toy even in pre-hardball times.