Modifications

- XM1-FSED - designed for test purposes. 11 units were produced.

- M1 is a basic model with 55 rounds of ammunition and a 105 mm rifled cannon.

- M1IP – strengthening the frontal armor of the turret, electric release of the anti-aircraft launcher, modernization of the transmission and suspension.

- M1A1 – 40 rounds of ammunition, 120 mm smoothbore cannon, reinforced hull front armor, collective WMD protection system with air conditioning.

- M1A1HA - first generation uranium armor, turret armor enhancement.

- M1A1HC – second generation uranium armor, 42 rounds of ammunition, improved digital engine control and some other changes.

- M1A1NA – second generation uranium armor, strengthening the armor of the turret forehead.

- M1A1D - improvement of digital components, digital distribution panels for the fighting compartment and chassis.

- M1A1AIM - major modernization and repair.

- M1A1AIM Block I - major upgrades and repairs. ZPU thermal imaging sight, second generation thermal imaging camera for the main gunner's sight, integrated system for self-diagnosis of on-board systems, FBCB2-BFT terminal.

- M1A1AIM Block II /M1A1SA - third generation uranium armor.

- M1A1FEP is an analogue of M1A1AIM Block II for the USMC.

- M1A1KVT is a modification of the M1A1, equipped with a complex for simulating tanks produced in the USSR.

- M1A1M - for export to the Republic of Iraq.

- M1A1SA - for export to the Kingdom of Morocco.

- M1A1 Block III - an uninhabited fighting compartment with an automatic weapons system, a new layout of the internal volumes of the hull, new electronic equipment and a power unit. Experimental version.

- M1 SRV is a weight simulator of a monitor-mounted turret. An experimental prototype on the chassis of the M1 tank to study a new arrangement of units inside the tank hull.

- M1 TTB - an armored capsule designed for three crew members in the front of the tank, an uninhabited turret, an ammunition load of 44 unitary projectiles, placed in a two-row carousel magazine with a vertical arrangement of cells with an automatic loading system, an M256 smoothbore gun of 120 mm caliber. An experimental prototype on the chassis of the M1 tank, which was modified after testing the M1 SRV.

- M1 CATTB - 140-mm smoothbore tank gun with a multi-sensor target detection system and automatic loader, a hydropneumatic suspension system in the balancer, an improved integrated power unit based on a diesel engine. Experimental project.

- M1A2 - a new gunner's sight with an eye-safe rangefinder and stabilization in two planes, a thermal imaging observation device for the driver, an independent thermal imaging panoramic sight for the commander, an IVIS combat information and control system, a commander's cupola with 8 periscopes. Strengthened turret armor by filling the frontal parts with uranium armor of the 2nd generation and increasing their size. The gun's ammunition capacity is 42 rounds.

- M1A2 SEP – 2nd generation thermal imaging cameras mounted in the commander’s and gunner’s sights, FBCB2 troop control system. The frontal parts of the turret are filled with 3rd generation uranium armor, which increases resistance against cumulative weapons. Air conditioning, color displays.

- M1A2 SEP V2 - sights with infrared and electro-optical sights, advanced color displays to display the tactical situation, a power plant subject to modification and communications equipment compatible with information and combat networks of infantry formations and units. Technologies developed under the Combat Systems of the Future program have been introduced.

- M1A2S is an upgrade of the M1A1 and M1A2 for the Kingdom of Saudi Arabia. Gas turbine engine LV-100-5, reinforced armor for the frontal projection of the turret and hull, dynamic protection of the chassis. Replacement of fire control and communication systems, 120 mm M-256 cannon.

- TUSK - thermal imaging sight for the turret installation of the M240 machine gun loader, shields to protect the commander and loader during observation from open hatches, a complex of dynamic protection to increase the protection of side projections from cumulative weapons, spaced armor of the bottom, a headset for communication with infantry, an additional M2 machine gun on installation (placed on the gun mantlet), remote-controlled installation, thermal imaging sight of the commander's ZPU.

- M1A3 - Improved road wheel suspension, lightweight 120mm cannon, lighter armor, improved roller durability, long-range precision weapons, gearbox and improved engine. Under development.

Army and weapons

The history of the Abrams tank dates back to the 1960s, when the United States teamed up with Germany to create a universal tank for NATO. The project of the promising MBT-70 MBT began to be developed by the Allies based on the practice of using tanks during the Second World War. By the end of the 60s, 3 prototypes were prepared, all of them weighed about 50 tons and were designed for a crew of 3 tankers. The armored vehicle was equipped with an automatic loader designed by ), and also had a multi-fuel engine of 1350 hp. But later the partners disagreed, because the United States wanted a combat vehicle with a small-caliber gun but capable of firing existing ammunition, while Germany wanted a tank with a large-caliber gun.

In the early 70s, the United States refused to cooperate with Germany in the design of a single tank, and the prototype, designated XM803, remained a prototype. Pushed by the arms race with the Soviet Union, the United States began creating its own MBT called the XM1.

XM1 prototypes. US Army Proving Ground in Maryland. 06/06/1987

The tank acquired its trivial name - “Abrams” on behalf of the commander-in-chief of American troops in Vietnam. General Abrams, being the chief of staff of the ground forces, personally managed the development at first.

At the first stage, experts were taken from the army and put forward a number of requirements for the promising vehicle. Then the theoretical characteristics were reviewed and processed by Chrysler. In 1976, after a series of tests compiled on a competitive basis, the military chose a version of the tank designed by .

The first production M1 Abrams MBTs were manufactured in 1980 at the state tank factory in Lima, PC. Ohio, but mass production started only in September 1981. In 1982, the tank division of Chrysler Corporation acquired the division of Land Systems, the largest American military-industrial corporation General Dynamics. In the same year, serial production of Abrams began at another state tank plant - the Detroit Arsenal, Warren, PC. Michigan. Both plants are leased by General Dynamics Corporation. The normal production rate was 70 tanks per month; the record was October 1986, when tank builders at both factories produced 103 Abrams. Production of the “basic” Ml version ended in January 1985; a total of 2,374 tanks of this modification were built.

Characteristics of the M1 tank.

Abrams M1 tank design and armament.

The welded hull has an upper frontal armor plate located at a large angle to the vertical, this reduces its penetration against armor-piercing projectiles.

A control cabin of 2.5 m3 is located in front of the hull. The driver sits on a soft seat that can be adjusted in height.

Driver's place.

If the hatch is closed, he sits with his legs raised, reclining. The driver's access to his workplace is possible with the turret turned backwards only through a hatch in the upper frontal armor plate (there is no emergency hatch in the bottom of the hull). Three fixed periscopic observation devices are mounted in the hatch cover. The tank's movement controls include a T-shaped motorcycle-type steering wheel, connected through a corresponding lever to an automatic transmission. In front of the column there is a gear shift lever that can be set to the “neutral”, “reverse” and “forward” (two) positions. The fuel supply is adjusted by rotating the tips of the steering column handles.

In the middle part of the hull and turret there is a fighting compartment (10.4 m3). In this compartment, to the right of the gun there are seats for the commander and gunner, and to the left there is a rotating seat for the loader. The Abrams commander's seat can be lowered when the hatch is closed, and raised in a traveling manner after the hatch is opened.

Layout of crew members in the M1 tank.

Place of the commander (rear) and gunner (right).

The turret includes a rifled 105-mm M68E1 cannon, which is stabilized in 2 planes, as well as a 7.62-mm M240 machine gun coaxial with it. The gun is aimed at angles from -9° to +20° vertically.

The main part of the gun's ammunition is located at the rear of the turret in armored containers (44 shots), and the remaining 11 shots are located in front of the loader on the turret floor (3) and in armored boxes in the hull (8). Shots for the gun are divided into: M774 and M883 (depleted uranium cores), armor-piercing sub-caliber projectiles with finned projectiles with a separating pan M735 (tungsten core), M494 (shells with ready-made arrow-shaped striking elements), M456 (HEAT), M416 (smoke) .

The turret is equipped with a 12.7 mm Browning M2 anti-aircraft machine gun. It can be aimed at angles from -10° to +65°. A MAG-58 is additionally mounted in front of the loader's hatch. The ammunition for the machine guns consists of 11,400 rounds of 7.62 mm caliber and 1000 12.7 mm rounds. For protection purposes, on each side of the turret there are 66-mm six- or eight-barrel grenade launchers M250 (or M257) for firing smoke grenades, ammunition - 12 grenades, firing range - 30 m.

M250 and M257 grenade launchers.

The tank also has additional weapons: a 5.56 mm M-16A2 rifle with 210 rounds, a 40 mm hand grenade launcher with 18 grenades, four 9 mm pistols with 400 rounds and 8 M67 hand grenades.

On the M1A1 tank, the 105 mm rifled gun was replaced by a 120 mm smoothbore gun from the German company Remington. In the United States, the German gun was redesigned, changing the design of the cradle and breech. Due to more massive shells, the tank's ammunition load was reduced to 40 rounds. It contains: M827 (armor-piercing sub-caliber ammunition with a tungsten core) and M829 with a depleted uranium core. The possibility of using standard German ammunition - finned armor-piercing sub-caliber and multi-purpose cumulative fragmentation shells - cannot be ruled out. A new function has been added to the OMS - calculating ammunition consumption by calculating barrel rollback.

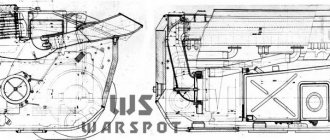

Fig 2. Layout diagram of the Ml ABRAMS tank

: 1 - 105 mm rifled gun; 2 — periscope device for the driver; 3 - 7.62 mm coaxial machine gun; 4 — gunner’s telescopic sight; 5 - gunner; 6 — main gunner's sight; 7 - grenade launcher for setting up smoke screens; 8 — tank commander’s control panel; 9 -12.7 mm machine gun; 10 — commander’s main sight; 11 — commander’s sight for firing from a machine gun; 12 - tank commander; 13 - 7.62 mm machine gun; 14 — hatch; 15 — auxiliary fan; 16 — anemometer; 17 — ammunition compartment; 18 — gas turbine engine AGT-1500; 19 — air filter; 20 — aft fuel tanks; 21 — main fan: 22 — transmission; 23 — engine air intake; 24 - loader; 25 — cartridge box of a coaxial machine gun; 26 — blocks of electronic equipment; 27 - front fuel tanks; 28 - driver; 29 — steering column; 30 — brake pedal; 31 - main control panel.

Diagram of the M1A1 main battle tank.

OMS

The gunner's sight is mounted on the roof of the turret under the armored cap; in the inactive position it is covered with a shutter. The sight has a thermal imaging channel for night vision, a laser rangefinder and an optical head with 3- and 10-fold magnification. The thermal imager has two magnification levels (3 and 10), providing target detection in large (7.5 x 15°) and small (2.5 x 5°) field of view modes. The laser rangefinder and IR system are manufactured by Hughes Aircraft. Determination of the distance to the target is provided by a laser rangefinder at distances of 0.2-8 km, and a thermal imager is used to see the target in the dark at ranges of up to 2 km. Using an electronic tracking system, the sight is synchronously aligned with the gun in the vertical plane. The control panel is connected to the electro-hydraulic drives of the implement stabilizer. The commander has an attachment for the gunner's main sight (can simultaneously conduct observation) and a periscope sight for firing from a 12.7 mm machine gun. Both the commander and the gunner can fire the cannon.

The gun and the coaxial machine gun are stabilized in 2 planes. The turret and gun stabilization drives are electro-hydraulic, manufactured by Cadillac Gage. The gun pointing speed is 6.3 degrees/s, and the turret rotation speed is 23 degrees/s.

The tank also has additional monocular unstabilized sights developed by the Kol-Morgen company: the commander has an M919 with 3x magnification (it is connected to the heavy machine gun by a parallelogram mechanism and is located in the hatch cover), the gunner has an M920 with 8x magnification. In addition to sighting devices, there are prismatic devices for monitoring the situation. There are 6 devices installed in the commander's tower, 1 prismatic device on a rotating base has a loader.

Experts emphasize that the gunner has much greater capabilities for detecting targets, unlike other crew members. The lower level of instrumentation for the loader and driver is justified by their workload due to their immediate functional responsibilities, and for the tank commander - by cost savings. Thus, the commander can detect targets using either the ocular reflex of the gunner's sight or his own periscope monocular sight. Through the latter it is possible to conduct observation only during the day, and the monocular deflection of the GPS sight does not allow the commander to conduct an autonomous (independent of the gunner) search for targets.

American designers are trying to solve this problem and are actively developing new command instruments. from the USA is designing an independent thermal imaging sight CITV (Commanders - Independent Thermal Viewer), which will allow the Abrams commander to carry out all-round visibility and detect targets during the day, at night and in poor visibility conditions.

The fire control system of the M1 tank uses the XM21 digital computer. Data from target speed sensors, gun trunnion roll, wind and laser range finder sensors are automatically entered into the ballistic computer. Only data on barometric pressure, barrel wear, charge temperature, ammunition type, and sight alignment calibration data are entered manually.

After detecting and identifying the target, the gunner, holding the crosshair of the sight on it, presses the laser rangefinder button. The range value is displayed in the gunner's and commander's sights. The gunner then selects the type of ammunition by setting the four-position switch to the appropriate position. Meanwhile, the loader loads the gun. A light signal in the gunner's sight notifies that the gun is ready to open fire. Angular corrections from the ballistic computer are entered automatically. A drawback is the presence of only one eyepiece in the gunner's sight, which increases eye fatigue, especially while the tank is moving.

Engine compartment of the Abrams tank

The engine and transmission are located in the rear of the tank. The X-1100-3B automatic hydromechanical transmission is located in a common unit with the AGT-1500 gas turbine engine.

AGT-1500 engine in a single unit with X-1100-3B transmission.

According to American experts, a gas turbine engine, compared to a diesel engine of the same power, has smaller dimensions and weight, a service life 2-3 times longer, and a relatively simple design. Some foreign experts emphasize that replacing the AGT-1500 engine on the M1 tank can be done in one hour. In addition, the gas turbine engine can be refueled with various types of fuel: motor gasoline, kerosene, diesel.

Engine replacement for M1A1, Company A, 2nd Tank Battalion. Operation Iraqi Freedom. Camp Habbaniyah, Iraq. 01/29/2006.

Removing the M1A1 engine and transmission. 108th Cavalry Regiment, 48th Brigade, 3rd Infantry Division. 10/19/2005. Mahmudiyah, Iraq.

AGT-1500 has a mass of 3.855 tons with a length of 3.022 m, a width of 2.032 m and a height of 1.194 m. It is a 3-shaft engine with a 2-stage axial-centrifugal compressor, a two-stage power turbine with an adjustable first-stage nozzle apparatus, and a stationary annular plate heat exchanger and an individual combustion chamber of tangential location. The working and nozzle blades of the 1st stage of the high-pressure turbine are cooled by air taken from the compressor outlet and supplied through holes in the blade shanks. The maximum gas temperature in the turbine is 1193°C.

A gearbox located inside the heat exchanger housing reduces the speed on the gas turbine engine output shaft to 3000 rpm. Reducing the design speed of the turbine from 26,400 to 22,500 rpm made it possible to replace the previously used two-stage planetary gearbox with a single-stage one. The fuel supply regulator is a conventional hydromechanical one. The electronic control system provides the necessary sequence of operations when starting the engine, and also turns it off if the permissible temperatures or rotor speed are exceeded.

The engine is equipped with a stationary plate-drum-cylindrical heat exchanger. It is assembled from ring plates made of stainless steel, soldered along the contour, reinforced with longitudinal tie bolts and forming a cylindrical drum that covers the turbine diffuser. Gas air channels are created by holes in the plates and gaps between them. The operating pressure in the heat exchanger is 14.76 kg/cm2, the degree of heat recovery when the engine operates at the design operating power (70 percent of the maximum) reaches 72 percent. The compactness of the heat exchanger and the rationality of its layout allowed the developers to achieve relatively small dimensions of the gas turbine engine.

Since 1979, work has been carried out to increase the power of the AGT-1500 engine to 1800 hp. without significant changes to its design. American experts claim that in the future this figure can be increased to 2000 liters. With.

The X-1100-3B automatic hydromechanical transmission provides four forward gears and two reverse gears. It consists of an automatic locking torque converter, a planetary gearbox and a continuously variable hydrostatic steering mechanism. The tank's chassis includes seven road wheels (on each side) and two pairs of support rollers, a torsion bar suspension, and tracks with a rubber-metal hinge and removable rubber cushions.

The track roller disks are made of aluminum alloy. Blade hydraulic shock absorbers are installed on the first, second and seventh road wheels. The mileage of currently used T156 tracks is 1000 - 1700 km, depending on road conditions, terrain and weather. However, according to the initial requirements, it had to reach 3200 km. Therefore, the issue of using the new T158 tracks, the testing of which has already been completed, is now being considered.

The tank is equipped with a U KB radio station of the AN/VRC-12 range, which includes an RT-246 transceiver, an R-442 commander's radio receiver, an LS-445 loudspeaker and a C-2742 commander's remote control. The frequency range of the radio station is 30-76 MHz, the communication range is 25-30 km. For internal communication, the AN/VIC-1 tank intercom is used, to which an external telephone line can be connected.

Protection of the Abrams tank

To protect against cumulative ammunition, the sides of the hull and the top of the chassis are covered with hinged armor screens. Crew members are isolated from ammunition and fuel by armored partitions.

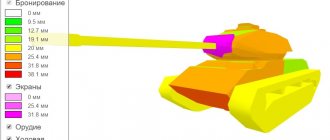

Crew protection scheme

If there is a fire inside the fighting and transmission compartments, the automatic fire-fighting equipment system is activated almost instantly. The liquefied gas Halon is used to extinguish the fire. The American fire-fighting equipment system installed on the tank uses dual-spectrum sensors with an operating wave range of 0.8 - 1 micron (near infrared) and 7.0 - 30 micron (far). According to the company's specialists, analytical and experimental studies indicate that the indicated spectral bands are observed during a fire or explosion in a hydrocarbon environment, but very rarely occur during non-fire impacts. In addition, in the spectrum of 7.0 - 30 microns it is possible to obtain a significantly higher signal-to-noise ratio than in the spectrum of 2-6 microns. The output signal of the sensor is generated only if there is IR radiation in both spectra that exceeds the response threshold in intensity. In order to make the sensor insensitive to a cumulative jet (passing through the car, but not causing a fire), a third IR sensitive element was included in it, which provides additional information to the electronic logic circuits of the control unit.

The first improved version of the M1 Abrams tank, which appeared in October 1984, was produced until May 1986 (a total of 894 units were delivered). It mainly differed from the original in improved armor protection. At the same time, work was carried out to improve the combat characteristics of the tank, especially firepower. As a result, a modernized version was created, designated M1A1 (the former name “Abrams” is often added to it). Its production began in August 1985, and the first production samples in mid-1986 arrived at the US Army tank unit stationed in Germany. In total, it was planned to produce about 4,200 of these machines.

The M1A1 Abrams tank is equipped with a system of protection against weapons of mass destruction, which, if necessary, ensures the supply of purified air from the filter ventilation unit to the crew members' masks. It also creates excess pressure in the fighting compartment to prevent radioactive dust or toxic substances from entering it. There are radiation (AN/VDR-1) and chemical reconnaissance devices. The air temperature inside the tank can be increased using a heater. An AN/VRC-12 radio is used for external communication, and a tank intercom is used for internal communication. The new model has the same transmission and final drives, but modified taking into account the results of their operation on the M1 Abrams tanks. The armor protection of the turret has been somewhat strengthened. The combat weight of the modernized tank increased to 57 tons.

In 1988, production of M1A1 Abrams tanks began, in which the armor of the frontal parts of the hulls and turrets contains depleted uranium inclusions. The density of the latter is 2.5 times higher than that of steel armor. According to American experts, the use of this technology has significantly improved armor protection, including from the effects of cumulative ammunition. At the same time, the combat weight of the tank with such armor increased by 1.5 tons. It is noted that the low level of natural radioactivity of depleted uranium is safe for crew members. The first vehicles of this series have already arrived at the tank units of the US ground forces stationed in Germany; a total of about 3,000 of them are planned to be produced.

Specialists, in accordance with the contract concluded with the US Army, continued work on further improving the M1A1 Abrams tank. The new variant, designated M1A2, is a modernized version of the currently produced M1A1 Abrams tank. The set of improvements, united under the name “Block-2,” includes an independent thermal imaging sight for the tank commander, a thermal imaging device for the driver, a CO2 laser rangefinder, as well as an on-board information system with means of displaying the situation.

An independent thermal imaging sight allows the commander to simultaneously search for a new target in smoke and darkness, and the gunner to fire at a previously detected one. The use of an on-board information system, which replaced the current fire control computers with a single electronic complex, including a processor for processing signals from all sensors, situation display indicators and weapon control units, has significantly reduced the preparation time for a shot. The thermal imaging sight is installed on the roof of the turret in front of the loader's hatch. The image of the observed terrain (the device can be rotated 360) is transmitted to the screen located in front of the commander.

According to Western experts, the effectiveness of the M1A2 Abrams tank in attack compared to the base model is 54 percent higher, and in prepared defense - by 100 percent. Combat rate of fire is 2 times greater.

As additional equipment, a mine clearing trawl in the form of rollers and teeth can be attached to the M1 tank.

Installing a roller attachment is a very long process. The nozzle itself weighs 9072 kg and consists of rollers and a winch. The mine clearing tank has a speed limit of 15 km/h, and each roller, due to the pressure created, leaves a cleared strip 1.1 meters wide.

The installation of mine clearing blades weighs 3,150 kg and takes up to 1 hour to install. The design of the device provides for raising the blades and lowering them into the ground up to 310 mm. The tooth installation leaves behind 2 cleared strips of 1.5 m each.

Roller trawl for mine clearance. Pictured is an M1A1 from Fort Polk, Louisiana. 08.11.1998.

A trawl for mine clearance in the form of teeth. The photo shows M1A1 with a tooth trawl.

Based on the experience gained as a result of urban battles, Abrams tanks are equipped with an urban survival kit - Tank Urban Survival Kit (TUSK). It includes:

— all-weather thermal imager for the driver;

— VDZ plates installed on the sides of the tank provide protection against portable anti-tank weapons with cumulative warheads;

— a loader’s thermal imager and an armored shield that allows you to hit targets outside the transparent front arc;

— in the rear part of the chassis there is a telephone that provides direct communication with the dismounted landing of the tank. This helps the tank crew when selecting targets in the city and targeting them.

— distribution panel to ensure protection of the electrical circuit of the TUSK kit.

Additionally, the TUSK kit can include a standard remote-controlled weapon station armed with a 12.7 mm machine gun, which will provide protection at close range. And also a camera to monitor the vulnerable aft area.

Urban Survival Kit - TUSK.

Subsequently, the Americans were faced with the enemy’s active use of ammunition based on the impact core, which led to the installation of additional ARAT 2 dynamic protection units, which are mounted on top of the ARAT 1.

M1A1 tank with TUSK 1. 1st Platoon, Delta Company, 2nd Armored Battalion, 69th Armored Regiment. Baghdad. Iraq. 07.12.2007.

Subsequent modernization consists of the use of improved armor protection, a new 120-mm cannon (less weight) and ammunition for it, an automatic loader, a new control system, an automatic search, detection and identification system for targets, a more advanced suspension (possibly hydropneumatic), etc. .

Four Abrams tanks at various stages of improvement.

Army

Anniston

Arsenal . 03/01/2005

Tactical and technical characteristics of Abrams tanks.

| Main settings | |||

| M1 | M1A1 | M1A2 | |

| Manufacturer country | USA | ||

| Role | Main battle tank | ||

| Date of adoption | 1981 | 1985 | 1995 |

| Crew | 4 (commander, loader, gunner, driver) | ||

| Combat weight | 60 t | 63 t | 68 t |

| Ground pressure | 0.95 kg/cm2 | 1.05 kg/cm2 | 1.09 kg/cm2 |

| Length | 9.77 m | 9.83 m | 9.83 m |

| Width | 3.66 m | 3.66 m | 3.66 m |

| Height, total | 2.89 m | 2.89 m | 2.89 m |

| Height at the top of the tower | 2.37 m | 2.37 m | 2.37 m |

| Clearance | 483 mm | ||

| Engine, transmission and driving characteristics | |||

| M1 | M1A1 | M1A2 | |

| Engine | Avko Lycoming AGT-1500 - 1,500 hp. gas turbine engine | ||

| Transmission | Allison X1100-3B Cross-Drive Transmission. 4 forward speeds, 2 reverse. | ||

| Distance covered without refueling | 498 km | 479 km | 479 km |

| Tank capacity | 1,909 l - diesel, gasoline, kerosene | ||

| Highway speed | 72 km/h | 67 km/h | 67 km/h |

| Cross-country speed | 48 km/h | 48 km/h | 48 km/h |

| Speed uphill at an angle of 10 degrees. | 32 km/h | 32 km/h | 27 km/h |

| Speed uphill at an angle of 60 degrees. | 7.2 km/h | 7.2 km/h | 6.6 km/h |

| Overcoming obstacles | Without kit: 4 ft (1.2 m). With kit: turret roof, 7.79 ft (2.37 m) | ||

| Anti-tank ditch | 2.743 m | ||

| vertical wall | 1.244 m | ||

| Protection | |||

| M1 | M1A1 | M1A2 | |

| Armor | Similar to the English "Chobham" armor. Combined, in later modifications with the addition of depleted uranium. | ||

| Dynamic protection | In the “urban” configuration TUSK1 with ARAT emergency protection, as well as additional blocks on the TUSK2 configuration - ARAT Block II XM32 emergency protection, placed on top of TUSK1. | ||

| Active protection | N/A | ||

| Anti-radiation and chemical protection | Air filtration | Filtration - 95.5 l/sec. Creation of excess pressure in the compartment. | |

| Smoke screen | 6 or 8 66mm M250 or M257 smoke grenades on each side | ||

| Armament | |||

| M1, M1A1, M1A2 | |||

| Type | Installation | Ammunition | |

| 105 mm M68A1 rifled gun (M1) | in the turret, manual loading, stabilized. | 55. APFSDS-T, APDS-T, APERS-T, cumulative | |

| 120 mm M256 smoothbore gun (M1A1, M1A2) | in the turret, manual loading, stabilized. | 40 (42 M1A2), OFS APFSDS-T, HEAT-MP-T, Canister | |

| 7.62 mm M240 machine gun | Twin with cannon | 11,400 | |

| 7.62 mm M240 machine gun | Loader's weapon | ||

| 12.7 mm M2 machine gun | Commander's Weapon | 1,000 | |

| Secondary weapons: 5.56 mm M-16A2 rifle with 210 rounds, 40 mm hand grenade launcher with 18 grenades, four 9 mm pistols with 400 rounds and 8 M67 hand grenades. | |||

————

Discuss on the forum

Sources:

https://www.inetres.com/gp/military/cv/tank/M1.html

https://btvt.narod.ru/4/M1.htm

«Tankmaster "special edition M1 Abrams"

Performance characteristics

6.1 Dimensions

- Combat weight, t: M1 – 55; M1A1 – 57.15; M1A2 – 62.5

- Length, m: 7.92

- Length with gun, m: M1 – 9.77; М1А1, М1А2 – 9.83

- Width, m: 3.66

- Height. m: 2.43

- Equivalent thickness of the hull forehead, mm: M1 – 550; М1А1, М1А2 — 650

- Equivalent to the resistance of frontal hull armor (BOPS), mm: M1 – 450; М1А1, М1А2 — 550

- Equivalent to the resistance of the frontal armor of the hull (KS), mm: M1 – 550; М1А1, М1А2 – 650

- Hull sides, mm: 20 (35 before MTO)

- Hull stern, mm: 20

- Equivalent thickness of the tower forehead, mm: M1 – 700; М1А1 – 800; M1A2 – 900.

- Resistance equivalent of turret frontal armor (BOPS), mm: M1 – 380; М1А1 – 500; M1A2 – 700.

- Equivalent to the resistance of the turret frontal armor (KS), mm: M1 – 500; М1А1 – 700; М1А2 — 900

- Roof, mm: 70

- Ground clearance, mm: 483…-432.

6.2 Booking

- Type of armor: projectile-proof, rolled combined and steel

- Active protection: AN/VLQ-6 MCD (experimentally, on single copies of M1A1)

- Dynamic protection: ARAT (optional).

6.3 Armament

- Gun: M1 – 105 mm M68A1; М1А1, М1А2 – 120 mm М256

- Gun type: M1 – rifled; M1A1, M1A2 - smoothbore

- Barrel length, calibers: 50.92 for M68; 44.2 for M256

- Sights: gunner's main sight: combined (all-day) periscope monocular with built-in laser rangefinder. Anti-aircraft: periscopic monocular Kollmorgen Model 938. Reserve: telescopic articulated Kollmorgen Model 939

- Machine guns: 1 × 12.7 mm M2 HB and 2 × 7.62 mm M240

- Ammunition, rounds / 12.7 mm / 7.62 mm rounds: M1 – 55/900/11400; M1A1, M1A2 – 40 (17 of them belong to the first stage)/900/11400.

6.4 Mobility

- Engine: Avco Lycoming AGT-1500 gas turbine engine 1500 hp

- Engine power, hp: 1500

- Specific power, hp/t: M1 - 27.6 (22.6); M1A1 - 27.1 (22.3); М1А2 — 23.80

- Maximum speed on the highway, km/h: M1, M1A1 - ~65; М1А2 — ~67

- Cruising range on the highway, km: M1, M1A1 – 440; M1A2 - 465

- Suspension type: individual torsion bar

- Specific ground pressure, kg/cm²: M1 - 0.93; M1A1 - 0.95; M1A2 - 1.07

- Ditch to be overcome, m: 2.7

- Wall to be overcome, m: 1.2

- Fordability, m: 1.2 (2.0 with OPVT).

6.5 Other parameters

- Combat weight, t: M1 - 54.4; M1A1 - 61.34; M1A2 - 62.14; M1A2SEP - 63.1

- Layout scheme: classic

- Crew, people: 4.

History of creation and production

The development of the tank, which was subsequently given the designation M-1, began after the XM-803 program was closed in 1971. To reduce the level of technological risk, it was decided to create a new tank according to the classical design, using a high-ballistic gun as the main armament and with a crew of four people. After the tests were completed, a competition was established to build 462 tanks. As a result, Chrysler and General Motors became possible manufacturing companies. As a result, Chrysler became the winner with a version of the tank equipped with a gas turbine engine. At the beginning of 1981, the tank, designated “105 mm M1 cannon tracked tank,” entered service with the US Army. Production of this model ended in 1995. Work is currently underway to modernize the Abrams tanks. Improved tank models are intended not only for the US Armed Forces, but also for export.

Military vehicles based on Abrams

| M1 Grizzly CMV | Engineering vehicle. | |

| M1 Panther II | Machine for sapper work. Controlled remotely. | |

| M104 Wolverine | Machine for guiding crossings. | |

| M1ABV | An armored vehicle used by the US Marine Corps to clear minefields. |

Machine evaluation

9.1 Advantages

- A reliable and powerful engine, combined with a transmission and modern suspension, gives the tank greater or equal mobility compared to lighter tanks from other countries, if the ground can support the weight of the tank.

- The presence of M829A3 shells with high penetration (M1A2SEP) is considered a record holder for armor penetration.

- There is an opinion that the exhaust of a gas turbine engine significantly unmasks the tank for thermal vision due to its higher temperature than other analogues, but this has been refuted. We can say that a number of MBTs (Merkava, Leclerc) have the engine exhaust located under the turret, therefore facing the enemy, but because of this they are not considered highly visible in these parameters.

9.2 Disadvantages

- The sides of the hull are significantly thinner, even compared to most tanks from the Second World War. They are reinforced only by a bulwark made of mild steel with filler. Because of this, they are easily vulnerable to enemy fire and older models of grenade launchers. This problem was resolved only on TUSK with the help of remote sensing.

- Unlike most modern tanks, there are no guided weapons.

- Due to the lack of an automatic loader, the vehicle’s rate of fire is not high enough, because the loader quickly gets tired and his work efficiency decreases. In addition, in cases of failure of the automatic loader on other tanks, the loader’s duties have to be taken over by one of the crew members under less comfortable conditions. This makes the absence/presence of a loader a relative disadvantage/advantage.

- The vehicle does not have the ability to conduct regular artillery fire. At best, it can fire grapeshot at unarmored targets at minimum ranges, or cumulative projectiles that are as effective as anti-tank guided missiles. And, for example, the English tank Challenger 2 has ammunition equipped with plate (armor-piercing high-explosive) shells. For example, in the English Challenger 2 there are armor-piercing high-explosive shells (they are also plate shells). The Israeli Merkava 4 has a controlled OF. Tanks produced on the basis of Soviet developments are always equipped with OFZ and have been successfully used in wars for over 50 years.