Pure "sixty-four"

In 1964, at the Kharkov Malyshev Plant, a new Soviet medium tank “432”, designated T-64, went into production. In the previous material we talked about the layout, armor and armament of the vehicle, and today we will talk about the chassis of the founder of the famous family.

Perhaps the most criticized decisions in the T-64 tank were those taken to ensure mobility and maneuverability: the chassis, which was considered to not have sufficient reserves for the growth of the tank's mass, the engine, which caused criticism due to insufficient reliability and complexity in production, and an ejection cooling system , which allegedly did not provide sufficient cooling with increased engine power.

Engine compartment of the tank

“432”

They tried to change these elements of the tank in the design bureaus in Nizhny Tagil and Leningrad. There, in the image and likeness of the T-64, they created their T-72 and T-80 vehicles, which, repeating the concept - a system of views on the nature of possible combat operations, the formulation of goals and tasks facing tanks for the near and medium-predicted time - had constructive differences in chassis and engine. Proposed by chief designer A.A. Morozov's concept of the T-64 tank was relevant for its time - the 60-70s of the last century. History has decreed that nothing new has yet been introduced into mass production to replace it, and the problem here is not only funding, but also the lack of an ideology for using tanks in future wars.

Was the bet on the 5TD engine correct? Perhaps the best answer was provided by history itself. Chief designer of the T-90 tank V.I. Potkin, who took part in the creation of the T-72, wrote: “As a result of our joint work with the Kharkov people, an agreed decision was made to adopt for subsequent development a single MTO with the Kharkov 6TD-2 engine [development of the 5TD concept - approx. author], but with all tank engine systems created by Tagil residents"

. The USA also relied on a family of two-stroke boxer diesel engines as part of the Advanced Combat Engine (ACE) program, which, in fact, are a repetition at the modern technical level of the concept of the 4TPD, 3TD, 5TD, 5TDF, 6TD engines.

Increasing the mobility and maneuverability of tank forces on the ground has always been one of the main tasks, so the project included a number of measures that were supposed to ensure a sharp increase in the average speeds of the 432 tank, raising them from 20–25 km/h to 35–45 km/ hour. The maximum speed of the new tank was estimated at 65 km/h. The determining factor in ensuring such speeds was the reserve of free power, which could be obtained with a tank power density of at least 20 hp/ton. Therefore, the project adopted an engine with a power of 700 hp, which, with a tank weighing up to 34 tons, provided the required figure.

The main provisions for the power plant and chassis, which determine the maneuverability of the tank, are given below.

Engine and transmission

The 432 tank was equipped with a two-stroke turbopiston engine of the 5TD-F type - in fact, the 5TD from the 430 tank, boosted to the required power of 700 hp. The general layout of the power plant and the layout of the engine-transmission compartment remained the same as on the 430 tank and were characterized by a transverse engine arrangement and power output to two onboard gearboxes.

Unlike the “430” tank, the ejection cooling system was made not with an onboard, but with a stern location of the ejector and was mounted on a removable roof, when opened, the entire cooling system rose along with the roof, providing free access to all components and assemblies of the engine and transmission compartment .

Engine 5TDF or product “457”, view from the turbine side

In addition to solving access issues, the aft location of the cooling system ejector made it possible to obtain optimal geometric parameters, eliminate losses from recirculation and improve the operating conditions of the ejector itself - especially at high speeds.

The 5TDF engine was the most problematic issue at first. On April 18, 1961, in the midst of work on the 432 tank, A.A. Morozov made the following entry in his diary, having no illusions about the cloudless future of the machine:

“I don’t see much achievement in the West. The weight of the M-60 tank is 46.3 tons, this is not a victory, and if it weren’t for the 105 mm gun, it would be an ordinary vehicle. For us, this is a passed stage. We are laying down and solving more significant combat properties, with less weight and dimensions. Speaking about weapons, we cannot help but talk about everything else that is holding back the development of tanks in our country. First of all, these are engines. They simply don’t exist, and it’s not known when they will be. Aviation developed as a result of the progress of engines, but we do not have engines and are not developing work on them. Formally, there are research institutes, design bureaus, factories, but we do not deal with motors, research on them is carried out sluggishly. 5TD is not a hawk or even a bird in the hands. At best, it will be available in 5-7 years.”

Transmission

To describe the situation that developed at that time, it is worth citing the words of the chief designer of Uralvagonzavod L.N. Kartsev, said at an industry meeting in August 1960:

“The defense cannot yet keep up with the weapons, and the mass should not be more than 34 tons. The layouts shown are not real, they are not thought out, and we know this from our own experience. These arrangements confuse the chief designers. It is necessary to make promising layouts like “430” with improved weapons. Our team is not able to solve new complex problems.”

At the same meeting A.A. Morozov said:

“The issue of the long-term development of the industry has never been discussed or considered before. We worked spontaneously, that is, we made samples and then provided an “ideological basis.” My views are not shared or approved by many. What are the views? 1. The need to develop barreled weapons and the uselessness of creating platforms for missiles until the missile weapons themselves have been created. 2. The need for special nuclear protection for the tank. 3. The product should not be tied to its mass.”

For the “432” tank, a transmission was used, similar in its design to the 6-speed gearbox of the “430” tank, but in this one it was 7-speed, because it used a combination of clutches that was not used on the 6-speed gearbox, giving an additional gear. In the transmission, the gear ratios were revised in relation to the new range of speeds to ensure increased speeds, and the final drive gear ratio was changed. To ensure the use of the exhaust brake without depressing the clutch pedal in the transmission, the design of its control units was redesigned.

Final drive

The transmission control units were kept similar to those on the “430” tank and were redesigned only in relation to the 7-speed gearbox, as well as in the direction of minimizing the resistance of the oil channels and lines. To improve the clarity of control and better drainage of the gearbox, the transmission hydraulic system pumps were made 50% more efficient and moved from the engine to the gearbox.

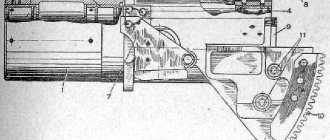

Chassis

All the main components of the chassis, except for the caterpillar, were taken in design similar to those made on the “430” tank and were redesigned only in relation to the new layout, which became wider in the lower part, as well as in the direction of further lightening individual components.

Unlike the “430” tank, by increasing the maximum tension in the torsion shafts to 13,200 kg/cm² instead of 9,000 kg/cm², the suspension torsion bars on both sides were positioned coaxially; in length they ended along the longitudinal axis of the machine. In order to reduce weight, the four middle rollers were made with a diameter of 500 mm instead of 550 mm for the outer ones and were significantly lighter.

Hydraulic shock absorber

Suspension

The design of the hydraulic shock absorber was changed, which, according to the layout conditions, was made with a cylinder diameter of 105 mm versus the previous 115 mm and was connected to the balancer directly through the wheel axis. The power of hydraulic shock absorbers has increased significantly. Finally, instead of three supporting rollers, four rollers were installed on each side. They were reduced in diameter, lightened and installed on brackets welded to the sides of the hull.

Regarding the smoothness parameters of the tank, it should be noted that, as shown by calculation analysis and tests of the suspension of the 430 tank, the latter had very high parameters of smoothness, which were quite suitable for the 432 tank with increased speeds - especially since Based on the suspension of the “432” tank, one would expect a slight increase in the smoothness parameters due to a slightly softer suspension (230 kg/cm versus 250 kg/cm) and more powerful hydraulic shock absorbers.

Outer track roller

The track for the “432” tank was designed with rubber-metal joints of the silent block type and was similar in design to the tracks used on American tanks. When developing the caterpillar, its design took into account the peculiarities of working with the metal band of the road wheel. The caterpillar was oriented to the already tested size of a rubber bushing with a diameter of 40 mm with a pin diameter of 30 mm. The caterpillar links and brackets were stamped.

The computational analysis and experimental testing of individual elements of this track carried out by VNII-100 showed satisfactory data on the strength of the system.

Encouraging results were also obtained after a preliminary check by VNII-100 and the Academy. Stalin, the decisive caterpillar parameter for a highly maneuverable tank; its efficiency turned out to be no lower than the accepted design one and should have corresponded to ~0.9 for a speed of 40 km/h versus 0.85 for a track with an open metal hinge, and for a speed of 65 km/h ~0.85 versus ~0.69, t .e. when moving at maximum speed, the use of this track should have saved about 100 hp. The assembled track had a width of 520 mm and provided an average ground pressure of ~0.79 kg/cm².

Caterpillar of the tank "432"

The chassis presented in the technical design had two shock absorbers on the outer support rollers of increased diameter (550 mm) compared to the rest (500 mm). This chassis was tested on a chassis model made on the basis of the OT-54 tank. Subsequently, the unification of the skating rinks was abandoned. Moreover, since 1970, the conventional track roller with internal shock absorption has been transformed into an important component of the chassis - the idler wheel. This led to a reduction in the cost of production of the tank, and also improved its driving characteristics, since the old version of the idler wheel did not have internal shock absorption.

Considering the presence of frequent braking of the tracks when turning, stopping and moving in reverse, during which the load on the guide wheels could reach 48 tons, their load turned out to be significantly higher than the load on the rollers. Therefore, the installation of support rollers in place of the guides led to their faster failure and the purchase of guide wheels from the Barnaul Tire Plant.

Track of the tank "432" during testing

This situation existed for quite a long time until a method was proposed in Dnepropetrovsk for treating rubber bonding surfaces with an abrasive based on apatite concentrate. This made it possible to achieve complete interchangeability and unification, as well as reduce manufacturing costs. Rollers of this type have been installed since 1981 on all production T-64s.

T-64 career finale

A total of 1,192 T-64 tanks were produced during serial production, of which 90 vehicles were produced in 1964, 160 in 1965, 294 in 1966, 330 in 1967, and 318 in 1968.

Tanks 1964–1965 produced at the end of the 60s were written off, the remaining vehicles were in service for a long time, although they had a significant drawback - unique ammunition for the D-68 cannon, which was not used in any other artillery system of the Soviet army.

Model for testing the chassis of object “432” based on the OT-54 tank

Between 1977 and 1981 almost all T-64s (object “432”) underwent a major overhaul, during which they were modernized to the level of the T-64A tank, but without replacing the main armament. After a major overhaul, the tank received the T-64R index, i.e. “Repair”, and according to the design documentation it was designated as “432A”.

In the last years of the existence of the USSR, the withdrawal of troops from the territory of the Warsaw Pact countries began. T-64 tanks located in the European part of the USSR were deployed to the bases of Atar (Kazakhstan) and Samarkand (Uzbekistan), and their place was taken by more modern T-64A and T-64B. The last T-64s on the territory of Ukraine, according to the Treaty on the Limitation of Conventional Arms in Europe, were cut down in 2007 at the Pyryatyn base. The tanks brought into the territory of the Republic of Belarus were disposed of at the repair plant in Borisov until the early 2000s.

T-64s withdrawn from Europe. April 1998, 140th repair plant, Borisov (Belarus)

The material can be completed with a fragment of A.A.’s speech. Morozov at a meeting at the plant named after. Malysheva January 12, 1966:

“You all witnessed how last year we were constantly honored with the attention of numerous commissions and responsible representatives of senior government organizations. This is understandable: tanks for the country are issue No. 2, and tanks follow missiles, even ahead of aviation.

Because of this, at the meeting of the Military Council, where I was supposed to report, Comrade Brezhnev directly asked me the question: “Did we do the right thing, Comrade Morozov, by choosing your tank?” I answered in the affirmative that we gained time, moved forward, swept aside everything that was unusable and pulled away sharply, and for this it was worth paying in money, time, and labor.”

Tactical and technical characteristics of the T-64 and vehicles of a comparable class:

| «432» | «430» | T-55 | M60 | |

| combat weight, tons | 34,0 | 36,0 | 36,0 | 46,3 |

| specific power, hp/ton | 20,6 | 16,6 | 16,1 | 16,2 |

| crew, person | 3 | 4 | 4 | 4 |

| length (with gun), mm | 8778 | 8785 | 9000 | 9309 |

| width along tracks, mm | 3250 | 3115 | 3270 | 3630 |

| width along shelves, mm | 3280 | 3145 | ||

| width along removable meshes, mm | 3430 | |||

| tower roof height, mm | 2146 | 2160 | 2230 | 2990 |

| ground clearance on the main bottom, mm | 480 | 484 | 480 | 457 |

| stamping ground clearance, mm | 455 | 454 | 467 | |

| ground clearance under driver, mm | 415 | |||

| tank weight, kg | 33 938 | 35 449 |

Note: the data for the “432” tank with a TPDMS rangefinder sight is given; when equipped with a TRLD rangefinder sight, the vehicle became 384 kg heavier.

Sources and literature:

- Report on the results of a study of operating conditions and reliability of the chassis of the T-64A tank // military unit 68054, 1970

- V.S. Dubov, V.A. Ivanov, L.S. Melnikov, G.A. Mikhailov, P.A. Osipov. Ejection cooling system of a motor installation with a V-46 engine // Bulletin of armored vehicles - 1976 - No. 2

- V.V. Polikarpov, A.F. Pustovalov. History of improvement of the T-64 tank during mass production // Bulletin of Armored Vehicles - 1988 - No. 11

- IN AND. Potkin. Tank breakthrough - Nizhny Tagil: "DiAl", 2013

- Bruce Brandle. US Army Opposed Piston Engine Research & Development (https://achatespower.com)

Tactical and technical characteristics of the T-64A

Crew, persons: 3 Developer: KhZTM Years of production: 1969—1987 Years of operation: since 1973 Number of produced, pcs.: more than 8000 Layout scheme: classic

Weight of T-64

– 38.5 tons

Dimensions T-64

– Hull length, mm: 6540 – Length with gun forward, mm: 9225 – Hull width, mm: 3415 – Height, mm: 2172 – Base, mm: 4242 – Track, mm: 3270 – Ground clearance, mm: 500

T-64 armor

– Armor type: combined multilayer – Hull forehead (top), mm/deg.: 80+105 (STB) +20/68° – Hull forehead (bottom), mm/deg.: 80 / 60° – Hull side, mm /deg.: 80 – Tower forehead, mm/deg.: 90+150 (aluminum alloy) +90

Armament of the T-64

– Caliber and brand of gun: 125 mm 2A46-1 – Gun type: smoothbore gun – Barrel length, calibers: 51 (6350 mm) – Gun ammunition: 37 – Firing range, km: up to 10 – Sights: TPD2-49, TPN1 -49-23, PZU-5 – Machine guns: 1 x 7.62 mm PKT; 1 x 12.7 mm NSVT

T-64 engine

– Engine type: 5TDF – Engine power, l. pp.: 700

Speed T-64

– Highway speed, km/h: 45–50 (maximum — 60.5) – Cross-country speed, km/h: 35–45

– Cruising range on the highway, km: 500–600 (700 with additional tanks) – Cruising range over rough terrain, km: 225–360 (310–450 with additional tanks) – Specific power, l. s./t: 18 – Suspension type: independent torsion bar – Specific ground pressure, kg/cm²: 0.84 – Climbable grade, degrees: 30 – Climbable wall, m: 0.8 – Climbable ditch, m: 2, 85 – Fordability, m: 1 (since 1976 - 1.8)

PROTECTION

The tank's survivability level was increased by installing additional protection on the hull and turret. The additional protection kit is designed to increase the level of protection against modern cumulative and armor-piercing sub-caliber projectiles with the minimum possible increase in tank weight. The additional protection kit consists of passive (applied) armor protection and built-in dynamic protection (EDP) “Knife” of Ukrainian design. The VDZ consists of a nose module and side screens installed on the tank hull, as well as modular sections located along the outer perimeter of the frontal and side sections of the turret, and containers installed on the roof of the turret. Installing the VDZ kit on one tank by the crew takes about 6 hours. The VDZ elements installed on the tank do not require special maintenance during its operation. The total weight of the additional protection kit is 3.5 tons.

The action of the "Knife" remote sensing device is based on the principle of influencing attacking ammunition with the help of a cumulative jet and explosion products of elongated shaped charges - "shaped knives". They destroy and destabilize the attacking kinetic munition or cumulative jet. The “Knife” complex has proven its effectiveness during numerous shelling tests using a wide range of 125 mm caliber OBPS, as well as modern 120 mm ammunition produced in Western countries, fully confirming the characteristics declared by the developer.

According to the manufacturer, after modernization, the resistance of the frontal and side projections of the T-64BM hull and turret relative to modern anti-tank weapons increases by approximately 2 times.

T-64 UKRAINIAN AF: MODERNIZE OR DISPOSAL?

Interestingly, back in 2013, the North Atlantic Treaty Organization (NATO) proposed to Ukraine not to modernize, but to cut into pieces and melt down old Soviet T-64 tanks. The destruction of the tanks was supposed to be financed from the NATO Partnership for Peace Trust Fund. Thus, the United States unofficially confirmed its readiness to allocate $1 million for the disposal of Ukrainian military equipment.

The NATO Partnership for Peace Trust Fund project began operating in 2006. According to the project, it was planned to dispose of 133 thousand tons of ammunition and 1.5 million small arms and light weapons over 12 years in four stages. According to the Center for Army, Conversion and Disarmament Research, there were about 2,000 units of surplus tank equipment in Ukrainian warehouses that could potentially be disposed of. The surplus property of the Ukrainian Defense Ministry was estimated at $1.25 billion. In 2012, $38.75 million of excess property was sold. In the realities of today, when, according to the statement of the President of Ukraine P. Poroshenko, Ukrainian units during the ATO as of September 2014 lost up to 65% of military equipment, the mentioned recycling program looks wild.