Armored repair and recovery vehicle BREM-1

In the early seventies, Soviet military experts came to the conclusion that it was necessary to create new special equipment designed to provide technical assistance to combat vehicles on the battlefield and on the march. The existing fleet of various equipment did not allow solving the entire range of existing problems without using various means, which is why it was necessary to create a completely new machine equipped with a set of various equipment. In order to create such equipment, a new project with the code “Winch” was launched, which resulted in the appearance of the armored repair and recovery vehicle BREM-1. By order of the Main Armored Directorate of the Ministry of Defense, the industry had to create a protected special vehicle with high maneuverability and mobility, as well as a set of special equipment. The main tasks of this equipment were the evacuation of damaged equipment from the battlefield with subsequent delivery to collection points, assistance in carrying out repair work, as well as performing various lifting operations in the field. The development of such a multifunctional vehicle made it possible to reduce the fleet of auxiliary equipment and thereby simplify the system for repairing damaged armored vehicles.

The creation of a promising repair and recovery vehicle was entrusted to OKB-174 of the Omsk Transport Engineering Plant. The development of the project was led by chief designer A.A. Morov and leading designer V.A. Stepanov. The project received the factory designation “Object 608”. The engineers' task was to create a special vehicle with a set of various equipment, built on an existing chassis. In order to speed up development and simplify operation, the chassis of the serial T-72 main tank was taken as the basis for the “Object 608”. Similar equipment was already in service, which simplified the construction of repair and recovery vehicles, and also facilitated their future operation due to unification across a large number of units.

General view of BREM-1. The crane boom is clearly visible. Photo: Wikimedia Commons

The use of a ready-made chassis and the enthusiasm of the design bureau staff made it possible to create a new project in a relatively short time. Already at the end of 1972, a set of documentation necessary for the construction of an experimental armored vehicle was prepared. The construction of “Object 608” was entrusted to plant No. 183 (Nizhny Tagil), which produced T-72 tanks. Assembly of the prototype did not take much time - it was ready for testing in March 1973. Soon after its construction was completed, the first inspections began at nearby test sites.

During 1973, the experimental “Object 608” passed the entire range of factory tests, after which it entered military testing grounds. Military experts tested the proposed vehicle in 1974-75. Based on the results of military tests, new special armored vehicles were recommended for adoption. On June 13, 1975, the USSR Minister of Defense signed an order, according to which the armored repair and recovery vehicle “Object 608” was put into service under the designation BREM-1. After this, preparations began for mass production of new equipment.

The BREM-1 was tasked with a wide range of auxiliary tasks, for which it had to be equipped with a variety of special equipment. With its help, the armored vehicle is capable of towing various equipment, including those stuck on various surfaces, transporting various loads, providing repairs, performing some excavation work, etc. In accordance with such technical specifications, the main aspects of the appearance of the promising machine were determined.

The basis for the “Object 608” was the T-72B tank, which influenced some of the features of its appearance. The repair and recovery vehicle has retained the power plant and chassis of the base vehicle, but some of its units have noticeable differences. The hull layout has undergone noticeable changes directly related to the tasks being performed. The habitable compartment with workplaces for all three crew members is located in the front part of the hull. The driver's workplace is located in the central part of the compartment; the commander is located on the right and shifted back. The place of the coupler-rigger with a set of necessary controls was placed on the left side and moved back relative to the commander.

All crew members received their own hatches in the roof of the vehicle. In addition, there was one escape hatch in the bottom, located behind the driver's seat. The main crew hatches are equipped with optical instruments for monitoring the situation. The driver can use prism devices during the day, and in the dark, the middle device should be replaced with a TVNE-4PA night vision device. The commander has a small rotating turret, which contains two prism devices and one combined (day and night) TKN-3. The hitch-rigger, like the commander, has a small turret, but it is not equipped with rotation mechanisms. The hitch-rigger has four TNP-160 prismatic devices, the same as on other roof hatches. There are no means for observation at the coupling operator’s workplace at night.

Close-up of the front of the car. Photo Armor.kiev.ua

Behind the back of the crew there is a so-called engine partition separating the habitable compartment and the engine room. The latter houses some of the special equipment designed to solve basic problems. Behind the engine room is the engine and transmission compartment with power plant units. Serial BREM-1s are equipped with V-84MS diesel engines with a power of 840 hp, which allows maintaining the main characteristics at the level of the basic main tank.

The hull of the Object 608 was built on the basis of the main T-72B tank and has similar protection. In the frontal projection, the crew and internal components of the vehicle are protected by a combined barrier located at an angle of 60° to the vertical. The side sheets and roof, in turn, provide protection from small arms and small-caliber artillery. Some of the external units of special equipment are also made of high-strength materials, which allows them to withstand small arms fire without damage.

BREM-1 is not a combat vehicle, but has some weapons for self-defense. The main means of defense is a large-caliber NSVT machine gun, located on a turret above the commander's hatch. The machine gun's transportable ammunition capacity is 400 rounds. If necessary, the crew can use three AKS-74U assault rifles with a total ammunition load of 360 rounds and 18 hand grenades. Also in the stowage of the habitable compartment there is a signal pistol and a supply of ammunition for it. An additional means of protection is thermal smoke equipment. With its help, “Object 608” can protect itself and the evacuated vehicle from observation and, as a result, attack.

One of the most noticeable elements of the special equipment of the BREM-1 vehicle is the 3.1 m wide bulldozer coulter located in the front part of the hull. This unit is mounted on levers and equipped with hydraulic drives that ensure its raising and lowering. A depth of up to 0.45 m into the ground is ensured. The main task of the bulldozer coulter is to hold the repair and recovery vehicle in place when using a traction winch. Due to the use of a powerful winch, existing tracks are not always able to provide the required traction with the supporting surface. In a number of situations, the opener can be used for excavation work. The hydraulic drives of the bulldozer coulter are controlled from the driver’s workplace using a pair of buttons.

A window with a roller device for dispensing the traction winch cable is provided in the frontal plate of the hull. The cable passes through the front compartments of the hull and enters the engine room, where the traction winch is located. This cable is intended for pulling out stuck equipment or, if necessary, for towing damaged vehicles if it is not possible to use a hitch. The cable has a length of 200 m and a diameter of 28.5 mm. For greater strength, the cable consists of several strands of spiral lay. The basis of the cable is galvanized steel wire.

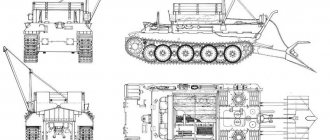

Scheme of BREM-1. Picture Gurkhan.blogspot.hu

The cable is wound onto the drum of a mechanical winch with planetary and transfer gearboxes. The design of the winch ensures that the cable is released at a speed of about 0.3 m/s. Winding is carried out at a rate of up to 0.217 m/s. A characteristic feature of the BREM-1 traction winch is its high thrust. Without additional devices, it is capable of creating a traction force (on the cable thimble) of up to 25 tf. The set of special equipment of the repair and recovery vehicle includes a separate pulley, with the help of which the traction force can be increased to 100 tf.

The engine room also houses an auxiliary winch driven by a hydraulic motor. It is equipped with a 400-meter cable and is capable of developing a traction force of up to 530 kgf. The auxiliary winch is designed to ensure the operation of the main one. Thus, it should be used to supply a fairly heavy traction winch cable to the towed vehicle. In addition, it is proposed to use it to move pulley blocks, for which special skids are transported on the machine.

The pulled out car can be towed. For this purpose, BREM-1 carries a semi-rigid towing device with double-sided internal shock absorption on the rear hull plate. In the working position, this device is attached to the towing unit of the vehicle, and its ends are secured to the hooks of the vehicle being towed. Towing a vehicle weighing up to 50 tons is possible.

The left front part of the engine room provides support mechanisms for the crane. To lift various loads, BREM-1 is equipped with a rotating jib crane with a lifting capacity of up to 12 tons. The design of the crane ensures the lifting and movement of various loads, however, the width of the service sectors and lifting capacity are limited by the weight of the load. For example, with a maximum load of 12 tons, work is possible within a sector 45° wide, and with a maximum boom reach (4.4 m), the lifting height of the load does not exceed 1.9 m above the ground. The crane is controlled using a separate remote control, which allows the operator to be outside the machine and monitor the operation of the systems without any difficulty. In the stowed position, the crane boom is laid along the body by turning it backwards. The hook is fixed at the bottom of the boom.

On the roof of the engine and engine compartments there is a special cargo platform equipped with rollers for moving around the body. Some of the equipment is proposed to transport spare parts containers, as well as tools necessary for repairing various equipment. The loading platform is a movable structure with a length of 1320 mm and a width of 1630 mm. There are folding sides with a height of 410 mm.

View of the car from the left-rear. Photo Armor.kiev.ua

The BREM-1 vehicle transports various equipment for repairs in the field. In particular, it is equipped with an ESA-1 electric welding machine. The method of powering this equipment is interesting: the standard starter-generator of the SG-10-1S power plant is used to supply energy. When using welding equipment, this device switches to generator mode and ensures that the necessary work is performed.

The fenders provide boxes and fastenings for transporting various equipment used for certain operations. So, on the left shelf, under the crane boom, a double-horned hook for the crane, a spare parts box, a shelving box with electric welding and accessories, two pulley blocks, as well as two jacks with a lifting capacity of 30 t are stored. On the right fender there is a box for the remaining pulley blocks and transport skids. In addition, another box of spare parts is transported there. In the aft part of the starboard side there are mounts for a manhole pipe included in the set of equipment for underwater driving.

BREM-1 has a full set of radio-electronic equipment for internal and external communications. The crew must use TSH4 headsets connected to the R-174 intercom. Also installed in the car is a VHF radio station R-173 and a receiver R-173P. Using this equipment, the crew of a repair and recovery vehicle can maintain voice communication with other equipment on the battlefield.

Being built on the basis of the T-72B main tank, the Object 608 has similar dimensions and weight. The combat weight of this armored vehicle is 41 tons. The maximum length is 7.98 m, width is 3.46 m, height is 2.42 m. It is noted that the absence of a turret and any other large habitable compartments protruding above the hull made it possible to reduce frontal projection and thereby increase the survivability of the vehicle in the conditions of solving assigned tasks under enemy fire.

The 840-horsepower V-84MS engine allows the BREM-1 to reach speeds of up to 60 km/h on the highway. When driving on a dirt road, the average speed does not exceed 40-45 km/h. When towing a T-72 or similar tank, the maximum speed on a dirt road does not exceed 10-15 km/h. On rough terrain, maximum speeds are further reduced.

The rear of the car. The towbar and loading platform are clearly visible. Photo Armor.kiev.ua

Several fuel tanks are installed inside the hull; in addition, it is possible to install additional barrels at the rear of the hull. With a fuel reserve of 1,730 liters, the repair and recovery vehicle can travel up to 700 km along the highway. On rough terrain, the range is noticeably reduced. When driving on a dirt road with a tank on a hitch, the range can drop to 150-200 km.

The armored repair and recovery vehicle BREM-1 was put into service in mid-1975. Soon preparations began for mass production of this equipment, which was to be carried out in Nizhny Tagil. However, according to some sources, due to various circumstances, the first pilot batch of production vehicles was built only in 1985. By this time the project had undergone some changes. In particular, the location of the machine gun mount was changed and the design of the bulldozer coulter was modified.

The use of an existing serial tank as a basis made it possible to establish mass production of new equipment and begin full deliveries to the troops. BREM-1 was supplied to evacuation platoons of repair and restoration battalions of tank and motorized rifle divisions, as well as other units for the corresponding purpose. The mastery of new equipment has allowed repair units to increase the efficiency of their work in evacuating and restoring damaged equipment.

By using a number of original technical solutions, the authors of the Object 608/BREM-1 project managed to create a very interesting special armored vehicle with high performance. In particular, the characteristics of the traction winch are of particular interest. This device, when using a chain hoist, is capable of developing a force of up to 100 tf. According to some reports, this is enough to pull out any modern domestic armored vehicles stuck in mud or other similar surfaces. It is reported that ground freezing is not a hindrance, and BREM-1 successfully pulls out tanks along with a large lump of frozen soil. The only problem in this case is the correct emphasis on the ground using a bulldozer coulter.

Some repair operations can be carried out using the existing crane. Among other things, this unit can be used when replacing a tank’s power plant in field devices. The composition of the remaining elements of special equipment is determined in such a way that the BREM-1 crew can provide comprehensive support to the damaged equipment.

The use of BREM-1 during the evacuation of the SU-100 after the parade in Moscow, May 2010. Photo Ifun.ru

For obvious reasons, the use of repair and recovery vehicles usually does not attract the attention of the general public. However, in May 2010, everyone could watch the operation of BREM-1 right in the center of Moscow. After the Victory Parade, an emergency situation occurred: one of the SU-100 self-propelled artillery systems fell from a tank semi-trailer and overturned onto the roof. To return the armored vehicle to the correct position, the BREM-1 traction winch was used. With its help, the self-propelled gun was put on board and then returned to the tracks, after which it became possible to send it for repairs.

By the early nineties, Soviet industry had managed to build a fairly large number of armored repair and recovery vehicles based on the T-72B tank. After the collapse of the Soviet Union, this equipment went to all newly formed states. In addition, several contracts were completed for the supply of similar machines to third countries. Thanks to these agreements, BREM-1 was added to the fleet of equipment of the ground forces of the GDR, Iran, Iraq, Syria, etc.

The development of the fairly successful project “Object 608” continued after the collapse of the USSR. Thus, currently, potential customers are offered a modernized version of the vehicle under the designation BREM-1M. Unlike the original, it is built on the basis of the T-90 tank and has the appropriate characteristics. In addition, during the modernization, the vehicle received a new crane with an increased boom length and a greater lifting capacity, increased to 20 tons. Due to this, the BREM-1M, unlike its predecessor, has the ability to lift the turrets of existing tanks without any special training. BREM-1M also features an updated traction winch with a force of 35 tf, which can be increased to 140 tf using a pulley.

A certain number of BREM-1s are still in use by the Russian armed forces. The purpose of this equipment is to assist units equipped with tanks of the T-72, T-80 and T-90 families. It can be assumed that this equipment will retain its place in the troops for a long time, and will be abandoned no earlier than the full-scale decommissioning of existing tanks begins.

Based on materials from the sites: https://armor.kiev.ua/ https://dogswar.ru/ https://t-80b.ru/ https://rem-battalion.ru/ https://uvz.ru/

Testing and production of the Bergepantera ARV

"Bergepanther" could not only pull, but also push tanks that had lost momentum. To do this, two square stops were placed in the bow of the vehicle, and the Bergepanther itself was equipped with a wooden beam transported on the left side.

The Bergepanther's tasks were not limited to towing and evacuation of damaged tanks. "Bergepanther" could be used as a mobile workshop, for transporting goods, and even as a mobile power generator. Many devices were developed for the Bergepanther to make standard operations easier: repairing the track tension mechanism, a jack for replacing road wheels, and kits for replacing a shot off drive wheel.

On March 1, the Bergepanther was demonstrated to the Inspector General of the Panzerwaffe, Colonel General Guderian. The demonstration took place at the Burke training ground near Eisenach.

On April 7, Hitler was informed about the good performance characteristics of the new BREM and was shown several photographs. Additionally, the Fuhrer was informed that the monthly production of Bergepanthers was 20 vehicles. In addition, it was planned to convert a number of disabled Panthers into Bergepanters. Although tank battalions sometimes independently removed the turrets from damaged Panthers, thus turning them into ammunition carriers and ARVs.

The production of 40-ton winches was carried out by Raupach (Gerlitz). Later, the production of winches was moved to a new plant in Varnsdorf. 20-30 winches were produced monthly.

The Bergepanther Ausf.A (Sd.Kfz.179) ARVs themselves were produced on the basis of the standard Pz.V. tank chassis, to the design of which only minimal changes were made.

The crew members' seats were located in the front of the vehicle. At the front there was a mount for a 20 mm cannon intended for self-defense. The gun was covered with an armor shield. Mounts for anti-aircraft machine guns were installed in the front of the hull on the left and right. All cars were equipped with a radio station. The capacity of the fuel tanks increased to 1075 liters. The body was produced by Ruhrstahl from Göttingen.

Since October 1944, "Bergepanthers" began to be produced on the basis of the Ausf.G chassis. The production of this modification continued until the end of the war. In addition to the Henschel company, the Bergepanter was produced by the Demag Werk Dusseldorf-benrath company.

A total of 297 vehicles were produced, 46 of them without a winch.

BMM-80 "Symphony" armored medical vehicle

In the early 90s, on the basis of the BTR-80, the Gorky Automobile Plant began to produce the BMM-80 “Symphony” (GAZ-59039), which is a multi-purpose floating medical vehicle for solving problems of medical support for events carried out in areas of combat operations and emergency situations.

It is designed to solve problems of searching, collecting and evacuating the wounded from the battlefield, from centers of mass casualties and providing first medical aid for emergency indications during transportation in various natural and climatic conditions, as well as for use as a mobile dressing room with a medical team. Created on the basis of the BTR-80 while maintaining the main components and assemblies, the BMM can operate in difficult terrain at any time of the year and day.

The crew of the car consists of 3 people. In the body of the vehicle there are 7 places for transporting the wounded, and there are also 2 places on the roof for transporting an additional 2 wounded on stretchers.

The machine equipment includes:

- Six-seater seat with dressing straps;

- Racks for installing medical equipment and stretchers;

- Wash basin;

- Safe;

- Drinking water tank;

- Tent to accommodate 12 wounded.

The vehicle is equipped with communications equipment, a protection system against weapons of mass destruction, fire-fighting equipment, water pumping equipment, and a habitability system. The body of the BMM has embrasures for firing from service weapons.

The machine kit includes a tent-shelter, which can be deployed in the form of a separate tent measuring 5.6x3.5x2 meters or in combination with a BMM, forming a functional unit. In this case, the tent-shelter is connected to one of the side doors of the car with a vestibule.

Special equipment of the BMM includes: racks for installing stretchers with a loading device and an awning from the outside of the machine;

- shelving and boxes for placing medical equipment;

- a drinking water tank with a capacity of 40 l;

-washbasin with elbow control faucet;

-six-seater seat with seat belts.

Options

- BMM-1 - evacuation of wounded from the battlefield,

- BMM-2 - battalion first aid station

— BMM-3 – mobile dressing room with a medical team and an automatic dressing complex AP-2

Characteristics of the Bergepanther ARV

A country:GermanyType:Armored repair and recovery vehicleDate of issue:1943Length:6.93 mWidth:3.42 mHeight:2.7 mArmor, forehead:80 mmArmor, side:40 mmArmor, tower:NoCrew:3-5 peopleEngine:1x carburetor, 600 hpTravel range:150 kmMaximum speed:46 km/h (on highway)Weight:43 tonsWeapons:1x 20 mm Kw.K.38 automatic cannon, 2x 7.92 mm MG.34 machine gun