Characteristics of the Mark IV Churchill infantry tank

A country:Great BritainType:Infantry tankDate of issue:1941Length:744 mmWidth:325 mmHeight:245 mmArmor, forehead:101 mmArmor, side:76 mmArmor, tower:89 mmCrew:5 peopleEngine:Bedford 350 hpTravel range:144 kmMaximum speed:27 km/hWeight:39.6 tonsWeapons:1x 57 mm gun, 1x 40 mm gun, 2x 7.92

“British Mark IV Churchill infantry tank.” Design, modifications and combat use"

The history of the creation of the heavy tank Mark IV "Churchill" (A22)

The heavy infantry tank Mark IV "Churchill" (Infantry Tank Mk. IV Churchill A22) is the most protected and widespread English tank of the Second World War. The car had not only a disgusting appearance, but also a bunch of other shortcomings (Sir Churchill himself, as you know, joked about this that it had fewer shortcomings than the tank named after him), but managed to visit all military theaters of the Second World War , was delivered to the USSR under Lend-Lease, served in some modifications until the 1950s, and in general, according to the reviews of the tankers who fought on it, it was very good.

According to its intended purpose, the Mark IV Churchill heavy tank was created as a complement/replacement for medium tanks of the Matilda II type, which were slow and at the same time quite vulnerable to the new German guns.

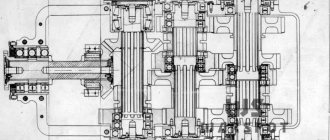

Drawing of the Mark IV Churchill heavy tank

Despite the crudeness and primitiveness of the design, which was even to some extent a step back to the concept of tanks of the First World War (due to the tracks seemingly covering the hull), the tank could overcome ditches and trenches of great width quite well, and was relatively easy to manufacture and maintain.

The prototype Mark IV "Churchill" A22 was built by Vouxhall in 1940. Serial production began in the summer of 1941 and continued until December 1945.

In total, during the war years, the industry produced 5,640 Mark IV Churchill tanks.

Mark IV Churchill tanks of the first models. Pay attention to the second barrel on the front plate - the howitzer is at your service!

Modifications

Mk IV was actively used for a variety of experiments. The most popular modification of the tank was the Tadpole, or Tadpole. The Tadpole track drive was significantly lowered at the rear, but had an extended bearing surface. At first they even wanted to rebuild all the Mk IV tanks according to this scheme, but the conversion was not carried out, so there were very few Tadpoles.

Sometimes a Stokes mortar was attached between the lugs of the chassis at the rear, which, in fact, made the tank the first example of a self-propelled mortar.

Design of the heavy tank Mark IV "Churchill" (A22)

The British Mark IV Churchill tank had a classic layout with a rear-mounted engine and transmission, and a front-mounted control compartment. The tank's body had a rectangular box shape and consisted of rolled armor plates attached with rivets to an angle frame.

The crew of the Mark IV Churchill tank consisted of 5 people. The tank commander was located in the turret, with the loader and gunner on his right and left sides. The driver's position was located almost in the center of the hull, but shifted to the starboard side; to the left of the driver was a machine gunner, who initially (on the first Churchill model) was also the operator of a howitzer located in the front plate of the tank hull (starting from the second model - replaced by a machine gun).

The crew boarded and disembarked the tank through two double-leaf rectangular hatches in the turret roof. The right hatch was used by the loader, the left by the commander and gunner. Also, two double-leaf rectangular hatches were located in the roof of the front part of the hull; they were used by the driver and machine gunner.

Heavy tank Mark IV "Churchill" in profile

The tank's turret had the shape of a weak hexagon and was made by casting (models Mk. I, Mk. II, Mk. IV, Mk. V, Mk. VI), riveting on a frame (Mk. III) and a combined method (Mk. VII and Mk. VIII). In the latter case, the front part was cast, the rest were welded from rolled armor plates.

The rotation of the tower was carried out using an electric drive or manually.

The chassis of the Churchill tank consisted of eleven dual support rollers with a diameter of 254 millimeters, a idler and a drive wheel on one side. Individual suspension, spring type. The axis of each roller was secured to a balancer, which at one end was hinged to a bracket welded to the tank body, and at the other end rested against a spring attached to the bracket.

It is interesting that almost every road wheel had a special purpose: the first and last (on both sides) were raised and did not touch the ground, working only if the machine overcame obstacles. The 2nd, 9th, and 10th had a shortened suspension travel and worked mainly when the tank was moving on soft and swampy ground.

Heavy tank Mark IV "Churchill" of the first model, the howitzer in the front plate is clearly visible. Already from the second model it was replaced with a machine gun.

"Churchill" with a "hole punch"

The British began working on a new heavy infantry tank in June 1940, after the defeat in France. The Infantry Tank Mk.IV, aka "Churchill ", proved controversial. It was not even completely clear why it was needed: the vehicle’s armament remained at the level of the existing Matilda, the armor was not much better, and in some places worse, and the weight increased to 40 tons, which negatively affected the mobility and reliability of the tank. The car was brought to life until 1942, when tests in Canada and North Africa showed

that the Churchill was at least ready for use in the army. However, one very significant problem was not solved: the tank's armament still remained at the pre-war level.

Gun and shells

Development of the 40 mm 2-pounder gun in Great Britain began back in 1932 to replace the 47 mm 3-pounder. The latter's projectile, although larger, had a muzzle velocity of only 1,850 feet (564 meters) per second; this made it difficult to aim at long distances and limited armor penetration. The new gun fired a projectile at a speed of 2,625 feet (800 meters) per second, which ensured penetration of 50 mm armor at an angle of 30° and allowed accurate fire at long ranges.

Such characteristics were outstanding for their time, but already in 1936 the military formulated a task for an infantry tank with anti-ballistic armor that could withstand hits from such shells. Based on this assignment, the Matilda was developed, the prototype of which arrived at the test site in 1938. It was clear that if Great Britain was able to develop such a tank, then sooner or later similar vehicles would appear abroad. In the same year, the Director of Artillery gave the task to develop a more powerful anti-tank gun. However, the General Staff did not share the opinion of the artillerymen and did not support the project. An experimental 57 mm caliber gun was created on its own initiative, which fired a 6-pound projectile with a muzzle velocity of 2,700 feet (823 meters) per second. During testing, the gun penetrated a 70mm plate at an angle of 30° when fired at point-blank range and at an angle of 20° from 1,100 yards (1,000 meters).

Towed version of the 6-pounder gun. Armored Museum in Saumur

In December 1939, the General Staff changed its mind, approving the construction of two prototypes of an anti-tank gun with such ballistics. The guns, called the Ordnance QF 6-pdr 7 cwt (7-central rapid-fire gun with a 6-pound shell), were finished testing by August 1940, but, oddly enough, the experience of the war in Europe had a negative impact on their introduction. The results of the battles showed that the 2-pounder can still very effectively destroy the armor of modern German tanks. The Germans themselves did not develop an anti-tank gun larger than a 37-mm cannon, so many British military personnel formed the opinion that there was no point in introducing a new weapon into the British army. In the summer of 1940, the British expected a German invasion at any moment, and it was necessary to build tanks using already proven technologies. In addition, 2-pounders were much cheaper for the state treasury than more powerful guns.

However, the Director of Mechanization understood that it was foolish to hope for stagnation in German tank building, and the armor of German vehicles would inevitably increase after a collision with British tanks. In the spring of 1941, information was received about new heavy German tanks Pz.Kpfw.V, Pz.Kpfw.VI and Pz.Kpfw.VII. Rumors about new powerful machines were able to awaken the General Staff from hibernation, but that was only half the battle. It was necessary to develop an installation for the gun, but work on it proceeded slowly. The idea that it would be nice to put a heavy gun in a heavy tank was only thought about in February 1941.

By May 2, 1941, there were no drawings for installing a 6-pounder on the Churchill; developments were only available for the Crusader, but the existing installation was unsatisfactory. For the Churchill, it was additionally necessary to develop a larger turret, since the existing one was too cramped. Since it was not yet clear what the new turret would look like, the designers began working on two installation options at once: with an internal mask for the turret made of rolled armor and with an external mask for the cast turret. Serial production of the 6-pounder was expected only by October; piece copies for testing were produced in a handicraft manner very slowly. By the end of May, 12 guns were expected to be assembled at the Royal Arsenal at Woolwich.

The military also worked on another drawback of the 2-pounder: the lack of a high-explosive fragmentation projectile. Its 40-mm shells were not large enough to have any effective high-explosive effect, but at least something could be done with the larger 6-pounder. Tests were carried out at the Lulworth artillery range back in July 1941. For use in the anti-tank gun, a 57-mm projectile from the QF 6-pounder 10 cwt naval guns, filled with trinitrophenol, placed in a casing from the anti-tank gun, was suitable. The projectile weighed slightly more than the 6-pounder armor-piercing projectile, but the difference was considered insignificant to affect the projectile's trajectory.

When fired from 50 yards (45 meters) with a reduced charge to simulate a shot from 700 yards (640 meters), the 242P delayed fuze and 242 instant fuze shells managed to destroy the sandbag barricade, but the targets behind it remained intact. . Firing an 11-inch (28 cm) thick brick wall produced slightly better results, with delayed-fuse shells exploding after penetrating the wall, sending shrapnel into the plywood shields. A shell with an instant fuse demolished the remains of the wall, but the target remained unharmed because it exploded too early. When shooting at the figures of soldiers installed in a trench, it was fuse 242 that showed a more effective effect, since the slow version exploded too late. The instant-fuse round was also more effective at targets in open areas.

Churchill Mk.III with 6-pounder Mk.III gun

These test results were considered unsatisfactory. For maximum effectiveness against infantry and fortifications, it would be necessary to carry two types of shells. Since the Churchill with a 6-pounder approximately carried only 84 rounds, the number of one or another type of shell would undoubtedly be insufficient for the battle. In addition, the presence of two types of high-explosive fragmentation shells could lead to their erroneous use. Then the use of a high-explosive fragmentation projectile was generally called into question, since officers believed that in the heat of battle the loader could grab a high-explosive fragmentation projectile instead of an armor-piercing one. As a result, the British decided not to equip the Churchill with high-explosive fragmentation shells at all, preferring to stick to the concept of using special close support tanks with larger caliber howitzers.

On May 4, 1942, the Canadians also demanded naval semi-armor-piercing chamber shells, since the armor-piercing effect of the 6-pound blanks was poor. The answer was not very encouraging: there are no semi-armor-piercing shells, work is underway on a chamber shell for the 6-pounder.

The chambered shell never arrived, but work on a high-explosive fragmentation shell for the 6-pounder did not stop. More than a year later, in October 1943, shells with a delayed action fuze type 244 appeared, which proved to be much better. However, some commanders requested an adapter to use the Type 251 instant fuze. The high explosive effect of the projectile itself was still low, and testers compared it to the 40 mm Bofors anti-aircraft machine gun round.

Sailors load the ship's twin 6-pounder 10 cwt guns. The British Royal Navy already had suitable 57 mm high-explosive fragmentation shells

The concrete-cutting effect of the 6-pounder also turned out to be low. The armor-piercing shells shattered, creating a hole 1.5–2 inches (38–51 mm) deep in the concrete, which was close to the effectiveness of the 20 mm Hispano cannon.

By 1943, interest in the 6-pounder had waned. Work was carried out only on sub-caliber shells for this gun to increase the effectiveness of existing vehicles, while new work was carried out on universal 75-mm guns and more powerful 17-pounder anti-tank guns. However, the largest number of Churchills were produced with 6-pounders.

Pumped up "prime minister"

Production of the Churchill with the 6-pounder gun did not begin until March 1942, more than a year after work began on a tank version of the gun, called the Ordnance QF 6-pounder 7-cwt Mk.III. Structurally, the hull of this tank differed little from its predecessors, but the turret changed very much. Unlike the cast turrets of the Churchill Mk.I and Mk.II, the new turret was welded. It also has a second pistol hatch. The tower rotated using an electric drive, which at maximum speed made a 360° rotation in 15 seconds.

"Churchill" Mk.III was radically different from its predecessor only in the turret

The viewing devices were no different from its predecessor: the gunner and loader each received a periscope. The commander had two periscopes located in a kind of commander's cupola, rotating independently of the large tower. In addition to the 6-pounder and coaxial machine gun, a Mk.I breech-loading mortar was installed in the turret. Also in the tank were a Bren light machine gun with an anti-aircraft gun and two Thompson submachine guns.

The tower could be assembled using traditional slats and rivets, but factories that could do such work were already loaded with orders. The only one left was from Renfrew (Scotland), which offered a welded structure. The retrogrades did not believe that the welding of such massive plates would withstand shelling, but tests in October 1941 showed that their fears were unfounded. Firing experimental turrets with a 2-pounder cannon and a 25-pounder howitzer showed that the seams were quite durable. Under fire they cracked, but not along the entire length. The required durability was achieved even without a traditional mild steel frame, which reduced the weight of the tower. The tank with this turret was put into service under the designation "Churchill" Mk.III, and in the end almost 700 of them were built.

A column of the most massive heavy tanks of the British Army. The Churchill Mk.IV is clearly identified by its cast turret and 57 mm gun barrel

A significant problem has also emerged. There was a shortage of thick armor suitable for welding in the country, and the army needed as many as 3,500 heavy tanks. I had to look for an alternative: I had to return to casting, fortunately I had experience in casting large parts. The cast tower turned out to be half a ton heavier than the welded one. These tanks, called Churchill Mk.IV, turned out to be the most numerous - 1,422 of them were built.

Already in May 1942, the appearance of the Churchills changed somewhat: the vehicles began to receive mud flaps covering the massive tracks, as well as improved air intakes. Like the early Churchills, the 6-pounder went through a modernization program. Modified tanks received the letter “R” in their registration number.

Installation of weapons on Churchill Mk.III and Mk.IV

As with the Crusader Mk.III, the military tested several versions of the lifting mechanism for the gun: a fixed one, with a flywheel for aiming the gun, and a free one, with a shoulder stock. Early Churchills were produced with the first option. A tank with such a mechanism arrived for testing at Lulworth in the first half of April 1942. Tests have shown that such a mechanism does not work well, especially on the move. The military demanded the development of a version with free vertical aiming, which had a significant advantage: the gun could be easily raised when the turret was rotated. Otherwise, it was necessary to either limit the declination to 4°, or install a cunning mechanism to automatically raise the gun so that it would not touch the sloths protruding far forward.

The results of the tests were twofold. Smoke in the fighting compartment when firing from a 6-pounder turned out to be at a satisfactory level, and it was possible to shoot without fear of being poisoned by powder gases, but work still had to be done on effective ventilation when firing from a coaxial machine gun. The ventilation of the control compartment was also unsatisfactory, and the driver had to be separated from the machine gunner by a special partition. As a result, ventilation problems plagued the Churchill Mk.III throughout the war.

The structure of the fighting compartment of the Churchill Mk.III and Mk.IV

Testing continued, and by May the list of deficiencies grew. In addition to the problems with the vertical aiming mechanism, there were shortcomings in the turret rotation mechanism. In addition, it turned out that the flash when firing a gun blinds the gunner, and it is impossible to adjust fire at a distance of less than 700 yards (640 meters). The shot also raised a large cloud of dust.

On June 27, the Churchill Mk.III was shown to a delegation of the Canadian military. Shooting from 800 yards (730 meters), we got good accuracy, and even from 1800 yards (1646 meters) the Churchill hit the target 33% of the time. In July, the tank took part in a race along a 2.8-mile (4.5 km) track, where it showed a top speed of 23 km/h over rough terrain. This was much worse than the Cavalier, Cromwell, Sherman and Ram medium tanks, as well as the light Harry Hopkins, but better than the early Churchills.

"Churchill" Mk.IV during sea trials

Another defect was soon discovered at the test site: the installation of the 6-pounder gun experienced significant problems with rolling. For the tests carried out on August 20-22, three Churchill Mk.IIIs were used. The results were dismal: even at a fairly low rate of fire, the guns of all tanks were stuck in an incomplete recoil position after 25, 26 and 31 shots, respectively. In all cases, the cause was jamming of the rollback brake shock absorber due to overheating. Changes had to be made to the design.

In the fall, the fight against the “childhood diseases” of the car continued. In the third ten days of September it turned out that the British-made 6-pounder guns had serious manufacturing defects that had to be frantically corrected. At the same time, the guns produced in Canada for installation on the Ram were of much higher quality. There were plenty of problems with the Churchill itself - for example, defects in the design of the turret ring led to rapid wear and tear of the turret rotation mechanism.

Churchill Mk.IV with Mk.V gun. A counterweight is installed on the barrel cut

Another change in 1943 was the installation of a new 6-pounder Mk.V gun with a 50-caliber barrel: the Churchill Mk.IV was tested with it on March 11th. When firing forward with maximum declination, the flow of powder gases could rip off the mudguards, and when firing backwards, it could destroy the tools on the engine plate and damage the canisters on the rack behind the stern. The new gun was lighter - 272 kg compared to 317 kg for the old Mk.III. The lighter barrel caused the gun to tip backwards, which was corrected by using a 30-pound (13.6 kg) barrel counterweight. In March, they also tested a mechanical shutter to protect the gunner's eyes from flash when fired.

Work on mistakes

The Churchill Mk.III and Mk.IV differed from their predecessors not only in their weapons. In the fall of 1942, a change was made to the design of these tanks that significantly increased protection. Instead of the archaic design with bolts and rails, the hulls, like the turrets, began to be assembled using welding. At first, the slabs were welded to a steel frame in the old fashioned way, but they quickly abandoned it. On October 7, the experimental corps was fired upon at the training ground and received positive results.

By May 10, 1943, a new latch for the driver's hatch on the Churchill Mk.IV was tested. Five heaped hits from a 2-pounder from 100 yards (91 meters) not only did not penetrate the armor, but also did not break the latch, although the impact of the 2nd and 3rd shells randomly opened the shutter of the viewing device. By this time, one pistol hatch had been removed from the turret. By 1943, the crews realized that the hatches were of little use, and began to weld a second one.

Design of the base of the control panel with increased resistance

However, even by the end of 1943, the tank's protection remained unsatisfactory. Even if the projectile did not penetrate the armor, the vehicle could fail due to damage to the units. So, on December 17, a new control panel was tested. The explosion of a single 25-pound high-explosive fragmentation shell on the inclined front plate of the tank had serious consequences: the entire weld connecting the vertical and inclined plates burst, the vertical plate was pressed into the hull, and the driver's inspection hatch was broken. The experimental control panel remained in place, but all the instruments were out of order. The casings and cylinders of the servo drives and brake mechanisms burst. Tests in March 1944 also showed that the roof of the control compartment could be broken by the ricochet of a high-explosive fragmentation shell hitting the turret's forehead. By this time, work on the Churchill Mk.IV was abandoned, since the new vehicles of the Mk.VII and Mk.VIII modifications were much more promising.

However, analysis of the armor protection of early versions of the Churchill continued. In January 1944, calculations were made of the vulnerability of the Churchill Mk.I–Mk.IV from air attacks. They showed that conventional 12.7mm bullets would not damage a tank, but armor-piercing bullets of that caliber fired from an aircraft in a steep dive from 500 feet (152 meters) could penetrate the roof. According to the report's author, the tank was well protected from bombs: even a direct hit from a 20-pound (9 kg) bomb did not necessarily disable the tank, not to mention close explosions, but fragments of a 500-pound (227 kg) bomb were highly likely They broke through the roof.

High-strength bolt design

Even after two years of improvements and bug fixes, the tank's reliability has not reached the proper level. In May 1944, survivability tests were carried out, in which six Churchill Mk.IVs, which already had an average range of 800 miles (1287 km), took part. The tests took 11 hours, including maintenance. The Churchills turned out to be much more capricious than their rivals, the Shermans (two M4A1, M4A2 and M4A4 each) and the Cromwells.

Heavy tanks took an average of 78 minutes to service, compared to 53 and 51 minutes spent on medium tanks. In total, the Churchills covered an average of 90 miles (145 km) at an average speed of 7.5 miles (12 km) per hour. Older cars with a range of 1,300 miles (2,092 km) managed only 70 and 81 miles (112 and 130 km). The tanks seemed very voracious: fuel consumption when driving on roads was 297 liters per 100 km. The low speed was more likely a consequence of poor choice of gears: in tests in April 1945, the Churchill Mk.IV averaged 7.7 miles (12.5 km) per hour on a track with poor ground and 8.7 miles (14 km) per hour on poor ground. per hour on the highway with good speed, while the heavier Churchill Mk.VII achieved speeds of 9.5 miles (15.3 km) and 11 miles (17.7 km) per hour respectively. Nominally the Mk.IV was faster than the Mk.VII (top speed 25.6 km/h versus 20.4 km/h), but in low gear on poor ground the slower tank performed much better.

A modernized Churchill Mk.IV in the storerooms of the Bovington Tank Museum. The vehicle has a 75 mm cannon and an improved commander's cupola.

The Churchill Mk.III and Mk.IV were not destined to become the best machines. Despite the increased power of the weapon, a lot of questions remained about the 6-pounder and its installation. The gun never received an effective high-explosive fragmentation projectile, and the tank’s level of protection turned out to be much worse than expected. The reliability of even modernized machines remained low. However, the combat qualities of the new tanks still increased, and British designers boldly moved towards the most advanced tank of the family, which became the Churchill Mk.VII. However, production peaked precisely with the intermediate Mk.III and Mk.IV - it was better to have mediocre heavy tanks in service than not to have any.

Sources and literature:

- Canadian Military Headquarters Archive, London (1939–1947) RG 24 C 2

- The National Archives of Great Britain

- David Fletcher. Churchill Infantry Tank - Osprey Publishing, 2019

Modifications of the Mark IV Churchill tank

Mark IV Churchill I

—the first production model of the tank, a 40 mm (2-pound) Mk IX or MkHA cannon in the turret and a 76 mm (3-inch) Mk 1 howitzer in the front hull. The fenders were missing. Ammunition capacity: 150 rounds for the cannon and 58 for the howitzer. 303 units produced.

Mark IV Churchill II

— instead of a 3-inch howitzer, a 7.92-mm BESA machine gun is installed in the front hull plate. 1127 units were produced.

Mark IV Churchill IICS

- 3-inch howitzer in the turret and 2-pounder gun in the tank hull.

Mark IV Churchill III

— 6-pounder Mk III gun in an oversized turret. The caterpillars are covered with wings. 675 units produced.

Mark IV Churchill IV

— “Churchill” with a cast turret instead of a welded one. 1622 units were produced.

Mark IV Churchill IV (NA 75)

- a version of the Churchill for the Mediterranean theater of operations (NA - North Africa), a 75-mm American MZ cannon with a coaxial Browning machine gun, borrowed from the Sherman. Browning machine gun in housing. 120 units were converted.

Mark IV Churchill V

— “Churchill” IV with a 95 mm howitzer. Ammunition 47 rounds. 241 units were produced.

Mark IV Churchill VI

— "Churchill" IV with a 75-mm English cannon.

Mark IV Churchill VII

- a new model with the thickness of the frontal armor of the hull increased to 152 mm and the thickness of the turret to 95 mm. An oversized turret with a 75 mm cannon and a commander's cupola. Strengthened suspension, new gearbox and other minor changes and improvements. Combat weight 41 tons. Max. speed 20 km/h. Ammunition 82 artillery rounds. Crew 5 people

Mark IV Churchill VIII

— “Churchill” VII with a 95 mm howitzer.

Mark IV Churchill IX

- Churchill III or IV, upgraded to Churchill VII, but with a 6-pounder gun.

Mark IV Churchill IX LT

- "Churchill" IX with a turret from "Churchill" III or IV (LT - Light turret - light tower).

Mark IV Churchill X

— "Churchill" VI, upgraded to the level of "Churchill" VII.

Mark IV Churchill XLT

— “Churchill” X with a turret from “Churchill” VI.

Mark IV Churchill XI

— "Churchill" V, upgraded to the level of "Churchill" VIII.

Mark IV Churchill XILT

— “Churchill” XI with a turret from “Churchill” V.

Mark IV Churchill heavy tank. The tracks are covered with “mud flaps”, which clearly does not add any external shine to the tank