Reasons for German success

German armored forces were created in a short time. For a long time, the service consisted mainly of light tanks and “only a small number of medium tanks.” However, as E. Middeldorf writes, “the 1940 campaign in France and the 1941-1942 offensive in Russia showed that armored forces, when used in a massive and maneuverable manner, can ensure the rapid destruction of the enemy and achieve major operational successes.”

Despite the fact that the enemy (that is, the USSR) in the first years of the war had a four- or even five-fold superiority in the number of tanks, the German armored forces defeated them. The reason that the Germans advanced to Leningrad, Moscow and Stalingrad, according to E. Middeldorf, was that the creation of their armored forces was based on the correct principles:

- “maximum flexibility and mobility ... in the use of armored forces;

- concentration of forces in a few decisive areas;

- skillful and decisive application."

Tank battle near Prokhorovka

ARMORED VEHICLES OF GERMANY 1939–1945

ARMORED VEHICLES OF GERMANY 1939–1945

The production of tanks in Germany after the First World War began in the summer of 1925 with the development of the Grotraktor machine. The massive production of armored vehicles, as well as the deployment of tank troops, coincided with the Nazis coming to power.

In October 1935, the first three tank divisions were formed. By the beginning of World War II, their number increased significantly. Six tank and four light divisions took part in the attack on Poland. Based on the experience of the Polish campaign, the latter (originally intended for combat operations together with cavalry) were reorganized into tank ones.

Germany had already fielded 19 tank divisions against the Soviet Union, and ended the war with 27 such formations (20 in the Wehrmacht and 7 in the SS).

The number of combat vehicles in tank divisions was uneven and on average ranged from 324 tanks in the initial period of the war to 120–140 at its final stage.

In addition to the divisions, the Wehrmacht had separate heavy tank battalions, the number of combat vehicles in which ranged from 35 to 55. In total, 10 such battalions were formed in the Wehrmacht and 3 in the SS troops. Individual battalions could be operationally subordinate to the commanders of tank or motorized divisions, which, in turn, were consolidated into tank corps, the number of which by the end of the war reached 14 in the Wehrmacht and 4 in the SS troops. The corps could be part of tank or field armies, or act independently. At the beginning of 1945, the Wehrmacht consisted of five tank armies. In addition, the SS troops had one tank army.

Self-propelled artillery could organizationally be part of tank and motorized divisions, as well as act independently as part of divisions and brigades of assault guns, anti-tank divisions of the reserve of the main command, etc. In the period from 1939 to 1945, about 25 brigades of assault guns and several dozen separate assault and anti-tank divisions and batteries.

As for the production of armored vehicles in Germany on the eve and during the Second World War, it should be noted that it never fully met the needs of the troops.

In accordance with the state, German tank units and formations were equipped, perhaps, only on the eve of the war - in August 1939. This situation is clearly illustrated by the following example.

On June 22, 1941, about 3,680 tanks were concentrated in the East, including the reserve of the Wehrmacht High Command (2nd and 5th Panzer Divisions), and about 350 in North Africa.

From June to November 1941, 2,251 tanks were irretrievably lost on all fronts; from June to November 1941, 1,813 combat vehicles were produced. As a result, the shortage amounted to 438 units.

Losses in assault guns were significantly lower, since their use at that time as a means of supporting infantry did not entail large losses.

From June to November 1941, losses in assault guns amounted to 75 units, and their production during the same period was 295 units.

The production of tanks and self-propelled guns reached its maximum at the end of 1944 - almost 1,800 vehicles per month. Since the production of tanks technologically required much more time and effort than the production of self-propelled guns, the share of tank production decreased in 1944. Tank production reached its highest level in August 1944 and amounted to 865 vehicles per month, while by the end of 1944 the monthly production of self-propelled guns of all types exceeded 1000 units.

In total, in 11 years, just over 50,000 tanks and self-propelled guns were manufactured in Germany, while in the USSR during the Second World War alone - 109,100 tanks and self-propelled guns, in the USA - 135,100, in Great Britain - 24,800. With five times fewer tanks and self-propelled guns than its main opponents, Germany was able to create such tank forces that throughout all the years of the war, right up to its last days, were able to deliver powerful blows. Here it is enough to recall the counter-offensive of German troops in the Ardennes in the winter and in the area of Lake Balaton in the spring of 1945. In both cases, having absolutely no superiority in tanks either on the Western or Eastern Front, the Germans managed to achieve it in the directions of the main attacks.

All this testifies to the high level of combat training of privates and officers of the German tank forces, as well as the reliability of armored vehicles, which made it possible to operate tanks and self-propelled guns for a long time without their failure for technical reasons. German designers managed to achieve good combat characteristics of their armored vehicles.

Good weapons, excellent optics and communications, reliable engines and chassis, comfortable working conditions for the crew - all this, coupled with excellent combat training of tank crews, enabled the Germans throughout the war to make do with fewer tanks and self-propelled guns than their opponents, and to inflict very significant blows on them. . Suffice it to mention that during the Second World War, Soviet tanks attacked on average 3 times, German tanks 11 times, and for one destroyed Panther, the Americans usually paid with five Shermans!

PRODUCTION OF ARMORED VEHICLES IN GERMANY

DESIGNATION OF GERMAN ARMORED VEHICLES

All tanks entering service with the Wehrmacht received the letter abbreviation Pz.Kpfw. (short for Panzerkampfwagen - armored fighting vehicle) and serial number. Modifications were designated by letters of the German alphabet in order and the abbreviated word Ausf?hrung - model, version, option.

Along with this, an end-to-end designation system was adopted for all Wehrmacht mobile assets: Kraftfahrzeuge Nummersystem der Wermacht. According to this system, a significant part (but not all!) of German tanks and self-propelled guns received designations consisting of the abbreviation Sd.Kfz. (short for Sonderkraftfahrzeug - special purpose vehicle) and serial number.

As a result, the full designation of the German tank, known to the reader under the “domestic” name T-1A, looked like this: Pz.Kpfw.I Ausf.A (Sd.Kfz.101). However, for simplicity, both the German army and the literature on tank technology use the simpler designation Pz.IA.

All tanks discussed in this reference book have similar simplified indices.

With self-propelled artillery units the situation is somewhat more complicated, mainly due to the abundance of classes and types. Assault guns had their own designation system, anti-tank guns, self-propelled howitzers and anti-aircraft guns had their own. At the same time, the official name of a particular self-propelled gun, as a rule, included information about the artillery system used and about the base tank chassis. For example, the name Sturmgesch?tz III indicated that it was an assault gun based on the Pz.III tank, and Panzerj?ger I was a tank destroyer based on the Pz.I. At the same time, the full designation of the latter was as follows: 4.7 cm Pak (t) auf Pz.Kpfw.I Ausf.B. It can be deciphered as follows: 47-mm Czech anti-tank gun on the chassis of a Pz.I tank, modification B. Please note that the caliber of artillery guns in Germany is measured in centimeters, but in this reference book both in the text and in the technical characteristics it is given in millimeters - more familiar to our readers. The only exceptions are the official names of tank and self-propelled guns.

A significant part of the Wehrmacht self-propelled guns also had indices according to the end-to-end designation system - Sd.Kfz.

Captured tanks were also designated Pz.Kpfw. and serial numbers starting from the number “700” (except for Czech ones). In addition, after the number, a letter was written in brackets in accordance with the previous nationality of the tank - t (tschechisch - Czech), f (franz?sisch - French), e (englisch - English), r (russisch - Russian), etc. .

Reasons for German failures

In 1943, during the summer offensive (Operation Citadel), German armored forces were defeated. E. Middeldorf modestly calls it a “failure.” In his opinion, the defeat at Kursk was caused by inconsistency in the actions of tank units and infantry. In the three advancing echelons in the direction of the main attacks, writes E. Middeldorf, the main force was “almost exclusively tank divisions.” During the first five days, they broke through from two to three deep-echelon defensive positions of the Red Army and in some areas advanced up to 25 km. The defeat began only when the “enemy” launched counterattacks on the exposed flanks, which the German infantry did not have time to cover.

“The balance of forces at Kursk,” writes E. Middeldorf, “was approximately one to two in favor of the Russians, while the combat regulations of most armies in the world require approximately three times the superiority of the attacker.”

A significant factor in the ineffectiveness of the German armored forces at Kursk, according to E. Middeldorf, was the intervention of Hitler, who, not being a military man, “determined in the smallest detail the time of the start of the offensive, the breakthrough areas, the grouping of troops,” etc. Because of this, contrary to the advice of the generals, "the enemy was attacked at his strongest point" and the German tank divisions "found themselves drawn into the labyrinth of Russian field fortifications, missing out on the element of surprise, both in terms of timing and location of attacks "

Summing up his analysis, E. Middeldorf argues that the German tank formations were innocent of the defeat at Kursk, and its “reasons ... should not be sought at all in the troops that participated” in this battle.

Soviet light tank T-26 (production 1931-1941)

The last tanks of the Third Reich

At the end of World War II, a very difficult situation arose in German tank building. It was not just the bombing of factories, the loss of significant territories and the lack of resources. The accumulated errors in planning the development and production of armored vehicles, as well as cases of unfair competition, had an impact. Let's try to figure out how in the last year of the war, under the new head of the Tank Commission, the Germans tried to put their tank building in order, and what came of it.

Lucky is the one who is lucky

By 1944, German tank building was in a very difficult situation. The Germans almost completely failed to develop light tanks. The official order for a new single reconnaissance tank arrived on September 15, 1939, and at the beginning of 1942, MAN provided the first sample of the VK 13.03, better known as Pz.Kpfw.II Ausf.L Luchs or as Pz.Sp.Wg.II Ausf .MAN (Panzerspähwagen - “armored reconnaissance aircraft”).

Pz.Kpfw.II Ausf.L "Lux" with a 50-mm gun in a lightweight turret from VK 16.02

It was planned to build 800 "Luxes", with the first 100 tanks supposed to leave the workshops by April 1943. Instead, they were assembled until January 1944, and then production stopped altogether. A catastrophic result in four years of war! Czech and BMM received similar assignments much later, on July 31, 1940, but provided the first prototypes earlier, and the Pz.Kpfw.38 nA turned out almost better than the Pz.Kpfw.II Ausf.L.

With the support of the Armaments Directorate, German firms eliminated Czech competitors, but were unable to cope with all orders, and in fact left the Wehrmacht without new reconnaissance officers. At the end of the war, the German tank industry did not have a promising light chassis in mass production. The tank builders of the Third Reich were able to achieve this result on their own, without the help of foreign spy-wreckers.

There were also serious miscalculations in the 20-ton class. A single base for a medium tank was conceived back in 1937, but the Germans continued to produce armored vehicles on the Pz.Kpfw.III and Pz.Kpfw.IV chassis throughout the war. With similar characteristics, they had fundamentally different designs, the reserves of which were exhausted already in 1943. However, even with Tigers and Panthers, the Germans could not completely abandon the construction of 20-ton chassis, since they were required for mass tank destroyers, self-propelled anti-aircraft guns and howitzers, etc. To fill this niche, companies carried out work to replace the aging “threes” and “fours”, but for various reasons the VK 28.01, Porsche Typ 245, Typ 250 and schwerer kleiner Panzerkampfwagen (“small heavy tank”) programs remained only on paper.

As for the Panther and the Royal Tiger, these were problematic tanks with low reliability. It is usually explained by wartime and extreme haste in designing and setting up production. Yes, this is partly true, but the inadequate approach of the Armament Directorate, which was failing even before the war, also contributed. For example, when developing gearboxes for a 700-horsepower engine, the Germans for some time ignored three-shaft and planetary gearboxes in favor of very expensive and exotic shaftless ones. As a result, to reduce the cost of the Panther, it was necessary to hastily create a three-shaft gearbox, the reliability of which left much to be desired, and the planetary gearbox was not tested at all on the Tiger before the defeat in the war.

Schwerer kleiner Panzerkampfwagen with 105 mm PAW 1000 launcher

In the face of the impending catastrophe of the end of the war, the Germans needed to produce as many cheap, standardized armored vehicles as possible, which would simplify both production in factories and service in the troops. But German tank building continued to provide the Wehrmacht with the problematic Tigers and Panthers, as well as a whole zoo in the light and 20-ton weight classes. It was necessary to improve the design of promising tanks and carry out belated unification. These issues were resolved by German tank specialists in the last months of the war.

On a single chassis

In December 1943, the director in Kassel, Gerd Stieler von Heidekampf, became head of the Tank Commission, replacing Ferdinand Porsche. As an experienced manager, von Heidekampf believed that the German tank program was crazy. According to him, heavy industry lacked the high-volume production experience inherent in automobile enterprises, the development of new designs was never carried out rationally, which led to an overly wide range of models, and in some cases the designs were too complex. Under von Heidekampff, the Tank Commission lost its role as an independent competitor and generator of new ideas, but in general German tank building began to develop more consistently. Under these conditions, the Germans finally took up their zoo.

Pz.Kpfw.III/IV - medium tank on a single chassis

On January 4, 1944, at a meeting of the Tank Commission, the requirements for the Pz.Kpfw.III/IV medium tank were approved. As the name suggests, it was a new car on a single chassis, combining successful developments in the “troika” and “four”. The turret with the gun and cooling system were taken from the Pz.Kpfw.IV, and the ZF SSG 77 gearbox and rotation mechanism from the Pz.Kpfw.III. The engine remained the same HL 120 TRM, but the final drives of the “troika” type were strengthened. The chassis was rebuilt. It consisted of six road wheels with a diameter of 660 mm with internal shock absorption on board.

The blocked suspension on leaf springs was made according to the Pz.Kpfw.IV type, and the 540 mm wide tracks were made with an eye on the Tiger II. Ground clearance was increased to 520 mm. The new hull received good sloping armor. The thickness of the upper frontal part was 80 mm at an angle of 50°, the upper part of the side was protected by armor 30 mm thick at 36°. True, to simplify things, the Germans decided to power the tower with a flexible electrical wire, so it did not have circular rotation (only a 270° rotation in both directions). But the ammunition capacity increased to 100 rounds.

Fragment of the drawing of

Sturmgesch ü tz auf Pz.IV dated January 17, 1944.

540 mm tracks, new road wheels and inclined sides are visible, and all air windows have been moved to the roof. These developments were used on a single chassis III/IV. At the same time, the Leichter Panzerjäger III/IV tank destroyer was designed on a single chassis. It was classified as light (leichter), since German tank destroyers were divided only into light and heavy. A successful conning tower from Jagdpanzer IV with a 75 mm PaK 42 L/70 gun and 80 mm frontal armor at an angle of 50° was installed on a single chassis.

In March 1944, Department No. 6 of the Armament Directorate entered into contracts for the production of three prototype single chassis. In June, the start of production of the Pz.Kpfw.III/IV in February 1945 was discussed, but a month later it was decided to devote all efforts to the production of the Panzerjäger III/IV self-propelled gun, which was named Panzer IV lang (E). According to the plans, Alquette and MIAG switched to producing a new car in November 1944, Krupp in January 1945, and VOMAG and Nibelungenwerke in March. Thus, the zoo of Pz.Kpfw.IV, StuG III, StuG IV, Jagdpanzer IV, Panzer IV/70 (V) and Panzer IV/70 (A) was replaced by a single vehicle. This was a sound decision, because a single tank destroyer was armed with a powerful PaK 42 gun, but unlike the Panzer IV/70 (V) and (A), it did not have problems with weak final drives and an overloaded chassis.

The promising self-propelled gun

Panzer IV lang ( E ) was designed to replace several types of vehicles at once.

The Germans tested different types of suspensions for a promising chassis, and in September 1944 they assembled an armored hull for the Panzer IV lang (E), but a month later the program of a single tank destroyer was stopped in favor of an even simpler and cheaper alternative.

Family 38D

American aviation pushed the Germans to the final decision on unification. In November 1943, it was subjected to massive bombing, as a result of which the production of the StuG III dropped significantly. Then the Germans decided to launch production of its analogue at Czech factories. BMM did not have the equipment to assemble 20-ton class armored vehicles, so it quickly designed the leichten Sturmgeschütz auf 38(t) - a light assault gun based on the Pz.Kpfw.38(t) and Pz.Kpfw.38 nA Later on At Guderian's insistence it was renamed Jagdpanzer 38(t). In terms of armament and the thickness of the frontal armor, the vehicle was approximately equivalent to the StuG III and Jagdpanzer IV, but was much simpler and cheaper. Cramped, blind, unreliable and slow, the Jagdpanzer 38(t) had one decisive advantage: ready for immediate mass production.

Comparison of chassis 38(t) and 38 D, as well as different layout options

On September 26, 1944, the High Command of the Wehrmacht ground forces announced the decision to expand production of the Jagdpanzer 38(t) with a Tatra diesel engine to . This may seem strange - after all, both the StuG III and the Panzerjäger III/IV being prepared to replace it were much better in their characteristics than the Jagdpanzer 38(t). However, the command demanded to produce as many armored vehicles as possible - up to 1000 self-propelled guns at Alquette monthly, despite the fact that this plant never surpassed the mark of 500 StuG III per month.

The Jagdpanzer 38(t) turned out to be the simplest, cheapest and most mass-produced alternative. On October 4, the Tank Commission decided to leave only three types of chassis in production: the light 38(t), the medium "Panther" and the heavy "Tiger II". All self-propelled guns, reconnaissance vehicles, ARVs, etc. were to be produced only at their bases, and the remaining chassis of the old types were to be gradually phased out of production. At the same time, the program for a single Pz.Kpfw.III/IV chassis was canceled.

Jagdpanzer 38 D tank destroyer with 75 mm PaK 42 L/70 gun

In response, Department No. 6 of the Armament Directorate reported that the 38(t) chassis was not suitable for production in German factories due to different equipment. In addition, the Czechs used a planetary gearbox, while the Germans traditionally preferred three-shaft and shaftless designs. The Alquette design bureau, under the leadership of chief engineer Michaels, immediately began reworking the Jagdpanzer 38(t) to German standards, simultaneously eliminating its many shortcomings.

On the new Jagdpanzer 38 D tank destroyer, the suspension, final drives and turning mechanism were strengthened, the slope of the lower side sheets was abandoned and the hull was made wider. Air-cooled diesel engine Tatra 103 with a power of 220 hp. through a gearbox and shaft it was connected to a five-speed ZF AK 5-80 gearbox. The maximum speed was 40 km/h, and the fuel supply of 380 liters was enough for 500 kilometers on good roads and 300 kilometers off-road. The designers provided for the possibility of increasing the width of the tracks from 350 mm to 460 mm, and the transition to a new suspension on buffer springs made it possible to increase the maximum weight from 16.7 to 20 tons. Three weapon options were offered: 75 mm PaK 39 L/48 and PaK 42 L/70 guns, as well as a 105 mm Sturmhaubitze 42/2 howitzer.

Aufkl ä rer 38 D reconnaissance aircraft with a 20 mm automatic cannon in an open turret

Based on the 38 D chassis, the Aufklärer 38 D reconnaissance tank was designed. The hull was made longer and lower, the frontal armor was reduced from 60 to 30 mm, and the weight was reduced to 14 tons. The gear ratio was changed in the gearbox, increasing the maximum speed to 52 km/h. Two weapon options were provided: an open turret with a 20-mm automatic cannon and a machine gun, or installation of a 75-mm L/48 AK 7 B 84 gun without a muzzle brake in an open wheelhouse. Note that the turret, the installation, and the diesel engine were unified with armored vehicles. The result was a light, high-speed tank with a height of only 1.64 meters and a ground clearance of 500 mm. At its base it was planned to produce the Bergepanzer 38 D light armored vehicle, the Kugelblitz 38 D anti-aircraft self-propelled gun, an armored personnel carrier and a self-propelled 120 mm mortar.

By launching the 38 D program, the Germans resolved several issues at once. The army received long-awaited reconnaissance tanks, the zoo of five different self-propelled guns with 75 mm guns was replaced by Jagdpanzer 38 D and 38 (t), and outdated chassis were finally discontinued.

In January 1945, the Germans planned to produce the first five Jagdpanzer 38 D at Alquette in March, and then increase monthly production to 800 vehicles in December. VOMAG was scheduled to build the first five Jagdpanzer 38 Ds in July and reach a monthly pace of 300 vehicles in December. In March, plans were adjusted: Alquette was preparing two prototypes by April, and the first production self-propelled guns were expected in June. On April 5, Alquette sent gearboxes to complete assembly, but the further fate of the Jagdpanzer 38 D is unknown. Preparations for production were interrupted with the end of the war, the factory documentation burned, and the winners could easily identify the captured prototypes as ordinary Jagdpanzer 38(t) and scrap them.

Aufkl ä rer 38 D variant with a 75 mm gun in an open wheelhouse

As for the Aufklärer 38 D, they wanted to launch its production at MIAG. In January 1945, they planned to receive the first five tanks in March, and then the pace increased to 300 vehicles in December. In March, the plans were revised: instead of reconnaissance aircraft, they decided to use the chassis on tank destroyers and ARVs. The AK 7 B 84 gun mount was tested in Kummersdorf back in February, but work on it was expected to be completed in April 1945.

German tank builders spent a lot of effort creating a new single chassis, but the war ended just when they could get the first fruits of their work.

Development of "Tiger II"

According to the plans, the Tiger II remained in production, and no one thought to replace it, but the crude design required serious work on the mistakes.

There were no questions about the tank's armament or the thickness of its frontal armor, but the same could not be said about reliability. Thus, during testing of the captured “Royal Tiger” in the USSR, many problems were revealed: a car with a mileage of 444 kilometers on the odometer lost oil from the right fan drive, the tracks and pins broke, the final drives and drive wheels failed twice, engine wear caused to an increase in fuel consumption to 971 liters per 100 kilometers on a country road. And this was not a complete list of defects! As a result, due to a lack of spare parts, the tests could not be completed.

New over-engine plate of the Tiger II tank, drawing dated November 24, 1944

Engineers gradually rid their brainchild of its shortcomings. In June 1944, the clutch in the cooling system drive was improved. Caterpillars made from composite tracks performed poorly both in terms of their own survivability and wear of the drive wheel, so from March 1945 the series switched to conventional Kgs 73/800/152 tracks and drive wheels with 18 teeth. A new over-engine plate was developed, on which, for ease of access to the engine, the size of the hatch was increased and its cover was divided into three parts, and the grilles were also changed. According to chief engineer Erwin Aders, the new cover was planned to be installed around the 700th production tank, but, for obvious reasons, it did not come to that.

The OG 40 12 16 B gearbox could withstand the loads, but due to its complex design, questions still remained about it. The Germans were concerned that its production might be disrupted and were considering switching to the AK 7-200 gearbox from the Panther. However, this gearbox was weak even for a 45-ton tank, and it was plagued by third-speed breakdowns. A good alternative was the PP33 planetary gearbox, which was designed under the guidance of planetary gear expert Erich Puls. It had a very simple layout with eight forward and reverse gears with an excellent speed range of 18.63. PP33 passed bench tests, and in 1945 they planned to test it on the Tiger, but did not have time.

Testing of the PP33 gearbox (right) took place at stand PP37 (left) in Leipzig from January 5 to June 19, 1944

A separate discussion is the power plant. German tank builders never managed to perfect the HL 230 engine. Since November 1943, its power was limited to 600 hp. at 2500 rpm (versus the original 700 hp at 3000 rpm), and in March 1944, with a new piston design, the compression ratio was reduced from 1:6.8 to 1:6.4. 600 hp motor was clearly not enough for the 70-ton Tiger II, so a replacement was required. On January 23, 1945, several alternative options were discussed with the participation of von Heidekampf and Colonel Holzhauer of Section 6.

worked on a new HL 234 engine with 800–900 hp. with direct fuel injection. It was roughly the same size as the HL 230, so the engines were interchangeable. At the same time, the problem with unreliable carburetors, which was known two years ago, was eliminated. It was the HL 234 that was the favorite, but Maybach did not bring it to working condition, and as a result, tests on the tank failed.

Sla 16 engine installation drawing dated November 29, 1944

The main competitor was the Sla 16 air-cooled diesel engine, which Simmering was also working on. It was more economical and more powerful than the HL 230 (750–770 hp versus 600 hp), but, according to the chief engineer of heavy tanks Erwin Aders, the X-shaped layout required a complete redesign of the engine compartment, as well as changes to the armored hull and the track tension mechanism.

In April 1945, the second prototype of the Sla 16 diesel engine, after successful bench tests, was installed on the Jagdtiger. To do this, we had to remove the partitions of the standard cooling system, remake the rear plate for a different arrangement of exhaust pipes, and also install a new sub-engine frame and above-engine plate (unfortunately, based on the available data, we cannot say exactly what it looked like). The fuel supply was similar to the serial self-propelled gun, but was located in three tanks instead of seven. The Germans could well have rebuilt production to a new model with a diesel engine, but replacing engines on already built tanks and self-propelled guns was quite difficult, which cannot be said about the HL 234. There was another reason for the refusal: they planned to deploy the assembly of the first series of 100 Sla 16s instead of an aircraft engine DB 605, but the production capacity was already required for Tatra diesels and could not be rebuilt twice.

In addition to the HL 234 and Sla 16, two more engines were discussed. worked on a two-stroke water-cooled diesel engine T8 M118 according to the V-8 design with an output of 800 hp. The new engine was assessed as simple and high-torque, while it fit into the engine compartment of the Tigers and Panthers, but it was far from mass production. Finally, they designed a 16-cylinder H-shaped air-cooled diesel engine LD 220 with a power of 700 hp, which was considered as a spare in case of failure of the Sla 16. Note that of the four promising engines for the Tiger II, three were diesel.

Draft design for installing a 105 mm gun

on

the Tiger II

As for weapons, the Germans planned to introduce a sight with a stabilized field of view, a gun stabilizer and a rangefinder, which required minor modifications to the turret, and also replace the MG 34 machine gun with an MG 42. Received a contract to develop a gun stabilizer, and Ernst Leitz also worked on sights with a stabilized field of view and rangefinders. At the end of November, she presented a preliminary design for installing a 105-mm gun with a barrel length of 68 calibers in the Tiger II turret. The Armament Directorate refused the proposal, since this weapon was not accepted for service, and the transition to separate-case loading would reduce the rate of fire.

According to the urgent tank development program, in April 1945 the Tiger II was supposed to receive a rangefinder and a sight with a stabilized field of view, and in August - an HL 234 engine. Next in priority were the Sla 16 and T8 M118 diesel engines, a gun stabilizer and protection against toxic agents. gases

"Panther" Ausf.F

Until the very end of the war, the Panther remained a rather crude tank. Due to unreliable final drives, a weak turning mechanism and problems with the engine and gearbox, it simply could not cover significant distances under its own power. This happened for two main reasons. Firstly, the Panther was a very massive vehicle by German standards, and serious changes threatened to unacceptably reduce the rate of its production. Secondly, MAN was distracted by the design of the Panther II, the transition to which stalled already in May 1943. After that, all that remained was to implement the developments on the “Panther II” on the production “Panthers”.

Final drives were the Panther's weakest point»

At a meeting on January 4, 1944, in addition to the requirements for the PzIII/IV, it was decided to accept new final drives from MAN and prepare equipment for their production. With this, however, great difficulties arose. Despite all efforts, it was not possible to significantly improve the reliability of serial final drives, since the sizes of gears and bearings were limited by the track, drive wheel and brake. Planetary final drives performed very well in tests, but their production was much more complex and expensive, so the Military Technical Bureau of the Armament Directorate (Heerestechnisches Büro) opposed them. Discussions went on for a year and a half, but came to nothing, and the Panthers continued to break down.

In March 1944, production of the Panther Ausf.G began with a more technologically advanced hull similar to the Panther II. Meanwhile, work continued on a new turret, originally intended for the Panther II. On March 1, 1944, she presented a preliminary design for the “Turm Panther (schmale Blende)” - that is, a turret with a narrow mask. Soon the order was transferred to , and it, in cooperation with Skoda, developed the Schmalturm tower. Compared to the serial version, it was easier to manufacture, better armored with a similar weight (120 mm front, 60 mm sides and rear) and was equipped with a rangefinder, and the compact mantlet practically eliminated ricochet into the hull roof. Like the Tiger II, it was planned to use an MG 42 machine gun and a sight with a stabilized field of view.

"Panther"

Ausf.G with "Schmalturm" turret . The production “Panther” Ausf.F would have looked something like this.

By May 1945, factories were supposed to switch to a new modification of the “Panther” Ausf.F with a Schmalturm turret, reinforced hull roof armor, new driver and radio operator hatches, as well as an assault rifle StG 44 instead of the MG 34 machine gun. Like the Tiger II, according to plans in August, the Panthers switched to the HL 234 engine. In addition, a simplified AK 5-200 gearbox with five speeds, new turning mechanisms and diesel engines were considered. Before the end of the war, the Germans managed to produce several Schmalturm towers and Ausf.F hulls. It was believed that the tanks were never assembled, but photographs of Panther Ausf.Fs built with Ausf.G turrets were discovered.

Finally, we cannot fail to mention the installation of the 88-mm KwK 43 L/71 gun in the Schmalturm turret. This idea was proposed in the fall of 1944, and the tower was taken with minimal changes. In order to somehow fit the breech, the trunnions had to be moved 350 mm forward. Instead, Daimler-Benz proposed increasing the diameter of the shoulder strap by 100 mm, to 1750 mm, and placing the stern plate vertically to increase internal volume.

Draft design of the Panther with an 88 mm gun

At a meeting on February 20, representatives of the Armament Directorate reviewed the projects and decided to join forces to develop the Schmalturm turret with a shoulder strap with a diameter of 1750 mm, but with an inclined rear plate, and Krupp was finalizing the 88-mm gun and designing its installation. At the same time, the overall weight of the Panther increased by a ton - perhaps this is why Panzerwaffe Inspector General Wolfgang Thomale believed that Panthers with an 88-mm gun needed to be equipped with planetary final drives. The Germans planned to build a prototype Panther from structural steel with an 88 mm gun in June, and if successful, launch mass production in the last quarter of 1945.

Panzerwaffe 46

In one article it is impossible to consider all the programs of the end of the war - for example, rigidly fixed guns and night vision devices were left without attention. But even what has already been listed is quite enough to understand how German armored vehicles generally developed in 1944–1945. and what tanks and self-propelled guns the Panzerwaffe would have fought with if the war had continued after the spring of 1945. To the chagrin of lovers of the gloomy Teutonic genius, there is no talk of any launch into production of the Panther II and E-series vehicles: the first hovered in the air in the spring of 1943, and the E 50 and E 75 projects were never completed.

The plan for mid-1945, which von Heidekampf told the Americans about during interrogation

Instead, the Germans planned to finally discontinue production of the old types of chassis, and instead produce light armored vehicles based on the 38(t) and 38 D, while simultaneously developing the Panther and Tiger II designs. According to von Heidekampf, by mid-1945 it was planned to produce 2000 light, 450 medium and 200 heavy vehicles per month, but it remains a mystery how this plan was going to be implemented. Von Heidekampf also pointed to the following list of high priority developments:

- rigidly mounted guns (recoil was entirely absorbed by the armored hull);

- development of programs 38(t) and 38 D;

- improvement of the Panther and Tiger II designs

- development of new engines;

- introduction of sights with a stabilized field of view;

- development of the Kugelblitz self-propelled anti-aircraft gun;

- introduction of night vision devices.

In general, by the end of the war, German tank building began to develop more intelligently, and existing and developed tanks and self-propelled guns could more than withstand Allied technology. The problem was that the Centurions, Pershings, IS-3s, T-44s and T-54s were already on the way - in the future, the Germans would inevitably find themselves in the position of catching up, and not a trace would remain of their former superiority.

The author expresses gratitude to Alexander Sotnikov and Alexander Volgin for their assistance in working on the article

Sources and literature:

- BAMA (Bundesarhiv)

- Interrogation protocol of Gerd Stieler von Heidekampf, June 28, 1945

- Thomas L. Jentz, Hilary L. Doyle. Paper Panzers: Panzerkampfwagen, Sturmgeschütz, and Jagdpanzer (Panzer Tracts Nr. 20–1) - Panzer Tracts, 2001

- Thomas L. Jentz, Hilary L. Doyle. Paper Panzers: Aufklärungs-, Beobachtungs-, and Flakpanzer (Panzer Tracts Nr. 20–2) - Panzer Tracts, 2002

- Thomas L. Jentz, Hilary L. Doyle. Panzerkampfwagen Panther II and Panther Ausführung F (Panzer Tracts Nr. 5–4) - Panzer Tracts, 2006

- Thomas L. Jentz, Hilary L. Doyle. Germany's Tiger Tanks. VK45.02 to Tiger II: Design, Production & Modifications - Schiffer Publishing, 1997

- Walter J. Spielberger. Die Panzer-Kampfwagen 35(t) und 38(t) und ihre Abarten - Motorbuch Verlag, 1990

- Walter J. Spielberger. Der Panzerkampfwagen Panther und seine Abarten - Motorbuch Stuttgart, 1978

- https://www.panzerbasics.com

- https://yuripasholok.livejournal.com

Assessment of Soviet armored forces

It would also be unfair on our part to belittle the strength and combat effectiveness of German tank formations. However, wars are not lost solely by the mistakes of the losers. The winners also make their contribution to the victory.

E. Middeldorf pays tribute to the Soviet tank industry. He writes that thanks to her work, since 1943, the USSR had a 7-fold superiority of tanks over Germany. More than 35,000 T-34 tanks alone were produced. In total, the Soviet military industry produced about 150,000 tanks, while the German one produced only 25,000.

Soviet medium tank T-34-85

If there is one thing E. Middeldorf forgets to say, it is that already near Kursk the Red Army was able to oppose the German tanks with its powerful tank “fist”. According to the Russian Ministry of Defense, the RKA deployed 3.4 thousand tanks on the Kursk Bulge, and the Wehrmacht only 2.7 thousand.

Another feature of the German general’s analysis is also striking. He does not seem to notice that already, at least since 1943, Soviet tactics in the use of tank forces have also acquired flexibility and mobility, the ability to concentrate on decisive directions, and commanders begin to act decisively and skillfully.

Objectivity in some places returns to E. Middeldorf when assessing the German retreat of 1944-1945. “The strategic initiative,” he writes, “at this time passed to the Russians. ... The enemy carried out offensive operations on continuously changing directions of the main attack. ... At the end of the war, the enemy often carried out several simultaneous breakthroughs, expanding them along the front and in depth.”

The Red Army offensive went along a front of 3,000 km, and “about 25 German tank formations, not sparing people and equipment, continuously rushed along the front line.” Against the backdrop of numerical superiority and the strategic initiative of the Soviet troops, German tank counterattacks were carried out less and less often, “German armored forces were fragmenting their forces, and the best weapons of the ground forces were losing their sharpness.”

LiveInternetLiveInternet

nomad1962

all author's posts As in other branches of the German armed forces, the customer in the development of this or that type of tank (self-propelled gun) was the main command of the ground forces, which developed the tactical and technical requirements for the design of this or that model, and determined for which combat missions it was being created one or another sample. It was to solve these problems that a special structure was created within the main command of the ground forces - the department of armaments of the ground forces, which from April 1940 until the end of the war was headed by General of Artillery E. Leeb. The Armaments Directorate had several headquarters that were engaged in the following: the development of new types of weapons, ammunition and equipment and their testing;

placing orders for the production of weapons, ammunition and equipment at industrial plants; ensuring mass production of weapons, equipment and ammunition at industrial plants; military acceptance of finished weapons, equipment and ammunition from industrial enterprises; collection and accounting of captured weapons and equipment.

Assembly of Jagdpanzer 38 (t) Hetzer tank destroyers at the VMM plant in Prague. Summer 1944 (YaM)

By the beginning of 1941, more than 25 thousand people worked in the arms control structure. The headquarters, which was engaged in the development of new types of weapons and equipment, were subordinate to the so-called weapons testing departments - Waffen-Pruf or WaPruf for short, of which there were 13 in 1944. Each department worked on its own topic (communications, optics, engineering equipment, small arms, artillery, tank , missile weapons, etc.). The departments were subordinate to special testing grounds where new samples were tested. If necessary, training grounds or training centers of the Wehrmacht or Luftwaffe could be used for this. Armored vehicles were dealt with by the 6th Weapons Testing Department (WaPruf 6), which was headed by Colonel Holzhauer from 1943 until the end of the war (in the following text of the work, for ease of perception, the 6th Department will be called the “Tank Weapons Testing Department”). This department oversaw the development, testing and organization of mass production of new types of armored weapons, as well as army vehicles and tractors. By order of the headquarters of the Army Armaments Directorate, department officers developed tactical and technical requirements for the creation of new types of equipment, while they worked closely with engineers and designers of the relevant companies and factories, and also supervised the work of civilian specialists. The department had a test site at Berka. Work on the design of new models in this department was led by Major General, engineer E. Kniepkamp, whose position can be translated as “chief designer of the tank weapons testing department.” He was known as the author of the so-called “checkerboard” chassis, which was used on all German half-track tractors and armored personnel carriers, as well as on the Tiger and Panther tanks. The activities of industrial enterprises involved in the production of military equipment (including tanks) were supervised by the Reich Ministry of Arms and Ammunition, created on March 17, 1940, which was renamed the Reich Ministry of Arms and War Industry on March 2, 1943. Its activities were led by F. Todt, and after his death, from February 9, 1942 until the end of the war, by A. Speer. The Reich Ministry had a technical department headed by O. Saur, which supervised the work of the so-called committees (tank, artillery, aviation, etc.). Each of them oversaw their own branch of production, placing military orders at enterprises and monitoring their implementation.

The Pz tank destroyed by the troops of the 3rd Ukrainian Front. IVAusf.J. Hungary, March 1945. According to the “crisis” tank production program, in 1945 these vehicles and their chassis were to be discontinued, like the Pz chassis. Ill (ASKM)

In addition, within the structure of the Reich Ministry of Armaments there was a so-called “tank commission”, which at one time was headed by the designer F. Porsche. It was created as a kind of advisory body to resolve issues related to the development of new models of armored weapons. The commission often worked closely with representatives of the tank weapons testing department, as well as with officers from the headquarters of the tank forces. In addition to the Army Weapons Directorate and the Reich Ministry of Armament, there was another structure in the Third Reich that participated in the work on creating new types of armored vehicles - the headquarters of the Inspector General of Tank Forces. This position was approved by Hitler on February 28, 1943 with the appointment of Colonel General G. Guderian to it (he held it until March 28, 1945). The functions of the inspector general included organizing and training tank units, providing the front with personnel and equipment, distributing armored units manufactured at enterprises, summarizing the combat experience gained in the use of tank units, developing regulations and manuals, and the like. Subordinate to him were reserve and training units, as well as schools and colleges of tank forces. The Inspector General of Tank Forces reported directly to Hitler. Guderian's new position did not imply his participation in the process of developing new models of armored vehicles. However, taking advantage of his position and influence (“the father of German tank forces,” after all), he was often present at discussions of new projects and gave his recommendations. And the fact that Guderian reported directly to Hitler allowed him to interfere in issues of tank production. To be fair, it must be said that after Guderian was appointed Chief of the General Staff of the Army in July 1944 (while he remained Inspector General of Tank Forces), most of his responsibilities were taken over by the Chief of Staff of the Inspector General of Tank Forces, Major General Tomale. As you can see, the system for designing tanks in Germany and organizing their serial production was carried out according to a rather complex scheme. The design order was issued by the main command of the ground forces and went to the weapons department, which, in turn, “lowered” it to the tank weapons testing department, which was allocated funding specifically for these purposes. The WaPruf 6 department developed detailed tactical and technical requirements and entered into a design contract with a company, often bypassing the Reich Ministry of Armaments.

Tank destroyer Jagdpanzer IV/70 (V), abandoned by the crew on the near approaches to Berlin. April 1945. The car was most likely recently received from the factory, as it is painted in a single color without camouflage, any markings or numbers

After the project was ready, it was discussed by representatives of the tank weapons testing department and the “tank commission” (or employees of the Reich Ministry of Armaments), then a prototype was made and tested under the control of WaPruf 6. If the vehicle met the requirements for it, it was accepted for service. The decision on this issue was made by the main command of the ground forces, often after the approval of Hitler (as commander-in-chief). The latter was required to receive appropriate reports (by the Weapons Office or the Reich Ministry of Armaments). Often Hitler was personally present at the demonstration of prototypes. After the model was adopted for service, issues of serial production of the tank or self-propelled gun were necessarily agreed upon with the Reich Ministry. At the same time, some of the issues the arms department had to resolve directly with the manufacturing company. This, first of all, concerned the organization of supplies of a number of components and parts, such as weapons, optics, communications equipment, etc. Thus, the armament department of the main command of the ground forces was the customer, and the Reich Ministry of Armament was the contractor. True, there was one nuance - the production of armored vehicles (or any other weapons) was carried out by private companies, with whom the arms department paid for the products produced. As a result, the Reich Ministry was, as it were, an intermediate link between the customer and the direct executor - the manufacturing company. This, naturally, created additional bureaucratic red tape when solving problems related to organizing the production of weapons and military equipment.

Jagdtiger heavy tank destroyers in the Nibelungenwerke assembly shop in St. Valentin. January 1945. On the side of the leftmost car is its number -54 and the shooting date 01/16/45

The headquarters of the Inspector General of Tank Forces could have introduced some “element of destabilization” into this process by insisting, when designing a prototype, that some of its requirements be met. We should not forget that all of the above structures (the Armaments Directorate, the Reich Ministry of Armaments, the manufacturing company, the headquarters of the inspector general) had different subordination. This required a very clear organization of all work. This was often extremely difficult to do, as a result of which a lot of time was spent solving some problems or developing a sample, and the resulting results were unsatisfactory. When compared with similar structures of the Red Army, the tank weapons testing department (WaPruf 6) in purpose and functions approximately corresponded to the main armored department of the commander of the armored and mechanized forces of the Red Army. True, the German department dealt only with the development of samples, and also, if necessary, provided assistance in organizing their mass production. All other problems of the German tank forces (acceptance of finished products, repairs, personnel training, formation and staffing of units, etc.) were dealt with by other units, and in various structures: directly in the weapons department, in the main command of the ground forces, in the headquarters of the general inspector of tank forces. Thus, in the Red Army, all issues related to tank forces were concentrated in one hand - the management of the commander of armored and mechanized forces, while in the German army this was “spread out” across different departments and headquarters. In addition, in the USSR there was a People's Commissariat for the Tank Industry, created at the beginning of the war. It included all tank (with the exception of GAZ) and armored hull factories, as well as factories for the production of diesel engines and other equipment. The leadership of the People's Commissariat of Tank Industry worked closely with the administration of the commander of the armored and mechanized forces of the Red Army. Such strict centralization in wartime conditions greatly facilitated the work, while in Germany it took considerable time to coordinate the activities of various military and civilian structures.

Repair and recovery tank Bergepanther, knocked out in the Budapest area. February 1945. These vehicles were used to evacuate armored vehicles from the battlefield, but their number was extremely small

In mid-1943, to improve the organization of production of armored vehicles, on the initiative of A. Speer, the so-called “commission for the development of tanks” was created. It included not only the heads of the Reich Ministry of Armament and companies producing armored vehicles, but also the military - representatives of the armament department of the ground forces, the testing departments of tank (WaPruf 6) and artillery (WaPruf 4) weapons, as well as the headquarters of the inspector general of tank forces. The chairman of the commission was a representative of the Henschel company, Doctor of Technical Sciences S. Hedkamp. If necessary, employees of various departments, both military and civilian, were involved in the work of the commission. The creation of such a body, consisting of representatives of various departments, made it possible to more quickly make decisions on various problems arising in the production of tanks. By the fall of 1944, 16 companies were producing tanks and self-propelled guns in Germany, and another 9 produced armored vehicles and armored personnel carriers. In addition, 20 factories of various companies supplied armored parts and armored hulls to ensure the assembly of equipment, and 9 supplied artillery weapons (see tables). From the second half of 1944, the bombing of German industrial enterprises by Allied aircraft increased significantly. For example, two-week bomb attacks on Daimler-Benz factories led to the complete destruction of the diesel engine plant in Berlin-Marienfeld and the truck production workshop in Gaggenau, 85% of the engine and body shops in Sindelfingen, and 70% of the main workshop in Stuttgart (where cars were produced).

Courtyard of Ml AG in Braunschweig after its capture by American troops. May 1945. Up to 30 armored hulls of Jagdpanther tank destroyers and six hulls with wheelhouses (located separately) of assault guns are stacked here

To ensure uninterrupted production of tanks and self-propelled guns, the Reich Ministry of Armaments tried to “disaggregate” production. For this purpose, individual assembly lines or workshops from the main factories were transferred to other places. For example, in September 1944, some of the Daimler-Benz equipment was removed from the main plant in Berlin, placing it in small production areas in the areas of Küstrin, Teltow and Falkensee, as well as in the Sudetenland and Pomerania. On the one hand, this made it possible to preserve separate assembly lines from attacks by Allied aircraft, on the other hand, it created additional problems associated with organizing the transportation of finished products and the delivery of the necessary raw materials to numerous production sites. Indeed, in the production of the Panther, in addition to the main assembly plants of three companies (Daimler-Benz, MAN, MNH), another 133 enterprises or companies were involved, from which armored parts, engines, weapons, optics, communications equipment, tracks, castings of black and non-ferrous metals and much more. Naturally, with the “unbundling” the number of enterprises increased significantly. By the way, another interesting point: for example, out of eight Daimler-Benz enterprises, tanks were assembled at only one. The rest were engaged in the production of aircraft engines, cars and other products. It is interesting to provide data on the number of workers involved in tank production. For example, at the MAN plant as of March 1, 1945, 5,448 people were involved in the production of “Panthers”, of which 124 worked in various positions in the administration, 841 in auxiliary production, 3,983 manufactured various components and assemblies of the “Panther” and 500 were engaged in assembly of tanks. Of the 5,448 people, 5,023 were men (of which 2,719 were foreigners) and 425 were women (of which 230 did not speak German). Work went on around the clock, in two 12-hour shifts. The MAN plant was not the largest among German enterprises involved in the production of tanks. But for comparison, in 1944, the smallest plant, of the four that produced the T-34 (No. 183, No. 112 “Krasnoe Sormovo” and No. 174), factory No. 174 in Omsk, employed 14 thousand people.

The assembly workshop of Skoda Hetzer tank destroyer hulls in the city of Pilsen after the bombing by American aircraft. 1945 At this enterprise only the production of armored hulls was carried out, and the assembly of “Hetzers” was carried out at the Skoda plant in Königgrätz (the German name for the city of Hradec Králové) (YAM)

Hulls of the Panther tanks Ausf. G at the Ruhrstahl plant in Hattingen. The photo was taken after the capture of the enterprise by Allied troops in the spring of 1945. Please note that the cases were assembled on special tilters (YM)

Heavy tank "Royal Tiger", knocked out in the Budapest area. February 1945. This machine was supposed to remain in production in 1945

On October 4, 1944, the so-called “crisis” tank production program was adopted. Its main task was to reduce the range of products, as well as to possibly simplify and reduce the cost of production of armored vehicles. As a result, a decision was made: to leave only three types of tracked vehicles in production - “Hetzer”, “Panther” and “Royal Tiger”. The production of the Pz.III and Pz.1V chassis was supposed to be stopped, and all freed up capacity was to be switched to the production of three approved types of tanks and self-propelled guns based on them. In November 1944, the Kshrr company proposed a number of conceptual developments in which it proposed to strengthen the armament of the combat vehicles that were in production. It was assumed that this could be done with minimal modifications. The company sent preliminary designs to the Inspector General of Tank Forces, who, in turn, handed them over to the tank weapons testing department (WaPruf 6). On January 20, 1945, a discussion of the proposed options took place. The military believed that the idea of the Kshrr company was only to strengthen the weapons with the existing armor protection. Representatives of the tank weapons testing department believed that it was also necessary to strengthen the armor. With the roughest calculations, it was clear that the weight of the vehicles would increase, which would require strengthening the suspension and a number of other components and assemblies, and, consequently, restructuring production. Of the projects proposed by Krupp, several options aroused the greatest interest. One of them is the installation of a turret from a Pz.IV tank on the Herzer chassis. Despite its apparent attractiveness, the tank weapons testing department rejected this development - the 16-ton Hetzer already had a maximum weight, and further increasing it would require strengthening the suspension, a more powerful engine and transmission. Also, there was no support for the option of installing an 80-mm PAW 600 jet gun in a “quadruple” turret instead of a 75-mm cannon.

Jagdpanzer 38 Starr tank destroyer, armed with a 75 mm recoilless rifle. 1944 It is clearly visible that the shape and armor of the mask differ from the serial “Hetzer” shown in the adjacent photo

The project to install the 75-mm Pak 42 cannon on the Jagdpanzer 38 chassis (with a rear-mounted fighting compartment) was approved, especially since the production of the Jagdpanzer IV/70 with similar weapons based on the “four” was planned to be discontinued. At the same time, the military noted that moving the fighting compartment to the rear of the Hetzer would require serious modifications to the vehicle, and strengthening its armor would increase its weight to 18 tons. As a result, the chassis will be heavily overloaded. The Kshrr company's proposal to create a tank destroyer on the Panther chassis, armed with a 128-mm cannon, the same as on the Jagdtiger, was not approved. In the proposed version, the fighting compartment was located at the rear of the hull, which required a major redesign of the base chassis. In addition, preliminary calculations showed that the mass of the 128-mm Jagdpanther would be at least 51 tons, which would undoubtedly have a negative impact on the mobility and reliability of the vehicle. They also rejected the Jagdtiger option with a more powerful 128-mm L/66 gun (with a barrel length of 66 calibers). And the proposed projects on the Pz.IV chassis (with the installation of a “narrow” turret from the Ausf.F Panther) were not considered at all due to the upcoming cessation of production of the base chassis. True, in their conclusion, representatives of the tank weapons testing department (WaPruf 6) wrote that the final decision on this issue rests with the leadership of the ground forces weapons department. But even the latter’s “Krupp” proposals did not find support. The fact is that by this time there already existed, although not fully developed, a program for the production of armored vehicles. Let's consider what kind of combat vehicles could be expected to appear in 1945 according to the “crisis” tank production program.

Jagdpanzer 38 (t) "Hetzer" tank destroyer, front view. In 1945, this machine was supposed to be replaced by another - Jagdpanzer38 D

Jagdpanzer 38 STARR Back in 1943, engineers from Kshrr and Rheinmetall-Borsig began work on designing recoilless rifles for arming tanks and self-propelled guns. The advantages of such artillery systems were obvious - cheaper production, an increase in the internal volume of the combat vehicle and transportable ammunition. The main problem that needed to be solved in the manufacture of such a gun was how to dampen the recoil when firing a shot. In the spring of 1944, the Alkett company produced a prototype of the 75-mm StuK L/48 cannon without recoil devices, which was installed in the Jagdpanzer 38 tank destroyer. To compensate for recoil, the gun had a rigid mount - the recoil force was transmitted directly to the body of the self-propelled gun. Testing began in May and continued intermittently until September 1944. The vehicle with such an artillery system was designated Jagdpanzer 38 Starr (Starr - “rigid” or “fixed”).

General view of the Jagdpanzer 38 Starr with a 75 mm recoilless rifle. 1944

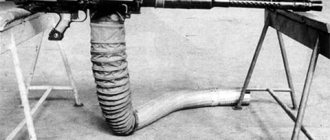

Top view of a Tatra 103 diesel installed in a Jagdpanzer 38 Starr (YAM)

In addition to the small gun pointing angles, the installation revealed other shortcomings: when fired, the sight flew off the mount, and other parts broke. And the recoil force transmitted through the horizontal aiming flywheel turned out to be so great that the gunner, holding the flywheel at the moment of the shot, could not move his hand for two days. The accuracy of shooting at distances of 500 and 1000 meters also left much to be desired. However, representatives of the departments for testing artillery weapons (WaPruf 4), as well as sights and optical instruments (WaPruf of the Army Armament Directorate) gave a positive opinion on this artillery system, recommending that its design be refined and mass production of such guns begin. As a result, the Armament Directorate issued an order for the production of a batch of 100 recoilless 75-mm StuK L/48 guns, which were planned to be installed on the Hetzer tank destroyer. Tests of the second prototype of the Alkett recoilless rifle carried out in September 1944 showed that, despite a number of changes being made to its design, the artillery system is not suitable for combat use. To solve the problem, engineers from the Rheinmetall-Borsig company were involved, who conducted special research and made a number of changes to the design of the gun. First of all, they redesigned the lifting and turning mechanism, as a result of which it was possible to significantly reduce the impact of recoil force on guidance flywheels. The installation of the sight was changed - now it did not fail when shooting, as it was before.

And the recoil force transmitted through the horizontal aiming flywheel turned out to be so great that the gunner, holding the flywheel at the moment of the shot, could not move his hand for two days. The accuracy of shooting at distances of 500 and 1000 meters also left much to be desired. However, representatives of the departments for testing artillery weapons (WaPruf 4), as well as sights and optical instruments (WaPruf of the Army Armament Directorate) gave a positive opinion on this artillery system, recommending that its design be refined and mass production of such guns begin. As a result, the Armament Directorate issued an order for the production of a batch of 100 recoilless 75-mm StuK L/48 guns, which were planned to be installed on the Hetzer tank destroyer. Tests of the second prototype of the Alkett recoilless rifle carried out in September 1944 showed that, despite a number of changes being made to its design, the artillery system is not suitable for combat use. To solve the problem, engineers from the Rheinmetall-Borsig company were involved, who conducted special research and made a number of changes to the design of the gun. First of all, they redesigned the lifting and turning mechanism, as a result of which it was possible to significantly reduce the impact of recoil force on guidance flywheels. The installation of the sight was changed - now it did not fail when shooting, as it was before.

Jagdpanzer 38 Starr tank destroyer with a 75 mm recoilless rifle, rear view. In addition to the new gun, this vehicle received a Tatra 103 diesel engine with a power of 220 hp. s, for cooling of which an additional ventilation hood (YAM) was installed

In addition, the mechanism for attaching the gun to the front plate of the hull was changed from a cardan to a ball joint. The result was a fully functional artillery system, which was successfully tested in December 1944. In March 1945, a prototype Jagdpanzer 38 Starr with a modified gun entered testing at the Berka training ground, after which the vehicle was to be demonstrated to the head of the Army Weapons Department, General Leub, and then to Hitler. In December 1944 - January 1945, the VMM company manufactured ten Jagdpanzer 38 Starr tank destroyers of the so-called “zero” series. In February 1945, an order was issued for the first industrial batch of Jagdpanzer 38 Starr of 100 vehicles, but only four vehicles were assembled before the end of the war. Thus, the total production of Jagdpanzer 38 Starr was 15 units, including the prototype.

Scheme of cutting the frontal armor plate and installing the gun in the serial Hetzer (left) and Jagdpanzer 38 Starr (right)

The prototype Jagdpanzer 38 Starr, located at the Burke training ground, was blown up on Hitler's orders as Allied forces approached on March 23, 1945. Production vehicles entered the tank school in Milovice, but did not participate in battles. Ten of them were briefly used by the Czechoslovak army after the war, after which they were converted into regular Hetzers. By decision of the main command of the ground forces, in 1945 it was planned to arm the new Jagdpanzer 38 D tank destroyer with recoilless rifles (a detailed story about it below). For this, in addition to developing the 75-mm StuK L/48 recoilless gun, Rheinmetall designed other recoilless artillery systems - the 75-mm KwK L/70 and 105-mm StuH 42. In addition to the Jagdpanzer 38 D, the option of installing such “recoilless” guns on tanks was also considered "Panther" Ausf. F, for which the Kshrr company developed 75 mm and 88 mm guns. The prototype Jagdpanzer 38 Starr, in addition to the recoilless rifle, also differed from the serial Hetzers in its power plant. The vehicle was equipped with a Tatra 103 diesel engine with a power of 220 hp, developed by Tatra back in 1943 for the German heavy armored cars of the Sd series. Kfz. 234. This engine was also intended to power the new Jagdpanzer 38 D tank destroyer.

https://topwar.ru/37352-tankovaya-promyshlennost-germanii-k-1…

Is it necessary to summarize?

We won the Great Patriotic War. Our army defeated its opponents. It would seem, why remember some Middeldorf, and generally stir up the past? If the Germans had not reached Stalingrad, indeed, there would have been no need to remember. But in order not to repeat such “mistakes”, in order to be stronger than your enemy from the very beginning, you need to remember, analyze and learn to win not by numbers, but by skill (as Suvorov bequeathed).

Source - https://zen.yandex.ru/media/istok/bronetankovye-voiska-germanii-i-sssr-v-gody-voiny-po-ocenke-nemeckogo-generala-61765298fc439f693e104432?&

The history of the appearance of German tanks in the First World War

During the First World War, the Germans were able to create 8 tank companies, but only three were equipped with domestic vehicles.

Was the appearance of British tanks on the Somme on September 15, 1916 a surprise for the leadership of the German army? It turns out that no - there was no surprise, since the Germans were able to obtain some data about English developments. However, the German generals did not attach the necessary importance to this important information. Nevertheless, the War Ministry in October 1916 tried to create the production of domestic tanks. And, if you do not take into account the “modest” acquaintance with English tanks, the German designers had to start everything from scratch, just like their English and French colleagues.

Before the First World War, there was no experience in the production of all-terrain combat vehicles. However, in 1911, Lieutenant G. Burshtyn (Austrian railway worker) created a real project for the Motorgeschutz tracked armored vehicle, which was offered first to the War Ministry of Austria-Hungary and then to Germany. The military departments were absolutely not interested in him. But on 02/28/1912 Burshtyn received German patent No. 252815 for his invention, and on 04/25/1912 - Austro-Hungarian No. 53248.

Project of Chief Lieutenant Gunther Burstyn.

Nevertheless, let us note the very fact of applying to the Prussian War Ministry and receiving a patent, which is often perceived as a prelude to the history of German tank building. After the end of the First World War, reports were found about B. Gebel, who in Poznan in 1913 allegedly tested an all-terrain vehicle “armed with guns”, and in 1914 even wanted to show it in Berlin. This project was considered by the commission and declared unsuitable for war, however, as not feasible at all. After England used tanks in the First World War, a drawing of “the Kaiser’s vehicle for breaking through enemy ranks” appeared in the press, with 20-25 cannons and machine guns, spikes on the armor and “the size of a passenger carriage.” Of course, all this could not be taken seriously as a basis for practical work.

Marienwagen I

However, Germany had a sufficient level of technology and had the design and industrial potential to create new weapons. She was able to organize the production of tanks, because had highly developed artillery and steel production, as well as electrical and chemical industries, its own automotive and engine manufacturing. Industrialists in the fall of 1916 reported to the Kaiser and the military leadership that “The resources at the disposal of German industry are such that it is capable of supplying our valiant army with all the necessary weapons for many years.”

Durwagen

The German economy was in a difficult situation, but despite this, the military industry almost completely supplied the army's demands for technical equipment, ammunition and weapons, implementing the “Hindenburg program” (“intensification program”). Although the program itself did not provide for tanks. Motor transport was used in large volumes, both for delivering troops along the front and for delivering cargo to the troops. 20,000 vehicles were used to transport units on the Romanian front. There was also no shortage of drivers (mechanics) in the army.

Orionwagen

Several took on the design of combat tracked vehicles and produced an 18-ton combat vehicle based on an agricultural 3-wheeled tractor; In 1916, designer G. Bremer made a full-size model of an armored four-track military vehicle, which he developed on the basis of a half-track truck, by replacing the front wheels with tracks. Of course, such developments were purely experimental.

Sea trials of the first chassis of the A7V tank Berlin-Marienfeld, April-May 1917.

Demonstration on April 30, 1917. The man in uniform - Joseph Vollmer, gives an explanation to General Friedrich

As a result, the efforts of German designers were crowned with success and Germany received tanks. The Germans used them several times in World War I, but in small numbers. And only once (April 24, 1918) were they lucky - near Villers-Bretonneux, when Germany used 15 A7V tanks and about 20 captured British combat vehicles, during a large offensive of the Kaiser’s troops. 13 German tanks went on the attack with four infantry divisions, which achieved significant results. During the First World War, Germany was able to create 8 tank companies, but only three were equipped with domestic equipment (5 tanks each).

| Next > |

Concept for the development of the main battle tank of the German ground forces ch2 (2019)

V. Boryushin; V. Sokolenko, Candidate of Technical Sciences

In the first part* of the article, the main directions for the development of German armored weapons in the near future were considered, the progress of measures to modernize the country's existing tank fleet was highlighted, the concept for the development of MBT was outlined, and information was published on the creation of the Leopard tank of the promising 2A8 (2A7V) series.

Main battle tank "Leopard-3". The German military-industrial leadership associates the creation of a new generation MBT with the development of the Leopard-3 tank, or Leo 3, as it was originally called in the Bundeswehr. Currently, foreign experts also use the term “main ground combat system” (Main Ground Combat System).

In NATO countries, a ground combat system (GCS) is understood as a set of weapons (complexes) that are functionally interconnected and jointly used to solve certain combat missions.

The NBS usually includes from 10 to 18 types of armored vehicles controlled by a person. These include: tank; BMP, armored personnel carrier; command vehicles of the "company - battalion - brigade" link; combat reconnaissance vehicle; self-propelled gun-howitzer; self-propelled mortar; repair and recovery vehicle; medical machine and others; from four to seven types of unmanned vehicles, remotely controlled by a person, as well as unmanned aerial vehicles of various classes and purposes, with weapons, ground unmanned vehicles, multi-purpose unmanned general purpose vehicles for technical and logistics support.

The German Ministry of Defense first announced plans to create a new generation main battle tank as part of the NBS program on May 22, 2015. To develop it, the leading German manufacturer of armored vehicles, KMW, plans to join forces with the famous French tank manufacturer.

The new German-French enterprise, with more than 6,000 employees and a total financial turnover of about 2 billion euros (2.2 billion dollars in 2015), could become the main contractor capable of winning a contract to develop and produce MBTs for the Bundeswehr, France and other countries North Atlantic Alliance.

Today, the technical appearance and design features of the promising tank are in the design stage. Speaking in the Bundestag, German Deputy Defense Minister Markus Grübel said that “the concept of the new tank and the main technologies for its creation are planned to be developed between 2015 and 2018. Issues of joint R&D with German industry have already been agreed upon.”

The commander of the German Army, Lieutenant General Jörg Vollmer, at the beginning of 2017, “Leopard-2”, currently located in tank and motorized infantry brigades, will be completely replaced by the main NBS in the period from 2030 to 2040.” This system will be capable of “conducting dueling combat and delivering fire strikes in close combat within line of sight.”

From foreign information it follows that priorities in the development of the German-French vehicle are planned to be given to ensuring maximum crew survivability in combat, giving the MBT maximum combat effectiveness in various types of combat, and achieving low production costs.

When developing a new tank, innovative technologies will be used to ensure the ability to conduct network-centric combat operations in the information networks of the tactical level of the branches and branches of the armed forces of Germany and other NATO countries.

The firepower and mobility of the MBT is planned to be significantly increased compared to existing models.

Conceptual views on the design and layout of the Leopard-3 tank.

Technical designs for new generation tanks created earlier in Germany make it possible to form the following idea about the technical appearance and design and layout of the new combat vehicle.

Project 1981-1996. This German-French tank had the following design and technical features: a crew of three people (two of them, the commander and gunner, in a flat, low-profile turret);

120 mm, and in the future 140 mm smoothbore gun; automatic gun loader in the turret niche; automated cassette loading system - unloading ammunition on the battlefield from a transport-loading vehicle; chassis of the Leopard-2 tank. However, it was not possible to reach a common point of view between the participating countries, and in November 1982 France withdrew from R&D. After this, the German part of the project was named “Leopard-3”. Research took place in the following directions: development of a new turret on the chassis of the Leopard-2 tank, a new low-profile unmanned turret and a new chassis. However, this program was closed due to the lack of relevance of the work carried out at that time and the emergence of priority R&D aimed at increasing the caliber of tank guns.

Project 1985-1996.

This is one of the first projects of a new generation MBT with two crew members.

Western military media previously reported that a demonstration model had already been developed, tests of which showed that “with the technical level of automation of work processes, which is characteristic of that time, a crew of two people can perform all the tasks assigned to it as successfully as a crew of three or four people."