Beginning underwater fishing enthusiasts need to know how to make a homemade gun. This can be done even without special skills, professional tools and precision equipment. There are several key types of underwater guns, differing primarily in the method of throwing the striking projectile - the harpoon. The element that imparts acceleration to the striking projectile and imparts the energy necessary to overcome the resistance of water can be a spring, a special rubber band, vacuum and pneumatics. In addition, hydropneumatic, powder, gas guns and even double-barreled shotguns are produced industrially and made by numerous home-made craftsmen. But since to manufacture most varieties it is necessary to have experience in such work, a variety of materials and drawings to maintain exact dimensions, you should know how to make the simplest homemade underwater gun - an improved version of the so-called Hawaiian.

Beginning underwater fishing enthusiasts will be interested in a way to make a homemade gun without special skills, professional tools or precision equipment.

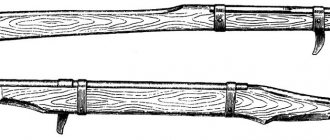

The Hawaiians, which appeared, as the name suggests, on the islands of Oceania, had an extremely simple structure. Initially, they consisted of a pole with a harpoon tip and a rubber band with a diameter of 10-15 mm, rolled into a circle. Having hooked the rubber band onto the thumb, the hunter used the back end of the pole to pull the rope back to the elbow, after which he grabbed the pole closer to the middle with his hand. After that, all that remained was to aim and unclench your hand so that the compressed rubber band would forcefully push the harpoon towards the target. However, the described method of catching fish is not very convenient for hunting, since holding the harpoon in the “cocked” state requires constant tension of the hand. This drawback can be easily corrected without complicating the design fundamentally, but simply by equipping the Hawaiian with a home-made trigger mechanism. Now let’s talk about exactly how to make a gun for hunting underwater - it’s extremely easy to make, effective and at the same time easy to use.

Preparing for work

In addition to sporting interest, making such a homemade product also makes economic sense, since a specialized hunting store will be happy to offer you the simplest harpoon gun for the price of a crossbow. In addition, a tool made to your taste will allow you to enjoy both processes - manufacturing and the hunt itself. Before you make your own underwater gun, you will need to stock up on the following:

- aluminum tube with an outer diameter of 10-15 mm and a length of 150 cm;

- PVC pipe 25-30 cm long, the inner diameter of which is slightly larger than the outer diameter of the aluminum tube;

- a rectangular steel skewer;

- M4 bolt 20-25 mm long with a nut, metal and rubber washers;

- M4 bolt 40-50 mm long;

- steel rectangle measuring 40×15×2 mm;

- three self-tapping screws 70-100 mm long;

- fishing rubber;

- ring-shaped elastic band;

- nylon thread;

- cutting boards with a thickness of at least 20 mm;

- epoxy glue.

Also, to make a gun for hunting aquatic life with your own hands, you will need the following tools: a screwdriver, pliers, a hammer, a chisel, a vice, wrenches, a rasp, a drill, hacksaws for wood and metal.

We also recommend reading:

We select and assemble an anchor for a PVC boat with our own hands. The secret tool of fishermen is the Tyrolean stick. Do-it-yourself lures for pike perch. DIY tackle for carp.

In addition to sporting interest, making such a homemade product also makes economic sense, since a specialized hunting store will be happy to offer you the simplest harpoon gun for the price of a crossbow

Separate a 20 cm long fragment from the skewer, clamp it in a vice so that 10-12 mm protrudes from the jaws, and bend the protruding section at a right angle. Having taken the resulting L-shaped part out of the vice, bend it in the direction opposite to the short part of the letter “L” so that you get an arc - a sector of an imaginary circle with a diameter of 50 cm. Drill a 4 mm hole in the middle of the part. In the center of the short tube, drill 2 opposite holes - with diameters of 5 and 4 mm and 2 - with a diameter of 5 mm, 1 cm from the edge. Also, in a short tube at a distance equal to the length between the hole and the bend of the L-shaped part, make a transverse slot measuring 8x2.5 mm. A centimeter from the edge of the aluminum tube, drill 2 opposite holes of 8 mm each, and then make a transverse slot measuring 8x2.5 mm in the center of the tube. From fishing rubber, make a tourniquet 1 cm thick, 40-45 cm long, and every 5 cm, tightly rewind it with nylon thread. From the board, cut a round plug corresponding to the inner diameter of the long pipe and drill a 4 mm longitudinal hole in it.

Parts and materials for their manufacture

It must be said right away that air guns have an overly complex design, so it’s better to stick with spring guns. This is the simplest and most affordable option for self-assembly. To assemble it, you will need the following elements:

- a metal barrel of suitable diameter with a wall thickness of approximately 1 mm;

- piston made of stainless steel;

- guide bushing (part of the piston);

- a powerful spring made of wire with a thickness of at least 1.5 mm;

- holder made of sheet brass;

- hook for harpoon line;

- a handle made of two symmetrical halves with a trigger mechanism, including a sear, a spring, a safety and a trigger;

- a harpoon with a diameter of 5 or 6 mm made of a steel rod of similar thickness.

.IRPP_ruby .ctaButton { background-color: inherit; margin-left: 10px; position: absolute; right: 0; top: 0; } .IRPP_ruby:after { content: ""; display: block; clear: both; }

Gallery: homemade speargun (25 photos)

Solid line model

Models with a continuous line are considered the most common today. They are distinguished by their compactness. It should also be taken into account that it will not be possible to install a wide sear on the models. At the same time, a variety of clips fit. In this case, assembling the gun must begin with the barrel. Screws must be attached from both the front and back. After this, the clip is installed.

If you make it yourself, you should calculate the length of the sear in advance. It is also important to consider that the edges of the clip must be carefully sharpened. This can be done using a file. After this, the line is installed directly. Next you can proceed to the fuse. Lastly, the cleaning rod and trigger mechanism are installed. When the capacitor is standing, then the mainspring is installed.

Assembling the gun

Now you need to assemble a gun from the kit prepared in this way. To do this, screw the L-shaped part with a short M4 bolt to the PVC pipe, inserting a rubber washer between them so that the short part of the L-shaped part fits into the cut in the pipe wall. The bolt head should not protrude above the inner surface of the tube wall, otherwise it will interfere with shooting. Additionally, secure the L-shaped part in the cut area with a ring-shaped rubber band.

Externally, this springy structure vaguely resembles a bicycle hand brake lever and serves as both a trigger and a sear - a part used to cock the weapon.

First, you need to insert a cut wooden plug, after lubricating it with epoxy glue, into the end hole of the aluminum tube. Then weld 3 self-tapping screws on one side and an M4 bolt on the other to the metal plate so that you get something like Neptune’s trident, where the M4 bolt is the shaft of the trident. Lubricate the M4 bolt with epoxy glue. The resulting trident should be screwed into the hole of the wooden plug. The homemade harpoon is ready.

Device with rectangular feeder

The design of a speargun with a rectangular feeder resembles a modification with a latch. First of all, you need to select a pipe for the model. Its thickness should be at least 10 cm. After this, you need to start cutting the tubule. Its thickness should be at least 0.6 cm. Next, it is possible to make an overlay. In this case, it is better to install the clip after the sear.

The fuse is used if desired. Next, to make a spearfishing gun with your own hands, you need to wind it quite tightly. All this is necessary so that the return is not large. The axis for weapons is most often selected as a steel type. An aluminum sear can be used. Various compensators are suitable for the model. The feeder must be carefully ground at the end of work. It should not touch the runners.

Trial

To tension the rubber and prepare the gun for firing, it is necessary to move the PVC tube, which acts as a cocking handle, forward to the tip of the harpoon until a characteristic click is heard, indicating that the metal part that has fallen into the slots of both tubes has fixed the gun in the cocked state. Now pressing on the protruding arc of the metal part will disengage it from the harpoon and a shot will occur. Tests carried out in water show that from a distance of about 1 m, the harpoon confidently pierces the wall of a plastic bottle filled with water , and it is quite difficult to remove it back due to the threads on the self-tapping screws.

Pneumatic model with latch safety

You can assemble a pneumatic underwater gun with your own hands for hunting only if you have parts from the machine gun on hand. First of all, the barrel is removed. In this case, the clip is attached from the bottom with an indentation of about 4 cm. Next, you need to install the sear. Compensators are not installed in all cases. In this situation, a lot depends on the type of fuse. The ramrod of the gun must be fixed at the base of the clip. The lock on the fuse is installed on the line side. In this case, it is necessary to watch the feeder. When changing position, it should not touch the fuse ring.

Solid wound model

You can make a model with continuous winding if you prepare a pipe with a wide collar in advance. Many people recommend using a three-clove sear for this purpose. The clip must be installed very carefully. Its width should match the tench. After fixing it, you can proceed directly to winding. At the same time, it should not be applied to the cleaning rod.

After completing the work, it is possible to work on the compensator. Then the feeder is attached directly along with the mainspring. Many experts in this situation advise using L-shaped latches. At the end of the work, all that remains is to fix the trigger mechanism, which can be removed from any gun.

Using aluminum winding

You can find a homemade speargun with aluminum winding quite often. Such a winding provides fairly high-quality sealing. As a standard, you can start assembling a weapon from the barrel. In this case, it is more expedient to select a small width clip. Thus, the winding will lie more closely. It is better to select a sear for a weapon with three teeth. In this case, the fuse is selected separately.

Much in this situation depends on the size of the tench. The compensator should be installed last. Additionally, it is important to pay attention to the trigger mechanism. It is quite difficult to make it yourself. Considering this, it is more advisable to use parts from an air gun.

Advantages

The advantages of such weapons include light weight and accuracy, which facilitates the capture of nimble predatory fish.

If you compare a spring gun, the basis of which is compression, with a gun with rubber bands, the result of such a comparison will clearly not be in favor of the latter.

A gun with rubber has twice as many parts as a gun with a spring. Soft rubber bands deteriorate quickly. Fast moving parts (strings and a rubber harpoon) are also ineffective. In terms of combat accuracy, it cannot be compared with spring weapons, since in the latter product the harpoon is located in a long barrel, which serves as a precise guide.

Model with overlay

Models with overlays are the most common. In terms of sealing, they are considered the best today. You need to start assembling a weapon with a barrel blank. In this case, the clip is attached only after the sear. The overlay itself must be fixed with glue. Its thickness should be at least 2.2 mm. If the model uses a fairly long cleaning rod, then the pad should be extended all the way to the holder. In the end, all that remains is to fix the latch on the barrel.