Description of the BAR Mark II Safari series

The Browning Mark II Safari series of self-loading carbines differs from the previous generation, which has the Long or Short Trac model indices, both externally and structurally. They are more elegant, do not look so massive, the butt in the stock version has almost no inclination relative to the receiver, which is always blued, and has SAFARI engraving on the left and right planes. The signature feature of BAR carbines – the gold-plated trigger – has been retained.

Design features are more significant.

- Retaining the classic Browning layout, in which the gas release mechanism is located under the barrel and covered by the forend, the Safari series gives hunters the ability to adjust the amount of gas released to adjust the weapon to suit different types and weights of bullets.

- In addition, the gas piston of the reloading mechanism and the chamber are plated with chrome. This increased the overall reliability of the mechanism and reduced the likelihood that a spent cartridge case would remain in the chamber.

The most interesting design solution was the use of the BOSS ballistic optimization system (it is installed optionally), which significantly increases the accuracy of fire. In fact, it is a muzzle brake, the length of which can be adjusted, due to which the bullet leaves the barrel at the moment when the vibration amplitude is minimal.

The Browning BAR Mark II Safari carbine in .308 Win is reviewed in this video review:

Advantages and disadvantages

- The weapon is extremely reliable and easy to use. Carbines of .308 Win caliber can be used to hunt everything from game birds to large ungulates and predators; to do this, you just need to choose a cartridge with a certain type of bullet: light, heavy, semi-jacketed... The adjustable gas piston system allows you to optimally configure the weapon.

- Despite the fact that the carbine's trigger is unregulated, has no trigger and no warning - a fixed force on the trigger is set at the factory, equal to 4 pounds (about 1700 grams) - the ergonomics of the trigger are well thought out. The safety flag button is located at the base of the rear branch of the trigger guard; it has a very simple operating algorithm. The bolt release release lever is located between the receiver and the forend. It is impossible to confuse these controls in the heat of the hunt.

- The number of bolt lugs has been increased to seven (the first generation carbines have four), the locking reliability has become higher, which also affects shooting performance.

- The Browning company produces carbines designed for both right-handers and left-handers; they differ only in the direction of installation of the bolt lever.

- The magazine ejection lever is located in front of the trigger guard; when pressed, the cover on which the cartridge container is attached is hinged. If desired, you can equip the magazine without removing it from the cover. This design is very convenient, since the removed magazine will not fall into snow or mud, and you will not have to search for it and clean it.

- The delivery set includes replaceable butt plates and spacers for changing the angle of its installation relative to the receiver. The stock is well made, the area of the notches is large - they almost completely cover the handle and half the surface of the fore-end, which guarantees a reliable grip in all situations. For production, dark noble walnut wood is used. It is doubtful that any esthete will find anything to complain about.

- The ability to install rails and brackets for optics is complemented by a pair of external sighting devices - adjustable or stationary (Batu system) entirely and a closed adjustable front sight. If necessary, they can be removed without any problems; they are attached to the barrel with small screws with metric threads.

The ballistic optimization system is both a plus and a minus.

- It allows you to achieve very high accuracy of combat through simple manipulations - increasing or decreasing the length of the muzzle brake relative to the point indicated in the tuning table.

- The MOA value may not exceed tenths. However, for it to work correctly, it is necessary to use cartridges of the highest quality, the power of which within the batch does not differ from each other by hundredths of a joule.

- In addition, the standard muzzle brake with holes significantly increases the sound strength of the shot (it reduces recoil). Therefore, there is another type of device - Conventional Recoil (CR), which has no holes. It increases not only accuracy, but also recoil force. The hunter will have to choose what is best for him.

The weight of the equipped carbine is more than 3.5 kg. It is too heavy for running hunts.

Browning Bar .308 Boss Shotgun

Purpose of Browning BAR 308 BOSS

The effective firing range of the .308 Win caliber carbine reaches 400 meters. With it you can hunt all types of game from wood grouse to bears. With the BOSS set up optimally, it can be a sniper rifle.

American Browning M1918 light machine gun (BAR)

J. M. Browning's automatic rifle BAR (Browning Automatic Rifle) was created in 1917. While working on the automatic rifle, the designer assessed the experience of the First World War. First of all, this was manifested in the introduction of a fire mode translator and a replaceable magazine. In the United States Army, the BAR became a light machine gun with the maneuverability of a rifle and operated by a one-man crew. The rights to manufacture the Browning Automatic Rifle were acquired, but the possibility of its production by others remained (Winchester). Production began in February 1918, but BAR's combat experience in World War I did not go beyond military testing. Despite this, both the French and the British rushed to order BAR. Under the obvious influence of this machine gun, the French created the Chatellerault light machine gun.

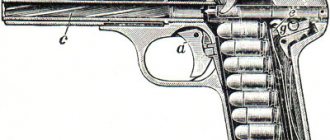

The design of the BAR machine gun was based on the Vickers-Berthier system of the 1908 model, which had minor modifications. The barrel in the receiver was fastened with a thread (this fastening did not allow the barrel to be replaced in combat conditions) and was equipped with a smooth muzzle sleeve - “extension”. At first, five and later four left-hand rifling were made in the barrel bore. Their stroke length was 254 millimeters. The automation worked thanks to the removal of powder gases from the barrel bore. The gas chamber is a closed type. The gas regulator, having three holes, was screwed in front of the guide tube. A swivel clamp and a wooden forend with a notch were attached to the guide tube.

The barrel bore was locked by a lever hinged to an eye located in the middle part of the bolt. The bolt was attached to the bolt frame through a hinged earring. There was a protrusion at the top of the milled receiver. A return spring was placed in the guide tube. While the moving system was moving forward, the shutter reached the stump of the barrel and stopped. The bolt frame, continuing to move, rotated the earring, and the rear part of the locking lever rose. The supporting surface of the lever was wound behind the supporting surface of the receiver protrusion. After the shot, the bolt frame moved back, lowered the lever and unlocked the barrel. An insert placed under the earring axis prevented premature unlocking. He did not allow the locking lever and the earring to lower until the bolt carrier reached the appropriate position. The cartridge case was removed by the bolt ejector and the rigid reflector of the trigger box. The bolt frame hit the buffer at the rearmost point. When firing, the charging handle remained motionless.

The trigger mechanism (trigger mechanism) allowed for both single and continuous fire. The insert, after the barrel bore was locked, struck the firing pin mounted in the bolt. Before locking, the locking lever did not allow the striker to advance, and when unlocked, it was retracted. That is, the combination of the locking lever and the protrusion of the striker acted as an automatic safety device. The trigger, equipped with a buffer spring, was mounted on a frame that was located inside the trigger box. When the trigger was pressed, the disconnector connected to it raised the front end of the trigger lever, releasing the bolt frame from cocking.

The translator-safety flag was located behind the trigger guard on the left. In the forward position (“F”), the disconnector rose and jumped off the trigger lever. He, in turn, returned to its original position, intercepting the bolt frame. If the flag was in a vertical position (“A”), the translator’s pin limited the rotation of the trigger lever in such a way that there was no disconnection, and the automation cycle was repeated. If the flag was turned back (“S”), the trigger was blocked by a pin.

A folding frame sight was mounted on the receiver. The stock, which had a semi-pistol protrusion, was put on the tail tube of the receiver and secured with a screw, reinforced with a metal back. The sling swivel was attached to it from below.

Food was supplied from a two-row box magazine. The arrangement of cartridges is staggered. The magazine latch was controlled using a button located inside the trigger guard. Thus, the shooter, in order to speed up reloading, could press the latch using the finger of the shooting hand. The machine gunner carried spare magazines on his belt in canvas pouches. The BAR design consisted of 125 parts, 11 of which were springs.

“Winchester” and “Colt” provided the weapon with a good finish, and its mass made it possible to fire bursts with acceptable accuracy, but only from point-blank range. The combat rate of fire in short bursts was 60 rounds per minute, in long bursts - up to 180 rounds per minute, provided that the magazines were changed quickly.

In 1922, the United States Cavalry adopted its own modification of the BAR Model 1922 as a light machine gun that was carried without a pack. The barrel was weighted to 1575 grams and equipped with transverse fins up to the middle of the length. The frame sight, which has a mechanism for introducing lateral corrections, was borrowed from the Browning M1919 heavy machine gun. A bipod (weight 1.42 kg) was attached to the guide tube in front of the forend; the legs were fixed in the combat position with spacers. In the recess of the butt there was an additional folding support. The sling swivels were “thrown” to the left side, similar to a cavalry carbine. The BAR Model 1922 was produced in small quantities.

US Marines prepare to land on Tarawa Atoll. Behind are the M1 Garand and M1918 Browning rifles.

US police used a self-loading version of the BAR "Monitor".

In 1937, the army received the M1918A1 light machine gun, which was slightly different from the M1918. We installed a sight similar to the Enfield M1917 rifle. A folding bipod was attached in front of the forend, and a folding shoulder support was attached to the back of the butt. The M1918A1 did not reach the level of the 1922 model, but it was the 1922 model that was completely withdrawn from service in 1940.

In 1941, just before the United States entered World War II, the significantly modernized BAR M1918A2 was adopted. Instead of continuous and single fire modes, continuous fire modes were introduced at different rates - 300-450 rounds per minute (flag “F” positions) and 500-550 rounds per minute (flag “A” positions). To simplify operation of the gas regulator head, it has been modified. The sight is a Browning M1919 type. A metal plate was mounted into the shortened forend, which protected the recoil spring and the forend from overheating. The barrel was equipped with a slotted flame arrester. The magazine guides were screwed to the trigger box, which reduced the risk of losing it. The shoulder support has been shortened. The stock had an additional support, but users almost immediately began to remove it (something similar happened with the DP stock support). The bipod was moved to the muzzle of the barrel and equipped with wide shoes. Thumbscrews were used for fixation. This position of the bipod limited the aiming sector and many machine gunners removed them, so over time the bipod was placed on the guide tube of the M1918A2 machine gun. In battle, machine gunners did not use the shoulder support either, so it was dismantled to make the weapon lighter.

A German soldier (possibly an officer) surrenders to an American soldier armed with a BAR M1918A2 automatic rifle

By the beginning of the war, the BAR was a squad and platoon weapon. The Americans continued organizational experiments during World War II, but each time the BAR again became the core of small fire groups. However, with a relatively light, non-replaceable barrel and limited magazine capacity, the machine gun could not provide long-term fire support. Even when firing in short bursts, the overheated barrel produced visible flames and smoke. It can be assumed that the lack of a light machine gun that satisfies all the requirements forced the Americans to introduce into the infantry squads soldiers armed with combat shotguns, which made it possible to conduct close combat in the thickets.

In addition to Marlin-Rockwell, Winchester Repairing Arms and Colts Patent Firearms, BAR was produced by New England Small Arms and IBM. The markings applied to the receiver included the inscription BROWNING BAR М1918 CAL 30 MFD BY (manufacturer's name).

Early production BARs were returned to factories during the war to be brought up to the level of the M1918A2. Since 1942, machine guns were equipped with a plastic butt, which was reinforced with a metal bottom plate and back of the head. In addition, there was a carrying handle. BARs were supplied to the UK for local defense forces between 1940 and 1941. American Marines preferred the M1918A2, which was modified in military workshops to give them a single-fire mode. In general, due to the large number of alterations and “local upgrades”, many variations of the BAR appeared.

The number of different models produced by BAR is estimated at 1 million pieces, of which more than 350 thousand model 1922, M1918A1 and M1918A2 machine guns were produced in the United States in 1922-1945 and during the Korean War. After the single 7.62 mm NATO cartridge (7.62×51) was adopted, the T34 machine gun was specially made for it, but this version of the BAR remained only an experimental one. Although the BAR М1918А2 was officially withdrawn from service in 1957, it continued to serve later. The machine gun finally left the world stage only in the 80s.

To unload the BAR you must: Detach the magazine by pressing the magazine release button located on the front of the trigger guard. Pull the charging handle back. Inspect the chamber through the receiver window. Return the charging handle to the forward position and pull the trigger.

American soldier with various US Army weapons.

In the picture (counterclockwise): 1. Self-propelled howitzer NMS M7. Considering the prefabricated bow piece (not one piece) and the lack of folding sides of the wheelhouse, this cannot be a later model M7B1. The familiar name "Priest" is not suitable, since it was used in the UK, not in the USA. On the turret is a 12.7 mm (50 caliber) Browning M2HB machine gun. 2. 37 mm M3 anti-tank gun. 3. Easel 7.62 mm (30 caliber) Browning M1919A4 machine gun. 4. Thompson M1928A1 submachine gun. 5. Browning M1918A2 Automatic Rifle (BAR). 6. "Browning" M1917A1. Like the M1919, a 7.62 mm heavy machine gun. 7. 60 mm M2 mortar. 8. 81 mm M1 mortar.

In the inner circle are an M1 self-loading carbine, a Springfield M1903 rifle and a Colt M1911 A1 pistol; in the soldier’s hands is a Garand M1 self-loading rifle.

Procedure for partial disassembly of BAR M1918A2:

1. Unload the machine gun. 2. Turn the contactor flag down, remove the contactor, separate the trigger box and pistol grip. 3. Pull the charging handle back a little until the axis of the earring and the hole on the receiver are aligned. Pull out the axle and separate the charging handle. 4. Remove the bolt carrier liner. 5. Remove the return spring rod. 6. Lower the tube lock flag. Remove the checkbox. Separate the tube with the bipod. 7. Pull the bolt frame forward. 8. Move the shutter latch to the left. Remove the bolt from the receiver.

Assembly was carried out in reverse order.

Technical characteristics of the main models of BAR machine guns:

Model – M1918; Caliber – 7.62 mm; Cartridge – .30-06 Weapon weight – 7.26 kg (without magazine); Weapon weight - 7.805 kg (with loaded magazine); Weapon length – 1195 mm; Barrel length – 610 mm; Number of grooves – 5; Initial bullet speed – 823 m/s; Fire modes - o/n; Rate of fire – 600 rounds per minute; Combat rate of fire – 40/180 rounds per minute; Sighting range – 1460 m; Effective range – 600 m; Magazine capacity – 20 rounds.

Model – M198A1;

Caliber – 7.62 mm; Cartridge – .30-06 Weapon weight – 8.41 kg (without magazine); Weapon weight - 8.965 kg (with loaded magazine); Weapon length – 1194 mm; Barrel length – 600 mm; Number of grooves – 4; Initial bullet speed – 750 m/s; Fire modes - o/n; Rate of fire - 400 rounds per minute; Combat rate of fire – 40/180 rounds per minute; Sighting range – 1365 m; Effective range – 600 m; Magazine capacity – 20 rounds.

Model – M1922;

Caliber – 7.62 mm; Cartridge – .30-06 Weapon weight – 8.62 kg (without magazine); Weapon weight - 9.165 kg (with loaded magazine); Weapon length – 1194 mm; Barrel length – 595 mm; Number of grooves – 4; Initial bullet speed – 735 m/s; Fire modes - o/n; Rate of fire – 600 rounds per minute; Combat rate of fire – 40/180 rounds per minute; Sighting range – 91-1365 m; Effective range – 600 m; Magazine capacity – 20 rounds.

Model – M1918A2;

Caliber – 7.62 mm; Cartridge – .30-06 Weapon weight – 8.82 kg (without magazine); Weapon weight - 9.365 kg (with loaded magazine); Weapon length – 1219 mm; Barrel length – 610 mm; Number of grooves – 4; Initial bullet speed – 855 m/s; Fire modes – n; Rate of fire – 350-500 rounds per minute; Combat rate of fire - 180 rounds per minute; Sighting range – 1372 m; Effective range – 600 m; Magazine capacity – 20 rounds.

Model – M1924;

Caliber – 7.62 mm; Cartridge –.30-06 (M1, M2) Weight of weapon with a long heavy barrel – 8.5 kg (without magazine); The weight of the weapon with a shortened barrel is 7.12 kg (without magazine); The weight of the weapon with a long heavy barrel is 9.045 kg (with a loaded magazine);; The weight of the weapon with a shortened barrel is 7.665 kg (with a loaded magazine); Weapon length – 1112 mm; Heavy barrel length – 607 mm; The length of the shortened barrel is 457 mm; Fire modes - o/n; Rate of fire – 600 rounds per minute; Combat rate of fire – 40/180 rounds per minute; Sighting range – 200-1600 m; Magazine capacity – 20 rounds.

After 1945, the United States sold off BAR machine guns and also supplied them to “friendly regimes.” In the countries of the Middle East and Southeast Asia, these machine guns are still used today.

Foreign modifications of BAR machine guns

Belgium

(FN) bought a license to produce the M1918Al BAR after its introduction. The Belgian version was somewhat modernized: the barrel was made heavier, it was equipped with transverse ribbing up to half its length, the gas regulator handle was enlarged, the return spring was installed in the butt, magazine well covers were introduced, as well as windows for ejecting cartridges, a folding bipod was installed, and an enlarged one was installed in the forend. heights, grooves for the bipod were made.

Such weapons as a light machine gun were produced from 23 to 39 for the Belgian army under the 7.65 mm Belgian Mauser cartridge, 7 mm Spanish Mauser cartridge and 7.92 mm Mauser cartridge for China (model FN 1930, 7.92 mm), Chile (FN 1930, 7 mm), Poland (FN 1928, 7.92 mm), Sweden (here the 6.5 mm BAR modification in service was designated Kulspruta m/21), even in .30-06 caliber for the United States. In addition, the machine gun was supplied to Argentina, Greece, Great Britain, Thailand, and the Netherlands. Beginning in 1932, the barrel was made replaceable (FN-30). The machine gun's markings included the monogram FN, BROWNING PATENTED, year of manufacture and serial number. It was performed over the magazine socket on the receiver. FABRIQUE NATIONAL DARMES DE GUERRE HERSTAL-BELGIQUE - above the magazine on the left side of the receiver.

As of 1940, the Belgian Army infantry regiment was armed with 52 heavy machine guns and 108 FN-30 light machine guns. The war interrupted production, but immediately after its end it was resumed. As a result of the next modernization, Model D was created. Using a spring buffer, the rate of fire was changed (M - “high rate”, F - “low rate”, S - “fuse”), the assembly and disassembly of the mechanisms was simplified, the sector sight and front sight were changed, a pistol grip was installed, a replaceable barrel was equipped with a carrying handle, the forend was reduced in size, and the folding bipod bushing was fixed to the guide tube. Model D was perhaps the most successful modification of the BAR, but its creation was clearly late. Production of this model lasted until 1967. For the Belgian army chambered for the American 7.62 mm 30-06 cartridge, for the Egyptian army chambered for the 7.92 mm Mauser cartridge. Models D and FN-30 were used for a long time in Africa and the Middle East. FN used the BAR system during the creation of a single MAG machine gun, created in 1958. In the United States, a similar experiment was carried out during the Second World War - an experimental T10E3 machine gun, which had a belt feed, was also based on the BAR scheme

Sweden

The Swedish modification of the BAR machine gun was produced under the designation M37. Swedish designers were among the first to transfer a recoil spring to the buttstock, or more precisely, to a tube located behind the receiver (this was also done in the Soviet DPM). The quick-change barrel, which has a folding handle, was secured using a special lock. A folding front sight, a rack-mounted sight, and a pistol grip were installed. Folding tubular bipods were mounted with a coupling on the guide tube. Since the M37 machine gun did not have a fore-end, the bipod was used as a foregrip during hand-held shooting. The sector-shaped magazine was designed for 20 rounds of 6.5-mm Swedish Mauser. This modification of the BAR is currently in the reserve units of the Swedish army.

Poland

The Poles tested several light machine guns in 1924. The Belgian version of the BAR was recognized as the best, preferring it to the Lewis model 1924, Madsen, Mle 1924 Chatellerault, Vickers-Berthier, Prague-24 (predecessor of the ZB-26). At the same time, the Belgians, at the request of the Polish side, had to make some changes: lengthen the barrel, change the design of the bipod and sight, improve the ejector, bolt, trigger mechanism, butt. At the end of 1927, after testing by the troops, the machine gun chambered for the 7.92 mm Mauser cartridge was adopted for service under the designation Wz.28. They ordered 10 thousand pieces and acquired a license for production, which began after the end of deliveries from Belgium in 1930. Production was established in Warsaw at the state arms factory and continued until the start of World War II.

The translator-fuse Wz.28 had three positions, which were designated by the letters “B” (fuse), “C” (continuous), “P” (single fire). The combat rate of fire ranged from 40 to 60 rounds per minute. The return spring and buffer were located in the butt. The lid of the window for ejecting cartridges was locked with a swinging lever. Sights - front sight and frame sight with diopter rear sight. In the folded position, the aiming range was 300 meters, in the raised position from 400 to 1600 meters in increments of 100. An anti-aircraft sight was also installed on the machine gun - in this case it was placed on a tripod machine. The machine gun had a pistol grip and a folding bipod with spacers. Two variants of the Wz.28 were produced: the first with a flame arrester and a front sight safety device, the second had a shortened buttstock, but it lacked a front sight safety device and a flame arrester.

By August 1939, 10,710 machine guns were produced. However, even if we take into account Belgian supplies, it was not possible to fully satisfy the army’s needs for machine guns (although 600 were exported), so in 1939 the Poles used outdated machine guns. The German Wehrmacht used Polish captured Brownings under the designation MG.28 (p). During the occupation, the plant in Warsaw produced these machine guns for the Germans. On the other hand, the Polish Brownings ended up in Soviet warehouses after the 1939 campaign. With the beginning of the Second World War, these machine guns, along with other obsolete and captured weapons, went into battle. For example, in the fall of 1941, 1928 Brownings were used by the militia in the defense of Moscow.

Technical characteristics of foreign modifications of the BAR machine gun:

Model – FN Model D;

Caliber – 7.62 mm; Cartridge – 30-06; Weapon weight – 9.18 kg (without magazine); Weapon length – 1143 mm; Barrel length – 508 mm; Number of grooves – 4; Initial bullet speed – 854 m/s; Fire modes - o/n; Rate of fire – 400 and 650 rounds per minute; Sighting range – 800 m; Magazine capacity – 20 rounds.

Model – M/37;

Caliber – 6.5 mm; Cartridge – 6.5×55; Weapon weight – 9.53 kg (without magazine); Weapon length – 1168 mm; Barrel length – 610 mm; Number of grooves – 6; Initial bullet speed – 745 m/s; Fire modes - o/n; Rate of fire – 500 rounds per minute; Magazine capacity – 20 rounds.

Model – Wz.28;

Caliber – 7.92 mm; Cartridge – 7.92×57; Weapon weight – 8.85 kg (without magazine); Weapon length – 1110 mm; Barrel length – 610 mm; Number of grooves – 4; Initial bullet speed – 760 m/s; Fire modes - o/n; Rate of fire – 500 rounds per minute; Sighting range – 1600 m; Magazine capacity – 20 rounds.

Specifications

| Characteristic | Meaning |

| Type | Self-loading carbine with gas piston |

| Caliber | .308 Win (cartridge 7.62x51) |

| Barrel length (mm) | 559 |

| Twist pitch (inches) | 12” |

| Barrel coating | Polished blued |

| Magazine capacity | 4 + 1 in chamber |

| Lodge | Semi-pistol, Turkish walnut |

| Overall Length (mm) | 1092 |

| Weight, kg) | 3,58 |

Design

- A self-loading carbine that operates on the principle of a gas piston. The return mechanism is located under the barrel and is covered by the forend. It is possible to adjust it - a screw with a metric thread is installed in the gas chamber channel. The gas piston is chrome plated.

- The barrel is made by cold forging; the connection to the receiver is permanent. The receiver is machined from a solid metal billet using the milling method. It is closed, there is only a groove for the bolt handle and an ejector window. The chamber is plated with chrome, the outer coating is blued.

- The bolt rotates when locked and has seven lugs.

- The trigger mechanism is unregulated, the force on the trigger is 1.7 kg. The safety button is located on the rear branch of the trigger guard. It moves perpendicular to the axis of the trunk. The extreme right position is “Fire”, the leftmost position is “Stop”. The slide stop release lever is located on the right side of the receiver, between it and the forend.

- The magazine is removed by pressing the lever located at the front branch of the trigger guard. It is installed on a hinged lid and can be completely removed.

- The stock with a pistol grip is secured to the receiver with a screw. It is straight, without cushions or ridges. Turkish walnut wood was used in its production. The forend is also made of wood and is removable. The fastening screw is located under the front swivel.

- The receiver has holes with metric threads for installing rails and brackets for optical sights. There is a rear sight and a closed adjustable front sight. The rear sight can optionally be adjustable (on a slider with a remote ruler) and fixed, on a long prismatic base (Batu system).

Browning BAR BOSS Safari carbine cal. 30-06

Description of the Browning Bar .30-06 Light Long Trac Executive carbine

A self-loading carbine that operates on the principle of a gas piston. It was produced by the Browning arms company - both directly in its historical homeland, Belgium, and in the USA. Now out of production, but still found in the list of offers in gun stores (it is possible that it is already made in China).

An interesting design detail is that the piston and return mechanism are located under the barrel.

You can read about what it is from its model index:

- BAR - Browning Automatic Rifles, automatic rifles of the Browning system.

- 30-06 SPFLD - 7.62 caliber cartridge with a 63 mm long case.

- Light – light (nickel-plated) receiver.

- Long Trac – long bolt stroke (for cartridges with a long sleeve).

- Executive - artistic execution (usually Ltd Edition is added to the model index).

BrownCompositeing BAR LongTrac cal. 30-06 is discussed in this video:

Advantages and disadvantages

- If this is really a Browning, then the quality of the weapon is beyond doubt and has excellent shooting qualities. It is reliable (rather indestructible), perfectly balanced and very beautiful, and with a receiver decorated with engraving, it can even be considered a work of art.

- The carbine bolt has four lugs; when the barrel bore is locked, it rotates, so in terms of shooting qualities - combat accuracy, range - it is similar to hunting weapons with bolt-action bolts and is superior to models in which it is free or tilted.

- The trigger mechanism is unregulated, without warning and trigger. The pressing force is set at the factory to 1.8 kg, and the operating instructions specifically note that changing this parameter is strictly not recommended. The trigger is gold plated, the guard is made of polymer.

- The safety button is located on the rear branch of the trigger guard, this is convenient, but you need to adapt to this position of this trigger element.

- The manufacturer offers models for left-handed shooters; their receivers and bolts are incompatible with carbines designed for right-handers.

- In this luxurious design, the carbine is produced only for the 30-06 SPFLD cartridge. This caliber is not universal, it is more suitable for African hunts for elephants and rhinoceroses. They can be shot at distances of more than three hundred meters, which requires the hunter to have more skill in handling weapons than the ability to outwit the beast.

The beauty of the Executive Ltd Edition model makes it inaccessible to most hunters - the price starts from five hundred thousand rubles.

- The chic stock made of dark walnut wood is very comfortable; it can be adjusted to the shooter’s hand using a set of interchangeable butt plates, as well as spacers between it and the receiver, allowing you to change the angle of inclination.

- There is a set of external sighting devices, consisting of a rear sight and a front sight, the use of which is appropriate for driven hunts and shooting at moving targets, when a large viewing angle is required (the optical frame reduces it). The rear sight is non-adjustable, with a white stripe along the aiming line, and the front sight is equipped with a red fiber-optic thread.

Due to the complexity of the design, it is better not to disassemble the carbine yourself, leaving this task to master gunsmiths. It is very difficult to clean. For example, cleaning the barrel is done from the breech by pulling a brush on a cord along the channel. And many hunters do not clean the mechanism at all, limiting themselves to lubricating it with technical fluid such as WD.

Browning Bar 30-06 Light Long Trac Executive (photo)

Purpose

Used for hunting large ungulates and predators if the expected shooting distance is more than three hundred meters.

Varieties

BAR Long Trac carbines (Oil Finish is also added to the model indices, since they lock the bolt stop after the last cartridge is fired) are also produced in a less luxurious design, and are also chambered for the universal caliber .270 Win, used for hunting small ungulates at a distance shooting up to 400 meters.

Operating principle of the BOSS system

- The ballistic stabilization system consists of a muzzle brake, the length of which can be adjusted, and a lock nut. Its operation is based on the fact that the wavelength of barrel vibrations for cartridges of the same caliber and bullet type is the same. By decreasing or increasing the length of the muzzle brake, it is possible to ensure that the bullet exits the barrel at the moment when the sinusoid of oscillation crosses the conventional zero.

- The tuning table included with the rifle is based on empirical (experimental) results obtained by shooting several hundred rounds of the same caliber on a bench. The shooter, knowing the type of cartridges used, screws the locknut onto the threaded part of the barrel to the whole value of the measuring ruler that is indicated for them in the table. After this, the muzzle brake is applied. If the values in the table are fractional, then tenths are set by a rotating dial ring attached to the lower edge of the muzzle brake.

Adjusting the BOSS consists of firing three rounds in succession, measuring the distance between the impact points on the target and changing the position (plus or minus) of the muzzle brake relative to the empirically calculated point, which is indicated in the adjustment table. Typically, three to four series of three shots are sufficient for optimal tuning. It is not recommended to turn the tuning dial more than 0.5 divisions at a time.

Experienced hunters in the following video will talk about the advantages and disadvantages of Browning BAR-2 and H&K carbines (Heckler and Koch):

Disassembling the carbine

Performed when it is necessary to clean the gas piston mechanism and trigger. The design is so reliable that in normal cases you can only remove the forend, pull the return mechanism weight down and treat the surfaces with a technical fluid like WD-40. Complete disassembly is carried out in several stages.

- Unload the carbine by removing the magazine, twisting the bolt, removing it from the bolt stop, and performing a test release.

- Unscrew the front swivel and the screw under it, remove the forend, pulling it towards the muzzle.

- Unscrew the gas chamber nut from the muzzle end.

- Pull back the recoil mechanism weight, then push the piston out of the chamber using a flathead screwdriver with a narrow blade, moving from the receiver to the muzzle.

- Open the magazine hopper cover and remove the two guides. One of them may not come off, so knock out the bolt stop lever shaft and remove it.

- Pull the bolt back, remove the guide of the return mechanism from the gas chamber and remove it all with the weighting material, springs and rod.

- knock out two trigger pins on the receiver and remove it.

- Remove the bolt handle by pulling it back and a little more so that a gap forms between it and the cylinder. Insert a screwdriver into it and pry the latch lever. After this, the bolt is removed from the receiver without any problems.

- Knock out the pin on the bolt stem, remove the firing pin, spring and cylinder with lugs.

Operating principle

The carbine mechanism works using the principle of a gas piston.

- To load the rifle, press the lever on the front arm of the trigger guard. Separate the magazine from the cover. Place four cartridges in it in a checkerboard pattern.

- Pull the shutter. The weapon is ready to fire. If necessary, it can be put on safety by sliding the flag-button on the trigger guard from left to right.

- After firing the last cartridge and if there is a magazine in the hopper, it is placed on the bolt stop, from which it is removed using a lever on the right side of the receiver.

Shooting from the Browning Bar 30-06 Long Trac is presented in this video:

Tuning

If the spent cartridges are not removed from the chamber vigorously enough, you can adjust the gas mechanism. To do this, follow the first two points from the section above. Place the rifle with the bolt handle facing up.

On the channel connecting the barrel and the gas chamber, find a slotted screw. Turn it counterclockwise a quarter turn. Assemble the carbine, test fire 2-3 rounds. If necessary, reduce the cross-section of the gas channel by tightening the screw 1/16 or 1/8 of a turn.

Next, let's look at the reviews and prices of the Browning BAR Mark II Safari carbine in .308 Win Boss caliber.

Similar models

Now the North American company Browning has begun producing updated BAR Mark III models, which have almost the same design. The main difference is the use of cold forged barrels instead of drilled ones.

Carbines such as the Browning BAR MK 2 Safari 30-06 Boss, as well as the Browning BAR .30-06 Sprg, are also very popular. Light Long Trac Composite fluted.

However, this is where the choice of carbines ends. Thus, among semi-automatic models one can also name the M82 Barrett Firearms, Vepr Super, Merkel SR1, etc.

Assembly of the Browning Bar Long Trac carbine is shown in the video below:

Analogs

- The BOSS Ballistic Optimization System is used exclusively by Browning and all operating instructions specifically state that it is not used on other brands of rifles.

- In terms of layout - a gas piston mechanism under the barrel - the BAR Mark II Safari carbines are similar to Benelli self-loading carbines, with Browning being the original source. Benelli products are less durable - the barrel is attached at one point to the rod of the gas release mechanism, which is why the effective firing range does not exceed 200 meters, and the axis of the dispersion ellipse, when using low-quality cartridges, reaches a meter.

- Among other self-loading models we can name TOZ-99, Saiga.

We talk in detail about which carbine for hunting is better to choose separately.

This video compares the Benelli Argo and Browning BOSS 308 carbines: