The German MP-40 submachine gun, which was called the “Schmeisser” in the USSR, is as legendary a weapon as the PPSh assault rifle or the Mosin rifle. Thanks to Soviet cinema, the typical image of a Hitler soldier became a young man with rolled up sleeves, firing from the hip with an MP-40. It should be noted right away that the MP-38/40 submachine gun was neither the most common nor even the most popular type of small arms in the German army. But at the same time, the MP-38/40 is one of the best types of submachine guns of its time. True, he had nothing to do with the talented German weapons designer Hugo Schmeisser.

History of creation

The German military began to develop a healthy interest in submachine guns quite a long time ago, back in 1915. But the terms of the Treaty of Versailles dictated completely different realities - this type of weapon was allowed only for police forces. Despite this, the famous weapons engineer Heinrich Vollmer concentrated as much as possible on the development of such a promising type of weapon. He created weapon models one after another, constantly improving their performance characteristics. So, in 1925, the Volmer Maschinenpistole VMP1925 was released, which resembled the MP-18, but differed only in a 25-round disc magazine and a wooden handle. A year later, VMP1926 appeared. Even later, the VMP1928 model was created with a 32-round disc magazine. The next model in this chain of weapons was the VMP1930 PP. Outwardly, it was very similar to its predecessor, but was easier to disassemble/assemble and more reliable during operation. This was achieved by using a telescopic spring in the design. This model was even mass-produced and a total of 400 units were produced, most of which were exported.

A year later, Erfurter Maschinenfabrik bought the rights to Vollmer submachine guns, and in 1932 the Erma Maschinenpistole (EMP) appeared. The design of the new weapon was an almost identical copy of the 1930 model.

MP 40 submachine gun

This is interesting: in the Soviet Union the MP-38/40 was called the “Schmeiserr”, although the German gunsmith had nothing to do with this weapon.

The story begins with EMP36

In 1933, the NSNRP party came to power in Germany. The German army was growing and it needed to be provided with weapons. For this reason, the EMP36 PP appeared, which was an intermediate model between the EMP and MP38. The full name of the weapon is ERMA ERFURT EMP 36 .

He had common features with each of his “brothers”. In general, the modified mechanics of the weapon had the features of the Volmer submachine gun. The wooden stock was also replaced with a folding metal one, and the wooden stock was replaced with a metal one. As for the front wooden handle, a magazine socket was marked out instead. The store itself was slightly tilted to the left and forward relative to its axis. This shift in the symmetry of the center of gravity significantly improved the accuracy and accuracy of fire.

EMP 36 is a melee firearm with a folding stock for destroying enemy personnel at a distance of up to 200 m. The weapon used a standard 9x19 mm Parabellum cartridge (a description can be found on our website world-weapons.ru). A 32-round box magazine with new parts was specially designed for this weapon. This weapon also included a support hook for firing from armored vehicles and other shelters. The weapon had a good rate of fire - 600 rounds/min.

Submachine gun EMP 36

Due to the fact that mass serial production of this type of weapon was brewing, German gunsmiths decided to use a new method of manufacturing parts using cold stamping from a steel sheet, but alas, they failed. The parts turned out to be unreliable, so the head of the company decided to return back to the easel method after receiving an assignment from the Wehrmacht Ground Forces Armament Directorate to develop a new submachine gun for paratroopers and tank crews.

The weapon was produced in limited quantities. To date, a little more than 3,000 MP 36 units have reached us in combat-ready condition. Of these, about 2,000 are in the United States.

From the history of the creation of MP38, MP38(L)

From 1936 to 1938, the EMP36 was modernized and transformed into the MP38. At the beginning of 1938, the management of the Erma company received an official order for the production of a submachine gun for the Wehrmacht forces. A little later, on June 29, 1938, the MP38 was officially put into service. It was the second submachine gun adopted for service after the MP-18.

MP 38 L submachine gun with folded stock

At the initial stage, weapons were produced at a very slow pace. During 1938, only about 1000-2000 units were produced. At the beginning of World War II, the German army possessed 9000 MP38 units. During the period from September to December 1939, another 5,700 units were produced, and in the first half of 1940, the Wehrmacht received another 24,650 units. In total, about 40,000 MP38s were produced by the companies Haenel and Erma.

MP-38 submachine gun being tested

In the MP38, the receiver was made not by stamping, but by milling. Due to such a high cost, it was necessary to simplify the design of the weapon as much as possible - the use of plastic in the manufacture of the fore-end, the use of an aluminum alloy for the frame of the pistol grip.

MP 38 L submachine gun with unfolded buttstock

Almost a year later (late 1939-early 1940), the experimental MP38(L) was developed. The weapon was very structurally different from its parent and was of higher quality and technology, as well as better adapted for mass production. These are like advantages. As for the downsides, its production was significantly more expensive. The main differences between the MP38(L) and the MP38: most of the parts were made of aluminum by casting, the cheeks of the pistol grip were made of wood, there were no longitudinal ribs on the body and a completely different magazine socket.

History of development, production of MP40

At the end of 1939, development was completed and small production of the new MP40 began. Mass serial production of the modernized MP40 submachine gun began in March 1940. The MP40 was produced at the Steyr (began production first), Erma and Haenel factories. As for the rate of production, at first it was low, but by August 1940 the production volume amounted to 10,000 units/month. In the period 1940-1944, the above-mentioned companies produced a total of approximately 706,350 MP40 units.

At the beginning of 1940, the MP40 began to enter the army in large quantities. It was primarily armed with airborne units and special forces, and then went to riflemen, officers and sergeants. Last but not least, it was supplied to artillery crews and drivers of conventional and armored vehicles. Thus, it was possible to almost completely satisfy the Wehrmacht forces with weapons.

MP38/40 submachine gun

In the period from January 1940 to December 1941, the army received 234,750 units of this weapon, and in 1942-1943 - another 464,144 submachine guns, of which almost 80% were received by the army, the rest were distributed to the aviation and navy.

The total number of MP40s manufactured is over 1 million units.

The Haenel company produced about 160,000 weapons and was the first to stop producing the MP40 - in 1942 and began producing new Sturmgewehr assault rifles. Erma stopped production of the MP40 at the beginning of 1944, and Steyr stopped production a few months later (it produced about 350,000 units).

MP 40 submachine gun

This is interesting: a movie myth is how Wehrmacht soldiers fire continuously from the hip with MP40s. In fact, the shooting was aimed with the butt resting on the shoulder in small bursts of 2-5 shots.

In the Wehrmacht infantry units, the concentration of MP-40s was relatively insignificant. These weapons were primarily armed with platoon and squad commanders, Airborne Forces personnel and the crew of armored vehicles/tanks.

MP 40 submachine gun

Historical information about the MP41

In 1941, designer Hugo Schmeisser, guided by the wishes of the infantrymen, introduced a hybrid of the MP28.II and MP40 - MP41. From the first he got the bracket, trigger and wooden stock, from the second he got the bolt, bolt box and barrel, as well as the return mainspring. A lighter bolt and a reinforced return mainspring increased the rate of fire to 750-800 rounds/min. This led to rapid wear and tear of the weapon. For this reason, the rate of fire was later reduced to 600 rounds per minute. But in this variation, the weapon lost its relevance, because the MP 40, which had proven itself, already existed.

MP 41 submachine gun

The weapon had a wooden butt, which ensured better shooting accuracy. There were also 2 fire modes - automatic and semi-automatic. Unlike the MP40, the new submachine gun was much more difficult to produce (production was only 100 units/day). Despite the better performance characteristics, the Armament Directorate still considered it inappropriate to start producing weapons exclusively for the needs of the infantry.

MP-41 submachine gun without magazine

The production of the MP41 submachine gun was carried out by the Henel company, which produced 26,000 weapons in 1941 and another 1,500 in 1944. Most likely, the weapon was produced by order of the ally of Romania and some other Balkan countries. MP 41 was produced in small quantities, and in total about 50,000 units of this PP were produced.

A little about EMP-44

In 1942, Erma engineers began developing a new submachine gun for installation on armored vehicles and fortifications, equipped with 2 magazines. The weapon received the index EMP-44, but all work was curtailed, and the company transferred the device for attaching 2 magazines to MP40/1.

Submachine gun EMP 44 without and with 2 magazines

Facts about MP40/1

MP40/1 or Gerät 3004 - an experimental version of the MP40 for 2 magazines. Ultimately, the PP turned out to be extremely bulky, heavy and inconvenient. The weapon's ammunition supply system was also unsuccessful - weapons and magazines were extremely sensitive to various contaminants.

MP 40/1 submachine gun with two magazines

A couple of dozen pieces were produced in total. Today, only 5 copies of the MP40/1 weapon have survived, which were produced by Erma and Steyr from the second half of 1942 to the first half of 1943.

MP 40/1 submachine gun left view

This is interesting: of the 5 surviving copies of the MP40/1 to date, three were obtained by the US military in 2009 during the war in Afghanistan.

The appearance of Mp-40

The first small batch of MP-40 was produced at the end of 1939. In March 1940, mass production of this submachine gun began. During 1940, all German factories that produced MP-38 models switched to producing MP-40. By the end of the summer of 1940, MP-40s were produced at a rate of 10,000 per month. The MP-40 submachine gun was produced by 3 German companies:

- Steyr;

- ERMA;

- Haenel.

During the period from 1940 to 1944, these companies produced more than 700,000 copies of the MP-40. During the war, the needs of the German army for submachine guns were satisfied almost 100 percent. Although official statistics speak of 1,000,000 MP-40 SMGs produced during all the years of the war, according to Soviet intelligence there were more than 1,100,000 of them.

The MP-40 device differed favorably from the MP-38 design in its simplicity of design and production. This model widely used stamped parts that had a sufficient margin of safety, for example, the pistol grip frame was stamped. The MP-40 body lost its stiffening ribs, and the socket into which the magazine was inserted lost its holes.

The case of the first modernization of the MP-40 is very interesting. Faced with the Soviet Shpagin submachine gun, the Germans decided to copy its safety device. In the second half of 1940, all new MP-40s received a fuse on the right side. This fuse device was also used in earlier MP-40 models, which were sent en masse for revision.

Although the Mp-38 was produced in only one modification, the Mp-40 boasts several versions, since during the war years they constantly tried to reduce the cost of the Mp-40 design. According to weapons experts, a total of about 5 different modifications of the MP-40 were produced, although this is quite difficult to prove. All changes were made gradually, at different factories at different times. In addition, the soldiers themselves often changed or rearranged parts from faulty submachine guns to working ones. In 1944, the German command issued an instruction in which it was strongly recommended that the production of new MP-40s use parts that remained in warehouses. The submachine gun, assembled from parts from different years of production, was impossible to attribute to any specific modification of the MP-40. The description of just such a “prefabricated” model is sometimes considered a separate modification of the MP-40.

In 1941, the German designer Hugo Schmeisser proposed his own model of a submachine gun for infantry, which he created taking into account the wishes of front-line soldiers. The performance characteristics of this model, which Schmeiser called MP-41, were significantly superior to the MP-40. Mp-41 was a combination of two PP – MP 28/II and MP-40. Due to the use of a wooden stock and butt, the overall accuracy of the new model when firing exceeded that of the conventional MP-40. Unfortunately, the MP-41 was never accepted into service, since it was considered an unacceptable waste to produce a separate modification of the PP for infantry.

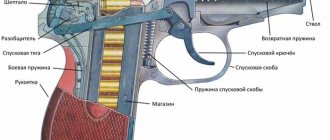

Design. Principle of operation

The MP40 striker-type trigger can only be fired in bursts. There are no safety devices; instead, there are two slots for the bolt handle on the left side of the bolt box. The first groove is located in the breech of the casing and is intended for preparation for firing, the second is located near the chamber and is necessary for completely locking the barrel bore in the stowed position.

MP 40 submachine gun

The weapon's sights are a rack-mount sight with two viewfinders. The first sight is permanent, designed for a distance of 100 m, the second is folding for a distance of 200 m.

MP-40 submachine gun disassembled

The principle of recoil of a free bolt with a stationary barrel is the basis for the operation of the MP38 and MP40 PP automatics. This “roll-out shot” principle was developed by Hugo Schmeisser. According to this approach, at the moment the barrel is locked with a massive bolt, the striker striker and the cartridge primer come into contact. The submachine gun has a relatively low rate of fire - 600 per minute. The reason for this is a weak return spring, the heavy weight of moving parts and the presence of a pneumatic damper. But this drawback can also be considered a plus, because due to the relatively low rate of fire, accuracy improves and it becomes possible to fire single shots.

At the bottom of the weapon barrel there is a kind of “hook” for the convenience of firing from various shelters, the sides of armored vehicles, etc.

MP 40 handle pads

The main parts of the MP40 are as follows:

- gate;

- barrel and receiver;

- trigger box with fire control handle and shoulder rest;

- trigger mechanism;

- return mainspring;

- shop.

Shutter design

The weapon's bolt has a cylindrical shape. In front of it there is a cup, which at the moment of the shot houses the rear part of the cartridge case. At the bottom of the bolt there are grooves for the passage of the jaws of a removable magazine and a weapon rammer, which pushes a new cartridge out of the magazine and into the chamber. There is also a slot for a reflector of spent cartridge cases.

Shutter and needle (striker) MP-40

The rear part of the bolt has a fixed cocking handle. In addition to the main function, it also served as a fuse - with its help it was possible to fix the bolt both in the front position (using the lateral displacement of the chip placed on it, which engages with the cutout for the cocking handle on the receiver) and in the rear ( the handle is inserted into the side extension of the rear part of the slot).

MP40 grip and stock

As for the early versions of MP38/40 and MP 40, they did not have the feature on the bolt handle described above. There was only a simple hook that was fixed in only one position - back. Such a simple design was very unreliable - the weapon could fire spontaneously if there was a fairly strong impact along the axis of the weapon or if it was shaken (for example, when jumping from a vehicle or landing from the air).

This is interesting: the Germans tried to solve the lack of a sliding feature by making special safety straps that were put on the barrel and fixed the bolt in the forward position.

Later, starting in August 1942, this problem was solved by issuing a decree to convert all MP38/40 with hook handles into handles with a chip by cutting out a groove for the safety in the front of the receiver.

The weapon's firing pin had a special feature - it was a separate part located in the internal channel of the bolt. Its base also served as a stop for the return mainspring.

MP-40 recoil spring and telescopic casing

The recoil spring, together with the base of the firing pin and the surrounding telescopic casing of tubes, formed a separate assembly unit that did not require maintenance under normal operation. These tubes filled with air served as a simple fire retardant. This approach simplified the design of the trigger mechanism and made it possible to abandon the single-fire function. In addition to the function of a retarder, the steel tubes also reliably protected the spring from mechanical influences.

Telescope MP 40

Some later MP40 releases lacked the pneumatic retarder and telescopic shroud. This approach had a direct proportional impact on the reliability of the weapon, because the spring was strengthened, and the protection against contamination was leveled.

Bolt box of a submachine gun

This part is made of rolled cheap carbon steel. On top there was a base for a sight, in which a bar with an aiming post was placed. The stand had a slot for a stationary sight at 100 m and a folding bar for shooting at 200 m. Quite often, such a sight was replaced with a sector sight, divided in increments of 50 meters at a distance of up to 300 meters.

Shutter MP-40

A magazine receiver is placed in front of the bolt box. This part is made of sheet metal or aluminum and has a reflector and magazine release inside. Above the magazine receiver on the right side of the bolt box there is a cartridge ejector window.

Weapon magazine and ammunition

The PP magazine has a box-shaped, straight shape. The cartridges in it are arranged in a checkerboard pattern. Ammunition was delivered by a feeder with a steel spring made by extrusion. This significantly reduced the cost of production. When loading ammunition into the chamber, the front end of the cartridge case is fixed into its ledge.

MP40 magazine

The weapon uses a 9x19 mm Parabellum cartridge. At the initial stage, cartridges were of 2 types: with a round-topped conical bullet and a flat-topped conical bullet. Further, during the Second World War, the variety of bullets expanded significantly - both jacketed bullets with a steel (P.08 mE) and lead core (P.08 SE) and non-jacketed surrogate bullets made of metal-ceramic mass were used. As for the latter, it was of the greatest interest, as it had sufficient power, accuracy and a flat flight path. The cartridge used cylindrical shells with a non-protruding flange. They were made from steel, aluminum, brass and bimetal.

Possible additions to weapons

As for the various additional “devices” for this weapon, they are a silencer, a magazine filler and a winter trigger.

Silencers

At the official level, mufflers were not used for the MP38/40 models, but in reality there were even several models of them. If you believe official documents from 1944, then in total about 1000 - 1500 units of various variations of mufflers were manufactured. All of them were made. The model range of mufflers from Hub L41 to Hub L50 is known. For example, in 1942, two types of mufflers were developed - Hub L41 and Hub L42. The first was created by the Brandenburg company Arado, the second by the Schneider-Opel community. Hub L41 weighed 700 g, had a length of 295 mm and a diameter of 43 mm. The Hub L42 model had a length of 350 mm, a diameter of 45 mm and weighed 600 g. Each of the suppressors required a special cartridge with a lighter charge and a somewhat heavier bullet - a certain close-range cartridge Nahpatrone 08.

MP-40 submachine gun with silencer

Winter trigger

In German it sounds like Winterabzug. This device made it possible to fire a weapon without taking off the mittens. I met very rarely. Externally, it was a thin-sheet metal box with a removable sidewall and a trigger. It was located below the “factory” trigger guard.

Winter trigger for MP-40

Store filler

This “thing” made filling the magazine with cartridges much easier. The Magazinfüller is a special device in a metal case that is attached to the neck of the magazine. In its upper part there was a special lever, with the help of which the magazine was filled with cartridges.

MP 40 assault rifle magazine filler

Modern use

Yes, yes, that happened. However, PPSh-41 continued to be produced in China until the beginning of 2000, and in some places it is still being made, so there is nothing surprising in this. And the MP-40 remained in service with the Norwegian police forces back in the 60s of the last century. In addition, it was actively used by both Israelis and Arabs during countless conflicts in the Gaza Strip. So the MP-40 is an assault rifle with a rich history.

By the way, the famous MP-5, which is in service with many police and military units around the world, has nothing in common with the PP we are discussing. Firstly, it operates according to a semi-blowback design. Secondly, in fact, it is a smaller copy of the G-3 rifle.

Finally, there are also MP-40 pneumatic assault rifles on sale, which are demilitarized barrels (as in the situation with PPSh-41). However, such specimens are still rare, and their cost is high. Usually we are talking about rough layouts.

Assembling and disassembling weapons

In order to disassemble the weapon, it is necessary to carry out the following manipulations:

- First of all, we disconnect the magazine of the submachine gun.

- Pull down the locking bolt by the button. Next, rotate it a quarter turn to the left or right.

- We take the weapon by the neck of the magazine and the pistol grip and rotate them relative to each other counterclockwise. The trigger must be pressed at this moment. Next, we separate the receiver along with the neck and barrel by pulling it forward.

- We remove the bolt from the receiver.

A German soldier cleans an MP-40.

We assemble the weapon in the reverse order.

Store characteristics

Sector magazine, capacity – 32 rounds. Appearance - straight, stamped steel. It is impossible to confuse it with sector magazines from PPS or PPSh, since it is straight, while domestic PP used curved models (due to the characteristics of the 7.62x25 cartridge). By the way, the MP-40 magazines were not particularly loved by infantrymen, since it was very difficult to equip them manually; it was necessary to resort to the help of a special device.

It was inserted into the straight neck of the receiver, protruding beyond the weapon, and secured with a push-button clamp. In practice, it soon turned out that the neck should be protected from contamination in every possible way, since it was very difficult to clean it in combat conditions. The standard ammunition for a Wehrmacht soldier in those days was about 190 rounds.

Project evaluation. Advantages and disadvantages

This project can be assessed in different ways. It has both positive and negative sides. We will try to consider them in detail.

This weapon has a pretty good design. Initially, it was developed as a compact weapon for paratroopers, special forces and other troops. For this reason, a folding stock was developed for it, which ultimately became a death sentence - the durability of the hinge joints left much to be desired. They quickly wear out and become loose. Apparently, this was the reason for the development of the MP 41 with a classic wooden stock. But the project did not take root, because there was no interchangeability of parts and barrel.

Soldier with MP 40

As for the advantages, the weapon was quite compact for that time, simple and easy to maintain, convenient to use, technologically advanced and surprisingly durable in extremely aggressive environments. According to HWWA standards, the PP MP 38/40 easily fired at least 30,000 rounds of cartridges with a reinforced powder charge. It was also subjected to various influences - temperatures from -50 °C to +50 °C, lack of lubrication, exposure to salty sea water for 4 days, as well as tests with dust, dirt and sun, and a drop from a height of 5 meters.

The weapon has the ability to install various muzzle attachments - silencers, muzzle compensators, add-ons for firing over-caliber cartridges. This is ensured by the presence of a thread at the end of the barrel, covered with a screw-on sleeve.

German soldiers with MP 40

As for the quality of shooting, the submachine gun has also proven itself well. The weapon is easy to control, has a high accuracy of fire and has excellent accuracy. The bullet, even at a distance of 200 m, has good stopping power.

Possessing such a huge number of positive characteristics, it is no wonder why the submachine gun has gained fame as a truly world weapon.

As for the shortcomings, there are some, but they are few:

- extremely short-lived hinge design of the folding stock;

- modest ballistic performance of the cartridge - the bullet has a weak muzzle velocity, poor bullet flight flatness. If we take the Soviet analogues of those times PPSh and PPS, then the ballistic performance of the 7.62x25 mm Mauser-Tokarev cartridge is a good order of magnitude better.

- lack of a barrel casing - during prolonged shooting it became heated to the point of being impossible to hold on to without gloves;

- the ergonomics of the weapon is not at the best level - the weapon is quite massive; the cocking handle is inconveniently placed on the left, which interferes with wearing the weapon on the chest (“presses” into the fighter’s chest); a weapon magazine protruding strongly downwards, making it difficult to conduct hidden fire from trenches and shelters (the shooter needs to stick his head out strongly when shooting);

- more complex cleaning in the field (compared to PPSh and PPS).

Finnish soldier with MP 38/40

Also, during combat operations on the territory of the USSR, a certain unreliability at sub-zero temperatures was revealed, but this is relevant not only for the MP 40.

This is interesting: before the start of World War II, the MP 38/40 submachine gun was supplied only for export - to Hungary, Finland, Romania, Spain, Yugoslavia, and Poland. The licensed release was launched in the USA, Turkey, Argentina and Austria.

Almost all of these shortcomings were leveled out in the post-war modification of the MP 40 - Star Z-45, but that’s another story and article.

Old developments and new design

This was not accidental, since by that time the company’s engineers already had a backlog in the form of the Erma 36 submachine gun they had created. The main developer of this weapon was Heinrich Volmer.

His outstanding innovation was the use of cold stamping from rolled sheets. At that time, no one else was doing this. It was on the basis of the Erma that he created the MP-38, from which the MP-40 assault rifle subsequently “grew.” There were no wooden parts, which greatly facilitated production; food was supplied from a sector detachable magazine with 32 rounds. It soon became clear that the progressive stamping technique only produced parts of not very high quality, and therefore manufacturers had to return to complex and expensive milling.

By the way, the Germans were unable to bring cold stamping technology to perfection throughout the war. At first they did not have a strict need for this, but after that they no longer had the resources and time. Hugo Schmeiser tried to rectify the situation: he took the MP-40 assault rifle, the technical characteristics of which we are describing, as a basis, creating his own MP-41. But it was already too late.

Application of MP 38/40. Wehrmacht weapons or captured partisan weapons? Post-war fate

This weapon was extremely widely used both by the satellites of Nazi Germany and by itself during the Second World War. In 1940, by order of the OKH, the submachine gun was adopted as the main individual small arms of junior officers of the infantry forces, tank crews, armored vehicle drivers and other troops.

Fighter Rosa Kachar NOAYU with captured MP 40

Due to the fact that the PPSh was more cumbersome than the MP 40, the latter was in good demand among the Soviet partisan and underground movement. Another advantage was the possibility of using silencers.

In addition to the Soviet underground, the submachine gun was actively used by parts of the French resistance movement "Maquis", Polish scouts, and Yugoslav partisans.

After the end of World War II, these weapons did not fall into oblivion, but were produced and actively used in various armed conflicts for a very long time. In Germany itself, they tried to forget about the MP 40 due to the fact that it was a weapon from the time of the Third Reich.

Soviet partisans with MP 40

The submachine gun was in service with the Norwegian army until 1990, the Hungarian army, the Yugoslav armed forces until the end of the 1950s, and the Turkish armed forces until the end of the 1980s; in France it was in service with the army, police and the French Foreign Legion. In England, the weapon was used by SAS special forces until the 1970s.

The massive use of weapons by all armed parties to the conflict occurred during the Vietnamese War of Independence. It was in service with the Israeli army until the 1970s and was actively used during the Arab-Israeli wars.

Colonel Lapshov with MP 40

The weapon was used during the Algerian War of Independence and during a series of wars in Iraq and Iran. The US Marine Corps and Airborne Forces used weapons during the war in Vietnam and Korea.

The weapon was used or produced in China, Pakistan, Afghanistan, Egypt, Portugal, Palestine, Ireland, Croatia, Chechnya.

So plural

Hugo or not Hugo?

Very often this weapon is called “Schmeisser”. The MP-40 assault rifle is more likely a “Volmer”, since Hugo Schmeisser himself had nothing to do with its creation. Well, except for the store design borrowed from his inventions. The famous gunsmith created the MP-18, MP-28 and, subsequently, the MP-41. By the way, the first two models never entered service with the German army. The generals (like their Soviet colleagues, by the way) considered submachine guns to be “toys” that could only be used by the police.

But the rise to power of Hitler, who, contrary to popular belief, was never a layman, allowed the gunsmiths to expand to their full potential. Already in 1938, they received a government order to create a submachine gun that could be used to equip troops, armored vehicle crews, gun service personnel, medics and other persons who were not entitled to a full-size rifle or carbine. Ultimately, the order went to the Erma company.

Comparative performance characteristics of MP36, MP 38, MP 41

| Model: | MP 36 | MP 38 | MP 40 |

| Caliber: | 9 mm | ||

| Cartridge: | 9x19mm Parabellum | ||

| Weight without cartridges, kg: | 3,96 | 4,18 | 3,97 |

| Weight with cartridges, kg: | 4,65 | 4,85 | 4,7 |

| Length with stock folded/unfolded, mm: | 620/831 | 630/833 | 864 |

| Barrel length, mm: | 248 | 251 | |

| Rate of fire, rds/min: | 600 | 800 | |

| Effective range, m: | 100 | ||

| Sighting range, m: | 200 | ||

| Initial bullet speed, m/s: | 360/380/400 | ||

| Years of production: | 1936 — | 1938–1940 | 1940–1944 |

Flaws

The invasion of the USSR revealed other shortcomings.

It turned out, in particular, that a low rate of fire with an excessively heavy bolt was a bad idea, since in the cold and even with slight contamination the automation stopped working. partially got out of the situation by starting to install a stronger return spring, but as a result of this, the rate of fire sharply increased and the reliability of the mechanics, which were not designed for such loads, decreased. So the MP-40 is an assault rifle that the Germans did not have time to “bring to mind” at that time.

Equipment

The standard package includes an 8.4 V battery, an instruction manual, a magazine for shells and shooting balls. The weapon manufacturer is required to provide a warranty card and a weapon passport. All of these elements must be requested by the buyer at the point of sale.

You should also pay attention to the presence of a special device that acts as a loading accelerator. The need to use this device is due to existing problems that may arise when manually loading a machine gun. The kit also includes a cleaning rod for cleaning weapons. Battery charger is not included.

Complete set of pneumatic automatic machine Schmeisser MP-40

Operation and combat use

The MP 40 was actively used in World War II by the troops of the Third Reich. Used in Poland, France, Italy, Africa, Holland, the USSR, etc. In 1940, by order of the General Staff of the Ground Forces (OKH), submachine guns were adopted as individual small arms for infantry (junior officers), vehicle drivers, tankers and some other categories of military personnel. It was also actively used by fighters of the Ukrainian Insurgent Army and served as a trophy in the USSR. It was especially often used by Soviet intelligence officers before the advent of the PPS as it was more compact and effective at short range than the PPSh.

0

American soldier with trophies

Additional accessories

Store filler (German: Magazinfüller). To facilitate full filling of the magazine with cartridges, a special device was used, consisting of a metal body, which was attached to the neck of the magazine. At the top of the device there was a lever with which the cartridges were recessed into the magazine. Winter trigger (German: Winterabzug). It was a box made of sheet metal with a removable side panel and a trigger, which was located below the standard trigger guard, which made it possible to press it with a mitten finger. At the front, such devices were extremely rare.

0

MP 40 submachine gun with winter trigger installed, right view

0

MP 40 submachine gun with winter trigger installed, left view

0

Winter trigger

0

Winter trigger with cover removed,

Silencers. As far as we know, silencers for the MP 38 and MP 40 submachine guns were not officially accepted into service, but there were several experimental versions. The mufflers were designated Hub L, and mufflers from Hub L41 to Hub L50 are known. In 1942, two types of mufflers were developed and tested. The first was developed and manufactured by Arado Flugzeugwerke from Brandenburg, it was designated Hub L41, the other, Hub L42, was proposed by the Berlin partnership of designers and entrepreneurs Opel Schneider. The length of the Hub L41 muffler was 295 mm, diameter 43 mm, weight 0.7 kg. The silencer involved the use of special nahpatrone 08 ammunition (close combat cartridge) with a reduced charge and a heavier bullet than the standard cartridge. The Hub L42 muffler weighed 0.6 kg with a diameter of 45 mm and a length of 350 mm. This muffler also required the use of nahpatrone 08. According to documents dated April 1944, approximately 1000 mufflers were manufactured, 500 Hub L41 and 500 Hub L42. Although the first type of mufflers was developed by Arado, all thousand mufflers were manufactured by Opel Schneider.