When you hear the word “mine,” your imagination immediately pictures an explosive device buried in the ground. First appearing in French, this word was originally associated with land and meant “mine”, “undermining”, which were often used during siege warfare. During military operations, fortified and protected cities were attacked with the help of trenches and approaches dug into their walls, followed by the placement of explosive charges filled with gunpowder. At first, a mine was used to describe an underground horizontal mine near the enemy’s walls; later, this word began to be used to refer to the explosive device itself. The word “sapper” also appeared in French. It was the name given to the person who undertook and undermined enemy fortifications.

Story

The use of explosive mechanisms filled with destructive elements in many wars has proven one hundred percent effectiveness of their use in eliminating fortified structures, enemy infantry and military equipment. Discoveries in the field of chemistry: the appearance of xyloidin, pyroxylin, liquid nitroglycerin, TNT and saltpeter - as well as mankind’s already rich experience in warfare - served as a good impetus for the improvement of explosive devices.

Primitive plantings under enemy walls using safety cords are a thing of the past. Their place was taken by modern products using special capsules - detonators and electric ignition systems.

Due to their secrecy, explosive mechanisms buried in the ground have always been considered very dangerous. But time has shown that their effectiveness is not one hundred percent, since the mine directly eliminated only the object that came into contact with it, and left others undamaged. A much better result could have been achieved if the mine had been above the ground. But in that case it would be visible. This shortcoming in the mine field required an immediate solution, which was the device called OZM-72. Let's take a closer look at it.

"Black Widow"

The PMN pressure anti-personnel mine has been in service with engineering units of the Russian Army since 1950, as well as a number of CIS countries and foreign countries. The “Black Widow,” as it was nicknamed by the American military during the Vietnam War, is a fairly powerful high-explosive mine. It is not equipped with damaging elements; damage to the target is caused by an explosive - 200 grams of TNT. The light weight of the product (550 grams) allows the sapper unit to stock up on these mines in reserve and quickly turn a wide area of terrain into an impassable “swamp” for enemy infantry.

Detonation, as the name suggests, occurs when the mine cover is pressed. Such an explosion results in death or very serious injuries. This mine could be found in any country affected by armed conflict in the second half of the last century. It was the PMN that deprived the leg of one of the leaders of the Chechen bandit underground, Shamil Basayev, when he and his accomplices were breaking out of Grozny in January 2000.

Mine OZM-72: performance characteristics (tactical and technical characteristics)

The type of device belongs to anti-personnel fragmentation explosive mechanisms that jump out with circular damage.

Steel is used to make the mine body.

The total mass is 5 kg, of which 660 g is explosive.

Diameter – 10.8 cm, body height – 17.2 cm.

The OZM-72 mine is designed for a weight of 1 to 17 kg, the temperature range of use is from –60 to +60 degrees, the damage radius does not exceed 30 m. The combat service life is not limited. The mine is not equipped with self-destructors and does not contain elements that would not allow it to be removed or neutralized.

GRAZM consisting of 4 people

This method is the simplest and is used in conditions of lack of strength and resources, on narrow roads (with a roadway of up to 4 m).

Numbers 1 and 2 check their half of the road and the side of the road using a mine detector and probe. The 3rd number and the GRAZM commander visually check the surrounding area for the presence of mines and landmines controlled by wires and radio - in bushes, trees, light poles, roadside buildings, etc.

The GRAZM may include a calculation of the MRS, moving 10-15 m ahead, searching across the entire width of the roadway.

In hot climates, the effective work time of an MRS dog is no more than 30 minutes. To complete the task in the recommended way, two MPC calculations are required, working alternately.

When the road width is more than 4 m, it is also advisable to use two MRS calculations working in parallel.

The 3rd number can search using the OSI device, alternately scanning one and then the other side of the road and the adjacent strip of terrain.

Design Features

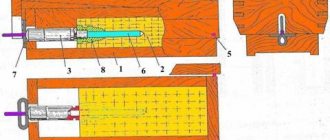

The elements of OZM-72 are:

- Guide glass. Steel is used for its manufacture. At the bottom of the glass there is a special chamber intended for attaching a tension cable connecting the glass to the impact mechanism. The glass contains a housing with an explosive charge and fragments.

- Charge. TNT is used as a charge for the OZM-72 mine, which fills the internal cavity of the clip. Located at the top of the central hub.

- Explosive charge. Designed to push an explosive device out of the ground to a height of 1 m. To make an expelling charge, black powder collected in a fabric bag is used. The charge is contained in a special tube.

- Impact mechanism. Located at the bottom of the central hub.

- Detonating capsule. It is placed in the socket of an additional detonator and is mounted only at the moment when the OZM-72 mine is directly installed.

- Carbines and cables. Designed for attaching explosive mechanism pins with guy wires.

- Wire stretchers. When installed, they are wound into coils and reach a length of up to 15 m. They are intended for arranging tripwire traps.

- Pegs made of wood and metal. Wooden stakes are used for arranging trip wires, and metal stakes are used for securing mines in frozen ground and installing a cable with carabiners. For the production of metal stakes, a duralumin corner is used.

Methods of neutralization

The technology for neutralizing a mine depends on the type of detonator installed. If a controlled fuse of the EDP-r type is used, then it is necessary:

- Disconnect the electric detonator from the control network.

- Unmask the mine and remove the fuse.

- Remove the device from the installation site.

If the MON-50 mine is equipped with an MVE-72 fuse, then its neutralization is impossible. In this case, it is destroyed by trawling in accordance with the instructions. When using less common fuses VZD-6ch or VZD-144ch (delayed action fuses), mine clearance is carried out exclusively by trained sappers in accordance with the instructions for this type of detonator.

Purpose

The OZM-72 explosive device is designed to completely eliminate or temporarily incapacitate enemy infantry. The degree of damage from fragmentation elements, which are metal balls, can be different: from eliminating one soldier to several. This became possible due to the fact that OZM-72 anti-personnel mines are hidden in the ground and are not visible from the outside. And the expelling charge in their mechanism throws up the device, which explodes above the ground at a height of 1 m with a circular lesion of up to 30 m.

Non-contact explosive device NVU-P2

The device is designed to register enemy personnel and control the detonation of one or a group of up to 4 ammunition. Used with anti-personnel fragmentation ammunition POB, anti-personnel fragmentation mines OZM-72 and MON-50. Provides alternate detonation of ammunition in autonomous mode, as well as selective or group detonation using a remote control.

Performance characteristics:

| Product contents: | |

| 1 | |

| 1 | |

| 4 | |

| 1 | |

| 24 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 0,1 | |

| 1 | |

| 1 | |

| Product type | non-contact, seismic operating principle |

| Overall dimensions max, mm: | |

| 200x110x62 | |

| 198x140x100 | |

| 130хØ145 | |

| 661x598x221 | |

| Weight max, kg: | |

| 1,55 | |

| 2,1 | |

| 2,2 | |

| 36,5 | |

| Long-range cocking time, min | 3,0 +- 0,3 |

| The product reacts to: | |

| Product response radius, m | up to 20 |

| The product does not work and remains operational: | |

| when vehicles pass at distances, m | over 30 |

| 50 | |

| over 20 | |

| over 50 |

The product provides:

- multiple, using the remote control, transfer to a safe state and back;

- repeated, using the remote control, switching to a combat state from autonomous mode to controlled mode and back;

- sequential detonation (up to four) of ammunition in autonomous mode;

- selective detonation and detonation of four ammunition in one gulp in a controlled manner;

- discrete setting by the remote control of the self-liquidation time of ammunition in autonomous mode for a period of 7, 14 or 28 days;

- monitoring the condition and modes of the product;

- light indication on the control panel: - about the condition of the product - combat, safe; - about the operating mode of the product - autonomous, controlled; — about the receipt of a command to detonate ammunition in autonomous mode; — about the appearance of a target in the response zone in a controlled mode; — about the integrity of the control line;

sound and light indication when a target appears in the response zone

Operating temperature range, °C - from -40 to +50.

Guaranteed shelf life - 10 years.

How does the OZM-72 mine work?

The principle of operation of the mine is to eject, with the help of an expelling charge, from a guide cup to a meter height a bursting steel shell consisting of metal, cylindrical pieces capable of scattering after an explosion within a radius of up to 30 meters. The mine is detonated upon contact with a trip wire attached by pegs and connected to the fuse pin.

It could be MVE-72. In this case, it is enough to touch the electrical wire connected to the pin. Also, an MUV is used as a fuse, which uses mechanics rather than electricity. To trigger a mine, the enemy needs to hook a stretched wire - a trip wire connected at one end to the fuse. Subsequent detonation produces an ejection above the ground from the charge cup, which is represented by a steel shell filled with TNT. When explosives interact, the shell forms round and cylindrical destructive elements that fly off in all directions.

Combat use

Army photos on Shutterstock: Army and military photos.

This mine began to be considered a very powerful weapon after its first combat use. It took place during the war in Afghanistan under tragic circumstances.

On April 20, 1984, in the Panjshir Gorge, during a military operation, paratroopers of the 2nd Parachute Battalion of the 345th Parachute Regiment landed. The OZM-72 mine, installed during previous hostilities, detonated. According to some reports, several dozen people became victims, although such losses are not listed in official reports. According to legend, after this the soldiers nicknamed the OZM-72 mine “The Witch.”

There are known cases when groups of reconnaissance and special forces, having completed a combat mission, planted a mine in advance on the retreat routes, on the way to the assembly point. The “spirits” chasing Soviet soldiers blew themselves up on it and died in dozens and stopped the pursuit.

The engineering shell was also actively used by federal troops during the first and second Chechen campaigns. Until the end of the 90s, the principle of operation of the mine was not clear to opponents. So, when the OZM-72 fell into the hands of the militants, they blew themselves up with it, trying to install it on the ground. Also, some sappers used the OZM-72 as an assault grenade when fighting in the city.

It was especially effective when liberating a building from the enemy, who occupied the upper floors of high-rise buildings. To do this, the cable connecting the bottom cover and the charge was unfastened or cut. Under the influence of the expelling charge, the striking elements of the OZM-72 jumped to a height of 18-20 meters, where detonation occurred.

Bookmark stages

How is OZM-72 laid? The explosive mechanism is installed manually into the ground or snow.

The bookmarking process consists of the following steps:

- arrangement of a hole with a diameter of up to 200 mm with further placement of a mine in it;

- installation of a detonating capsule;

- installing a metal peg at a distance of 50 cm from the mine;

- fastening the cable with carabiners to the guy wire;

- installing one wooden peg with a wire passed through it for the entire length; the end of the guy rope must be attached to the top of the second peg; It is imperative that the wire between the wooden stakes sag a little - 20-30 mm is enough;

- unscrewing the protective cap covering the mine igniter;

- bringing the fuse pins into combat condition;

- connecting the prepared trip wire to the fuse pin using a carabiner;

- camouflage of an installed mine.

2.5. Actions of the squad upon detection of a landmine installed in an uncontrolled version

- When a landmine installed in an uncontrolled version is detected (usually with the help of MRS crews, by a sapper with a mine detector), the sapper informs the group commander with a set signal. The group commander gives the command: “Prepare to repel the attack.” The sapper moves to a safe distance, while marking the boundaries of his verified area on the ground.2.5. Actions of the squad upon detection of a landmine installed in an uncontrolled version.

- The sapper who discovered the contactor carries out additional reconnaissance and the location of the landmine installation. A landmine is destroyed on the spot by an overhead charge. It is strictly forbidden to remove (remove) a detected landmine.

- After destroying the landmine. The area is being inspected. The sappers return to the designated boundaries of the checked areas and continue to carry out the task of reconnaissance of the route.

Installation recommendations

- The metal peg should be driven into the ground so that its upper part is not visible. To do this, its top with the wire threaded through it should protrude no more than 150 mm above ground level. In this case, you need to dig it in towards the enemy. This can be easily determined by the special recess in the metal peg. When installing an explosive device, it must be directed towards the mine.

- It is recommended to pull the safety pin out of the fuse only after checking the reliability of holding the combat pin.

- Once the carbine is hooked onto the pin, it should not be pulled out. If this happens, it means that the metal peg is driven in poorly and moves to the side, thereby reducing the tension of the guy wire.

- Installation of the OST-72 anti-personnel mine is easily carried out in soft soil in the summer, and in winter - in frozen ground with further camouflage with snow. If you have to work with very soft soil, which is typical for swampy areas, it is recommended to use boards no more than 15x15 cm. Their thickness should be 25 mm. The use of boards guarantees the reliability of the shell coming out of the steel cup.

The modern development of military production makes it possible to take into account all the strengths and weaknesses of explosive devices. Thanks to this, mines today are in service in a wide variety: from the simplest products with primitive fuses and weak explosive fillers to the most complex remote-controlled mechanisms, the development of which uses the latest scientific achievements.

SLINGSHOTS, hedgehogs, WIRE SPIRALS AND inconspicuous wire nets

Slingshots, hedgehogs, wire spirals and inconspicuous wire nets (WM) are used for installation on roads, in trenches, to cover passages and damage in barriers, as well as in swampy areas and in winter.

Portable wire fences: a – slingshot b – hedgehog

It takes 4 people an hour to make a slingshot. Material: poles 3.5 m long – 1 pc.; 1.5 m long – 6 pcs.; barbed wire – 7 kg.

It takes 1 man-hour to make a hedgehog. Material: stakes 1.5 – 3 pcs. long; barbed wire – 2.5 kg.

Wire fences are made from one row of stakes braided with five strands of barbed wire or reinforced with guy wires with an additional two or three horizontal threads stretched across them.

Wire fences

Installing 100 linear meters of reinforced wire fence requires 30 man-hours.

Material: single-strand barbed wire – 4–5 skeins; staples – 5 kg; stakes 175 cm long – 34 pcs.; stakes 70 cm long – 67 pcs.

The wire net on low stakes is made 4.5–6.0 m wide. The 70 cm long stakes are driven in rows at a distance of 1.5 m from each other in a checkerboard pattern with an elevation of 25–30 cm above the ground surface. Each row of stakes and spaces between the rows they are braided with wire in two threads, one thread stretches with loops.

Wire net on low stakes (spottykach).

The installation of 100 linear meters of wire netting on low stakes 6 m wide requires 120 man-hours. Material: single-strand barbed wire – 20 skeins; snobs – 15 kg; stakes 70 cm long – 350 pcs.

The abatis is made of trees with a diameter of at least 15–18 cm, which are felled (and the trees are not completely separated from the stumps) towards the enemy. It can be reinforced by mines and the braiding of trees with barbed wire.

Spiral wireThrow-in wireUnobtrusive wire networks (WM)

Natural obstacles included in the general barrier system are reinforced:

- Anti-personnel mines are installed in swamps, in places where gates can be constructed, and on trails. Existing roads are being destroyed or mined.

- Ascents and descents with a steepness of less than 45° are escarped or mined.

- Gullies with steep slopes of less than 2 m and a width of less than 5–6 m are brought to the size of anti-tank ditches.

- Anti-personnel mines are installed on the slopes into the ravine, at the bottom of the ravine and on its bank in the probable directions of enemy movement.

- Anti-personnel mines are installed in the forest, on clearings and roads, and rubble is also created.

Masking of barriers is achieved by choosing means for barriers and their locations in accordance with the nature of the terrain, using artificial masks and constructing false barriers. When laying minefields, the mines are camouflaged to match the background of the surrounding area. Crews to mine installation sites move along communication channels, trenches and existing paths. When installing mines on a grass surface in holes, the turf must be carefully rolled back and, after laying the mines, the areas with the grass surface must be carefully sealed, preventing soil from being scattered in the grass. Do not leave caps from under mines and fuses, milestones and indicators at the installation sites.