The appearance of tanks on the battlefield was one of the most important events in the military history of the last century. Immediately after this moment, the development of means to combat these formidable machines began. If we look closely at the history of armored vehicles, we will, in fact, see a history of confrontation between the projectile and the armor, which has been going on for almost a century.

In this irreconcilable struggle, one side or the other periodically gained the upper hand, which led either to the complete invulnerability of the tanks or to their huge losses. In the latter case, every time voices were heard about the death of the tank and the “end of the tank era.” However, today tanks remain the main striking force of the ground forces of all armies of the world.

Today, one of the main types of armor-piercing ammunition that is used to combat armored vehicles is sub-caliber ammunition.

Not just against armor

In addition to the armor-piercing projectile, a new 30-mm high-explosive fragmentation incendiary ammunition is also being developed.

It should also be lethal to light armored vehicles. This will be achieved thanks to the technology of non-contact detonation of a projectile in flight at a precisely calculated time. The automatic cannon will be able to create a real shower of fragments. This method is especially effective against infantry in trenches and other shelters. It will also come in handy when shooting at small drones. The optimal moment for the explosion of ammunition in the air will be calculated by the standard weapon control system of the combat vehicle. It will also send a detonation command to the optical sensor of the projectile through a special laser.

Bullet_3

25-mm armor-piercing finned sub-caliber projectiles M919

Photo: twitter.com

According to the developer, the advantages of such a scheme are its simplicity and low cost. It does not require complex modernization of the gun itself. Only a laser programmer will need to be installed on the combat vehicle.

According to news agencies, last year the Ministry of Defense ordered a trial batch of such ammunition for testing. They will be tested with guns for armored vehicles and helicopters, as well as with rapid-fire anti-aircraft guns.

Currently in Russia there are three main models of 30 mm guns. They are all designed for the same set of projectiles, which were created back in the 1970s and 1980s. Therefore, the development of new ammunition will increase the capabilities of several lines of equipment with guns of this caliber.

Concrete-piercing shells

Concrete-piercing shells are intended for firing at reinforced concrete defensive structures , strong stone and brick buildings adapted for defense, as well as strong enemy dugouts. Also, if necessary, concrete-piercing shells can be used for direct fire at tanks and other armored targets. The only modern tank in the world that has a concrete-piercing shell is the Abrams.

There are a huge variety of different ammunition in the world, which is associated with a constant arms race. This article does not contain the entire list. The following were missed: lighting, propaganda, incendiary, thermobaric, biological, chemical, nuclear shells.

Description

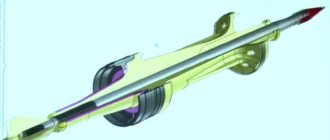

Feathered sub-caliber armor-piercing projectile. The process of separating the sectors of the pallet.

Sub-caliber armor-piercing shells are designed to destroy heavily armored objects, in particular tanks. Such a projectile, as a rule, has neither a fuse nor an explosive charge; its armor-piercing effect is entirely due to the kinetic energy of the projectile.

A sub-caliber armor-piercing projectile consists of a coil or other shaped body (pallet), into which a heavy core with a diameter usually about three times smaller than the caliber of the gun is inserted. The material for the core is metal-ceramic hard alloys, which have high strength and hardness. In the middle of the 20th century, this role was predominantly played by tungsten carbide; later, heavy alloy cores made of depleted uranium or tungsten alloys became widespread. The pallet ensures that the core is retained in the barrel, and serves as a kind of piston, taking on the gas pressure when fired, thereby ensuring acceleration of the entire projectile. Due to the smaller mass of the projectile than that of a conventional armor-piercing projectile, the muzzle velocity of the sub-caliber ammunition increases significantly (according to some data, up to 1700 m/s versus 800-1000 m/s), which provides increased armor penetration.

When a projectile hits the armor, a massive core punches a hole of small diameter in it, its kinetic energy is partially spent on destroying the armor, but mostly turns into heat. Fragments of the core and armor heated to high temperatures fly into the armored space in a diverging cone, striking the tank crew, disabling mechanisms and equipment and creating numerous fires. In addition, cores made of depleted uranium, due to their high pyrophoricity, spontaneously ignite upon destruction.

In terms of their action, sub-caliber armor-piercing projectiles have significantly greater armor penetration than caliber armor-piercing projectiles. During Operation Desert Storm, tank units of the US Armed Forces as part of the coalition forces used the M829 armor-piercing projectile - a depleted uranium sub-caliber projectile - to hit targets at distances of up to 3000 m.

Uranium Ammunition: Shells

The history of armored forces is the history of the confrontation between armor and projectiles. Periodically, one or the other opponent took the lead, which, as a rule, led either to the virtual invulnerability of the tanks, or, conversely, to significant losses. In the 70s, clouds gathered over the projectile. Although journalists, impressed by the significant losses of tanks from anti-tank missiles during the Arab-Israeli Yom Kippur War (1973), predicted the death of the tank, military analysts understood that this was one of the last wars in which tanks with traditional armor played a key role. monolithic steel. In all tank-building powers, the development of new armor structures based on multi-layer combined armor was in full swing. The USSR, which was significantly ahead of its opponents in this race, by that time had already been building T-64 tanks with combined armor for ten years (although they were not intended for export and did not participate in the 1973 war). The 105-mm cannon found on most NATO tanks of that period could not cope with these tanks. Work to increase armor penetration was carried out in several directions, one of which was depleted uranium (DU).

Literature

- Shirokorad A.

God of War of the Third Reich. - M.: AST, 2003. - Karman U.

History of firearms. - M.: Tsentrpoligraf, 2006. - Kozyrev M., Kozyrev V.

Unusual weapons of the Third Reich. - M.: Tsentrpoligraf, 2008. - 399 p. — ISBN 978-5-9524-3370-0; BBK 63.3(0)62 K59.

- Hogg Y.

Ammunition: cartridges, grenades, artillery shells, mortar shells. - M.: Eksmo-Press, 2001. - Irving D.

Weapons of Retribution. - M.: Tsentrpoligraf, 2005. - Dornberger V.

V-2. - M.: Tsentrpoligraf, 2004. - Katorin Yu. F., Volkovsky N. L., Tarnavsky V. V.

Unique and paradoxical military equipment. - St. Petersburg: Polygon, 2003. - 686 p. — (Military History Library). — ISBN 5-59173-238-6, UDC 623.4, BBK 68.8 K 29.

Story

The emergence of BOPS was associated with the insufficient armor penetration of conventional armor-piercing and sub-caliber projectiles for rifled artillery in the years after World War II. Attempts to increase the specific load (that is, lengthen their core) in sub-caliber projectiles encountered the phenomenon of loss of rotational stabilization when the projectile length increased beyond 6-8 calibers. The strength of modern materials did not allow the angular velocity of rotation of projectiles to be increased any further.

In 1944, for a 210 mm caliber gun of the K12(E)

German designers created a caliber projectile with a drop-down tail. The length of the projectile was 1500 mm, weight 140 kg. With an initial speed of 1850 m/s, the projectile was supposed to have a flight range of 250 km. A smooth artillery barrel 31 m long was created to fire feathered shells. The shell and gun did not leave the testing stage.

The most famous project using an ultra-long-range finned sub-caliber projectile was that of Chief Engineer Conders. Conders' gun had several names - V-3

, “HDP-High Pressure Pump”, “Centipede”, “Hardworking Lizhen”, “Buddy”. The 150 mm multi-chamber gun used a swept-finned sabot projectile weighing in different versions from 80 kg to 127 kg, with an explosive charge from 5 kg to 25 kg. The caliber of the projectile body ranged from 90 mm to 110 mm. Different versions of the projectiles contained from 4 folding to 6 permanent stabilizer feathers. The elongation of some projectile models reached 36. A shortened modification of the LRK 15F58 cannon fired a 15-cm-Sprgr swept projectile. 4481, designed at Peenemünde, and saw action, firing at Luxembourg, Antwerp and the US 3rd Army. At the end of the war, one gun was captured by the Americans and taken to the United States.

Feathered anti-tank gun shells

In 1944, the 8N63

80 mm caliber, firing a feathered cumulative projectile weighing 3.75 kg with an explosive charge of 2.7 kg. The developed guns and shells were used in combat until the end of World War II.

In the same year, she created the PWK smoothbore anti-tank gun. 10.H.64

caliber 105 mm. The gun fired a feathered cumulative projectile weighing 6.5 kg. The projectile and gun did not leave the testing stage.

Experiments were carried out on the use of high-velocity arrow-shaped sub-caliber projectiles of the Tsp-Geschoss type (from the German Treibspiegelgeschoss - sabot projectile with a pallet) for anti-tank warfare (see below “arrow-shaped projectiles of anti-aircraft guns”). According to unconfirmed reports, German developers at the end of the war experimented with the use of natural uranium in sub-caliber finned projectiles, which ended in vain due to the insufficient strength of unalloyed uranium. However, even then the pyrophoric nature of uranium cores was noted.

Anti-aircraft gun projectiles

Experiments with swept-finned sabot shells for high-altitude anti-aircraft artillery were carried out at a training ground near the Polish city of Blizna under the leadership of designer R. Hermann

). Anti-aircraft guns of 103 mm caliber with a barrel length of up to 50 calibers were tested. During the tests, it turned out that arrow-shaped finned projectiles, which reached very high speeds due to their insignificant mass, had insufficient fragmentation effect due to the impossibility of placing a significant explosive charge in them. [] In addition, they demonstrated extremely low accuracy due to the thin air at high altitudes and, as a result, insufficient aerodynamic stabilization. After it became apparent that swept-finned projectiles were not suitable for anti-aircraft fire, attempts were made to use high-velocity sabot-finned projectiles to combat tanks. Work was stopped due to the fact that serial anti-tank and tank guns at that time had sufficient armor penetration, and the Third Reich was living its last days.

A little history

The first anti-tank shells were ordinary metal blanks, which, due to their kinetic energy, pierced tank armor. Fortunately, the latter was not very thick, and even anti-tank rifles could cope with it. However, already before the start of World War II, tanks of the next generation began to appear (T-34, Matilda), with a powerful engine and serious armor.

The major world powers entered the Second World War with anti-tank artillery of 37 and 47 mm caliber, and ended it with guns that reached 88 and even 122 mm.

By increasing the caliber of the gun and the initial speed of the projectile, the designers had to increase the mass of the gun, making it more complex, more expensive and much less maneuverable. It was necessary to look for other ways.

And they were soon found: cumulative and sub-caliber ammunition appeared. The action of cumulative ammunition is based on the use of a directed explosion, which burns through tank armor; a sub-caliber projectile also does not have a high-explosive effect; it hits a well-protected target due to high kinetic energy.

The design of the sub-caliber projectile was patented back in 1913 by the German manufacturer Krupp, but their mass use began much later. This ammunition does not have a high-explosive effect; it is much more like a regular bullet.

The Germans began to actively use sub-caliber shells for the first time during the French campaign. They had to use such ammunition even more widely after the start of hostilities on the Eastern Front. Only by using sub-caliber shells could the Nazis effectively resist powerful Soviet tanks.

However, the Germans experienced a serious shortage of tungsten, which prevented them from mass production of such projectiles. Therefore, the number of such rounds in the ammunition load was small, and the military personnel were given strict orders: to use them only against enemy tanks.

In the USSR, serial production of sub-caliber ammunition began in 1943; they were created on the basis of captured German samples.

After the war, work in this direction continued in most of the world's leading weapons powers. Today, sub-caliber ammunition is considered one of the main means of destroying armored targets.

Currently, there are even sub-caliber bullets that significantly increase the firing range of smooth-bore weapons.

An awl instead of a sledgehammer

From the name it is clear that sub-caliber ammunition is a projectile with a caliber noticeably smaller than the caliber of the gun. Structurally, it is a “coil” with a diameter equal to the diameter of the barrel, in the center of which is the same tungsten or uranium “crowbar” that hits the enemy’s armor. When leaving the barrel bore, the coil, which has provided the core with sufficient kinetic energy and accelerated it to the required speed, is divided into parts under the influence of incoming air currents, and a thin and durable feathered pin flies towards the target. In a collision, due to its lower specific resistance, it penetrates armor much more effectively than a thick monolithic blank.

The armor impact of such “scrap” is colossal. Due to its relatively small mass - 3.5-4 kilograms - the core of a sub-caliber projectile accelerates to a significant speed immediately after being fired - about 1500 meters per second. When it hits the armor plate, it punches a small hole. The kinetic energy of the projectile is partially used to destroy the armor, and partially turns into thermal energy. Hot fragments of the core and armor exit into the armored space and spread like a fan, striking the crew and the internal mechanisms of the vehicle. In this case, numerous fires arise.

An accurate hit from the BOPS can disable important components and assemblies, destroy or seriously injure crew members, jam the turret, pierce fuel tanks, undermine the ammunition rack, and destroy the chassis. Structurally, modern sabots are very different. Projectile bodies can be either monolithic or composite - a core or several cores in a shell, as well as longitudinally and transversely multilayered, with various types of tail.

The leading devices (the same “coils”) have different aerodynamics; they are made of steel, light alloys, and also composite materials - for example, carbon composites or aramid composites. Ballistic tips and dampers can be installed in the head parts of the BOPS. In short, for every taste - for any gun, for certain tank battle conditions and a specific target. The main advantages of such ammunition are high armor penetration, high approach speed, low sensitivity to the effects of dynamic protection, low vulnerability to active defense systems that simply do not have time to react to a fast and subtle “arrow”.

Arrow-shaped handgun bullets

Arrow-shaped bullets for handguns were first developed by designer Irwin Bahr.

, "Springfield", "Winchester" various arrow-shaped bullets were designed, having an arrow mass of 0.68-0.77 grams, with an arrow body diameter of 1.8-2.5 mm with stamped tail. The initial speed of arrow-shaped bullets varied depending on their type from 900 m/s to 1500 m/s.

The recoil impulse of the rifles when firing arrow-shaped ammunition was several times lower than that of the M16 rifle. During the period from 1989 to 1989, many modifications of arrow-shaped ammunition and special weapons for it were tested in the United States, but the expected advantages over conventional jacketed bullets (both medium and small caliber) were not achieved. Arrow-shaped bullets of low mass and caliber with a high trajectory flatness, had insufficient accuracy and insufficient lethal effect at medium and long distances. grain) (19.958 g) in a detachable pan. With an initial velocity of a swept bullet of 1450 m/s, the muzzle energy of a sniper gun is 20,980 J. At a distance of 800 meters, a sub-caliber feathered arrow made of tungsten alloy pierces an armor plate 40 mm thick when hitting at an angle of 30°; when firing at a distance of 1 km, the maximum excess of the trajectory above the aiming line is only 80 cm.

Hunting arrow-shaped bullets

Most types of elongated bullets for hunting smooth-bore weapons have an aerodynamic principle of flight stabilization and are classified as arrow-shaped projectiles. Due to the slight elongation of conventional hunting bullets in most models (1.3-2.5 and even less (for example, the Mayer bullet, which is also stabilized not by a turbine, but by a lancet method)), the shootiness (sweptness) of hunting bullets is not visually obvious.

The Russian Zenit bullets (designed by D.I. Shiryaev) and foreign Sovestra bullets currently have the most pronounced arrow-shaped shape. For example, some types of Sovestra bullets have an elongation of up to 4.6-5, and some types of Shiryaev bullets have an elongation of more than 10. Both arrow-shaped feathered bullets with a large elongation differ from other hunting lancet bullets in their high accuracy of fire.

Arrow-shaped feathered bullets of underwater weapons

In Russia, underwater ammunition of an arrow-shaped (needle-shaped) shape without fins is being developed, which is part of the SPS cartridges of 4.5 mm caliber (for the special underwater pistol SPP-1; SPP-1M) and MPS cartridges of 5.66 mm caliber (for the special underwater assault rifle APS ). Unfeathered arrow-shaped bullets for underwater weapons, stabilized in water by a cavitation cavity, are practically not stabilized in the air and require special, rather than standard, weapons for use under water.

Currently, the most promising underwater aerial ammunition, which can be fired with equal efficiency both underwater at a depth of up to 50 m and in the air, is cartridges for standard (serial) machine guns and assault rifles, equipped with Polotnev’s arrow-shaped feathered bullet, developed by at the Federal State Unitary Enterprise "TsNIIHM". Stabilization of Polotnev's bullets under water is carried out by a cavitation cavity, and in air - by the feathering of the bullet.

ISBN 978-5-9524-3370-0; BBK 63.3(0)62 K59.

- Hogg Y.

Ammunition: cartridges, grenades, artillery shells, mortar shells. – M.: Eksmo-Press, 2001. - Irving D.

Weapons of Retribution. – M.: Tsentrpoligraf, 2005. - Dornberger V.

V-2. – M.: Tsentrpoligraf, 2004. - Katorin Yu. F., Volkovsky N. L., Tarnavsky V. V.

Unique and paradoxical military equipment. – St. Petersburg. : Polygon, 2003. – 686 p. – (Military History Library). – ISBN 5-59173-238-6, UDC 623.4, BBK 68.8 K 29.

MOSCOW, July 23 – RIA Novosti, Andrey Kots.

If a modern tank is fired at with an armor-piercing “blank” from World War II, then, most likely, only a dent will remain at the point of impact—through penetration is practically impossible. The “layered” composite armor used today confidently withstands such a blow. But it can still be pierced with an awl. Or “crowbar,” as tankers themselves call armor-piercing finned sabot projectiles (BOPS). Read about how these munitions work in the RIA Novosti article.

Armor-piercing and feathered

As sources in the defense-industrial complex told Izvestia, new armor-piercing finned sabot projectiles (BOPS) are being created for the Russian Armed Forces. Development work began last summer at the request of the Ministry of Defense. Testing of the new product begins this year. Its design and characteristics are not disclosed.

The ammunition should dramatically increase the effectiveness of high-velocity automatic guns against armored vehicles. The projectile can be used not only on ground combat vehicles. The same guns are installed on the Mi-28 and Ka-52 attack helicopters.

For army aviation, increasing penetration is especially important. Rotorcraft can hit armored vehicles with fire from above, where their protection is weakest. Therefore, even 30-mm BOPS can pose a threat to modern tanks. For lighter equipment they are completely deadly

The ammunition can easily penetrate the walls of strong buildings, which is especially important in urban battles.

Bullet_1

Cartridges for the 30-mm 2A42 cannon of the Mi-28NE helicopter

Photo: RIA Novosti/Vitaly Belousov

In addition to power, sub-caliber projectiles, due to their design features, have high impact speed and accuracy. This makes aiming easier and reduces the flight time to the target. It will no longer be possible to evade the BOPS, and it will be possible to hit the enemy with the first shots.

American Army Bradley-class infantry fighting vehicles, German Marder, Puma, as well as their modern Turkish and South Korean counterparts can withstand, as their manufacturers claim, hits from Soviet 30-mm shells in the frontal projection, Viktor Murakhovsky, editor-in-chief of Arsenal of the Fatherland magazine, told Izvestia .

“In this regard, the emergence of new ammunition is relevant. And the direction for modernization was chosen correctly,” the expert noted. — 30-mm guns continue to be installed on domestic and foreign infantry fighting vehicles and armored personnel carriers. This indicates the demand and prospects, including export, of the new projectile.

30-mm automatic cannons are now the most common in the Russian ground forces, navy and army aviation. The choice of this caliber was made back in the USSR. After careful research, it was found to be the most effective for combating enemy lightly armored vehicles, military historian Alexei Khlopotov told Izvestia.

Bullet_2

MRAP Cougar in service with the US Army in Iraq

Photo: commons.wikimedia.org

“All the main ammunition for guns of this caliber were developed quite a long time ago,” the expert noted. — Considering the trends, the need for new models was discussed back in the late 1980s, but their development was not started for a long time due to the economic problems that followed the collapse of the USSR. Since then, the protection of light military equipment has become much more reliable. Not only new alloys and types of armor appeared, even the appearance of the vehicles changed greatly. MRAPs are powerful armored vehicles for transporting personnel.

Standard ammunition is still coping with its task - destroying infantry fighting vehicles, armored personnel carriers and MRAPs. However, it is necessary to work for the future. BOPS will make it possible to fit them into existing dimensions with a significant increase in armor-piercing, explained Alexey Khlopotov.

In the 1990–2000s, several technically advanced countries developed BOPS for small guns. They are now in service with some NATO member states. An example is the common 25-mm M919 projectile, used in the ammunition of American M2 Bradley infantry fighting vehicles.

There is a known case when in 2003 in Iraq, such an infantry fighting vehicle burned an Abrams tank with “friendly fire” from its rapid-fire cannon. Its small projectiles penetrated the armor of the rear of the vehicle and damaged the engine and ammunition.

Caseless and jet

One way to radically improve modern weapons is to invent a reliable caseless cartridge. It will greatly simplify the design by eliminating mechanisms for automatically ejecting spent cartridges. Along with the cartridges, most of the causes of malfunctions in automatic weapons will disappear. And this is not to mention the fact that the ammunition load will become lighter. Since the average weight of a soldier's equipment has exceeded 30 kilograms, the weight of the cartridges is an important factor.

Cartridge with a “flying away” sleeve

You can get rid of the cartridge case, as a separate element of the cartridge design, by merging it with the bullet. This is what the Italian Bruno Civolani, the creator of the 9mm AUPO cartridge and the Benelli CB-M2 submachine gun, did in the 1980s.

Regular 9mm cartridge compared to 9mm AUPO

At the rear of the cartridge there was a “cup” filled with gunpowder, and along the wall there was a highly flammable “primer charge”. It detonated when the striker hit the wall of the “glass” and ignited the gunpowder. That, in turn, burned the diaphragm covering the bottom of the cartridge. Powder gases were released, and the bullet completely left the barrel.

Most likely, Civolani was inspired by the patent of the American Walter Hunt, the inventor of the Rocket Ball bullet, who lived in the 19th century, but it is unknown how the Soviet designer Vladimir Alekseevich Gerasimenko came to a similar decision.

For his VAG-73 pistol, Gerasimenko made an all-steel cartridge and developed a capsule that burned entirely. To prevent the ammunition from “eating” the rifling of the barrel, the designer equipped it with a leading brass belt, like on an artillery shell.

Unfortunately, nothing is known for certain about the characteristics of the VAG-73. The work was carried out on a proactive basis, and the pistol did not make it to testing.

One thing is clear - the fate of Gerasimenko’s pistol was predetermined from the very beginning - the cartridge would have been very expensive to produce. But the Benelli CB-M2 was tested by the military and received positive reviews, but was not allowed into mass production.

Jet Gyrojet

Another type of caseless cartridge is the “mini-rocket” of the American MBA Gyrojet pistol.

The body of this large (13x50 mm) steel cartridge is solid, but miniature holes are drilled at an angle in its bottom around the primer. Through them, the powder gases formed during the shot gradually escape, creating jet thrust. The space landing forces from the techno-fantasy universe of Warhammer will be armed with something similar in 38,000 years.

The creators of Gyrojet, Robert Maynard and Arthur Beale, sought to create a silent weapon that would outperform classic pistols. They partially succeeded.

A shot from the Gyrojet was practically silent, and at a range of fifty meters the energy was twice that of the Colt M1911 pistol ammunition. However, the Gyrojet bullet accelerated slowly - according to the recollections of the owners, at the exit from the barrel it could be stopped by substituting a palm.

In addition, the Gyrojet was not distinguished by its accuracy of fire. Unlike Gerasimenko, Maynard and Biel did not solve the problem of rifling wear and limited themselves to a smooth barrel. The “mini-rocket” was stabilized by the rotation obtained due to the swirling jet stream, and therefore easily strayed from its trajectory.

Some American soldiers bought the Gyrojet for the Vietnam War, but quickly became convinced of the uselessness of this weapon in real combat. As soon as a thin twig or dense foliage was in the line of fire, the trajectory of the shot shifted in an unpredictable direction. Instead of a low-noise and powerful weapon, the Gyrojet turned out to be a technical curiosity.

Armor-piercing sub-caliber projectile and its description

As we noted above, such ammunition is ideal for shooting at tanks. It is interesting that the sub-caliber does not have the usual fuse and explosive. The principle of operation of the projectile is entirely based on its kinetic energy. If you compare it, it is something similar to a massive high-velocity bullet.

The subcaliber consists of a reel body. A core is inserted into it, which is often 3 times smaller than the caliber of the gun. High-strength metal-ceramic alloys are used as core material. If previously it was tungsten, today depleted uranium is more popular for a number of reasons. During the shot, the entire load is taken by the pallet, thereby ensuring the initial flight speed. Since the weight of such a projectile is less than that of a conventional armor-piercing projectile, by reducing the caliber it was possible to achieve an increase in flight speed. We are talking about significant values. Thus, a finned sabot projectile flies at a speed of 1,600 m/s, while a classic armor-piercing projectile flies at 800-1,000 m/s.

Sub-caliber bullets

In addition to sub-caliber projectiles, there are also bullets that have the same design. Such bullets are widely used for 12 gauge cartridges.

12-gauge sub-caliber bullets have less mass, after firing they receive greater kinetic energy and, accordingly, have a greater flight range.

Very popular 12-gauge sub-caliber bullets are: the Polev bullet and the “Kirovchanka”. There are other similar 12 gauge ammunition.

story

Steel plates penetrated in tests by naval artillery, 1867

The late 1850s saw the development of the ironclad warship, which carried wrought iron armor of considerable thickness. This armor was virtually immune to both round cast iron cannonballs in use and to the newly developed explosive casing.

The first solution to this problem was carried out by Large Sir W. Palliser, who, with the Palliser shot, invented a method of hardening the head of a pointed cast iron shot. By casting the projectile point downwards and forming the head in the iron mold, the hot metal suddenly cooled and became very hard

(resistant to deformation through martensitic phase transformation), while the rest of the press - molds, are formed from sand, allowed the metal to cool slowly and the body of the shot to be

rigid

(resistant to crumbling).

These cooled iron shots proved very effective against wrought iron armor, but were not effective against compound and steel armor, which was first introduced in 1880. A new offset, therefore, had to be made, and forged steel rounds with water-hardened points take the place of the Palliser shot. At first, these forged steel rounds were made from ordinary carbon steel, but as armor quality improved, the projectiles followed suit.

During the 1890s and thereafter, steel armor became common, initially only on thicker armored ships. To combat this, the projectile was made from forged or cast steel containing both nickel and chromium. Another change was the introduction of a soft metal cover over the point of the shell - the so-called "Makarov Soviets", invented by the Russian admiral Stepan Makarov. This "cap" increased penetration by softening some of the impact of shock and preventing the armor-piercing point from being damaged before it struck the armored face or body shell from breaking. It can also aid penetration at an oblique angle, keeping the point from veering away from the face armor.

basic information

The key difference between sub-caliber shells and conventional armored shells is that the diameter of the core, that is, the main part, is smaller than the caliber of the gun. At the same time, the second main part - the pallet - is made according to the diameter of the gun. The main purpose of such ammunition is to defeat heavily armored targets. Usually these are heavy tanks and fortified buildings.

It is worth noting that the armor-piercing sabot projectile has increased penetration due to its high initial flight speed. The specific pressure when breaking through armor has also been increased. To do this, it is advisable to use materials that have the highest possible specific gravity as a core. Tungsten and depleted uranium are suitable for these purposes. Stabilization of the projectile's flight is achieved by fins. There is nothing new here, since the principle of flight of an ordinary arrow is used.

Free cheese

The armor penetration of a projectile, that is, the thickness of the armor that the projectile is capable of penetrating, depends to a large extent on the lateral load that the projectile can exert on the armor. And it is higher, the higher, on the one hand, its mass and, on the other hand, the smaller the diameter of the projectile. The emerging contradiction can be resolved by increasing the density of the core material. The main candidate here is tungsten, which has a density of 19.3 g/cm3, that is, almost 2.5 times more than steel. However, tungsten is expensive, rare and very labor-intensive to process. Depleted uranium, which has almost the same density (19.03 g/cm3), is much less machine-intensive and, moreover, is virtually free for any state with a nuclear program. True, it is slightly radioactive, very toxic (only five times less toxic than mercury), and besides, it is also pyrophoric, that is, it tends to ignite in air, especially in powder form when heated. This, of course, creates significant problems in the production of products from it.

Armor penetration indicators

Comparative assessment of armor penetration indicators is associated with significant difficulties. The assessment of armor penetration indicators is influenced by rather different methods of testing BOPS in different countries, the lack of a standard type of armor for testing in different countries, different conditions for placing armor (compact or spaced), as well as constant manipulations by developers of all countries with firing distances of the armor being tested, angles of installation of the armor before testing, various statistical methods for processing test results. Homogeneous rolled armor is accepted as a material for testing in Russia and NATO countries; composite targets are used to obtain more accurate results.

According to published data [ source not specified 644 days

], increasing the elongation of the flight part to a value of 30 made it possible to increase the relative thickness of the pierced rolled homogeneous armor of the RHA standard (the ratio of the armor thickness to the caliber of the gun, b/dп) to the following values: 5.0 in 105 mm caliber, and 6.8 in 120 mm caliber .

Russia

- BOPS Svinets-1 3BM59

- not announced, but since a projectile with a uranium core, compared to a tungsten one, has approximately 15-20% greater armor penetration, you can compare this projectile with the Svinets-2 3BM60 projectile to calculate that it has an armor penetration of about 700 mm / 0° and 350 mm/60°; available for the latest modifications 2A46. - BOPS Svinets-2 3BM60

– 600 mm/0°, 300 mm/60°; available for the latest modifications 2A46. - BOPS Mango-M

– 280 mm/60°, available for all modifications of 2A46. - BOPS Vacuum-1

– 900/0°; for the 2A82 gun. - BOPS lead

more than 1000 mm

a number of other US

- BOPS M829A1

for a 120 mm caliber gun (USA) - 700 mm; - BOPS M829A2

- 750 mm; - BOPS M829A3

- 800 mm; often mentioned over the years “800+” - M829A4

BOPS has not been announced; outwardly it is quite consistent with its predecessor. Referring to the words of the developer, they call it 770.

Germany

BOPS DM53 for the Rheinmetall L/55 cannon of 120 mm caliber with an increased barrel length Lstv = 55 klb. — 750 mm (D=2000 m). Projectile length 740 mm, diameter 22.7 mm, head length 84 mm (total from the end of the core to the beginning of the head 656 mm), weight about 5 kg.

Of the known BPS of other countries, no record-breaking ammunition has been observed in recent decades, which has little to do with the actual state of the situation, especially in the sense of additional data (for example, the number of shells and guns and the security of the carrier).

When polyethylene is more reliable than steel

After World War II, the area of cumulative projectiles began to rapidly develop, which soon achieved significant combat effectiveness. Old solutions for protecting tanks by increasing the thickness of the armor and obtaining stronger steels could not give the desired results, because the shaped charge cut through the armor like a knife through butter.

The pioneers of the trend were the Germans, and then all the leading countries of the world mastered these technologies.

In cumulative ammunition, at the moment of detonation under a pressure of half a million atmospheres, a narrow directed jet is formed, created by a special conical recess in the explosive. The speed of the jet is about 10 kilometers per second. The process is similar to washing away a pile of sand with water coming under pressure from a fire hose.

It is quite clear that there was practically no point in increasing the strength of the armor to protect the tank from cumulative ammunition. But the designers continued to search for optimal angles of inclination of the planes and increase the armor. For example, the forehead of the cast turret of the American M-48 Patton-3 tank, which appeared in the early 50s, had a thickness of 178 millimeters. Its British peer, the Concarron, carried approximately the same turret with a 200 mm thick gun mantlet. The Soviet main battle tank T-55 had a turret armor thickness of 200 millimeters. In the end, it came to 250–300 mm armor.

However, with the sides of the hull it turned out to be more difficult, since it was not possible to “dress up” the vehicle on all sides with 200–300 mm protection, because speed, maneuverability and maneuverability are also the most important characteristics that determine the survivability of the tank. And then protective screens of small thickness, about 10–15 millimeters, began to be used against cumulative ammunition.

Of course, the cumulative jet penetrates the screens without any problems. But due to the fact that there is a certain gap between the armor and the screen, the ammunition fires prematurely. And the jet, reaching the armor, loses a significant part of its energy and “fizzles out.” The effectiveness of this technique was low, allowing to increase the survivability of the vehicle by 8–10 percent.

Soviet tank builders made a significant step forward, using multi-layer armor for the first time in the world in the T-64 tank. Thanks to this, survivability jumped by a third. The armor of this tank is a “sandwich” - a low-density filler is placed between two armor plates, creating a flowing effect.

extinguishing role. And here, as they say, every housewife has her own recipe for baking a layer cake. Aluminum, ceramics, fiberglass, polyethylene, polyurethane, and other materials in various combinations and proportions can be used as filler. The cumulative jet, having passed the external armor plate, finds itself in a different environment with different physical and chemical properties. As a result, it becomes defocus and loses energy. The protective properties against cumulative ammunition of composite armor compared to homogeneous armor can be higher by 40 percent or more.

Varieties

There are different types of sub-caliber ammunition designs:

- With a non-detachable pallet (English: Armour-piercing, composite rigid, abbr. APCR) - they represent a projectile body made of light metal with a carbide core. The entire flight to the target, such a projectile passes as a single whole, and in the process of penetrating the target’s armor protection, only the core is involved, which separates from the pan when it collides with the armor. Relatively large aerodynamic drag (like that of a conventional armor-piercing projectile) with a small mass leads to a significant decrease in armor penetration and accuracy with distance.

- With a non-separable pan, for use with a conical barrel (Armour-piercing, composite non-rigid, abbr. APCNR) - the design of the pan ensures its collapse when passing through a specially designed conical barrel, thereby reducing the cross-sectional area of the projectile and reducing aerodynamic resistance.

- With a detachable sabot (English: Armour-piercing, discarding-sabot, abbreviated APDS) - the design of the projectile after exiting the barrel ensures that the sabot is torn off the core by the incoming air flow or, in the case of a rifled gun, by centrifugal force. Due to the small diameter of the core, low air resistance during flight is ensured.

- An armor-piercing feathered sabot projectile (English: Armour-piercing, fin-stabilized, discarding-sabot, abbreviated APFSDS) is a sub-caliber projectile with a detachable pan, where the core is equipped with a small fin to ensure flight stability and increase accuracy.

About cumulative

Such ammunition was first used by Nazi Germany in 1941. At that time, the USSR did not expect the use of such projectiles, since their principle of operation was known, but they were not yet in service. The key feature of such projectiles was that they had high armor penetration due to the presence of instantaneous fuses and a cumulative notch. The problem encountered for the first time was that the projectile rotated during its flight. This led to the dispersion of the cumulative arrow and, as a result, reduced armor penetration. To eliminate the negative effect, it was proposed to use smooth-bore guns.

When polyethylene is more reliable than steel

After World War II, the area of cumulative projectiles began to rapidly develop, which soon achieved significant combat effectiveness. Old solutions for protecting tanks by increasing the thickness of the armor and obtaining stronger steels could not give the desired results, because the shaped charge cut through the armor like a knife through butter.

The pioneers of the trend were the Germans, and then all the leading countries of the world mastered these technologies.

In cumulative ammunition, at the moment of detonation under a pressure of half a million atmospheres, a narrow directed jet is formed, created by a special conical recess in the explosive. The speed of the jet is about 10 kilometers per second. The process is similar to washing away a pile of sand with water coming under pressure from a fire hose.