Internal ballistics, shot and its periods

Internal ballistics is a science that studies the processes that occur during a shot, and in particular during the movement of a bullet (grenade) along the barrel.

Shot and its periods

A shot is the ejection of a bullet (grenade) from the bore of a weapon by the energy of gases formed during the combustion of a powder charge.

When a small weapon is fired, the following phenomena occur. When the firing pin strikes the primer of a live cartridge sent into the chamber, the percussion composition of the primer explodes and a flame is formed, which penetrates through the seed holes in the bottom of the cartridge case to the powder charge and ignites it. When a powder (combat) charge burns, a large amount of highly heated gases are formed, creating high pressure in the barrel bore on the bottom of the bullet, the bottom and walls of the cartridge case, as well as on the walls of the barrel and the bolt.

As a result of the gas pressure on the bottom of the bullet, it moves from its place and crashes into the rifling; rotating along them, moves along the barrel bore with a continuously increasing speed and is thrown out in the direction of the axis of the barrel bore. The gas pressure on the bottom of the cartridge case causes the weapon (barrel) to move backward. The pressure of the gases on the walls of the cartridge case and barrel causes them to stretch (elastic deformation), and the cartridge case, pressing tightly against the chamber, prevents the breakthrough of powder gases towards the bolt. At the same time, when firing, an oscillatory movement (vibration) of the barrel occurs and it heats up. Hot gases and particles of unburnt gunpowder flowing out of the barrel after a bullet, when meeting air, generate a flame and a shock wave; the latter is the source of sound when fired.

When fired from an automatic weapon, the design of which is based on the principle of using the energy of powder gases discharged through a hole in the barrel wall (for example, a Kalashnikov assault rifle and machine guns, a Dragunov sniper rifle, a Goryunov heavy machine gun), part of the powder gases, in addition, after the bullet passes through the gas outlet hole rushes through it into the gas chamber, hits the piston and throws the piston with the bolt frame (pusher with the bolt) back.

Until the bolt frame (bolt stem) travels a certain distance allowing the bullet to leave the barrel, the bolt continues to lock the barrel. After the bullet leaves the barrel, it is unlocked; the bolt frame and bolt, moving backward, compress the return (recoil) spring; the bolt removes the cartridge case from the chamber. When moving forward under the action of a compressed spring, the bolt sends the next cartridge into the chamber and again locks the barrel.

When firing from an automatic weapon, the design of which is based on the principle of using recoil energy (for example, a Makarov pistol, a Stechkin automatic pistol, an assault rifle model 1941), the gas pressure through the bottom of the cartridge case is transmitted to the bolt and causes the bolt with the cartridge case to move backward. This movement begins at the moment when the pressure of the powder gases on the bottom of the cartridge case overcomes the inertia of the bolt and the force of the return spring. By this time the bullet is already flying out of the barrel.

Moving back, the bolt compresses the recoil spring, then, under the influence of the energy of the compressed spring, the bolt moves forward and sends the next cartridge into the chamber.

In some types of weapons (for example, a large-caliber Vladimirov machine gun, a heavy machine gun model 1910), under the influence of the pressure of powder gases on the bottom of the cartridge case, the barrel first moves backward along with the bolt (lock) linked to it. Having passed a certain distance, ensuring that the bullet leaves the barrel, the barrel and the bolt are disengaged, after which the bolt, by inertia, moves to the rearmost position and compresses (stretches) the return spring, and the barrel, under the action of the spring, returns to the forward position.

Sometimes, after the firing pin hits the primer, there will be no shot or it will happen with some delay. In the first case there is a misfire, and in the second there is a prolonged shot. The cause of a misfire is most often dampness of the percussion composition of the primer or powder charge, as well as a weak impact of the firing pin on the primer. Therefore, it is necessary to protect ammunition from moisture and keep the weapon in good condition.

A lingering shot is a consequence of the slow development of the process of ignition or ignition of the powder charge. Therefore, after a misfire, you should not immediately open the shutter, as a prolonged shot is possible. If a misfire occurs when firing from an easel grenade launcher, then you must wait at least one minute before discharging it.

When a powder charge is burned, approximately 25-35% of the released energy is spent on imparting forward motion to the bullet (the main work); 15-25% of energy - for performing secondary work (plunging in and overcoming the friction of a bullet when moving along the bore; heating the walls of the barrel, cartridge case and bullet; moving moving parts of the weapon, gaseous and unburned parts of gunpowder); about 40% of the energy is not used and is lost after the bullet leaves the barrel.

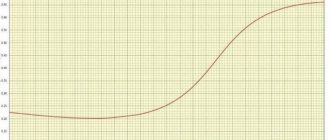

The shot occurs in a very short period of time (0.001-0.06 seconds). When firing, there are four consecutive periods: preliminary; first, or main; second; the third, or the period of aftereffect of gases (Fig. 1).

Shot periods: Po - boost pressure; Рм - highest (maximum) pressure: Рк and Vк pressure, gases and bullet speed at the moment of the end of gunpowder burning; Pd and Vd gas pressure and bullet speed at the moment it leaves the barrel; Vm - highest (maximum) bullet speed; Ratm - pressure equal to atmospheric

The preliminary period lasts from the start of combustion of the powder charge until the bullet casing is completely inserted into the rifling of the barrel. During this period, gas pressure is created in the barrel bore, which is necessary to move the bullet from its place and overcome the resistance of its shell to cut into the rifling of the barrel. This pressure is called boost pressure; it reaches 250 - 500 kg/cm2 depending on the rifling design, the weight of the bullet and the hardness of its shell (for example, for small arms chambered for the Model 1943 cartridge, the boost pressure is about 300 kg/cm2). It is assumed that the combustion of the powder charge in this period occurs in a constant volume, the shell cuts into the rifling instantly, and the movement of the bullet begins immediately when the boost pressure is reached in the barrel bore.

The first, or main , period lasts from the beginning of the movement of the bullet until the complete combustion of the powder charge. During this period, combustion of the powder charge occurs in a rapidly changing volume. At the beginning of the period, when the speed of the bullet moving along the bore is still low, the amount of gases grows faster than the volume of the bullet space (the space between the bottom of the bullet and the bottom of the cartridge case), the gas pressure quickly increases and reaches its greatest value (for example, in small arms chambered for 1943 - 2800 kg/cm2, and for a rifle cartridge - 2900 kg/cm2). This pressure is called maximum pressure. It is created in small arms when a bullet travels 4-6 cm. Then, due to the rapid increase in the speed of the bullet, the volume of the behind-the-bullet space increases faster than the influx of new gases, and the pressure begins to fall, by the end of the period it is equal to approximately 2/3 of the maximum pressure. The speed of the bullet constantly increases and by the end of the period reaches approximately 3/4 of the initial speed. The powder charge is completely burned shortly before the bullet leaves the barrel.

The second period lasts from the moment the powder charge is completely burned until the bullet leaves the barrel. With the beginning of this period, the influx of powder gases stops, however, highly compressed and heated gases expand and, putting pressure on the bullet, increase its speed. The pressure drop in the second period occurs quite quickly and at the muzzle - the muzzle pressure - is 300-900 kg/cm2 for various types of weapons (for example, for a Simonov self-loading carbine - 390 kg/cm2, for a Goryunov heavy machine gun - 570 kg/cm2) . The speed of the bullet at the moment it leaves the barrel (muzzle speed) is slightly less than the initial speed.

For some types of small arms, especially short-barreled ones (for example, a Makarov pistol), there is no second period, since complete combustion of the powder charge does not actually occur by the time the bullet leaves the barrel.

The third period, or the period of aftereffect of gases , lasts from the moment the bullet leaves the barrel until the moment the action of the powder gases on the bullet ceases. During this period, powder gases flowing from the barrel at a speed of 1200-2000 m/sec continue to affect the bullet and impart additional speed to it.

The bullet reaches its highest (maximum) speed at the end of the third period at a distance of several tens of centimeters from the muzzle of the barrel.

This period ends at the moment when the pressure of the powder gases at the bottom of the bullet is balanced by air resistance. Tags: fire training

TOPIC No. 3: Basics and rules of shooting.

LESSON #1: The phenomenon of a shot. Initial bullet speed. Trajectory and its elements. Direct shot. Normal (tabular) shooting conditions. The influence of external conditions on the flight of a bullet. Penetrating (killing) effect of a bullet.

A shot is the ejection of a bullet (grenade) from the bore of a weapon by the energy of gases formed during the combustion of a powder charge.

The gas pressure reaches its greatest value when the bullet is 4-6 cm from the beginning of the rifled part of the barrel. At this point, the pressure of the powder gases reaches 280-290 MPa. As a result, the speed of the bullet increases.

The initial velocity of a bullet is the speed of the bullet at the muzzle of the barrel. It depends on the length of the barrel, the mass of the bullet, the mass of the powder charge, its temperature, humidity and other factors.

When fired, the pressure of the gases on the bottom of the cartridge case causes the weapon (barrel) to move backward. This movement is called recoil. It is felt as a push in the shoulder, arm and ground.

In addition, when fired, the barrel of the weapon makes oscillatory movements (vibrates). Barrel vibrations, weapon recoil and other reasons lead to the formation of an angle between the direction of the axis of the barrel bore before the shot and its direction at the moment the bullet leaves. This angle is called the departure angle.

When moving in the air, a bullet is subject to the forces of gravity and air resistance. The force of gravity is directed downwards and causes the bullet to gradually lower, and the force of air resistance is directed towards the movement of the bullet and continuously slows down its movement, and also tends to tip its head back. Under the influence of these two forces, the bullet flies in the air not along the throwing line, but along an unevenly curved line located below the throwing line. The curved line that the bullet's center of gravity describes when flying in the air is called the trajectory.

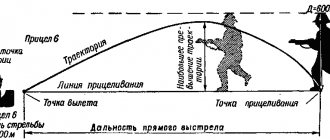

A shot in which the trajectory does not rise above the aiming line above the target throughout its entire length is called a direct shot.

In addition to gravity and air resistance, the flight of a bullet is influenced by atmospheric pressure, air humidity and temperature, and wind direction.

Atmospheric pressure decreases by an average of 9 mm Hg for every 100 m increase in terrain. Art. Therefore, when shooting in the mountains, the density and force of air resistance decrease, and the bullet’s flight range increases.

Changes in air humidity have a negligible effect on air density and, therefore, on the range of the bullet, so it is not taken into account when shooting.

As the air temperature increases, its density decreases, and as a result, the force of air resistance decreases and the flight range of the bullet increases.

With a tailwind, the bullet flies further than with no wind, and with a headwind, it flies closer.

When firing from the same weapon, due to a number of reasons, each bullet describes its own trajectory and has its own point of impact, which does not coincide with the others. Bullets are scattered. The phenomenon of bullet scattering is called natural dispersion.

Firing validity is the degree to which the firing results correspond to the assigned fire mission.

Gun shots and their effects on the body

When a gun is fired, three waves are formed: muzzle, ballistic and explosive.The guns have a muzzle brake, so the greatest air pressure after a shot is created on the sides of it. In addition, when firing from large-caliber guns, infrasounds are generated, which, together with the muzzle wave, can injure the ears.

There are three types of hearing organ response to gunfire:

- mechanical, when the eardrum is damaged due to a sharp increase in pressure;

- pain, which is caused by sharp irritation of the nerve endings in the eardrum;

- acoustic, which causes traumatic damage to the organ of Corti, which is accompanied by loud ringing in the ears.

An air shock wave is formed when shells, mines, etc. are fired and exploded. It can be muzzle, ballistic, or explosive.

A muzzle wave occurs as a result of the ejection of powder gases from the barrel bore under high (3000 atmospheres or more) pressure. They compress the surrounding air at the muzzle, creating a positive wave phase lasting several tens of milliseconds.

The resulting compression is transmitted to increasingly distant layers of air, which extends over a considerable distance. The positive phase then gives way to a negative phase when the pressure drops below atmospheric pressure.

The use of brakes attached to the muzzle of the barrel to reduce the recoil energy of the gun leads to the fact that the energy of the muzzle wave spreads to the sides, up, down and back and increases the possibility of hitting artillery crews, especially when the wave is reflected from surrounding objects (various buildings, trees and so on.). The larger the caliber of the gun, the higher the excess pressure in the positive phase.

The emergence of a muzzle wave is accompanied by the formation of high-intensity sound waves, and in large-caliber guns mainly low-frequency sounds arise, in small-caliber guns - high-frequency sounds.

A ballistic wave is formed due to the vibration of air particles caused by a flying projectile. Its energy is usually low, so its damaging effect affects only at close range (about 1 m).

A blast wave is formed at the moment of explosion of a projectile (mine, bomb, etc.) as a result of an extremely rapid (explosive) chemical transformation of solids into gases with the release of heat and the formation of heated gases compressed to several thousand atmospheres, expanding the compression front at a speed of up to 5-5. 25 km/s.

The blast wave, like the muzzle wave, is characterized by a two-phase action (compression phase and air rarefaction phase). As it propagates, its pressure and speed drop, and, ultimately, it turns into an ordinary sound wave with a predominance of infra- and ultrasonic frequencies in its spectrum.

The larger the area of the body, the stronger the damaging effect of the front of all types of air shock waves. The impact of a layer of compressed air causes short-term deformation of the human body and associated trauma to organs and tissues, which in mild cases leads to damage to the eardrums, and in severe cases it causes a closed craniocerebral injury and numerous injuries to internal organs.

Thus, when firing from guns, the artillerymen are affected by

- pressure changes,

- infra- and ultrasonic vibrations

- ultra-strong impulse noise (140-170 dB), characterized by a steep increase in sound pressure, short duration of action and a relatively slow decline..

The gas-flame jet that occurs when launching rockets, like the shock wave, causes an instant increase in pressure on the surface of the body and multiple lesions such as closed injuries. However, due to the longer duration of action (tenths of a second or a second), gas-dynamic pressure causes much more severe damage in the body, often incompatible with life, in addition, burns of varying degrees from the action of highly heated gas flows, as well as bruises and damage to various parts of the body in as a result of the knockback effect.

Powder gases flowing from the muzzle brake of artillery systems (especially recoilless rifles) to the sides and back create an additional danger of hitting artillery crews and friendly troops when placing guns in engineering structures (trenches, pillboxes, bunkers). Among the unfavorable factors should also be the contamination of clothing and skin with fuels and lubricants, both during the operation of moving objects of artillery equipment (artillery tractors, etc.), and during disassembly and cleaning of the material part of the guns.

Artillerymen need to use anti-noise during firing, learn to hide behind the gun shield during a shot (protection from a muzzle wave), tear off trenches and crevices to protect against enemy shell explosions and air bombs.

When firing from closed objects or ship casemates, when the wind blows from the front and blows powder gases into the room, there is a danger of poisoning the gun crew with powder gases, which contain a lot of nitrogen oxides.

Moreover, it must be taken into account that the clinical picture of poisoning by them can develop after a latent period (after 12-20 hours) and lead to death. With prolonged exposure to low concentrations of nitrogen oxides, chronic airway inflammation can develop.

Therefore, in such rooms, care must be taken to ensure proper supply and exhaust ventilation.

Shot. Explosion

A shot is the ejection of a bullet (projectile) from the bore of a firearm by the pressure of gases formed during the combustion of a powder charge. A charge of gunpowder, when burned, turns into gases with very high pressure and high temperature. When the pressure reaches a certain value, the bullet begins to move at an ever-increasing speed. Entering the air when leaving the barrel, the bullet, by inertia, retains the movement it received.

The science that studies the movement of a bullet (projectile) is called ballistics. Based on the nature of the forces acting on the bullet, ballistics is divided into internal and external. Internal ballistics studies the movement of a bullet in the barrel under the influence of powder gases and all the phenomena that cause and accompany this movement. It is designed to solve the problem: how to impart the highest speed to a bullet without exceeding the permissible pressure of powder gases in the bore of a weapon. External ballistics studies the movement of a bullet after the action of powder gases on it ceases after the bullet leaves the barrel. It solves the problem: at what angle to the horizon and at what initial speed should a bullet of a certain weight and shape be thrown in order for it to reach the target.

EXPLOSIVES AND THE PHENOMENON OF EXPLOSION.? Explosives are unstable systems and chemical compounds that are capable of rapid transformation into a gaseous state under the influence of minor external influences (impact, friction, injection, heating, etc.). The process of this very rapid chemical transformation of explosives into other, more stable substances is accompanied by the release of heat and a large amount of highly heated elastic gases, significantly exceeding the density of atmospheric air. Hot gases, the products of explosive decomposition, expand and are capable of producing large amounts of mechanical work in a short period of time.

An explosion is the phenomenon of an extremely rapid physical or chemical change in a substance, accompanied by an equally rapid conversion of its potential (latent) energy into mechanical work.

This work is carried out by the ejected gases, which tend to expand and thereby create a sharp increase in pressure in the environment surrounding the explosion site. A very sharp increase in pressure is a characteristic feature of an explosion. An accompanying sign of an explosion is a strong sound.

A chemical reaction accompanied by an explosion is called an explosive transformation.

CHARACTERISTIC SIGNS OF AN EXPLOSION. ?The short duration of the process is the speed of transition of explosives from a solid or liquid state to a gaseous state, i.e., to the final system of transformation products.

Depending on the chemical composition of explosives and the conditions under which the explosion occurs, explosive transformations occur at different speeds - from hundredths to millionths of a second. Thus, a charge of smokeless powder burns out in a rifle in 0.002 seconds, 1 kg of dynamite explodes in 0.00002 seconds. This rapidity of the explosive transformation process explains the enormous power of explosives compared to other energy sources, despite the fact that the energy reserve per unit weight of explosives is usually less than that of other combustible substances (oil, gasoline, coal, etc. .). An idea of the power of explosives can be obtained, for example, from the fact that the explosion of 1 kg of such a weak explosive as black powder is capable of producing work of 20 million horsepower, and 1 kg of TNT - about 55 million horsepower (assuming that all The heat released in this case will turn into mechanical work).

The formation of gases is the presence of a large number of gaseous explosion products capable of expanding and converting thermal energy into mechanical energy.

The amount of gaseous products released during an explosion at normal atmospheric pressure is expressed approximately by the following figures: 1 liter of pyroxylin produces 994 liters of gaseous explosion products; 1 liter of nitroglycerin - 1121 liters of gaseous explosion products; 1 liter of TNT - 1104 liters of gaseous explosion products.

From these figures it is clear that on average, during an explosion, 1 liter of explosives produces about 1000 liters of gas products.

TYPES OF EXPLOSIVE TRANSFORMATIONS. Depending on the chemical composition of the explosives and the conditions of the explosion, explosive transformations occur at different speeds at which rapid combustion, the explosion itself, and detonation can occur.

The rapid combustion of explosives is the process of explosive transformation that spreads throughout the entire mass of explosives at a speed of no more than a few meters per second. If this process takes place outdoors, it is usually not even accompanied by any sound effect. An example of this is the combustion in open air of, say, grains of black powder, which proceeds at a speed of 10-13 mm/sec.

In a closed volume, the combustion of explosives proceeds more vigorously than in air; Moreover, combustion in this case is accompanied by a sharp sound. A typical example of such an explosive transformation is the combustion of a combat charge of smokeless powder in the bore (velocity up to approximately 10 m/sec). Consecutive rapid combustion of explosives is accompanied by a more or less rapid increase in gas pressure in the barrel bore, which, as they form, spread in the direction of least resistance, while performing the work of moving and pushing a bullet or projectile out of the barrel bore.

The explosion itself is the process of decomposition of explosives, which occurs at enormous speeds, measured in hundreds of meters per second. Such an explosion is accompanied by a sharp increase in gas pressure at the explosion site, an impact of gases on the environment, which entails the splitting and crushing of surrounding objects located in the immediate vicinity of the explosion site. An example of this form of explosive transformation is the explosion of dynamite or compressed pyroxylin, which occurs at a speed of several hundred meters per second.

Detonation is a process that spreads through explosives at the maximum possible speed of explosive transformation, usually measured in thousands of meters per second. For example, the detonation speed of pyroxylin reaches 6800 m/sec, nitroglycerin - 8200 m/sec. By the end of the explosion, that is, by the time the entire charge has decomposed, the gases have not yet had time to expand and occupy the original volume of explosives. Because of this, enormous gas pressure immediately develops in all directions. Such a sharp jump in pressure and the impact of gases lead to the crushing of the obstacle into tiny pieces. Due to the fact that during detonation the gas pressure reaches an enormous value before the gases begin to spread along the line of least resistance, a destructive effect is also obtained in the case when the explosive charge is placed not inside the object being detonated, but outside. This property of detonation is widely used in demolition to destroy bridges, engineering structures, railway tracks, etc.

If an ordinary explosion occurs, as a rule, from the heating of explosives, then detonation in most cases occurs provided that the same or another explosive explodes in the immediate vicinity of the main charge (or even at some distance from it). An explosive that is capable of causing a detonation in another explosive is called a detonator.

CLASSIFICATION OF EXPLOSIVES ACCORDING TO THEIR APPLICATION. Depending on the application, explosives are divided into three large groups: initiating, high explosive (or crushing), propellant (or gunpowder).

Initiating explosives are distinguished by the fact that the usual form of their explosive transformation is complete detonation. In order to ignite a powder charge in a cartridge, you need a special explosive, called an initiating substance, which would give an initial impulse in the form of a beam from any external influence: impact, friction, heating a thread with electricity, etc. Therefore, initiating explosives are the most sensitive to external influences and easily explode from a slight blow, puncture, ray of flame, etc. They are used primarily for the manufacture of all kinds of igniters and equipment of primers used to initiate explosive transformations of other explosives.

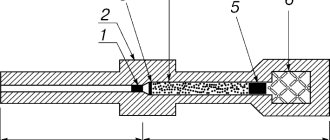

In small arms cartridges, to equip cartridge igniter capsules, an impact composition is practically used, consisting of initiating substances - a mixture of fulminate of mercury, berthollet salt and antimonium, which ignite upon impact. They are placed in a special device - an igniter primer or directly in the bottom of the cartridge case.

Cartridge capsules are filled with a percussion composition in a certain dosage. This is due to the following: on the one hand, an excessively strong charge of a detonator from fulminate of mercury cannot be made, since it can cause the detonation of not only crushing explosives, but also smokeless powders and, as a consequence, an accident; on the other hand, the igniter caps must be powerful enough to ensure the trouble-free operation of the combat charge.

High explosives, or crushing explosives, are those that, despite being relatively safe to handle, detonate without fail. They are usually detonated using caps of initiating explosives. The speed of explosive transformation of high explosives reaches several hundred meters per second. They are used as explosive charges for shells, aircraft bombs, mines and grenades. High explosives include pyroxylin, nitroglycerin, nitroglycol, dynamite, TNT, hexogen, etc.

Propellant explosives, or gunpowders, are those explosives whose transformations are characterized by rapid combustion, mostly occurring at a speed of several meters per second. Gunpowder is used in all types of firearms as a source of energy necessary to impart movement to the bullet (projectile). Therefore, of all types of explosives, gunpowder is of the greatest interest for shooting, which requires at least a general familiarization with their properties and features.

Based on their composition, physical and chemical properties, gunpowders are divided into two types: black powders (mechanical mixtures) and smokeless gunpowders (colloidal).

Smokey, or black, powder, in comparison with other types of currently known propellant explosives, is ballistically unfavorable and unproductive in terms of work: after the explosion, its powder gases increase their volume only 280-300 times the initial volume of the charge.

Therefore, smoked powders are not currently used as a propellant when shooting from automatic small arms, as well as when shooting bullets from rifles: they are completely replaced by smokeless powders.

SMOKLESS POWDER (COLLOIDAL). By the end of the 19th century, black powder, due to its low strength, could no longer meet the long-range requirements for firearms. It became quite obvious to military specialists that a further increase in the range of a weapon can be achieved by reducing its caliber with a significant increase in the initial speed of the bullet (projectile). This required the use of stronger propellant explosives.

The use of high explosives known at that time for throwing purposes was impossible due to the extremely high speeds of their explosive transformations. The search for new propellant explosives led to the discovery of the possibility of treating nitrocellulose (pyroxylin) with certain solvents, which made it possible to regulate the combustion rate of this strong explosive.

The chemical basis of smokeless powders are high explosives - pyroxylin and nitroglycerin.

Pyroxylin is made from substances rich in fiber or cellulose - cotton, wood, flax, hemp, etc., suitably treated with nitric and sulfuric acids. Pyroxylin is an almost white mass and does not differ in appearance from the material from which it is made.

Nitroglycerin is made from a mixture of pure dehydrated glycerin with nitric and sulfuric acids. It is a light, odorless liquid. Nitroglycerin is capable of dissolving some types of nitrocellulose.

The transformation of a high explosive - pyroxylin into a propellant - gunpowder is achieved by gelatinization. The gelatinization process consists in the fact that pyroxylin is treated with certain solvents, and therefore dramatically changes its physical basis, turning into a uniform plastic one, and then, when hardened, into a horn-like mass (solid colloid). Due to its greater density and viscosity, the explosive transformation of this mass occurs in the form of rapid combustion, as it becomes a propellant explosive.

Depending on the nature of the solvent used for gelatinization of pyroxylin, smokeless powders are divided into two groups: - smokeless pyroxylin powders, in which the solvents (volatile in nature) do not have explosive properties and are intended only to gelatinize pyroxylin, after which they are removed from the powder mass almost completely removed; - smokeless nitroglycerin powder, in which the solvent is nitroglycerin, which after gelatinization completely remains in the composition of the powder mass and forms a strong connection with pyroxylin.

Smokeless pyroxylin powders are made from a mixture of two types of pyroxylin: No. 1 and 2, which have different explosive properties. By changing the ratio of these two types of pyroxylin, the desired strength of smokeless powder and its burning rate are selected. So, for rifle powders, a mixture of one part pyroxylin No. 1 and one part No. 1 and 2 is used.

The technology for producing pyroxylin powders is as follows. Plant fiber (cellulose) is treated for a certain time and at a given temperature with a mixture of nitric and sulfuric acid. Then the so-called stabilization is carried out - removal of impurities - through several hot rinses. The resulting batches of nitrocellulose (pyroxylin) have different properties. To give the gunpowder more uniform properties, several batches of pyroxylin are mixed, which are then treated with an alcohol-ether (volatile) solvent. Under the influence of the alcohol-ether mixture, pyroxylin No. 2 dissolves, forming a sticky dense liquid (coldium), and pyroxylin No. 1 swells.

The swollen mixture is pressed through dies, obtaining various types of gunpowder: tubes, tapes, multi-channel cylinders. The gunpowder emerging from the matrices still contains up to 40% solvent, so before cutting it is dried at a temperature of 20-30 ° C for 24-48 hours. After cutting, the powder is sorted, dried for a second time, and dried. With thorough mixing, a plastic mass is formed, which is easy to machine and produce powder grains of the required shape and size.

To increase the rate of combustion of gunpowder, which is especially important for short-barreled weapons, it is made porous. For this purpose, powder grains can be in the form of a plate, tape, single-channel, multi-channel tubes, or cylinder. The shape of the grains of the powder charge in small arms cartridges is plate-shaped, tubular with one channel and granular with seven channels.

Powders whose grain surface area decreases as they burn are called degressive powders. This is, for example, a record and a tape.

Powders whose grain surface remains constant during combustion are called powders with a constant combustion surface (for example, a tube with one channel, a cylinder with one channel). The grains of such gunpowder burn simultaneously both inside and on the outer surface. The decrease in the outer combustion surface is compensated by an increase in the inner surface. So the total surface remains constant for the entire burning time, if you do not take into account the burning of the tube from the ends.

Powders whose grain surface increases as they burn are called progressive powders (for example, a tube with several channels, a cylinder with several channels). When the grain of such gunpowder burns, the surface of the channels increases. This creates a general increase in the burning surface of the grain until it disintegrates into parts, after which the process occurs according to the type of combustion of degressive-shaped gunpowder.

The advantage of pyroxylin powders compared to nitroglycerin powders is their relative safety in production, lower combustion temperature (2400 ° C), which extends the service life of the bore, and greater durability during long-term storage.

Smokeless nitroglycerin powder. In the manufacture of these types of gunpowder, the essence of gelatinization remains the same as for pyroxylin gunpowder. In this case, the solvent for pyroxylin is nitroglycerin, and both of these explosives in the gelatinized state are very closely related to each other.

The advantages of nitroglycerin powders, compared to pyroxylin ones, are as follows: speed of production (several hours instead of days); cheap to produce; more powerful action; greater physical stamina; greater adaptability to different conditions in which combustion occurs.

PHYSICAL AND CHEMICAL PROPERTIES OF SMOKELESS POWDERS. In appearance, smokeless powders are similar to horn or wood glue. Well-gelatinized gunpowder in thin plates and sheets is almost transparent. The color of gunpowder varies: from light yellow to dark brown. Fine-grained powders, when carefully treated with graphite (which is done to increase their density and prevent grains from sticking together), have a dark gray color and a shiny surface.

Smokeless powders are insoluble in water. Their hygroscopicity is insignificant. However, when storing smokeless powders in a damp place, their humidity increases (up to 2%), which reduces their ballistic properties, since water can displace nitroglycerin from the powder composition.

The specific gravity of different types of smokeless powders ranges from 1.55-1.63.

When burning gunpowder, there are three phases: ignition, ignition, combustion.

Ignition is the initiation of the combustion process in any part of the powder charge by quickly heating this part to the ignition temperature, which for black powder is 270-320°, for smokeless powder it ranges from 180 to 200°. As the temperature of the charge increases, the burning rate of the gunpowder increases, since the heat consumption required for heating decreases.

Ignition is the spread of flame over the surface of a charge.

Combustion is the penetration of flame into the depth of each grain of gunpowder.

A change in the amount of gases formed during the combustion of gunpowder per unit time affects the nature of the change in gas pressure and the speed of the bullet moving along the barrel. Therefore, for each type of cartridge and weapon, a powder charge of a certain composition, shape and weight is selected.

The powder charge of a rifle cartridge weighing 3.25 g burns out in approximately 0.0012 s when fired. When the charge burns, about 3 large calories of heat are released and about 3 liters of gases are formed, the temperature of which at the time of the shot is 2400-2900 °. The gases, being highly heated, exert high pressure (up to 290 Pa) and eject the bullet from the barrel at a speed of up to 900 m/s.

A certain amount of potassium nitrate is added to pyroxylin, which is washed out with hot water after cutting the gunpowder. When dissolved, it leaves pores in the grains of gunpowder. Depending on the required characteristics of the gunpowder, 45-220 parts by weight of saltpeter are added per 100 parts by weight of pyroxylin.

Smokeless powders have high productivity. Thus, 1 kg of gunpowder produces about 900 liters of powder gases during an explosion, which allows the pressure in the rifle barrel to develop up to 3200 atm.

Smokeless powders have significant strength and elasticity. The quality of smokeless powder is determined by how regular and uniform in shape and size the powder grains are - the uniform and regular formation of powder gases during a shot, and therefore the accuracy of shooting, largely depends on this.

Powder (combat) charges used in cartridge cases of domestic small arms consist mainly of smokeless pyroxylin powders. All data on gunpowder is entered into the passport, which is attached to each batch. Symbols consist of letters and numbers. The letters indicate the grain of the gunpowder, manufacturing technology, purpose, and the numbers indicate the size of the gunpowder, batch, year of manufacture, thickness of the gunpowder in tenths of a millimeter, number of channels. For example, P45 SV 1/75 K means that the gunpowder is porous (45 parts by weight of saltpeter are added per 100 parts by weight of pyroxylin), fresh, first batch, manufactured in 1975, K plant.

Sergey Monetchikov Photo by Vladimir Nikolaychuk