USSR rockets in WWII RS-82, M-8, RS-132, M-13

Work on the creation of unguided rockets in the USSR began in the late 20s. Various methods have been tried to stabilize the flight of a missile, from rotating it in flight, analogous to the rotation of a bullet, to stabilizing it using fins.

In the end, it was decided to switch to projectiles with four-blade tails; it was experimentally established that for the 82-mm RS the optimal tail span was 200 mm, and for the 132-mm RS 300 mm.

The calibers of Soviet rockets, 82 and 132 mm, were determined by the diameters of the powder bombs that were used in the jet engine. For an 82-mm projectile, 5 pieces with a diameter of 24 mm could be placed in the cylinder.

Simultaneously with the missiles themselves, their launchers were being tested. Their development followed the path of reducing drag on air flow, ensuring the reliability of projectile deflection and ease of operation. The use of groove-type launchers significantly improved the aerodynamic and operational characteristics of projectiles, simplified their manufacture, ensuring high reliability of projectile deflection. However, along with serial ones, a significant number of semi-makeshift launchers for 82-mm and 132-mm rockets were manufactured.

| 132 | ||

| Projectile length, mm | 620 | 935 |

| Explosive weight, kg | 0,36 | 0,90 |

| Rocket fuel weight, kg | 1,1 | 3,8 |

| Total projectile weight, kg | 6,8 | 23,0 |

| Projectile speed, m/s | 340 | 350 |

| Mach range, km | 6,2 | 7,1 |

| Radius of continuous destruction by fragments, m | 6-7 | 9-10 |

| Scattering when shooting at the name. targets from 1000 m | 14-16 | 14-16 |

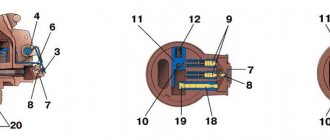

1 - fuse retaining ring, 2 - GVMZ fuse, 3 - detonator block, 4 - explosive charge, 5 - head part, 6 - igniter, 7 - chamber bottom, 8 - guide pin, 9 - powder rocket charge, 10 - rocket part , 11 — grate, 12 — critical section of the nozzle, 13 — nozzle, 14 — stabilizer, 15 — remote fuse pin, 16 — AGDT remote fuse, 17 — igniter.

Combat use

The first combat use of rockets took place on August 20, 1939 on the Khalkhin Gol River, by a flight of five I-16s armed with PC-82 rockets.

At 16:00 in the afternoon, Soviet pilots I. Mikhailenko, S. Pimenov, V. Fedosov and T. Tkachenko, under the command of Captain N. Zvonarev, flew out to carry out a combat mission to cover our troops. Over the front line they met Japanese fighters. At a signal from the commander, all five fired a simultaneous salvo of missiles from a distance of about a kilometer and shot down two Japanese planes. Soviet “missile-carrying fighters” took part in fourteen air battles and shot down thirteen Japanese aircraft in 9 days. Captain Zvonarev's unit did not lose a single vehicle.

This was, of course, a resounding success, however, it was facilitated by an extremely successful combination of circumstances - the Japanese, who did not know about the new Soviet weapons, flew horizontally at a constant speed in a tightly closed formation. In a maneuverable battle, a pilot using the RS-82 had virtually no chance of hitting an enemy fighter; it is for this reason that rockets in the Second World War were used in a massive attack either against bombers or when attacking ground vehicles.

In 1942, the PC-82 and PC-132 aircraft rockets were modernized and received the indices M-8 and M-13, however, the designers were unable to significantly improve their accuracy or reduce dispersion.

The average percentage of RS-82 hits on a tank from a distance of 400-500 meters was 1.1%, and on a tank column - 3.7%. At the same time, the RS-82 could defeat German light tanks such as Pz II Ausf.F, Pz 38(t), or Sd Kfz 250 armored vehicles only with a direct hit. An RS-82 explosion in the immediate vicinity of the tank (0.5-1 meters) did not cause any damage to it.

The results of the RS-132 firing were even worse. The attack conditions were the same as when firing the PC-82, but the launch range was 500-600 meters. The probable circular range deviation of the PC-132 at IL-2 gliding angles of 25-30° was approximately 1.5 times higher than for the PC-82. To destroy a light and medium German tank with a PC-132 shell, only a direct hit was required, but achieving a direct hit was extremely difficult.

Soon after the start of the war, new types of missiles appeared in the arsenal of Il-2 attack aircraft: RBS-132, which has an armor-piercing warhead to combat enemy armored vehicles, and ROFS-132 with improved accuracy of fire compared to RBS-132 or PC-132 . The low firing accuracy was also explained by the low speed of the rocket; for the RS-82 and RS 132 it did not exceed 340-350 m/sec. At the same time, the German R4/M Orkan missile had a flight speed of 525 m/sec, and their use against allied bombers was regarded as very successful.

The rockets were quite successful against enemy personnel and vehicles located outside of shelters. The main targets of ROFS-132 were thus large area targets - motorized columns, railway trains, warehouses, field and anti-aircraft artillery batteries.

During the Second World War, a single-seat Il-2 attack aircraft could carry eight RS-82 or RS-132 - four on each half-wing. The two-seater aircraft carried only four RS-82s or four RS-132s. In addition to the RS-82 and RS-132, the anti-tank RBS-82 was also used in aviation. The MiG-1, MiG-3, LaGG-3, Pe-3 fighters, as well as the Yakovlev and Lavochkin fighters - three on each half-wing - were also armed with rockets. On the Su-6 attack aircraft - ten RS-132, on the Il-10 - six RS-82 or RS-132, on the Pe-2 dive bomber - four RS-132, eight RS-82, on the Tu-2 - ten RS- 132.

WWII ammunition: German grenades, mines, shells

On the Antik1941 website you can purchase authentic models of German ammunition. This is an unloaded, completely deactivated weapon!

Here you will find models of grenades. machine gun belts, anti-tank missiles, etc. We provide a description of some of them below.

Hand grenade Stielhandgranaten 24

M-24 During World War I, the Stielhandgranaten 15 (16) grenade was developed and entered into service with German troops in 1916.

This hand grenade was a remote-action fragmentation-offensive grenade and was intended primarily to destroy enemy personnel with fragments and a shock wave.

In 1923-1924, minor changes were made to the previous design, as a result of which the grenade received the name Stielhandgranaten 24, and was produced in this form until the end of the Second World War. device Stielhandgranaten 24 1 – body, 2 – grenade handle, 3 – threaded adapter, 4 – cap, 5 – explosive charge, 6 – detonator capsule, 7 – adapter threaded igniter sleeve, 8 – grating igniter, 9 – wire loop, 10 – ceramic ring, 11 – cord, 12 – cap spring, 13 – high explosive, 14 – mercury fulminate, 15 – distance compound, 16 – grater mechanism. device Stielhandgranaten 24 1 – body, 2 – grenade handle, 3 – threaded adapter, 4 – cap, 5 – explosive charge, 6 – detonator capsule, 7 – adapter threaded igniter sleeve, 8 – grating igniter, 9 – wire loop, 10 – ceramic ring, 11 – cord, 12 – cap spring, 13 – high explosive, 14 – mercury fulminate, 15 – distance compound, 16 – grater mechanism. The Stielhandgranaten 24 hand fragmentation grenade is designed to destroy manpower in offensive and defensive combat, and in combination it could be used to combat armored targets, destroy obstacles and firing points.

In Russian and English-language literature, the Stielhandgranaten 24 grenade is referred to as M-24 (in German documents it was designated as Stiel. Hgr 24). In the German troops, the grenade received the nickname “macker”; in the Anglo-American troops it was often called a “potato masher” or “potato masher”. The Stielhandgranaten 24 grenade consists of a body with an explosive, a wooden handle with an ignition mechanism and a detonator. The grenade body was stamped from sheet steel with a sheet thickness of 1 mm. It is a glass with a closed bottom, in the center of which a central tube is pressed and a bushing is attached for screwing in the handle. A bursting charge and a detonator capsule are placed inside the housing. A substance based on ammonium nitrate (dynamon, ammonal) was used as an explosive. The ignition mechanism is a rubbing type mechanism. The grating mechanism includes a grating device and a pull cord. There is a white porcelain ring at the lower end of the lanyard. The upper end of the lace is attached to the grater of the grating device. The grating device is a tube in which the grating composition is located. A grater—a wire spiral—passes through the grating composition. A bushing is screwed into the tube, in the central channel of which a powder retarder is located. Before use, a detonator cap is inserted into the sleeve. The wooden handle has threaded bushings on both ends. The upper bushing is used to mount the grating device in it, as well as to screw on the grenade body. A safety cap is screwed onto the lower bushing. Inside, the handle has a through channel in which the pull cord of the grater mechanism is placed. The grenade body was painted in field gray or dark green tones, the finishing coating was applied to a surface previously primed with red paint. In this form, the grenade is used as an offensive one. Stielhandgranaten 24 as a defensive grenade Stielhandgranaten 24 as a defensive grenade fragmentation defensive jacket defensive shirt To use the Stielhandgranaten 24 as a defensive grenade, a steel jacket with notches made of a fairly thick metal or metal-ceramic composition was put on its body. To prepare the grenade for battle, you need to unscrew the body from the handle, insert detonator cap No. 8 into the body with the barrel facing the handle and screw it back to the handle. To use the grenade, you need to unscrew the cap at the bottom of the handle. A white porcelain ball will fall out of the handle on a silk cord. You should vigorously pull the string, holding it by the ball, and immediately throw the grenade at the target. If the grenade does not explode within the next 10-30 seconds, then it is not dangerous further. When you pull out the cord connected to the wire grater, the latter, being curled into a spiral, passing through the hole in the cup, straightens, creates friction and ignites the grater composition. The flame of the grating composition ignites the powder pulp of the moderator, which burns for 4.5-5 seconds. The fire from the powder pulp will be transferred to the detonator cap (fuse), which, when exploding, causes the detonation of the grenade's explosive charge. The explosion slowdown time was 4.5 - 5 seconds (very often the explosion occurred after 8 seconds). Grenade weight, g 500 Charge weight, g 160 Explosive type dynamon, ammonal Grenade length, mm 360 Grenade body length, mm 75 Grenade body diameter, mm 60 Throwing range, m 35 - 40 Deceleration time, s 4.5 - 5 Grenade weight combined with a comfortable handle and rational placement of the center of gravity, it provides a throwing range of 35-40 meters for a soldier of average physical ability. Well-trained and physically strong soldiers throw a grenade at a target at a distance of 60-65 meters. The guaranteed scattering range of fragments in the offensive version is 10-15 meters, in the defensive version up to 30 meters. Individual fragments can fly at a distance of more than 100 meters. Carrying Stielhandgranaten 24 grenades in combat conditions could be carried out in several ways: - behind the waist belt (the most common method); — behind the front belt straps; — in special canvas pouches slung over the shoulders, 6 pieces each; - tied in pairs with a cord (by the handles) and thrown over the neck; - in the shoulder version, attached to the ammunition (with the help of an additional belt); - in the tops of boots.

The Stielhandgranaten 24 grenades were stored in an incompletely loaded form (the detonators were stored separately). Due to the fact that wartime grenades were filled with surrogate explosives based on ammonium nitrate, it was necessary to ensure that the shells were not exposed to moisture. During the external inspection, special attention had to be paid to: the serviceability of the detonator caps and the integrity of the housings. The grenades were placed in special metal (by the end of the war wooden) boxes of 15 pieces, including 5 grenades that had a defensive metal jacket. The weight of the box with grenades was 15 kg. A label was glued on the outer surface and on the inside of the lid of the boxes and the following inscriptions were applied using a stencil method: - Option 1: 15 Stielhgr 24 15 Bz 15 SPR. Kaps Nr 8 Heeres-Munition Gesamtgewicht 15 kg, where 15 Stielhgr 24 - 15 hand grenades of the 1924 model, 15 Bz - 15 graters, 15 SPR. Kaps Nr 8 - 15 blasting caps No. 8, Heeres-Munition Gesamtgewicht 15 kg - ammunition total weight 15 kg. - Option 2: 5 Stielhgr 24 mit Splittering ver schen, where 5 Stielhgr 24 mit - 5 hand grenades arr. 24, Splittering ver schen - with defensive shirts. A stamp in the form of an imperial eagle was applied to the upper part of the body of the Stielhandgranaten 24 grenade with white paint; the order number and year of manufacture were applied by embossing, for example “ЯR905/1940”. The inscription “VOR GEBRAUCH SPRENGKAPSEL EINSETZEN” (install a detonator cap before use) was stenciled with white paint on the side walls of the grenade bodies.

The markings on the grenade handle repeated the markings on the body, but applied in the form of an extruded mark. The Stielhandgranaten 24 hand grenade was a simple and reliable close-combat weapon. The grenade design, developed and tested in the First World War, which at one time was one of the most successful and advanced, by the beginning of the Second World War was already clearly outdated.

However, this type of grenade was produced and used until the end of World War II. It should also be noted that, despite the constantly worsening situation at the fronts and the emergence of new, simpler and cheaper analogues of this grenade, the original version of Stielhandgranaten 24 was not taken out of production. This was facilitated by the simplicity of the design and streamlined production. In total, during the Second World War, more than 75 million units of Stielhandgranaten 24 grenades of all variants were manufactured. The grenades were stored and transported in wooden boxes of 30 pieces in an incompletely equipped form (fuses and detonator caps separately). Special nest-cages were made in the boxes. The boxes were stenciled with the following inscription: “Heers-Munition Gesamgewicht 12.5 kg” (Ammunition Total weight 12.5 kg). In addition, the label “30 Stuck Eihandgranaten 39 Zum Gebrauch 30 BZ fur Eihgr 39 und 30 Sprengkapseln Beipacken Wdg abgenommen Wdg” was pasted on. 1942 Ltg" (30 pieces of egg-shaped hand grenades model 39, 30 grate igniters for the egg-shaped grenade 39 and 30 detonator caps in a bag). The final equipment was produced at the battalion ammunition supply point, and was issued to the soldiers in the final equipped form.

However, the Stielhandgranaten 24 grenade had a number of disadvantages: Firstly, the explosive charge was susceptible to dampness and was also subject to caking (caking of explosives plays a role only during long-term storage, which is unlikely during war). This led to quite a few failures. It was difficult to achieve complete sealing of the housing in wartime production conditions. Secondly, the grating fuse was afraid of dampness. Also, if the ignition cord was not pulled out sharply enough, the grating composition did not ignite, and the grenade did not explode. Such a grenade could simply be thrown away. Thirdly, after pulling out the ignition cord, the grenade had to be thrown without fail, because after 4.5-5 seconds an explosion followed (in reality the explosion occurred only after 8 seconds).

Hand grenade Eihandgranaten 39

The Eihandgranaten 39 (M-39) hand grenade was a type of remote-action fragmentation offensive grenade with a grating fuse.

The grenade was adopted by the Wehrmacht in 1939 and was used by Germany throughout the Second World War. Until the end of the war, about 80 million grenades of this type were produced.

In appearance, it looks like a large egg and was an almost exact copy of the French OF 15 grenade of the 1915 model, but with a German-style grating type fuse. Structurally, the grenade consisted of an egg-shaped metal body, an ignition device and a detonator. The body of the grenade was stamped from two halves of thin iron, one of which contained a connecting tube with a sleeve for the detonator. The channel of the connecting tube has a thread for connecting the frame of the ignition mechanism to the grenade body. At the bottom of the body, late-release grenades have a loop with a ring for ease of wearing. Typically, grenades were hung in a ring from the straps of standard cartridge pouches to a Mauser carbine. The body was filled with an explosive substance - amatol (a mixture of ammonium nitrate and TNT). The ignition mechanism, in turn, consists of a frame in which there is a moderator, a detonator, a grater with a pull cord and a safety cap strip and a clamping nut. The grenade is equipped with a standard BZE grating fuse (BZE – Brennzünder für Eihandgranate). It consists of a body, a rubbing mechanism, a bushing with a retarder and a detonator capsule number 8 - Sprengkapsel Nr.8 (SPR. Kaps. Nr.8).

A nut is screwed onto the metal body, with which the fuse is screwed into the grenade body. Sometimes the nuts were equipped with claws for ease of screwing or unscrewing. There is a grating mechanism inside the body. At the bottom of the body there is a thread for screwing in a bushing with a powder retarder. During storage of the grenade, a safety thimble was screwed onto the sleeve. At the battalion ammunition supply point, before being given to the soldiers, the thimble was removed, and the detonator cap was screwed directly onto the sleeve.

The grating mechanism of the BZE fuse consists of a cap, a wire float with a cord and a capsule with a grating compound located in the upper part of the body. A wire float is passed through a grating compound. The second end of the lace is attached to the cap.