History of creation

At the beginning of 1942, Korshunov S.G. GSKB-30 at plant No. 58 named after. Voroshilov developed an offensive-type grenade for the new UZRG fuse of the E.M. Viceni system. The development was supposed to replace the RGD-33 and RG-41 that were in service at that time. The main reason for the creation of the RG-42 was the need to simplify the design of existing grenades in service, as well as the need to increase their industrial production.

RG-42 grenade

After the grenade was put into service, it received the index RG-42 (hand grenade model 1942).

Due to its extreme simplicity, the grenade was produced not only at arms factories, but also at a variety of factories and enterprises, which had equipment for spot welding and stamping in their arsenal. For example, these were canning factories.

Design

Structurally, the grenade is very simple and technologically advanced and is similar in many elements to the RG-41. It consists of a thin-walled cylindrical body, inside of which an explosive and a fuse are placed. The housing is closed at the bottom with a flat bottom, and at the top with a lid. A tube with a thread inside and a flange for screwing in a 1941 UZRG (a universal fuse for hand grenades) was attached to the top cover. It is also possible to use UZRG, as well as UZRGM-2. During transportation, the UZRG was stored separately from the grenades, and the tube opening was closed with a metal cap or plastic stopper.

Inside the grenade body there is an explosive of the TNT type (A-IX-1) weighing 110-120 g, around which a metal tape with notches in 4-6 layers is wound to create fragments during detonation. This approach was supposed to ensure the creation of a huge number of fragments and crushing of the hull into pieces. As a result of practical application, it was revealed that such a notch does not always lead to the declared crushing of the tape into fragments. There were also cases when a huge part of the tape flew off in a single fragment at a distance of over 25 m. For this reason, it is extremely difficult to say that the grenade is exclusively offensive, but most likely of a mixed type - offensive and defensive.

Design of RG-42

This is interesting: the grenade is one of the most popular grenades used by the Soviet army in the 1960-1970s.

According to the stated characteristics, the radius of fragmentation is 25 m, and the area of fragmentation damage is 30 square meters. m.

Grenades are packed in wooden boxes of 20 pieces each; fuses are also stored in two sealed sealed jars nearby.

Which is easier to produce: F-1 or RG-42

In the comments under the previous article “Hand-held high-explosive incendiary grenade,” an interesting discussion arose about what is easier to produce: F-1 or RG-42? I did not particularly interfere in this discussion, because I considered that the topic was worth a separate analysis. It is in this example that one can see the ambiguity of military-economic decisions.

These grenades, of course, need no introduction.

But still... General overview of technology

At first glance, a TNT can grenade, such as the RG-42 and its predecessor the RG-41, appears simpler to manufacture than the F-1. Working with sheet material does not require particularly sophisticated equipment. Cutting out the body blank, cutting or stamping blanks for the bottom and lid, joining them with a folding seam on a fairly simple rolling machine (these are widely used in the manufacture of cans), making a flange for the fuse and attaching it by soldering or welding. Indeed, during the war, housings for the RG-42 were produced at many factories, including canneries, in various kinds of workshops. The hulls were sent to the equipment factory.

A seaming machine that uses a folding seam to connect the wall of a can with the bottom and lid.

The body of the RG-42 grenade was made using a similar technology. The body of the F-1 is made by casting from cast iron or steel cast iron, which requires at least a minimally equipped foundry with a furnace for melting cast iron and a site for the production of flasks and rods. During casting, a hollow rod formed the internal cavity of the body; it was made from fireclay, kaolin or a sand-clay mixture. I was not able to find a description of the technology for casting specifically the bodies for the F-1, but obviously, the molds were made immediately per batch: six, eight, ten pieces, which depended on the productivity of the iron smelting furnace and the available casting equipment.

Cast iron casting looks something like this: assembled molds into which molten cast iron is poured from a ladle.

After the casting has cooled, the mold is broken, the rods are knocked out from the grenades, and the remnants of the molding sand are cleared. The hulls underwent mechanical processing (point boring and threading) and were sent to a special factory for equipment. Sometimes the equipment factory received unprocessed hulls and completed their processing.

The main thing in casting is to properly prepare the mold. This required specialists, modelers and moulders, without whom not a single foundry could cast anything. The rest of the work did not require skilled labor. In addition, the foundry required fuel consumption for melting cast iron and therefore had to be supplied with coke or charcoal. RG-42 did not require furnaces, coke, or qualified foundries. A fairly simply equipped mechanical workshop and hastily trained workers were enough. If there is a workshop with equipment and a master, then you can train the necessary operations in a day or two. The molder needs to be trained longer.

So, is everything obvious? Do not hurry.

How much metal and explosives are needed?

The other side of the issue is the metal consumption for a grenade. RG-42 consumes much less metal than F-1. This is not so difficult to determine if the weight of the charge and the weight of the UZRG fuse (55 grams) are subtracted from the weight of the grenade. The F-1 weighs 600 grams, and minus the 60 grams of charge and fuse, the body weight is 485 grams. RG-42 weighs 440 grams, and minus 150 grams of charge and fuse, the result is 235 grams.

The body of the RG-42 is almost exactly half the weight of the F-1. It should be taken into account that the weight of the body also includes the fragmentation element. Without it, the grenade body will be even lighter. This is a very significant point. A conventional million RG-42 grenades will require 235 tons of metal, and a conventional million F-1 - 485 tons. Of course, in the conditions of a major war, when metal is consumed on a scale of millions of tons, this is not that much. But still, in a warring economy, metal is in short supply, and from this point of view, the RG-42 looks more preferable.

Metal shortages in war can reach extremes.

This photo, of course, is staged, but in the UK they actually cut beautiful grilles into scrap metal . However, the RG-42 has a much larger charge weight, 2.5 times more than the F-1. A conventional million RG-42 will require 150 tons of TNT, while the F-1 will require only 60 tons. This is where the first ambiguous situation arises in deciding what kind of grenades to produce. What to choose? Increased consumption of metal or increased consumption of explosives? This issue within the framework of a warring economy is resolved based on the balances of receipts and expenditures of both. Based on the experience of World War II, it can be judged that the bottleneck was precisely explosives. Its production required specialized enterprises, special equipment, trained personnel and a whole range of raw materials and chemicals. The production of the same TNT was limited not only by the capacity of special plants, but also by the production capacity of toluene, nitric and sulfuric acids. In general, if there is not enough TNT, then it is more advisable to use a grenade with a smaller charge, that is, F-1.

And again an ambiguous moment arises. If a decision is made to equip hand grenades with ersatz explosives like ammonium nitrate, then it is more advisable to use the RG-42. The TNT equivalent of nitrate is 0.35, that is, 150 grams of charge will be equivalent to 52.5 grams of TNT, and the RG-42 with such a charge will be approximately equivalent to the F-1 in TNT equipment. Mixed explosives based on ammonium nitrate are more powerful (igdanite, say, has a TNT equivalent of 0.8), but in this case, a larger capacity body, like the RG-42, is an advantage.

Thus, already in this case difficult situations arise with unobvious choices. In general, we can say that the type of grenade and whether it is equipped with one or another type of explosive is determined primarily by the available explosive production capacity and the general development of the chemical industry. For example, in Germany during the world wars there was little oil and, as a result, little toluene, but there were good capacities for the production of synthetic ammonia and ammonium nitrate. Therefore, the Germans gravitated towards using saltpeter in hand grenades, and therefore used a body made of sheet metal.

What metal exactly?

Metal also varies. F-1 is made of cast iron, and RG-42 is made of sheet steel. The technological difference is very large. Pig iron is the first product obtained from iron ore by smelting in blast furnaces. Although the technology of non-domain iron production is now developing quite rapidly, nevertheless, the blast furnace process still dominates in world metallurgy.

Sheet metal, on the other hand, is a final product. It requires smelting cast iron, then converting it into steel in steel-smelting furnaces. According to the technology of the first half of the twentieth century, steel ingots were first rolled on blooming mills, then on several rolling mills, producing a slab - a steel plate with a thickness of 75 to 600 mm. Then this billet was rolled several times on sheet mills to obtain a steel sheet of the required thickness (in our case, 1-2 mm). Hot-rolled thin-sheet products were more often produced, which were more widely used than cold-rolled sheets. Finished products in sheets or rolls were sent to consumers. In the second half of the twentieth century, technology changed somewhat. The advent of continuous casting of steel made it possible to move to cast slabs, from which higher-quality sheet products were obtained.

Here, for example, is the sheet rolling shop 3000 of OJSC Mariupol Metallurgical Plant named after.

Ilyich." Stan-3000 rolls sheet steel with a thickness of 6 to 50 mm. You can see how this grandiose structure is a large sheet rolling mill. Obtaining a semi-finished product for F-1 requires only one blast furnace, and for RG-42 - an entire full-cycle metallurgical plant that produces all types of products, from cast iron to finished rolled products. The production of steel sheets requires many operations, special equipment and qualified specialists. Therefore, it is incorrect to compare only the manufacture of housings for F-1 and RG-42 grenades. The technology must be considered as a whole, together with the production of semi-finished products. And then the F-1 production technology turns out to be much simpler.

Moreover, the F-1 grenade can be produced in a very primitive metallurgical plant, smelting cast iron in an 18th-century blast furnace from bog ore and charcoal. Casting of housings can be organized right there, pouring metal from the blast furnace directly into molds.

A blast furnace built at the Seversky plant in the Urals in 1860.

In such a blast furnace it is quite possible to melt cast iron and immediately cast grenade bodies. It is also interesting to note a couple more points based on data from the Novovyatsky Mechanical Plant No. 608, which during the war and after it produced equipment for F-1 and RG-42 grenades, and for the latter also made cases. Firstly, when receiving cases from suppliers, the plant rejected some of them. For F-1, the average defect rate was 16% (out of 2.7 million cases, 451 thousand pieces were rejected), and for RG-42 - 31% (out of 3.5 million cases, 1.1 million pieces were rejected). That is, the apparent simplicity of manufacturing housings for the RG-42 resulted in a high percentage of defects and wasteful consumption of valuable sheet metal. The scrap could have been melted down, but it was obviously more profitable to melt down the defective F-1 hulls. Secondly, although there is no way to compare the cost of casings of these types of grenades, there is still an interesting indication in the materials of plant No. 608 that the RG-42 became cheap only with mass, in-line production. When the plant was just starting to master the production of RG-42 hulls, they cost 18.9 rubles apiece, and with the development of mass production, the cost dropped to 5.5 rubles. Thus, the RG-42, produced in small workshops and non-core factories, was an expensive grenade. If we assume that the F-1 hull cost about 6 rubles, then for the price of a semi-handicraft RG-42 it was possible to make at least three hulls for the F-1. This is not surprising, since sheet metal is much more expensive than cast iron, and there is more machining of the RG-42 body blanks.

This leads to another important conclusion. The mass production of RG-42 can be decided only if there is a developed metallurgy, which has sufficient capacity for the production of sheet metal, as well as if there is a developed mechanical engineering industry. The RG-42 is a byproduct of the automotive industry, which requires a lot of sheet metal. Therefore, countries with a developed automotive industry (during the Second World War - the USA and Germany, as well as the USSR) gravitated towards making grenades from sheet metal.

The F-1 prototype, the French F-1 grenade, did not come from a good life. The Germans captured two-thirds of the main French coal fields in the Pas-de-Calais region. One third remained with the French, but the mines there were located almost immediately behind the trenches. There were mines that the Germans shelled with machine guns, and special armored shelters were built for the miners. Coal production was cut by half. In 1915, France produced 20 million tons of coal, and received another 20 million tons from Great Britain, although in 1913 it consumed 64 million tons of coal. The French also lost almost all of their iron ore production, production fell from 21.9 million tons in 1913 to 0.6 million tons in 1915. The needs were met by melting scrap metal and supplies from the allies, but even so, iron consumption fell by half compared to pre-war times. It was at this time that a new grenade appeared. In France there were many small iron deposits, known since the Middle Ages, in which ore could be mined to smelt several tens of thousands of tons of cast iron in the simplest blast furnaces and on charcoal. Let's say, 1000 tons of cast iron is enough for 2 million F-1 grenades. One blast furnace with a capacity of 50 tons per day (this is a very small furnace) could produce 15 thousand tons of cast iron in a year, which would be enough to make 30 million grenades.

So the F-1 grenade is a grenade that can be produced even with extreme depletion of the economy, using the lowest grade iron ores, charcoal and the bare minimum of qualified engineers and workers. Even if large steel mills have been reduced to radioactive ruins, there is still room for F1 production.

And what is the verdict? If we consider the issue comprehensively, it turns out that the F-1 is simpler and cheaper to manufacture than the RG-42. So in World War III the lemon will still be in service and will take pride of place in the infantry armament.

Principle of operation

The principle of operation of the grenade is as follows. When a fighter pulled the pin, the drummer did not descend from the combat platoon. This is due to the fact that the trigger lever fork was located in the recess of the striker and securely fixed it in the upper position. After a soldier threw a grenade, the trigger lever was removed from the recess of the striker in the absence of pressure from the thrower's fingers. After which the striker, with its sting, under the influence of the spring, punctured the igniter primer and “set fire” to it. Then, over the course of 3.2 - 4 s, the flame moved to the remote part of the fuse, after which it reached the detonator capsule, which in turn exploded, leading to the detonation of the explosive. Next, the cylindrical body of the grenade ruptured and fragments scattered in different directions.

Fragment tape RG-42

To unload a grenade, it was necessary to unscrew the fuse from it, then place it in a pouch and close the hole with a plastic or metal stopper.

To use a grenade you need:

- Take the grenade in your hand, confidently pressing the safety lever to the body with your fingers.

- Unclench the “antennae” of the cotter pin (pins).

- Pull the pin and throw a grenade into the enemy's ranks.

RG-42 hand grenade

RG-42 with UZRG fuse

In order to simplify the design of anti-personnel fragmentation grenades and, as a consequence, the possibility of increasing their industrial production at the beginning of 1942 at GSKB-30 at plant No. 58 named after. K.E. Voroshilov designer S.G. Korshunov under the fuse of the system E.M. Viceni - UZRG - “unified fuse for hand grenades” developed an offensive grenade.

After being put into service, the grenade was given the index RG-42 (hand grenade of 1942).

The new UZRG fuse used in the grenade has become the same for both the RG-42 and the F-1.

The RG-42 grenade was used both offensively and defensively.

The RG-42 in appearance resembled the RGD-33 grenade, only without a handle.

Hand grenade mod. 1942 (RG-42) with a fuse, the UZRG belonged to the type of remote-action fragmentation offensive grenades. It was intended to defeat enemy personnel. The grenade explodes in water, snow, mud, etc.

The hand grenade consisted of the following parts: - a simple cylindrical grenade body with a tube for the fuse, - an explosive charge, - a wooden plug or metal cap, - a UZRG fuse.

The body of the grenade is made of metal and served to place an explosive charge and fuse, as well as to hit the enemy with fragments when it explodes. The grenade body is closed at the bottom with a flat bottom and at the top with a lid. A tube with a flange was attached to the top of the housing cover, inside of which there was a thread for screwing in the UZRG fuse and for sealing the explosive charge in the housing. When storing and carrying the grenade, the tube was closed with a plastic stopper or metal cap.

A metal tape in 3-4 layers is wound around the charge inside the body; it serves to form fragments when a grenade explodes.

To increase the number of lethal fragments, the surface of the tape is cut into squares. During the explosion, they formed light fragments, and contributed to the fragmentation of the hull. Based on application experience, it was revealed that this notch did not always contribute to the organized crushing of the tape into fragments; it often tore in the most arbitrary manner. RG-42 with UZRGM fuse

The explosive charge, which served to explode the grenade, was placed inside the body between the inner layer of the tape and the walls of the central tube.

The explosive charge of the grenade is safe when storing and handling the grenade. It exploded only from the explosion of the fuse detonator. The explosive charge of the grenade consisted of explosive A-IX-1 (TNT) weighing 110 - 120 g.

When an RG-42 grenade was detonated, up to 1000 fragments were formed, the radius of their lethal effect was up to 15 - 20 m, the radius of scattering of individual fragments was up to 25 m. The reduced area of fragmentation damage was 30 m2.

The fuse consisted of a striking mechanism and the fuse itself. The striking mechanism was assembled in a tube and included a firing pin with a screw mainspring, a trigger (safety) lever and a safety pin with a ring. The fuse itself included an igniter primer, a low-gas moderator and a detonator primer. The fuse was carried separately from the grenade and screwed into the hole in the body immediately before use. The fuse of the grenade ignited at the moment it was thrown, and the grenade exploded after 3.2 - 4 seconds. after ignition it ignited. A stopper or metal cap serves to protect the central tube.

When the safety pin was pulled out, the ignition mechanism (striker) did not descend from the cocking mechanism, since the fork of the trigger lever was located in the annular recess of the striker and firmly held it (striker) in the uppermost position. When throwing, the trigger lever was released from the pressure of the fingers and with its fork came out of the annular recess of the striker. The firing pin, under the action of the mainspring, pierced the igniter capsule with its sting and ignited it. The beam of fire from the igniter primer ignited the remote part of the fuse and, having passed through it, after 3.2 - 4 seconds. was transferred to the detonator cap, which, when exploding, detonated the explosive charge of the grenade. The body of the grenade burst and fragments scattered to the sides.

It was possible to discharge a grenade only if the safety pin was not removed from the fuse. To unload a grenade, it was necessary to remove the fuse, wrap it in paper or rags and place it in the nest of the grenade bag; insert a wooden plug into the flange hole or put on a metal cap.

| Grenade weight, g | 400 |

| Charge mass, g (explosive type) | 110 - 120 (TNT (TNT)) |

| Grenade length, mm | 121 |

| Grenade diameter, mm | 54 |

| Damage radius, m | 15 — 20 |

| Number of fragments, pcs. | 1000 |

| Throwing range, m | 35 — 40 |

| Deceleration time, s | 3.2 — 4 |

Due to the dampness of the powder pressing of the retarding composition, the UZRG fuse, due to its improper storage during the war, sometimes did not fire, although the igniter primer functioned correctly.

Therefore, at the end of the war, UZRG fuses were packed in special rolled up cans, and a can opener was included to open them. UZRGM fuse a – general view;

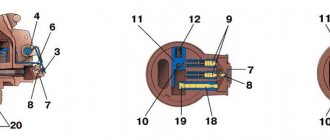

b – in section; 1 – impact mechanism tube; 2 – connecting sleeve; 3 – guide washer; 4 – mainspring; 5 – drummer; 6 – striker washer; 7 – release lever; 8 – safety pin; 9 – retarder bushing; 10 – moderator; 11 – igniter capsule 12 – detonator capsule. To train soldiers in 1942, the GG-42 training grenade was created in appearance, resembling the RG-42 combat grenade. In addition, when training to throw hand grenades, mock grenades were used at the rate of 1-2 for each student. Models of grenades could be made independently. To do this, a thick-walled pipe is cut into sections, both sections are welded or sealed with round plates 3.5 - 4 mm thick. A hole with a diameter of 30 - 35 mm is drilled in one of them. and cut the thread. A thread 8-12 mm long is also cut on the pin simulating the fuse, and a hole is drilled in the upper part for a pin with a ring. The pin and the ring are made of wire. The cylinder is filled with lead or sand to the required weight.

To use the RG-42 grenade you must:

1. Take the grenade in your hand so that the safety lever is pressed tightly against the body; 2. Unclench the antennae of the safety pin; 3. Pull the pin from the fuse and throw the grenade at the target.

In the 1960s, the fuse on the RG-42 grenade was replaced with a modernized UZRGM, as on the F-1 and RGD-5 grenades. The fuse of the UZRGM grenade was intended for the remote explosion of the explosive charge of a grenade; it was more technologically advanced to manufacture than the fuse of the UZRGM.

The RG-42 grenade turned out to be easy to manufacture and reliable in operation. It was widely used in the Great Patriotic War. For many years after the war, it remained in service with the Soviet army and was used in the Russian army and a number of other countries. The RG-42 grenade has been repeatedly used in combat in many military conflicts. In China, a copy of the RG-42 grenade is in service and is produced under the designation “Type 42”. In Russia, production of RG-42 grenades has been discontinued.

| RG-42 |

Combat use and production

Due to its simplicity, the grenade was actively used during the Second World War by all parties to the conflict.

After the end of World War II, the grenade was supplied to some armies of the socialist bloc and remained in service with the Red Army, the Russian Army and the armed forces of other countries. Their production was established in several countries (Romania, Poland, China).

RG-42 grenade

In 1950-1953, these grenades were used in the Korean War by the Korean People's Army. After the end of the war, the production of grenades was established within the country.

A little later, the RG-42 was used by South Vietnamese partisans during the Vietnam War.

In 2000, grenades were removed from service in the post-Soviet space, but their use did not stop. For example, the use of grenades was noticed during the armed conflict in Donbass (Ukraine).

Weapon of Victory: RG-42 - combat tin can

- Articles

- April 25, 2022, 09:00

As part of the “Weapons of Victory” series, the Kuban24 portal talks about the unique and most popular grenade of the Great Patriotic War - RG-42. All over the world, historians and weapons specialists call the invention of designer Korshunov the most ingenious and pragmatic solution in the history of the military industry.

Instead of canned food - pomegranates

RG-42 is a uniquely simple and technologically advanced grenade model, its design replicating a tin can. This made it possible, during the war, to organize its mass production not only at defense enterprises, but also at canning factories in the food industry. This allowed it to become the most popular grenade of the Great Patriotic War. Decoding RG-42 is standard - a hand grenade of the 1942 model. It was developed by designer Korshunov at the beginning of 1942.

During the war, the industry of the USSR had to be quickly put on a war footing: instead of canned food - grenade casings, instead of cigarettes - cartridges (the caliber of the 7.62 mm cartridge was approximately equal to the diameter of most common cigarettes).

The new grenade was a cylindrical body in the form of a thick-walled tin can, inside of which there were 110 grams of TNT. To increase the damaging effect, a steel tape rolled up in several layers with notches to form fragments was laid inside along the walls. A handle was attached to the top cover of the case, into which the fuse was screwed.

The scattering range of the fragments was about 25 meters, and the radius of continuous destruction was 5 meters. The RG-42 was considered an offensive weapon. The detonation time was 3.2-4.2 seconds. The grenade was famous for its highest reliability - approximately one in a thousand products did not work. They were unpretentious in storage and were almost not afraid of moisture.

The cases were made at canning and food factories. Then the blanks were sent to factories, where all that remained was to fill them with explosives and adjust the fuse. Unlike the famous “limon” F-1, the RG-42 did not require casting molds, nor did it require high professionalism of the workers. It was necessary to have the skills to operate a simple seaming machine, so women and children assembled the casings for these hand weapons.

Economy class grenade

Comparing the RG-42 with the “limon”, the following fact should be noted: the “combat tin can” required 235 grams of metal, and the F-1 - as much as 485 grams. When making 1 million grenades, this is 235 and 485 tons, respectively. In war conditions this was very important.

It should be noted that all participants in World War II experienced a shortage of metal. For example, in Great Britain, the military departments even had to cut off ancient cast-iron fences and grilles from architectural monuments to be melted down for the defense industry. So once upon a time, Emperor Peter I, during the Northern War, melted bronze church bells into cannons.

The production cost of one RG-42 in 1944 was 5.5 rubles, and the F-1 “limon” was almost three times more expensive. But there is an important point! If for the production of F-1 cast hulls it was possible to use the lowest quality iron ore, then the RG-42 produced from sheet steel required metal of at least medium quality.

Still relevant today

The RG-42 was produced until 1955, after which it was withdrawn from service in the USSR, but even today an unknown quantity of these explosive products is stored in warehouses and is being gradually disposed of. In addition to the Great Patriotic War, this grenade was used in the wars in Korea and Vietnam. There is information that reactivated reserves of RG-42 were used in the 21st century during the military conflict in eastern Ukraine.

In the second half of the 20th century, the RG-42 was in service with Czechoslovakia, Poland, Romania, Bulgaria, Yugoslavia, North Korea, Vietnam, East Germany and China. It is curious that a number of these grenades were used by the Finnish army.

After 1955, Korshunov’s invention was produced in Poland and Romania under the brand name “RG-42”, and in China today it is in service under the designation “TYPE-42”.

Authors: Alexey Kulikov

Grenade modifications

- RG-42 - a grenade that is still produced by the Romanian plant Uzina Mecanică Mija;

- RG-42 - previously produced in Poland, the RG-42 grenade.

- Type-42 is a Chinese-made grenade. It is being produced now and is in service with the army.

- The K-51 is a non-combat Soviet grenade in a plastic case, in which the tear irritant irritant was used instead of TNT.

- training version of the grenade with the designation on the body “UCH” (Soviet), CGR-42A (Polish).

Fragments of RG-42 grenade

Grenade device

RG-42 hand fragmentation grenade (Fig. consists of a body with a tube for the fuse, a metal strip, an explosive charge and a fuse.

consists of a body with a tube for the fuse, a metal strip, an explosive charge and a fuse.

Fig. 8. The design of the RG-42 hand fragmentation grenade: 1—body; 2—metal tape; 3—explosive charge ; 4 - fuse; 5 - tube with flange; 6 - bottom; 7 - cover

The body of the grenade is used to place an explosive charge, a metal strip, a tube for the fuse, as well as to form fragments when the grenade explodes. The body is cylindrical, has a bottom and a cover. A tube with a flange is attached to the lid to connect the fuse to the grenade and to seal the explosive charge in the body. When storing and carrying the grenade, the tube is closed with a plastic stopper or metal cap.

The metal strip is used to form fragments when a grenade explodes; it is rolled into 3-4 layers inside the body. To increase the number of fragments, the surface of the tape is cut into squares.

The explosive charge fills the body and serves to break the grenade into fragments.

The fuse of the UZRGM grenade (UZRGM-2) (Fig. 4) is intended to explode the explosive charge of the grenade.

Rice. 4. UZRGM (UZRGM-2) grenade fuse: a - general view; b - in section:

1 — percussion mechanism tube; 2 — connecting sleeve; 3 - guide washer; 4 - mainspring 5 - hammer; 6 — striker washer; 7 — trigger lever; 8 - safety pin; 9 — retarder bushing; 10 - moderator; 11 — igniter primer; 12 — detonator capsule.

Position of parts and mechanisms before and after the throw

The design of the fuse, the operation of the parts and mechanisms of the grenade are described here .