Two-factor protection

The fact is that the grenade is protected from accidental pulling out of the pin, and therefore an unnecessary explosion, by special metal tendrils. Before you pull out the pin, you need to bend them, because otherwise it is impossible to remove the ring from the grenade, even with your fingers. Unbending them with teeth or lips is extremely problematic. This takes a lot of time, which may not play the best role in the battle. Well, in the movies, the hero would be puffing and slobbering on a grenade if it were real.

And this is only the first stage. Let’s say we managed to straighten the protective tendrils. Another problem arises.

The ring with the pin is securely fixed in the grenade body, and in order to remove them, it is necessary to apply a force of several kilograms. Most often this figure is four kilograms. Training grenades require even more effort, since they are used many times and the pin is “planted” there more heavily. Is it possible to make such efforts with teeth?

Yes, it is possible, but it is extremely difficult and there is a very high chance of damaging your teeth or, even worse, your jaw. Moreover, some grenades have sharp, protruding elements in their structure. There is a chance that they will get caught on the edge of the mouth, which at best will lead to injury, and at worst, the soldier will not be able to throw the grenade away. What then should you do if one hand is busy and you need to throw a grenade?

F-1 hand grenade

The F-1 grenade has French roots and a long history. Under this designation, but in Latin transcription - F-1 - the grenade was adopted by the French army in 1915.

The French F-1 grenade had a percussion fuse.

The simplicity and rationality of the design of the grenade body played a role - the grenade was soon adopted for service in Russia. At the same time, the impact fuse was not sufficiently reliable and safe to use and was replaced by a simpler and more reliable remote domestic fuse designed by Koveshnikov. F-1 with Koveshnikov's fuse

In 1939, military engineer F.I. Khrameev of the People's Commissariat of Defense plant, based on the model of the French F-1 hand fragmentation grenade, developed a sample of the domestic F-1 defensive grenade, which was soon put into mass production.

For the F-1 grenade designed by Khrameev, the cast iron body of the grenade was somewhat simplified; it lost the lower window.

The F-1 grenade, like the French F-1 model, is designed to destroy enemy personnel in defensive operations. When used in combat, the throwing fighter had to take cover in a trench or other defensive structures.

Initially, the F-1 grenade used a fuse designed by F.V. Koveshnikov, which was much more reliable and easier to use than the French fuse. The deceleration time of Koveshnikov's fuse was 3.5-4.5 seconds.

In 1941, designers E.M. Viceni and A.A. Poednyakov developed and put into service to replace Koveshnikov's fuse a new, safer and simpler in design fuse for the F-1 hand grenade.

In 1942, the new fuse became common for the F-1 and RG-42 hand grenades; it was called UZRG - “unified fuse for hand grenades.”

The fuse of the UZRGM type grenade was intended to explode the explosive charge of the grenade. The principle of operation of the mechanism was remote.

After World War II, modernized, more reliable UZRGM and UZRGM-2 fuses began to be used on F-1 grenades.

The F-1 grenade consists of a body, a bursting charge and a fuse.

The body of the grenade is cast iron, with longitudinal and transverse grooves along which the grenade usually exploded into fragments.

In the upper part of the body there was a threaded hole for screwing in the fuse. When storing, transporting and carrying the grenade, a plastic plug was screwed into this hole.

The explosive charge filled the body and served to break the grenade into fragments.

The body served to connect the parts of the grenade and to hit the enemy with fragments during the explosion.

To increase the number of fragments, the surface of the body was made corrugated. When the body ruptured, it produced 290 large heavy fragments with an initial expansion speed of about 730 m/s. At the same time, 38% of the mass of the body was used to form lethal fragments, the rest was simply sprayed. The reduced area of scattering of fragments is 75 - 82 m2.

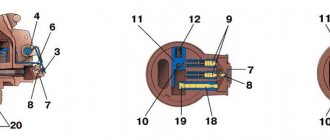

UZRG fuse: 1 — ignition mechanism tube;

2 — connecting sleeve; 3 - guide washer; 4 — mainspring; 5 - drummer; 6 — striker washer; 7 — trigger lever; 8 — safety pin with ring; 9 — retarder bushing; 10 — igniter primer; 11 — powder moderator; 12 — detonator capsule. The fuse consisted of a fuse and an igniting (percussion) mechanism, assembled together in the frame of the fuse. In the walls of the frame there were holes for a safety ball and a safety pin.

The UZRG fuse consisted of an igniter primer, a remote composition and a detonator primer. The ignition mechanism consisted of a firing pin, a mainspring, a safety ball, a safety cap with an outer lever, a cap spring and a safety pin with a ring. The drummer was placed inside the frame. At the bottom, the striker had a firing pin, and on the side there was a semicircular recess for a safety ball. The deceleration time of the UZRG fuse was 3.2-4.2 seconds.

F-1 grenades were stored and transported without fuses, with blank plugs screwed in instead. The ignition mechanism of the fuse was always cocked, the firing pin was cocked, and the mainspring was compressed. The striker was held in the cocked position by a safety pin, which passes through the holes of the frame and striker, and by a safety ball, which with one half entered into the hole of the frame, and the other into the recess of the striker. The ball was held in this position by a safety cap.

To load a grenade you need to: unscrew the blank cap, take the fuse and carefully screw it into the hole of the grenade.

F-1 with UZRGM-2 fuse

To throw a grenade, you must: take the grenade with your right hand and firmly press the outer lever of the safety cap with your fingers to the grenade body; while holding the lever, pull out the safety pin with your left hand; in this case, the firing pin and the safety cap are released, but the firing pin remains cocked, held by the safety ball; swing and throw a grenade.

The grenade was thrown from behind cover.

Grenades were delivered to the troops in wooden boxes. In the box, grenades, handles and fuses were placed separately in metal boxes. There was a knife to open the boxes. The walls and lid of the box were marked, indicating: the number of grenades in the box, their weight, the name of the grenades and fuses, the manufacturer's number, the batch number of the grenades, the year of manufacture and the danger sign. All supplies of grenades and fuses, except for portable ones, were stored in factory closures.

Soldiers carried grenades in grenade bags. The fuses were placed in them separately from the grenades, and each fuse had to be wrapped in paper or a clean rag.

In tanks (armored personnel carriers, self-propelled artillery units), grenades and fuses separately from them were placed in bags.

The F-1 grenade was widely used during the Soviet-Finnish military conflict of 1939 - 1940, on the fronts of the Great Patriotic War, and in other wars and military conflicts.

During the Great Patriotic War, soldiers affectionately called the F-1 grenade “fenyusha” and “limon” because it looked like a lemon in appearance. Usually, when conducting assault operations, one soldier had five to ten F-1 grenades.

The F-1 grenade was also readily used as a trophy by German soldiers, since there were no similar defensive grenades in service with the Wehrmacht.

The production of F-1 grenades during the war years was carried out at plant No. 254 (since 1942), 230 ("Tizpribor"), 53, in the workshops of the Povenetsky shipyard, a mechanical plant and a railway junction in Kandalaksha, the central repair workshops of the NKVD Soroklag, artel "Primus" (Leningrad), other domestic enterprises.

During the war, many non-core enterprises and organizations were involved in the production of F-1 grenades. By order of the City Committee of the All-Union Communist Party of Bolsheviks on December 28, 1941, production (casting and machining) of F-1 hand grenade cases was organized in the experimental workshops of the Leningrad Polytechnic Institute. In total, the workshops cast 11,000 cases. 5,000 unprocessed cases were delivered to plant No. 103, 4,800 of them were machined and transferred to the Pyatiletka factory. The order for the production of grenade casings was suspended on the instructions of the city committee of the All-Union Communist Party (Bolsheviks).

During the war, Leningrad enterprises mastered the production of a version of the fuse for a grenade using one of the brands of hunting gunpowder instead of special tubular gunpowder. In 1942, tests of such a fuse under the designation “PP-42” for the F-1 grenade were carried out at ANIOP (“Rzhev Test Site”). Grenades with RR-42 fuses were put into mass production only at enterprises in Leningrad. These implementations were temporary. There were other examples of unusual grenade production during the war.

Many inventions and design proposals are associated with the F-1 grenade. In August 1942, sergeant of the mortar battalion of the 284th Infantry Regiment N.K. Deryabin developed the “flea grenade” project. It was intended to defeat enemy personnel. The composition of the “flea grenade” included: an expelling charge, a firing pin with a striker and a nut, and an F-1 grenade with the fuse removed. The grenade exploded in the air at a height of 10-15 meters. It was proposed to use a grenade with a parachute for mining. But Deryabin's system turned out to be too complicated. According to military experts, the project was not implemented due to lack of practical value.

To train military personnel in the handling of remote-action hand fragmentation grenades, the techniques and rules for throwing them, a training and simulation URG hand grenade weighing 530 g was created, outwardly similar to the F-1 combat grenade. The URG grenade is equipped with a UZRG fuse simulator.

| training and simulation hand grenade URG with a simulated fuse |

The F-1 combat grenade is painted green (from khaki to dark green). The training and simulation grenade is painted black with two white (vertical and horizontal) stripes. In addition, it has a hole at the bottom. The fighting fuse has no color. In the training-imitation fuse, the pin ring and the lower part of the pressure lever are painted scarlet. Externally, the grenade has an oval ribbed body made of steel cast iron.

training split grenade F-1-A with Koveshnikov fuse: 1 - fuse core;

2 — detonator cap thimble; 3 — safety cap; 4 — outer lever of the cap; 5—delaying protrusion on the fuse frame; 6 — safety pin; 7 — igniter primer; 8 — powder composition; 9 — detonator capsule; 10 - drummer; 11 — fuse ball; 12 — mainspring; 13 — cap spring. Another training split grenade F-1-A (57-G-7214U) was developed by the Training Instruments Plant No. 1 in January 1940. The grenade had a quarter cutout of the body; instead of an explosive, plaster was poured. It was intended to demonstrate the design of the F-1 combat grenade. The F-1-A grenade was used for training in the Red and Soviet armies for a long time.

The F-1 grenade was widely used in military conflicts of the 1940-1990s in different parts of the world.

Copies of the F-1 can be considered the Chinese Type 1 grenade, the Polish F-1, the Taiwanese defensive grenade, and the Chilean Mk2.

The disadvantages of the F-1 grenade are not so much related to this sample, but are due to the general obsolescence of this generation of grenades. Corrugation of the body, as one of the methods of specified crushing, cannot fully ensure the formation of fragments of a satisfactory shape and the optimal distribution of fragments by mass. The crushing of the hull is largely random. The advantages of a remote fuse include failure-free operation, independent of the impact energy when a grenade falls, and whether it falls on the ground, in snow, in water or in swampy soil. But its drawback is that it cannot ensure an instant detonation of a grenade when it touches the target: the retarder has a specified burning time.

| Grenade weight, g | 600 |

| Charge mass, g | 60 |

| Explosive type | TNT |

| Grenade body length, mm | 86 |

| Length of grenade with fuse, mm | 117 |

| Grenade diameter, mm | 55 |

| Throwing range, m | 30 — 40 |

| Radius of fragments, m | 200 |

| Moderator burning time, s | 3.2 — 4.2 |

And the F-1 grenade, as one of the outstanding representatives of the classic type of hand grenades with a solid cast iron body of virtually natural crushing and a simple, reliable remote fuse, cannot compete with modern grenades for the same purpose - both in terms of optimal fragmentation action and versatility of action fuse. All these problems are solved differently at modern technical, scientific and production levels. Thus, the Russian Army created the RGO grenade (defensive hand grenade), which is largely unified with the RGN grenade (offensive hand grenade). The unified fuse of these grenades has a more complex design: its design combines remote and impact mechanisms. Grenade bodies also have significantly greater fragmentation efficiency.

However, the F-1 grenade has not been removed from service and will probably remain in service for a long time. There is a simple explanation for this: simplicity, cheapness and reliability, as well as time-tested are the most valuable qualities for a weapon. And in a combat situation, it is not always possible to counter these qualities with technical perfection, which requires large production and economic costs.

Creation

The history of the creation of the F-1 combat grenade began in the 20s of the last century. By 1922, the Red Army was armed with various types of foreign-made defensive grenades. Among them were the reliable English Mills grenades and the French F-1 grenades, which were distinguished by their well-thought-out shape and the dubious quality of the fuse, which detonated it immediately after impact, without maintaining a deceleration time.

In 1925, the Artillery Directorate of the Red Army identified a critical shortage of hand-held defensive ammunition in its warehouses and for the first time thought about the development and production of a perfect grenade with good lethality and a high-quality fuse.

Grenade fuse

As a result, the French F-1 was equipped with an F.V. system fuse. Koveshnikov and in 1928, after several tests and amendments, the Soviet F-1 grenade was adopted by the Red Army. The military quickly dubbed her “the lemon.”

At the initial stage, for the production of the lemon, the hulls were borrowed from foreign F-1s, but by 1930 the USSR had launched its own production.

Since 1939, under conditions of the increasing threat of war, the development of the defense industry of the USSR has accelerated significantly. At this time, Soviet engineers developed new models of military equipment and ammunition and improved existing ones.

Modernization has not spared F-1 either:

- in 1939, engineer Khrameev F.I. rationalized the grenade body by removing the lower window and replaced the simple cast iron used for its manufacture with steel, thereby increasing the destructive power of the ammunition;

- in 1941, designers E.M. Viceni and Bednyakov A.A. converted the F-1 by developing a cheaper fuse, which reduced the explosion delay time from 6 seconds to 3.5 - 4.5. It was called UZRG (unified fuse for hand grenades), and in the post-war years it was improved again.

Since then, F-1 grenades, in which the principle of explosion was changed, have been widely used in various military campaigns and despite the fact that they are outdated, and more modern hand grenades have been supplied to the army for a long time, “lemon grenades” have not disappeared from use to this day. her arsenal.

Where does the name "lemon" come from?

The F-1 hand grenade got its name back during the First World War. The opinion that the ammunition was named “lemonka” because of its shape, similar to the fruit of the same name, is erroneous. To dispel the myth, it is enough to plunge into history and find out that the lemon grenade is the prototype of the French hand grenade of the 1915 model. However, the design of the foreign analogue was not so perfect and, due to its sensitive fuse, it had to be handled with extreme caution.

The English fragmentation grenade was much more reliable. A smooth body and an improved fuse system with a pin distinguished it from its French counterpart. The developer of fragmentation ammunition was Captain Lemon. It was in honor of him that the soldiers of the Russian army named all grenades of various systems, similar in shape to the English ones.