In 1954, the new defensive grenade RGD-5 was adopted by the Soviet army, which very soon supplanted its predecessor RG-42. Together with the famous “limon” F-1, these two grenades became the most important element of the weapons of any soldier in the Soviet and then Russian army. They are still used today.

These grenades are effective and reliable, they are time-tested. In addition to the Russian army, the F-1 and RGD-5 are currently used by all armed forces of the former Soviet republics, as well as the armed forces of China, Iran, and Bulgaria. They are very popular in Africa, Latin America and the Middle East. But, despite this, it should be recognized that the F-1 and RGD-5 grenades are already obsolete.

Therefore, back in the mid-70s, work began on the creation of a new generation of hand grenades. The development was carried out by the designers of the State Research and Production Enterprise "Basalt". In the early 80s, tests of two types of grenades began: defensive RGO and offensive RGN. In 1981, they were adopted by the Soviet army.

The main difference between these ammunition and its predecessors is the impact-remote fuse, which is triggered upon collision with any hard surface, and not just after a certain period of time.

The RGN hand grenade is an anti-personnel fragmentation grenade that belongs to a large group of offensive grenades. This means that the radius of scattering of its fragments allows this ammunition to be used not only from cover. The impact fuse of the RGN grenade significantly increases its effectiveness and gives the enemy less chance of hiding from the effects of fragments.

RGN grenades (like RGO) were first used by Soviet troops in Afghanistan, then they were used during both Chechen campaigns and during the war with Georgia in 2008. There is information that RGN offensive grenades are used by armed forces in eastern Ukraine.

GRN grenade: eliminating the main shortcomings of F1 and all previous products

No matter how strange it may seem, the troops are still in service and actively using F1 grenades, developed almost a hundred years ago - in 1925. At the present time, it is not possible to improve the composition of the explosive compound, since it was already at the technical limit for chemical explosives, so the designers took a different route. The fuse and fragmentation system have been improved. It was necessary to eliminate the main shortcomings of the previous model grenades. They are all well known:

- Fuse with a three-second delay. This is the main drawback of F1 grenades and all others with a similar fuse. It is dangerous for the fighter throwing the grenade. In addition, the enemy often manages to take cover before the explosion occurs;

- Heterogeneous fragments: large, small, dusty, not posing a significant threat. All this makes the grenade’s destructive field extremely uneven, which is very inconvenient in combat conditions.

The RGN and RGO (RGD) hand grenade was developed taking these shortcomings into account. These were completely eliminated and a lot of interesting design solutions were used. The easiest way for designers to solve the problem of fragments.

In the main F1 grenade, fragments of a cast iron jacket were used as a striking element. This is a rather massive (500 g) thick-walled cast iron casting with a characteristic shape. The grooves on the body, according to the engineers, were intended to form large fragments with significant destructive force. However, analysis of countless tests has shown the opposite. Cast iron turned out to be too fragile a material. As a result, it was crushed almost to dust, and the remaining part (most often the upper hemisphere flew off in a large fragment).

In the RGN Grenade, ductile aluminum was used instead of cast iron. The shape of the fragmentation block became spherical. A network of deep grooves appeared. Moreover, they were made from the inside, and not from the outside, which is more consistent with common sense, since the detonation of a grenade and the destruction of the fragmentation jacket always occurs from the inside. Numerous tests were carried out, analyzing the dispersion of fragments and their size. The optimal mesh size of the groove grid was set to 2x2 mm.

Description of design

The RGN hand grenade consists of a body and an UDZ fuse, which has two overlapping trigger circuits.

The ammunition body consists of two aluminum hemispheres with a diameter of 60 mm. Their internal part has notches, which cause the formation of fragments during an explosion. In this regard, the military has many complaints about the RGD-5. The fact is that an offensive grenade should not have a significant scattering of fragments, in which case it becomes dangerous for the soldier himself. In RGD-5, fragments often scattered 20-30 meters, which is unacceptable. Thanks to the internal notch of the RGN, this problem was solved.

In the center of the grenade body there is a metal cup for tightening the fuse. A mixture of TNT and hexogen is used as an explosive. Its mass is 112 grams; when the ammunition detonates, 200-250 almost identical fragments are formed.

The main “highlight” of the RGN grenade is its UDS fuse.

After pulling the pin and throwing the grenade, the safety lever releases the firing pin. It rotates around an axis and punctures a special igniter primer, the function of which is to ignite three tubes with pyrotechnic compositions: a self-liquidator and two moderators.

After the flammable mixtures inside the tubes burn out, special pins enter them under the action of springs. This allows the safety slide to move to the side, and the bowl with the inertial load and the igniter capsule to go down. Thanks to this, the capsule is brought directly to the detonator - the grenade is cocked and ready to detonate when it encounters any obstacle. The above processes take 1.3-1.8 seconds.

The main element of the impact part of the fuse is the inertial load, which is a plastic ball with metal balls inside. He is responsible for detonating ammunition when colliding with an obstacle. When the grenade is in a non-combat position, the ball is tightly clamped between the bowl and the body. After the retarders burn out, it gets space and can move down. Any blow causes the ball to move the bowl, at the bottom of which there is a needle that strikes the primer.

The impact fuse may not work if the grenade gets into snow, sand, water or just soft ground. In this case, detonation occurs due to the third tube of the self-liquidator. It burns out in 3.2-4.2 seconds, depending on the air temperature.

The UDZ fuse has a plastic body, but all its main elements are made of metal.

Difference between offensive and defensive grenades RGN and RGO

The abbreviation RGN stands for Offensive Hand Grenade, there is a variant RGO (Defensive Hand Grenade). The latter is distinguished by a significantly larger radius of scattering of fragments. For this purpose, the design of the fragmentation jacket was changed. It consists of four aluminum spheres with a grid of 2x2 mm grooves. The RGN offensive grenade uses only two spheres. In the defensive one they are placed in two layers, which gives twice the number of fragments.

RGN offensive grenades have a smooth aluminum body in the shape of a ball. The grid of grooves is located on the inside. A powerful defensive version of the RGO has an external fragmentation sphere added to the main one with corrugation outward. The type of grenades is selected by touch. This skill is brought to automaticity in training.

Differences between training and combat grenades

The RGN and RGO training grenade is designed to practice throwing skills. To perform this skill well, you need to make hundreds, if not thousands of throws. For this purpose, the training model fully corresponds to the weight and size characteristics of a combat grenade. Only instead of the charge and fuse, a substitute is installed. Training grenades are painted black, combat grenades are painted green (khaki or olive). Interestingly, many films and TV series do not take this point into account. During filming, regular training samples of black color are used with all their might and passed off as combat ones.

RGN grenade fuse: inertial with classic duplication

The main F1 grenade in service has a classic capsule fuse with a moderator. In design, it differs little from a conventional weapon cartridge. This is important for the unification of production. When creating the RGN and the RGO, it was decided to abandon this design due to a number of shortcomings. An inertial mechanical fuse was used. In terms of dimensions, it turned out to be significantly larger, which is clearly noticeable in the appearance of the grenade. The official name of this fuse is Impact-Remote Fuse UDZ.

The inertial element is a heavy metal ball and a spring. The fuse itself is an ordinary pyrotechnic capsule with a moderator. In this it is similar to the F1 grenade. The striker is triggered by the clamp with a pressed hand when throwing. By analogy with F1, after the firing pin is fired, the bracket flies off. This is very convenient for indicating when the firing pin has ignited the primer and a grenade explosion is imminent.

After the primer is ignited by impact, the usual F1 grenade fuse, designed like a fuse, operates. Slowdown - 4.5 seconds. This is quite enough time for a throw. The difference is that the explosion can occur much earlier when hitting a hard surface. The operation of this mechanism is ensured by an inertial element and a metal spring.

The use of plastic for the fuse body looks quite unusual. It is molded from extruded impact-resistant polystyrene, usually white or gray. The use of plastic significantly reduces the cost of mass production. The designers chose this material because of its ability to take a very precise and complex shape when casting under pressure (extrusion). The fuse body required just such characteristics. If plastic was not used, it would have to be cast from brass, which would make the grenade heavy in weight and expensive to manufacture. The use of plastic does not limit the period and storage conditions. They are exactly the same as for regular F1 grenades.

Hand grenade RGN / RGO

| RGN (left) and RGO (right) |

Hand fragmentation grenades RGN (offensive hand grenade) and RGO (defensive hand grenade) began to be developed by Soviet designers S. Korshunov and V. Kuzmin at the Basalt enterprise in the late 1970s.

When developing the RGN (7G21) and RGO (7G22) grenades, the experience of combat use of grenades and mass production technology were taken into account. The need to create new grenades was dictated mainly by the “Afghan experience”, since the use of a remote fuse in grenades during combat operations in mountainous terrain allowed the enemy to take cover from its fragments in time, and also created the threat of self-destruction of the grenade launcher in the event of a grenade rebounding from an obstacle or rolling down a slope after the throw.

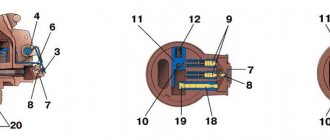

RGN 1 device - lower hemisphere;

2 - explosive mixture; 3 — upper hemisphere; 4 - glass; 5 - plug; 6 — shock-remote fuse; 7 - ring; 8 - lever. Unlike previous generations of grenades, the new grenades have some design features. They use a more powerful explosive charge consisting of hexogen and TNT.

In the early 1980s, RGN and RGO grenades underwent field and military tests and were adopted by the Soviet Army in 1981.

The RGN grenade is designed to destroy manpower in offensive operations, and the RGO in defensive combat.

RGO and RGN grenades have a greater degree of unification among themselves and the same type of fuse. A distinctive feature of grenades is the presence of a shock-remote fuse.

Both grenades consist of a body, an explosive mixture charge, a detonation block and an explosive fuse.

The RGN body consists of two hemispheres made of aluminum alloy 4 mm thick. The body of the grenade has internal notches. The ends of both hemispheres are turned so that the upper hemisphere can be placed on the edge of the lower hemisphere and connected by crimping the upper part. To ensure tightness, a polyethylene ring is placed between the hemispheres.

RGO 1 device - lower inner hemisphere;

2 — lower outer hemisphere; 3 - explosive mixture; 4 — upper outer hemisphere; 5 - glass; 6 - plug; 7 - cuff; 8 — upper inner hemisphere; 9 — shock-remote fuse; 10 - ring; 11 - lever. To increase the number of lethal fragments, the RGO body has two outer and two inner steel hemispheres with a thickness of 2.8 mm. The body of the grenade has internal and external (on the surface of the lower hemisphere) notches. This allows it to be distinguished by its appearance from the RGN offensive grenade.

In the upper part of the body of the RGN and RGO grenades, a thin-walled glass with a large thread (M20x2) is rolled using cuffs for screwing the fuse into it. During transportation and storage of grenades, a stopper is inserted or screwed into the glass to avoid contamination of the glass.

A detonation block is placed under the glass in a recess inside the explosive mixture.

Before the battle, the grenades are loaded, the cap is unscrewed from the glass and the fuse is installed.

RGN and RGO have the same fuse (called shock-remote) UDZ (7ZhZ), created by designer D. Denisov at NITI, and an explosive charge.

fuse UDS 1. fuse body;

2. safety bracket; 3. safety cotter pin with ring; 4. striker with mainspring; 5. striker tip; 6. igniter primer; 7. pyrotechnic moderator; 8. retarder stopper; 9. inertial body; 10. impact mechanism housing; 11. inertial body plate with rod; 12. counter-safety spring; 13. sting; 14. movable bar; 15. movable bar spring; 16. igniter primer of the movable bar; 17. detonating unit bushing; 18. detonator capsule of the detonating unit; 19. powder press-fit moderator; 20. self-liquidator; 21. self-liquidator retarder; 22. detonator capsule. The UDS fuse for the RGO and RGN grenades was developed, like the grenades themselves at the Basalt State Research and Production Enterprise. The design of the impact-remote fuse has become a significant novelty.

The UDS fuse has an interesting design feature. It has two triggering circuits: shock-remote and remote (self-destructive). The chains duplicate each other and the grenade explodes either from hitting an obstacle after the long-range arming time has elapsed (1-1.8 seconds) or (if the impact did not occur or it was not strong enough) after the self-destruction time has elapsed (3.2-4.2 sec).

The fuse is assembled in a plastic case and consists of a pin-safety mechanism, a target sensor, a remote device, a long-range cocking mechanism and a detonating unit. The pin safety mechanism ensures safe handling and includes a striker with a sting, a spring, a cotter pin with a ring, a plug, a bar and a capsule. The firing pin rotates on an axis (like a trigger) under the action of a torsional spring. The target sensor ensures that the fuse is triggered when it hits an obstacle and consists of a spherical weight (inertial body), a sleeve, a sting, a spring and a bushing. The remote device slows down the detonation after a throw by 3.2 - 4.2 seconds and includes a sleeve with a retarding compound and a detonator capsule. The long-range cocking mechanism is designed to cock the fuse 1 - 1.8 seconds after the throw (i.e., at a distance from the thrower) and includes two bushings with pyrotechnic compounds, a stopper, a slider, a primer and a spring. The detonating unit is fixed in a glass and consists of a primer - a detonator and a bushing. In the normal state, the firing pin is rotated to the upper (cocked) position and is held by a lever pressed against the body and secured with a cotter pin. The stoppers hold the engine with the primer in a position shifted to the edge of the fuse, so that the capsule is removed from under the sting and the engine spring is compressed. The load is pressed against the sleeve body, the movement of which is limited by the engine. Such a relatively complex design of the fuse ensures a combination of safe handling (6 stages of protection) with guaranteed operation.

| RGN | RGS | |

| Grenade weight, g | 310 | 530 |

| Charge mass, g | 114 | 92 |

| Explosive type | A-IX-1 | |

| Grenade body diameter, mm | 61 | |

| Grenade body length, mm | 63 | |

| Length of grenade with fuse, mm | 114 | |

| Self-destruction time, sec | 3.2 — 4.2 | |

| Long-range cocking time, sec | 1 — 1.8 | |

| Grenade throwing range, m | 30 — 45 | 20 — 40 |

| Radius of destruction by fragments, m | 8 | 16 |

After pulling out the cotter pin and throwing the lever, under the action of a spring, is thrown away from the grenade and releases the firing pin, which turns and pierces the primer with its sting. The beam of fire sets fire to the components of the remote assembly and the long-range cocking mechanism. After they burn out, the stoppers are retracted by their springs to the edge of the fuse and release the engine, which moves under the action of its spring towards the axis of the fuse, placing the primer opposite the tip of the target sensor. When encountering an obstacle, the load of the target sensor moves under the influence of inertia and causes a displacement of the sleeve, as a result of which the sting punctures the capsule. A beam of fire initiates a capsule - a detonator. The latter transmits the detonation to the detonation block, causing the grenade charge to detonate. The spherical shape of the load and its fastening make it possible to “catch” the inertia component in a wide range of angles.

In case of failure of the target sensor (fall into mud, snow, strictly “on its side”) the detonator capsule will be initiated from the detonator capsule of the remote device after the remote device burns out (3.2 - 4.2 s).

UDZ fuses are manufactured at JSC Velta.

When an RGN grenade explodes, it forms 220-300 fragments with an average weight of 0.42 g with an initial expansion speed of 700 m/s, the reduced expansion area of the fragments is 95-96 sq.m. 73% of the mass of the grenade body is used to form lethal fragments.

The RGO grenade produces 670-700 fragments weighing 0.46 g and a speed of up to 1200 m/s.

73% of the mass of the grenade body is used to form lethal fragments. The energy of RGO fragments is three times higher than that of RGN fragments, the reduced expansion area is 213-286 sq.m. The “controlled fragmentation” of the RGO provides a greater density of the destruction field than with a small number of heavy fragments (like F-1 or Mils), and at the same time greater safety for the thrower and his unit due to the rapid loss of lethal energy by fragments. In terms of fragmentation effect, the RGO grenade is inferior to the F-1 grenade. PUI-RGN (left) and PUI-RGO (right)

The RGO grenade is recommended to be used from some kind of shelter, from a trench, from an infantry fighting vehicle, tank, armored personnel carrier, etc. It is applicable to a moving target (manpower or equipment) and when thrown at any distance.

Grenades can be used in a wide temperature range from -50 to +50 °C.

Grenades are carried in a standard grenade bag, two at a time, or in equipment pockets. Packed in boxes of 20 pieces.

The high sensitivity of the fuse and the large area of scattering of fragments require additional training for personnel in handling them.

For use for educational and practical purposes, teaching throwing techniques in real conditions, the State Research and Production Enterprise "Basalt" has developed two types of practical training equipment PUI-RGO and PUI-RGN, which respectively simulate RGO and RGN grenades. They imitate combat grenades as much as possible, and the products are used multiple times.

The presence of RGN and RGO grenades in the troops did not lead to a complete replacement of the arsenal of old F-1 and RGD-5 hand grenades, the production of which is much simpler and is clearly inferior in cost to new models. At the same time, there is a significant accumulated stock of old-style grenades, so they will be used by the troops for a long time. However, there are situations where RGN and RGO grenades are irreplaceable, so special forces soldiers take grenades of old and new types during operations.

Differences between the impact-inertial fuse and F1

Immediately after pulling out the safety ring, the primer is ignited from the firing pin as in a regular firearm cartridge. If in the F1 grenade, it could only be triggered by the main fuse, then in the RGN and RGO, three moderators, built like a fuse cord, are ignited from one primer at once:

- Self-liquidating retarder. Triggers after 4.5 seconds, regardless of mechanical shocks and the position of the grenade body;

- The second and third moderators burn out in 1.1-1.8 seconds. After this, they mechanically approach the main charge with the help of a spring and when they hit a hard surface (which leads to the displacement of the inertial element, a heavy ball), an explosion occurs.

The installation of an impact-inertial fuse is intended to eliminate the disadvantage when the enemy had time to take cover when a grenade fell. The impact-inertial fuse has a number of advantages. Its main drawback is significant noise when triggered. It does not allow you to throw a grenade out of cover without revealing yourself. It must be said that in close-range battles (and this is where grenades are used), hiding the throw location is not required.

History of creation

The hand grenade has been known to man since ancient times. They began to manufacture such ammunition almost immediately after the invention of gunpowder, but before the advent of powerful high explosives there was no talk of high efficiency of grenades. At the beginning of the 15th century, their bodies began to be made of brittle cast iron, which during an explosion produced a significant amount of fragments. The main problem was the weak blasting effect of gunpowder, which is why hand grenades (they were called “grenades”) had to be made large and heavy.

Only a physically well-trained fighter could throw such ammunition (its weight ranged from one to four kilograms). No wonder the grenadier regiments were considered elite infantry units. Grenades were most often used during the assault or defense of fortresses; they were also very effective in boarding battles.

In addition to the imperfection of gunpowder as an explosive, early types of grenades had another significant drawback - the fuse. For this purpose, wooden tubes filled with gunpowder were most often used. Such a fuse could go out when it hits the ground, go off sooner or later, or even detonate in the hands of a fighter. Calculating the exact time of the explosion was extremely problematic.

Due to the above-mentioned shortcomings, by the middle of the 18th century, grenades were gradually going out of use; only a few assault units continued to use them, and grenades were also in service with fortress garrisons.

By the beginning of the 20th century, grenades were considered an old, primitive and ineffective weapon. These ammunition were practically never used, and their design has remained almost unchanged since the 17th century. At the very end of the 19th century, the Russian Artillery Committee generally ordered the removal of hand grenades from the army's weapons, due to their unreliability and low effectiveness. But in 1904, the Russo-Japanese War began - the first modern conflict, during which large-scale positional battles were fought. It was this war that showed that it was too early to write off the hand grenade.

It turned out that in conditions of trench warfare, a grenade is one of the most effective types of weapons for close combat. And since neither the Russian nor the Japanese military industry produced hand grenades, the soldiers had to start making them themselves. Grenades were made from artillery shells, pipe scraps and even bamboo sticks. For example, in besieged Port Arthur, almost 70 thousand hand grenades were made during its defense.

The military took into account the experience of the conflict in the Far East, so before the start of the First World War, the main powers already had more or less successful examples of hand grenades in their arsenal. Among the ammunition of that period, we can highlight the English Mills Bomb No. 5 grenade and the French F-1. Russian industry has mastered the mass production of the Rdultovsky grenade, the reliability of which, however, had many complaints.

During the First World War, the need for hand grenades was enormous and the domestic industry was completely unprepared to satisfy it. For example, in mid-1915, the front “ate” 3.5 million grenades every month, of which domestic manufacturers could produce only 650 thousand pieces. Therefore, these ammunition were purchased in huge quantities from the Allies.

In the 20s, hundreds of thousands of French F-1 grenades remained in army warehouses, which it was decided to modernize and use. Thus, in 1928, the famous Soviet F-1 appeared, which was a French ammunition with a Koveshnikov system fuse.

In 1941, a unified fuse for hand grenades was developed - UZRG, which was improved after the war. This is how the fuses UZRGM and UZRGM-2 appeared, and they are still used today in F-1 and RGD-5.

In the 70s, work began in the USSR on the creation of a new generation of hand grenades. They were handled by specialists from the State Research and Production Enterprise “Basalt”. A big problem for the progress of this project was the huge stocks of old grenades that were stored in army warehouses. In addition, RGD-5 and F-1 have a simpler design and are cheaper.

In the early 80s, the RGO and RGN were put into service. The first batches of ammunition were immediately sent to Afghanistan. Soviet soldiers appreciated the advantage of the impact fuse.

Currently, RGD-5 and F-1 remain the main grenades of the Russian army; production of RGO and RGN is ongoing, but its volumes are clearly insufficient. The new grenades are mainly used by various special units and have proven themselves to be reliable and effective weapons.