Such different brothers. Walther PPQ M2 Q4 and PPQ M2 Subcompact pistols

Some of the youngest offspring of the Carl Walther family include polymer pistols of the PPQ M2 Q4 and PPQ M2 Subcompact models. The first complements the Q Series Sport line with an Optics Ready option, while the second is a smaller version specifically optimized for quick draw from a holster.

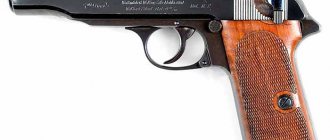

Carl Walther service pistols are among the most famous representatives of their kind in the world. In addition to the Walther P38 pistol, which went through the World War, which continued to be used by the Bundeswehr under the designation P1 before the adoption of the Heckler & Koch P8, the Walther PP (Polizei-Pistole), which appeared back in 1929 and released in 1931, allowed the traditional German manufacturer to gain a reputation , a smaller version of the Walther PPK (Polizei-Pistole-Kriminal). Beginning in the 1960s, the PPK became a staple in movie theaters, becoming famous as the service weapon of Ian Flemming's fictional British superspy James Bond. Since then, Walther brand weapons have been an integral attribute of “agent 007.” Moreover, not only PPK plays this role. Over time, they also became more modern versions - Walther P5 and Walther P99.

From the silver screen to reality

First introduced in 1996, the P99 is still present in various variants in the Ulm weapons manufacturer's program, and its P99Q version, specially developed for security forces, is currently used by the police in Bremen, Hamburg, Rhineland-Palatinate and Schleswig-Holstein. In addition, the P99Q serves as a kind of transition model to the PPQ family.

The full model designation of this pistol is PPQ M2 Q4 AM. The abbreviation AM stands for a long slide stop lever on both sides.

This family became available in 2011 and, according to the manufacturer, was developed not only in close cooperation with police special forces, but also taking into account the wishes of sports shooters. A significant technical difference between the P99Q and PPQ lies in the design of the firing mechanism. However, both versions are the so-called Striker Fired Pistol, that is, a pistol with a striker-fired trigger. While the P99Q has a partially cocked trigger mechanism, which Walther designates as a Quick Action, the PPQ is equipped with a fully cocked Quick Defense Trigger. In other words: the Walther PPQ is a kind of hammerless single action pistol.

The Quick Defense trigger has a trigger travel of approximately 7 mm and a force of approximately 25 N (equivalent to 2.55 kg), which remains almost unchanged with each pull. In addition, the firing mechanism is distinguished by a very short trigger reset (Trigger Reset) of 2.5 mm, which allows shooting at a very high pace.

PPQ line

Over time, the original PPQ appeared in the Walther catalog with the additional designation Classic. At first glance, it could be recognized by the double-sided magazine release lever, located in the trigger guard like the P99. The addition to the name Classic serves only to provide a clearer distinction from the models of the PPQ M2 family released on the American market in 2013. Walther then believed: “Americans only know the 1911 model.” As you know, the Colt M1911 has a magazine release in the form of a button on the left side of the handle. That is, based on the habits of American buyers, the PPQ M2 received a magazine latch in a traditional place, like the Colt Goverment.

What explains the name M2: an adjustable magazine release in the form of a button. The bolt cover behind the hammer module is secured with a spring-loaded cotter pin.

As with the original and M2 lines, there are also variants specifically adapted for use in naval units, designated Navy. While the Classic and Navy models only come in 9mm Luger and .40S&W, the M2 eventually came in a full-size version in .45 ACP. It is also intended primarily for the American market.

The protective plate on which the rear sight is located can be replaced with a base for mounting a collimator sight

Since 2014, Walther has supplied some PPQ M2 pistols to the German civilian market. Among them, over time, PPQ models of the Q line appeared, chambered for the 9 mm Luger cartridge, which are specifically aimed at buyers involved in shooting sports, which began in 2016 with the Q5 Match model. A little later, she received an almost exact copy of herself with a steel handle instead of a polymer one. Already at the end of 2022, the Q line was replenished with a “4-inch” (with a 4-inch barrel) sample PPQ M2 Q4, and in 2018, first of all, delighting users overseas, the subcompact PPQ SC caliber 9 mm Luger with a barrel 3 mm long appeared 1/2 inch. Both of these models were received by the editors of the German magazine DWJ for testing from the Ulm manufacturer.

The Q4 is supplied with a handle backrest in size M. Replacement backrests in sizes S and L are included in the delivery

But before moving on to both tested candidates, for the sake of completeness it would be worth mentioning two more varieties of PPQ models. To achieve certification in accordance with the Technical Directive 2008 (TR 2008), the Ulm team released the PPQ M3 and P3 models intended for law enforcement agencies in 2015. The P3 is equipped with a magazine catch in the trigger guard, while both models, in addition to changes in some details, have a partially cocked firing mechanism and a trigger pull of about 32 N, which complies with the requirements of TR 2008.

Common Features and Differences

Both models tested have recoil-based automatics, a Browning-Petter-ZIG locking system with an interlocking bolt, and a polygonal rifling barrel. In both models, the bolt is equipped with grip grooves on the sides, front and rear, to facilitate reloading. Both models feature a carbon steel slide protected by a matte black shadow finish. Both models have a long slide stop lever on both sides of the slide. While the PPQ M2 Q4 is equipped with a long ejector located on the outside of the bolt, which also acts as an indicator of the presence of a cartridge in the chamber, the PPQ M2 SC has an ejector moved inside the bolt for easier removal from the holster.

With PPQ Subcompact the ejector is located inside the bolt

In both cases, the handles are made of glass-filled polymer and have knurling, designated by Walther as Hi-Grip, a Picatinny rail at the bottom of the frame (Dust Cover), as well as a slightly concave trigger guard with knurling for the fingers. The pistols have three safety mechanisms: a trigger safety, a fall safety and a disconnector. In PPQ pistols, Walther has abandoned the additional manual lever safety. The M2 magazine catch can be moved to the opposite side in both cases; the part necessary for this is located in the plastic case in which the pistols are supplied. The Q4 also comes with two replaceable grip backrests for mounting and, in addition to the 15-round magazine in the weapon, two more backup extended magazines with a capacity of 17 rounds. The PPQ M2 SC also comes with three magazines (2x10 rounds, 1x15 rounds). Moreover, all three magazines have a different design of the lower part, so the length of the handle of a subcompact pistol can vary.

Walther supplies the PPQ M2 SC with three different magazines. Thanks to this, you can vary the length of the handle

Other differences can be found in the types of sights used and, of course, the overall dimensions of the pistols. While the PPQ M2 Q4, intended for sporting use, is equipped with a 3 mm front sight with a red light-gathering insert and a height and side adjustable LPA match rear sight with a 3 mm wide cutout, the PPQ M2 SC has a Walther three-dot phosphorescent sight on the top side of the bolt. It consists of a steel rectangular front sight 3.6 mm wide and a rear sight with a rectangular cutout 4.5 mm wide, which is placed in a dovetail groove milled into the bolt. The LPA match rear sight of the PPQ M2 Q4 is also located in the dovetail groove. But it is not milled directly into the bolt, but is located in the plate inserted into it. This protective plate is secured with two Allen screws and can be removed along with the rear sight for replacement with the most popular brands of red dot sights. The Q4 is priced at €969 and does not include a mounting plate. The more compact SC model costs 899 euros.

The micrometric rear sight PPQ M2 Q4 originates from the Italian manufacturer LPA. The light-gathering front sight made of red fiberglass helps the shooter thanks to the contrasting image in the sight. Under the muzzle of the barrel you can see the return spring guide protruding from the bolt. Accessory bar at front of handle meets MIL-STD-1913 standard

Assembly and disassembly

Of course, every gun owner should be clear that before disassembling the weapon, you need to make sure that it is safe, namely: after removing the magazine, you need to check that there is no cartridge in the chamber of the weapon. This procedure becomes even more important if during disassembly you need to pull the trigger of the weapon.

If the PPQ M2 Q4 is not completely disassembled, the bolt, barrel, recoil spring guide along with the spring itself, handle and magazine are separated

This is exactly the case with PPQ. After removing the magazine from the PPQ and checking that the weapon is loaded, the bolt is pulled to the rearmost position and returned back. Then, as already mentioned, you need to pull the trigger to decock the weapon - with the barrel, of course, pointed in a safe direction. Now you can clasp the barrel lock located above the trigger guard on both sides with the thumb and forefinger of your free hand and lower it down, after which the bolt is separated from the frame by moving forward. After this, you can remove the return spring from the bolt along with the guide and the barrel itself.

Comparing the disassembly of PPQ M2 SC and Q4, you pay attention to the different return mechanism

For assembly, the barrel is inserted into the bolt in the locked position, the return spring guide with its front end is placed in its place in the bolt, the rear end of the guide is tucked into the groove provided for it on the barrel. Now the shutter can again be inserted into the guide frames to move it to its rearmost position and, when released, allow the shutter to return forward. During this assembly procedure, the barrel lock is automatically moved to the locking position.

At the shooting range

When visiting the shooting range, we were able to verify the quality of both pistols. Both PPQ M2 Q4 and PPQ M2 SC worked reliably and without any marks. Of course, thanks to its full handle, the Q4 version felt better in the hand and, due to its greater weight, was more stable. But shooting from an SC with a magazine extension could not be called unpleasant. Both sights provided a clear and contrasting aiming picture. The Q4 match sight was a more comfortable solution when it came to adjusting it. For design reasons, the PPQ Quick Defense Trigger with pre-cocking is one of the best trigger mechanisms available in modern polymer pistols - and this cannot be denied.

The shooting results of both models met our expectations and did not differ from the performance of competing models. However, it should be noted that each time the best dispersion circles were obtained with different ammunition.

DWJ findings

With the PPQ M2 Q4 pistol, Walther follows the current trend. The company brought to the market a sports version of the PPQ, ready for the installation of a red dot sight. Anyone who needs this must pay about 50 euros more for the optionally available mounting plate. The PPQ M2 Subcompact (SC) is suitable for those German hunters who are looking for an easy-to-carry and reliable weapon for picking up wounded animals and/or as a weapon for self-defense. Both models tested exhibited the neat, solid workmanship typical of Walther firearms and functioned absolutely flawlessly. The price-performance ratio in both cases was absolutely adequate.

Andreas Wilhelmus, translation by Ilya Shaidurov

Walter PPQ Navy

Probably no one will be surprised by the fact that weapons used purely on land and those used near the sea should be different. We are not talking about versions of pistols and machine guns capable of firing in an aquatic environment, but about ordinary weapons adapted for shooting in the air, but at the same time being in close contact with sea water, which means it cannot be excluded from getting inside the weapon. Let's try to figure out exactly how such a weapon differs from ordinary models using the example of the Walter PPQ Navy pistol, which appeared relatively recently, but has already proven itself to be a reliable, durable and effective weapon.

First of all, you need to remember that sea water contains a fairly large amount of salts dissolved in it, which makes it especially destructive for weapon parts. Actually, there is no need to go into details here; every car enthusiast knows how salt can quickly destroy the body of a car; in the case of firearms, the situation is no better. Of course, regular cleaning and lubrication would almost completely compensate for the harmful effects of sea water on weapons, but cleaning the weapon completely after each accidental washing will make your hands fall off, so solving this problem falls on the shoulders of the manufacturer, and not the consumer. Unfortunately, “classical” coatings for the surfaces of parts cannot provide protection against the effects of salt water, so the methods that were suitable for coating parts in previous generations of P99 pistols are not suitable in this case. The way out of this situation was the shadowing process, which is a completely domestic development by D. A. Prokoshkin dated 1972, but widely used by various foreign companies, not only weapons companies, and positioned as unique and proprietary. True, in the case of the PPQ Navy pistol, this technology was truly improved. The fact is that the very essence of the shadowing procedure is that the part is immersed in salt molten at a high temperature, during which a film is formed on the surface of the part that is resistant to abrasion and completely protects the part from exposure to aggressive environments, such as sea water. But this process of processing parts also has a negative side in the form that the surface of the part becomes rough, and if you grind it back, the integrity of the protective coating may be damaged. The solution to this problem was the subsequent oxidation of the parts, which created another protective layer, after which polishing took place over the new layer and partially over the first, and then back oxidation. This guaranteed complete coverage of the part with a protective layer, which protects the part even after long-term use.

But not only are salts dissolved in water destructive to weapons, the design of the pistol itself is somewhat different in detail from weapons for land, although I would like to remind you once again that the pistol itself is not suitable for shooting underwater. Or rather, the weapon may be able to shoot, but ordinary cartridges, or rather their bullets, are not suitable for normal “flight” in water - in an environment with a density many times higher than air. Despite the simplicity of the weapon’s design, and in most cases, everything is really simple, individual components cannot work normally after water procedures. So, for example, in a PPQ Navy pistol, the firing pin moves along a channel in the bolt, but if this channel is filled with water, the movement of the firing pin will be significantly hampered. To solve this problem, a separate hole is provided in the bolt, into which water will be forced out when the firing pin moves and, as a result, a situation will not arise when the force of the firing pin is not enough to puncture the primer normally. The mainspring itself has greater rigidity required to overcome the resistance of water in the bolt channel by the firing pin. A similar solution to the problem is used in such well-known pistols as Glock. Thus, a pistol, even if it has lain in water for several days, can be removed and used immediately, without waiting for the water to flow out of the weapon, much less cleaning and drying it. It may seem stupid to some that such a weapon even exists, since not getting a gun wet may seem like a completely manageable task. However, even with all the efforts on the part of a person who owns such a weapon, such situations cannot be ruled out. Still, people trust this weapon with their lives and a pistol simply has no right to let them down.

The appearance of the PPQ Navy pistol is very similar to previous weapon models. At least, the silhouette of the pistol has remained virtually unchanged, but there are some innovations, so it’s impossible to do without a description. First of all, it is worth noting the surface of the weapon’s handle, which virtually completely eliminates the possibility of the pistol sliding in the shooter’s palm, regardless of whether there is water or a layer of silt between the handle and the palm. At the same time, the handle retains the ability to install rear parts of different sizes, which allows you to adjust the weapon to the size of the shooter’s palm. Of the safety devices, there is only a double trigger, which is quite sufficient provided that the weapon is equipped with a firing mechanism with an additional cocking striker, although a non-automatic safety switch would look very good on both sides of the weapon. Of the weapon controls, there is only a trigger, a long slide stop lever, and a magazine release button; there is also a slider designed for disassembling the weapon. The bolt casing has wide and deep notches that allow you to confidently pull the bolt even if it or the shooter’s hands are dirty with something slippery. The sights are open and consist of a rear sight and a front sight marked with light-accumulating paint. An interesting point is that the weapon can be equipped with two barrel options, one of which has a thread for installing a silent firing device; when it is removed, the thread is covered with a protective cap. It is also interesting that the silent firing device itself is produced by another company - Brügger & Thomet AG, while previously everything was produced only by Walther. Under the barrel of the weapon on the frame there is a seat for mounting a compact flashlight or laser designator, although many dispute the need for these devices in weapons, citing the fact that with the same laser designator the shooter is guided only by the laser target spot, which may not be visible from those or other reasons that may lead to a delay before firing.

The automatic operation of the pistol is built on the principle of working with a short stroke of the weapon's barrel, while the barrel engages with the housing-bolt through a protrusion above the chamber and a window for ejecting spent cartridges. The whole system works as follows. When you press the trigger, the firing pin of the pistol is cocked and then released. After hitting the primer, the initiating composition ignites, and then the gunpowder, which leads to the formation of a large amount of powder gases, which build up pressure with their increasing volume. Since the cartridge is located in the barrel of the pistol, the powder gases simply have nowhere to go and they tend to increase the distance between the cartridge case and the bullet in order to free up a larger volume for themselves. Thus, the powder gases with equal force push the bullet forward along the barrel and the cartridge case back towards the shooter. But the bottom of the cartridge case rests against the bolt of the pistol, which in turn is connected to the barrel through a window for ejecting spent cartridges and a protrusion above the chamber. Considering that the weight of the bullet is significantly less than the entire structure, it leaves the barrel before the automatic weapons begin to move. The movement of the moving elements in this case is ensured not by the fact that the powder gases put pressure on the sleeve, forcing it to push the bolt back, but by the fact that an impulse is transmitted through the sleeve to the bolt, so it is not the sleeve that pushes the bolt, but the bolt that removes the sleeve from the chamber. So, after the shot, the barrel and bolt begin to move back, while under the barrel chamber there is a protrusion with a figured cutout, into which a pin is inserted, passing through the frame of the weapon. This cutout is made in such a way that when the barrel moves backward, it interacts with the pin and forces the breech of the barrel to lower. This leads to the fact that the protrusion above the chamber of the weapon comes out of engagement with the bolt casing and the bolt continues to move alone, without the barrel. By removing the spent cartridge case and throwing it away, the bolt casing reaches its rearmost point and stops for a split second. Under the influence of the return spring, it begins to move again, but in the opposite direction, removing a new cartridge from the magazine, inserting it into the chamber and resting against the breech of the barrel, which forces the barrel to move forward. Conversely, due to the influence of the figured cutout and the pin passing through the frame of the pistol, the breech of the barrel is raised and the protrusion above the chamber engages with the window for ejecting spent cartridges, which locks the bore of the pistol.

The combination of one of the most reliable automatic circuits for a pistol, high-quality processing of weapon parts, reasonable use of plastic and the ability to adjust the weapon to the characteristics of the shooter’s palm made this pistol a truly excellent model, which, during its short existence on the weapons market, has become widespread not only in its homeland , but also beyond. It is also important that the weapon has dimensions and weight quite suitable for concealed carry, including daily carry. So the weight of the weapon is only 695 grams without cartridges in the version chambered for 9x19 cartridges, but if the weapon is designed for .40S&W ammunition, then the weight of the pistol will increase only by 10 grams, which creates a lot of questions that have no answers - a trade secret. The length of the pistol in the version for 9x19 cartridges is 180 millimeters, for .40S&W cartridges it is 184 millimeters, respectively, the barrel length is 102 millimeters and 106 millimeters. The thickness of the weapon is 34 millimeters, which is quite a lot, but provided that there are no elements protruding beyond the weapon itself, in practice this does not create any inconvenience. In both versions of the pistol, its height is 135 millimeters. There are also rumors that the weapon will be made for 9x21 IMI ammunition, but for now these are just rumors. The magazine capacity when using 9x19 cartridges is 10 rounds (for the civilian market), 15 or 17 rounds. In the case of .40S&W cartridges, the magazine capacity can be 10 rounds (the same for the civilian market), 12 or 14 rounds.

To summarize all of the above, it is worth noting that a weapon such as the Walther PPQ Navy, if not unique of its kind, is quite rare, since only relatively recently have firearms manufacturers returned to the understanding that models used on land and near water should differ from each other to ensure their trouble-free operation and even for cost savings. True, there is another opinion here - any weapon should be reliable and durable in a wide variety of operating conditions, but, unfortunately, achieving this will be too expensive. It would be interesting to draw a parallel with domestic models of short-barreled weapons adapted for use near sea water, but, unfortunately, there are none yet. However, such weapons can rather be classified as special weapons, and since now all efforts are aimed at providing the army and police with the types that are needed in the first place, blaming someone for the fact that “we don’t have such a thing” is not entirely correct, even though If only what was promised would appear in the near future, and only then it would be possible to think about other samples.