GERMAN "PUMA" 1940s

The car had two control posts - front and rear. The front driver was located on the seat in the center of the car. In front of him was a steering wheel on the steering column, the gearshift and range levers were on the right, the instrument panel was on the left. On the sides there were boxes with batteries and spare parts.

The driver's visibility was provided by three observation windows with multi-layer glass in front of the driver and two more - to the left and right of him in the side walls of the body. In combat conditions, they were covered with armored covers with slots. An emergency exit hatch was located in the upper part of the front plate.

The rear control station was used for driving in reverse without any preliminary turn of the armored car. The driver in this position could drive the car while watching the road through a window in the rear and an additional window on the left side. There were two exit hatches on both sides of his seat in the hull.

In the aft engine-transmission compartment there was a 210-horsepower, highly economical Tatra 103 diesel engine, developed by the Czech company of the same name, 12-cylinder, V-shaped, providing high power density. Its working volume is 14,825 cm3, the cylinder camber angle is 75°. Air cooling of the engine is a priority for using an armored car in hot climates and arid deserts. However, the developers had to install two fans at once, which ensured normal thermal conditions of the engine.

In the roof of the compartment there were ventilation blinds, on both sides of which there were engine service hatches. In addition, in its rear there was an additional ventilation hatch.

The mufflers were placed along the sides of the car's wings.

Sd.Kfz.234/4

Armored vehicle Sd.Kfz.234/4 with Pak 40 anti-tank gun

Torque to the wheels from the engine was transmitted through a three-speed gearbox with preselector control, which created the ability to move both forward and backward at six speeds.

The chassis of the armored car is four-axle all-wheel drive with all steering wheels. Each of them was attached to the body on balancers, the vertical stroke of which was damped by independent semi-elliptical leaf springs. The wheels had air brakes and were single-pitch with low-pressure tires and self-tightening rubber.

Communication was carried out using the Pu Spr Ger “f” radio station with a range of about 1 km when moving, and up to 3 km when parked. The whip antenna was installed at the rear of the tower.

This model of armored car was adopted by the Wehrmacht in 1943 under the designation Sd.Kfz.234/1. The vehicle was considered a reconnaissance vehicle and was in service with reconnaissance battalions of tank and motorized divisions.

In total, Bussing-NAG produced 200 of these armored cars from September 1943 to March 1945.

However, to combat Allied armored vehicles, which by 1943 were already protected by much more powerful armor, heavy armored vehicles with enhanced weapons were needed. German designers proposed using a 50-mm cannon on the Sd.Kfz.231, which was previously installed on the 20-ton Pz.Kpfw III medium tank. These machines were mass-produced since 1938, but by that time they had been discontinued; only a few still fought at the front.

Their KwK 39/1 L/60 gun was long-barreled with a barrel length of 60 calibers and could penetrate armor 57 mm thick with a Pzgr 40 sub-caliber projectile at a distance of 500 m at an impact angle of 60°, and at twice that range - 44 mm. This made it possible to quite effectively fight our T-70s and even T-34s, which, we recall, had 45 mm frontal and side armor.

The gun, intended for the VK 1602 Leopard reconnaissance tank, was placed in a welded oval turret developed by. The turret had frontal armor 30 mm thick and sloping sides of 14.5 mm each, with a mantlet thickness of 100 mm. A coaxial 7.92 mm MG42 machine gun was mounted on the right side of the gun. Three smoke grenade launchers were placed on the sides. To reduce recoil, the gun was equipped with a muzzle brake.

For communication, the crew used two radio stations. One of them - Fu Ger 12 Se - had a conventional two-meter whip antenna on the tower, the other - Ar Spr Ger “a” - an antenna with a “broom”, located on the left in the rear of the hull.

This modification had the index Sd.Kfz.234/2. It was produced from September 1943 to September 1944 - and 101 units were produced. Thanks to its firepower, maneuverability, and survivability, this vehicle, called the Puma, is considered the best heavy armored vehicle of the Second World War.

The firepower of the armored car was further enhanced by installing a 75-mm short-barreled cannon on it. The place of the rotating turret was taken by a stationary low superstructure, devoid of a roof, inside which there was a cannon and an MG42 machine gun. She could only point left and right in a 25° sector.

Basic data of German armored vehicles

These cars had the index “234/3”. From June to December 1944, 88 units were produced.

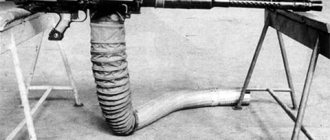

The next modification, Sd.Kfz.234/4, could already be considered a self-propelled anti-tank gun, because in its open-top wheelhouse they placed a serial Pak 40 cannon, which was simply removed from the wheels, but a protective screen was left with it. There was also an MG 42 machine gun in the wheelhouse. The firing sector remained the same as in the previous model - 25°. A sight was used for aiming

3x8. The ammunition load was very small - 12 shots and 1950 rounds. By March 1945, 89 such machines were produced.

From September 1943 to March 1945, about 500 Sd.Kfz.234 armored vehicles of all modifications were produced. However, despite the relatively small circulation, they were very popular among the Wehrmacht troops. In fact, they determined the directions for the further development of eight-wheeled combat vehicles, laying the foundations for the creation of current models.

V. TALANOV

We recommend reading

- WALKING ON WATER I live in Siberia, and from an early age I have been interested in hunting and fishing. Our Siberian places are wonderful. There are a lot of rivers and lakes. Rich in fish and game. Most of all I like to hunt waterfowl...

- ENGINE BLOCKS Every day we use a huge number of things and have almost stopped noticing them. But it turns out that in the production of seemingly insignificant things there is a lot hidden...

BMP "Puma" - current state of affairs

As is known, the Puma infantry fighting vehicle will in the future replace the Marder infantry fighting vehicle, which has long been in service with the German ground forces. According to the Bundeswehr command, in comparison with it the new combat vehicle

has outstanding characteristics

.

The design of the Puma incorporates unique technical solutions that make it possible to meet the requirements of maximum security, increased firepower and high tactical mobility. At the same time, it was possible to maintain the restrictions imposed by the technical specifications regarding the upper limit of the machine’s weight.

The design features of the Puma ensure its compatibility with new developments being implemented in the interests of the ground forces. In particular, we are talking about the project of promising combat equipment “Future Infantryman”, the integration of a combat vehicle into the control information system of the ground forces ( Führungsinformationssysteme, FüInfoSys

) and the introduction of a new generation of tactical radio communications.

BMP "Puma" at the training ground

Growing pains

The project name "Puma" is an acronym that translates from German as "armored vehicle at minimal cost"

(

Panzer Unter Minimalem Aufwand, PUMA).

At the same time, the progress of work is assessed as taking the longest time. The situation is illustrated by a report from the Ministry of Defense on the implementation of 15 promising weapons projects. The document is submitted annually, in March, to the Defense Commission of the German Bundestag.

The German government has set the completion date for deliveries of the Puma infantry fighting vehicle to the troops in 2022. According to data as of March 1, 2022 (the report for 2022 is classified), since the start of development in 1996 and according to estimates for 2022, the total duration of the project will exceed original time targets for 57 months. In terms of cost - by 55 percent, or by 1,226 million euros. At the same time, additional costs for improvements to infantry fighting vehicles and training equipment will amount to 585 million euros.

The main contractors for the production of the Puma infantry fighting vehicle were the Krauss-Maffei Wegmann ( KMW)

) and "Rheinmetall Landsysteme" (

Rheinmetall-Landsysteme, RLS

).

The vehicle concept is based on the project for a "new armored combat platform" ( Neue Gepanzerte Plattform, NGP

). The project involved the creation of a universal tracked base for various weapon systems.

The first several demonstration samples were produced in 2005, and in 2006 they were handed over to the troops. Further testing and testing revealed numerous flaws in the design, software and other elements of the platform. Their elimination led to delays and a significant increase in costs.

Lateral projection

Implementation

The first seven serial infantry fighting vehicles were placed at the disposal of the Army training center in Münster in April 2015. Especially for the Puma infantry fighting vehicle, a structure was deployed at the center for the introduction of new military equipment into the troops ( Einführungsorganisation, EFO

). Within this unit, training of instructors began in April 2015.

According to the signed agreements, the industry will supply 350 Puma combat vehicles to the Bundeswehr ground forces. According to plans, by March 2022 their number in units should be 237 vehicles. In reality, only 199. At the same time, the 2022 report notes the manufacturer’s efforts to eliminate the backlog. So, in 2022, instead of the planned 62, the manufacturer transferred 71 vehicles to the Bundeswehr.

Achieving full combat readiness of the entire fleet of Puma infantry fighting vehicles is scheduled for 2025.

Protection system of the Puma infantry fighting vehicle

The Puma's armor is modular and has two levels of protection. Protection option “A” is the least, but allows the vehicle to be transported by an Airbus A400M military transport aircraft. In this case, the weight of the infantry fighting vehicle with attached equipment does not exceed 32 tons, and the weight of transported additional equipment is limited to 1 ton.

At level “A” the Puma BMP is protected from the front from portable anti-tank weapons (for example, RPG-7), medium-caliber shells (up to 30 mm), artillery fragments, as well as from heavy mines weighing up to 10 kg.

Additional booking scheme

Level of protection “C” (combat) is achieved by using additional modular armor. It includes turret protection, frontal protection, side and roof armor. As a result, according to the manufacturer, the infantry fighting vehicle is capable of resisting anti-tank weapons, medium-caliber projectiles and aircraft cluster munitions ( Bombletts

).

In addition, serial infantry fighting vehicles with protection level “C” are equipped with reactive armor (ERA) from Dynamit Nobel Defense Group. Additional side skirts cover the drive to the middle of the rollers. The Bundeswehr purchased a total of 200 sets. The weight of one set is 1 ton and contains 500 kg of explosives. The time to install reactive armor reaches 3 – 4 hours.

The Puma infantry fighting vehicle is equipped with a WMD protection system manufactured by Dräger. Exhaust gases are mixed with fresh air and exhausted to the left of the chassis to reduce the infrared signature. Further reduction of infrared radiation is achieved by using an appropriate camouflage coating.

Elements of the MUSS system on the tower

The BMP is additionally equipped with an active jamming and suppression system of the MUSS type, from EADS,

designed to counter guided anti-tank missiles. The possibility of equipping the machine with an active protection system is also being considered.

After attaching the entire set of protective equipment, the total weight of the machine increases by more than 9 tons. The ability to configure protective elements allows you to achieve the required level of safety depending on the probable degree of threat. All protective components are capable of functioning autonomously. The failure of some elements does not affect the efficiency of others.