In 1943, the tank units of the Wehrmacht possessed vehicles that, unlike in 1941, were not inferior to the tanks of the Red Army, and in some performance characteristics were superior to them. The appearance of the new Panzer kampfwagen VI Tiger and Panzer kampfwagen Panther finally confirmed the advantage of the Panzerwaffe.

In order to correct the situation and restore parity, it was necessary to radically change the T-34 medium tank, which had been in service since 1940. The T-34-85 became such a tank, capable of giving battle almost equally to any Wehrmacht tank.

History of the creation of the T-34 tank

The history of the creation of the T-34 is closely connected with the history of the creation of the A-20.

After the A-32 was chosen as the basis for the future tank, it was ordered to increase its armor to 45 mm. But they did not waste the metal in vain and first checked its performance characteristics by simply loading ballast corresponding to the mass of additional armor plates.

T-34-76 T-34-76 in Poznan

T-34-76 in winter

T-34-76 in attack T-34-76 in battle

Column T-34-76

T-34-76 on the march

Shot down T-34-76

Monument T-34-76

Shot down T-34-76

Shot down T-34-76

Abandoned Damaged T-34-76 The crew of the T-34-76 prepares the tank for battle

T-34 with F-34 gun

T-34 T-34-76 T-34-76 in battle

T-34-76 inside Captured T-34-76

T-34-76 captured by the Germans

The new tank with increased armor received the factory designation A-34. In October-November 1939, the entire plant worked tirelessly. The government strictly set the task of building 2 models of the tank by November 7, so that they could take part in the parade. However, the tanks were never built on time. The main difficulties lay in the production of armor plates. When bent, cracks appeared in certain places. The large size (at that time) of solid armor plates also made working on them much more difficult.

Scheme T-34 mod. 1940 T-34 model 1940 registration crew

Meanwhile, on December 19, tests of the loaded A-32 ended. On the same day, a decree was issued “On the adoption of tanks, armored vehicles, artillery tractors and their production in 1940 by the Red Army.”

Extract from this resolution about A-32 (T-32):

“...The T-32 tank is a tracked tank, with a V-2 diesel engine, manufactured by plant No. 183 of the People's Commissariat of Srednemash, with the following changes:

Assign a name to the specified T-34 tank...” a) increase the thickness of the main armor plates to 45 mm; b) improve visibility from the tank; c) install the following weapons on the T-32 tank: 1) F-32 76 mm caliber cannon, coaxial with a 7.62 mm caliber machine gun; 2) a separate machine gun for the radio operator - 7.62 mm caliber; 3) separate 7.62 mm machine gun; 4) anti-aircraft machine gun of 7.62 mm caliber. Assign a name to the specified T-34 tank...”

Later, one of the conditions for the adoption of this tank was to overcome a 2000-kilometer range. The first A-34 (the future T-34) rolled off the plant's assembly line in January 1940, and the second in February. And immediately they were sent for factory mileage testing. However, after 250 km, the engine of the first one broke down, which further slowed down the “winding up” of the mileage.

By the end of February, the first car had covered 650 km, and the second – 350. It became clear that by March it would not be possible for each car to cover 2 thousand km, and yet state tests were scheduled for March. An emergency meeting was called at the plant, at which it was decided that the tanks would go under their own power to Moscow. This way they will cover the mileage and be on time. The chief engineer and designer of the machine, Mikhail Ilyich Koshkin, was appointed head of the expedition.

On the night of March 5th and 6th, the convoy set off. It included 2 A-34 tanks and two Voroshilovets tractors, one of which was equipped for sleeping places, and the other for a variety of spare parts and fuel. The route was strictly “secret”, bypassing all settlements and bridges. The first breakdown occurred approximately 80 km after the start of the run. One of the tanks had a broken clutch, which made the tank's movement impossible. Koshkin decided not to wait until the tank was repaired, but decided to move on, having first called a team from the factory for repairs.

The first tank arrived in Moscow on March 12, and already on March 17, both tanks were presented to the government on Ivanovo Square in the Kremlin. This unprecedented transfer had a serious impact on the health of designer Koshkin. He fell ill with pneumonia and died on September 26, 1940 in the Zanki sanatorium, where he was treated.

Stalin personally approved the car and said to provide all the necessary HTZ for mass production of the tank. The tank was put into service on June 7, 1940 and was produced until 1958. In the Russian Federation, the tank was officially withdrawn from service only in 1993. Some modifications of the tank are still in service in a number of countries in Africa, Southeast Asia and Latin America.

Use of the V-2 engine in civilian life

The full potential of the B-2 design could not be revealed either before or during the war - there was no time to unlock the potential. But a set of various small imperfections turned out to be an excellent basis for development, and the concept itself was optimal. After the war, the family was gradually replenished with tank engines V-45, V-46, V-54, V-55, V-58, V-59, V-84, V-85, V-88, V-90, V-92 , B-93 and so on. Moreover, the development has not yet been completed, and individual engines of the family are still being mass-produced.

The modern T-90 tank today is equipped with the V-84MS engine (840 hp) or its modernized version V-92S2 (1000 hp). Both of them are direct descendants and further development of the V-2 concept.

The T-72 tank, the main battle tank of the USSR, produced in a circulation of about 30 thousand copies, received a 780-horsepower V-46 engine. Russia's modern main battle tank, the T-90, was originally equipped with a 1,000-horsepower supercharged V-92 engine. Many of the points in the descriptions of the V-2 and V-92 completely coincide: four-stroke, V-shaped, 12-cylinder, multi-fuel, liquid cooling, direct fuel injection, aluminum alloys in the cylinder block, crankcase, pistons. For infantry fighting vehicles and other less heavy equipment, they created an in-line engine half from the B-2, and the first developments of such a design were carried out and tested in 1939. Also among the direct descendants of the V-2 is a new generation of X-shaped tank diesel engines produced by ChTZ (used on the BMD-3, BTR-90), which use halves in another dimension - V6. He was also useful in the civil service. In the Barnaultransmash association (formerly plant No. 77), the in-line D6 was created from the V-2, and later the full-size D12. They were installed on many river boats and tugs, on motor ships of the Moskva and Moskvich series.

The TGK2 shunting diesel locomotive, produced with a total circulation of ten thousand copies, received the 1D6 modification, and the 1D12 was installed on MAZ mining dump trucks. Heavy tractors, locomotives, tractors, various special machines - wherever a powerful, reliable diesel engine was required, you will find the closest relatives of the great B-2 engine. And the “144th Armored Repair Plant,” which served as part of the 3rd Ukrainian Front from Stalingrad to Vienna, still offers services for the repair and restoration of B-2 diesel engines. Although it has long since become a joint-stock company and settled in Sverdlovsk-19. And frankly, I can’t believe that the high overall power, trouble-free and reliable operation, good maintainability, convenience and ease of maintenance of modern engines of this family are just advertising hype. Most likely, this is actually the case. For that, thanks to everyone who created and improved this long-lived motor.

Armament of the T-34 tank

Since the original L-11 cannon was quickly replaced by the F-34, we will focus on the characteristics of the F-34.

Weight of gun, kg – About 1700 Ammunition, st. — 77 Initial flight speed of an armor-piercing projectile, m/s, — 662 Initial flight speed of a sub-caliber projectile, m/s, — 950 Initial flight speed of Oskol.-High-explosive. projectile, m/s, - 680 Sighting range, m, - 1500 Vertical aiming angles, degrees: -5° +28° Armor penetration: Degrees of inclination are measured in relation to a horizontal surface. Armor-piercing, At a distance of 500 m, mm/deg. — 84/90° Armor-piercing, At a distance of 1.5 km, mm/deg. — 69/90° Sub-caliber, At a distance of 500 m, mm/deg. — 100+/90° Rate of fire, rds/min – up to 5 Additional weapons: Two DT machine guns. One is paired with a gun, the second is a course gun.

8/ An animated monument

Photo: Uralvagonzavod

The T-34 became one of the main symbols of the Second World War and the most widespread monument to military valor - hundreds of T-34s stand on pedestals and in museums around the world as a reminder of the victory of Russian engineering and Russian weapons. An incredible fact: long ago, “museumized” T-34s can be started and made to move under their own power. Such cases have been recorded in Hungary, Israel and even Australia. And, of course, the “thirty-four” takes pride of place in Victory parades, usually opening the procession of heavy equipment.

Tactical and Technical Characteristics of the T-34 tank

Weight, t - 25.6 Crew, h - 4. Commander (aka gunner), Loader, Gunner-Radio Operator, Mechanic-Driver. Case length, mm — 5920 Case width, mm — 3000 Height, mm — 2405

Booking

Degrees of inclination are measured relative to the vertical. Body forehead (top), mm/deg. 45 / 60° Body forehead (bottom), mm/deg. 45 / 53° Hull side (top), mm/deg. 40 / 40° Hull side (bottom), mm/deg. 45 / 0° Hull stern (top), mm/deg. 40 / 47° Hull stern (bottom), mm/deg. 40 / 45° Bottom, mm 13—16 Hull roof, mm 16—20 Turret forehead, mm/deg. 45 Gun mask, mm/deg. 40 Tower side, mm/deg. 45 / 30° Tower stern, mm/deg. 45 / 30° Tower roof, mm 15 / 84°

Ride quality

Engine power, l. With. — 500 Maximum speed, km/h — 54 (According to other sources — 48). Cruising range on the highway, km - 300 Specific power, l. s./t - 19.5 Climbability, degrees. — 36°

Modifications and vehicles created on the basis of the T-34

T-34M - Began to be created due to comparison with the German tank Pz III Ausf.G, which was superior to the 34 in some respects. To improve the smoothness of the ride, a new engine was developed, but the power remained the same. After reworking the arrangement of internal components, the weight and length of the vehicle were reduced, and the ammunition load was increased to 100 rounds. The tank was put into service on May 5, 1941 to replace the standard T-34 model 1940, which was then in service. However, production could not be organized due to the outbreak of the war.

T-34-57 — A new 57 mm ZiS-4 cannon has been installed. It had better characteristics than the F-34. The tank was positioned as a “Tank Destroyer”. Officially, the tank was not accepted for service due to the excessive power of the gun (for 41-42). In 1943, 85-mm guns of greater power appeared. However, only 50 were produced.

T-34-57 undergoing testing

T-34-76 model 1941 - New turret with 52 mm thick walls and two hatches on the turret roof. But one of the most important innovations is the installation of a new 76-mm F-34 cannon.

T-34-76 mod 1941 - first on the right

T-34-76 model 1942 - A new turret shape has been developed. Thanks to the new turret, the ammunition capacity has increased to 100 rounds, and the projectile resistance has also increased.

T-34-76 model 1942

T-34-76 model 1943 - New air cleaners for the engine. New shock absorbers. New caterpillars. New gearbox. For the first time, a commander's cupola from the KV-1S was installed on the tank. The tank is also supplemented with all sorts of little things to “improve the quality of the vehicle.” Entered service on June 15, 1943.

T-34-76 model 1943

PT-34 - PT-3 mine trawl installed on the T-34.

PT-34

T-34-85 - See main article.

T-34-100 - Installed 100 mm D-10T gun. A 100-mm LB-1 cannon was also developed specifically for the T-34. By increasing the caliber of the gun, the turret was enlarged and the chassis was slightly redesigned. Not accepted for service due to the start of work on a more advanced T-54.

T-34-100 in winter 1945

Other equipment based on the T-34:

OT-34 - Flamethrower tank. The crew has been reduced to 3 people. The radio operator gunner has been removed. Entered service in 1942.

OT-34 looked little different from the serial T-34

SU-122 - Self-propelled artillery unit. The self-propelled gun is equipped with a 122-mm M-30S howitzer. Entered service at the end of 1942.

SU-122 with troops near Kharkov. August, 1943

T-43 - See main article.

SU-85 - Tank destroyer. 85 mm caliber gun D-5S. Entered service in August 1943.

SU-85M column in East Prussia. January, 1945.

SU-100 - Tank destroyer. 100 mm D-10S gun. Entered service on July 3, 1944.

SU-100 near Berlin. In the background is a T-34-85. April 30, 1945.

SU-101 and SU-102 - Tank destroyers. Designed to replace the SU-100. The SU-101 was equipped with a 100 mm D-10S gun, and the SU-102 was equipped with a 122 mm D-25-44S gun. They differed from the SU-100 in having stronger armor. Not accepted for service due to severe cramping inside the vehicle and the war having already ended.

SU-101 at the training ground. Autumn, 1942.

T-34T - Tractor . Entered service in 1942.

SPK-5 - Self-propelled slewing crane. Adopted into service in 1952.

TM-34 - Bridgelayer. Entered service in 1942.

T-100 - Egyptian modernization of the T-34 tank. Converted into a tank destroyer with a 100 mm BS-3 gun. Adopted into service in 1967.

T-100 in the Egyptian Museum.

Type 65 (Not exactly) - air defense installation. Equipped with two 37 mm cannons. Nothing is known about adoption.

Type 65

Description of design

Description of design

The T-34 tank had a classic layout with a rear-mounted transmission. Inside, the tank's hull was divided into four compartments: control, combat, engine and transmission.

The control compartment was located in the bow of the tank. It contained the driver's and radio operator's seats, controls, control instruments, a DT machine gun in a ball mount, part of the ammunition, a radio station (not initially installed on all tanks), surveillance devices, two compressed air cylinders for a spare engine start, spare parts , tools and accessories.

The fighting compartment was located in the middle part of the vehicle. It housed the seats of the tank commander (aka gunner) and turret gunner (aka loader). A turret was installed above the fighting compartment on a ball bearing, which housed weapons, part of the ammunition and surveillance devices. There was a hatch (later two hatches) in the roof of the tower for landing the crew.

The engine compartment was located behind the combat compartment in the middle part of the tank and was separated from it by a continuous collapsible partition with hatches closed with removable covers. An engine, two water radiators, two oil radiator tanks, and four batteries were installed in the engine compartment. The engine was located with its toe towards the stern; radiators - on both sides of the engine, parallel to the longitudinal axis of the tank.

The transmission compartment was located in the rear of the tank. It housed the main clutch with a centrifugal fan, a gearbox, side clutches with brakes, an electric starter, final drives and two fuel tanks.

In terms of its layout and the location of the main components and assemblies, the T-34-85 tank was basically identical to the T-34. The main differences were concentrated in the fighting compartment due to the completely different turret design. The latter housed three crew members - the tank commander, gunner and loader. The radio station was located in the turret (with the exception of early production tanks). The main part of the ammunition was located in the fighting compartment on the bottom and near the sides.

Control department of the T-34 tank. Driver's place. The black cylinder at the top left is the balancing mechanism of the hatch cover. To the right of the hatch, above the compressed air cylinders is a TPU device

Control department of the T-34 tank. Radio operator's place. At the top in the center is a ball mount for a machine gun. On the right is the radio station

The layout of the power compartment was distinguished by the location of the oil cooler on one of the water radiators, and the transmission compartment by the placement of two air cleaners in it.

The tank's hull was a rigid armored box with an oblong, rounded bow and stern. It was welded from rolled sheets of homogeneous armor MZ-2 (I8-S). To increase projectile resistance, the upper part of both sides was made inclined. The main parts of the hull are the bottom, bow, sides, stern, roof and transverse partitions.

The bottom, the main fastening element of the hull, consisted of front and rear parts, connected end-to-end by a weld. The connection was reinforced by a T-shaped steel beam, which was the lower part of the motor bulkhead frame. The beam was welded and riveted to the bottom on both sides of the joint. The thickness of the bottom in the front part was greater than in the rear. At the bottom there were: three hatches, closed with armored covers; six holes with plugs and eight cutouts - four on each side. In the front part of the bottom near the radio operator's seat there was an oval-shaped hatch for the crew's emergency exit from the tank.

In the engine compartment, a sub-engine installation was mounted on the bottom, consisting of two transverse brackets, to which two parallel frames were screwed with 36 bolts. The engine was installed on these frames.

The bow of the hull consisted of a front beam, three armor plates, a driver's hatch cover and an armored machine gun cap.

The upper frontal plate of the hull had a rectangular shape at the bottom, a trapezoid at the top and was butt welded to the front beam, side plates, fender liners and turret plate. On armored hulls manufactured by the Stalingrad Shipyard (plant No. 264) in 1942 and in 1942 and 1943, the upper front plate was welded to the side plates with a tenon joint.

The sheet had a stamping above the driver's head, a hole and hinges for attaching the hatch cover, and two bases for mirrored periscope viewing devices. The instruments were located at an angle of 60° to the longitudinal axis of the tank. At the top of the hatch cover there was a base for a central mirror periscope viewing device.

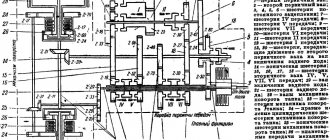

Tank body:

1 — final drive housing; 2 — striker fist of caterpillar fingers; 3 — balancer limiter stand; 4 — balancer support bracket; 5 — cutout for the balancer trunnion; 6 — hole for the balancer axis; 7 — guide wheel crank bracket; 8 — armored plug above the worm shank of the track tension mechanism; 9 — beam of the bow of the hull; 10 — towing hook; 11 — towing hook latch; 12 — bonks for attaching spare tracks; 13.16 — protective strips; 14 — armor protection of the machine gun; 15 — driver’s hatch cover; 17 — headlight bracket; 18 — signal bracket; 19 — handrail; 20 — saw bracket; 21 — bracket for external fuel tank

Armored mask of a ball mount for a machine gun

Cleaning welds on the hull of the T-34 tank

From the beginning of 1942, a driver's hatch of a simpler shape appeared with two prismatic viewing devices, borrowed from the A-43 tank. To protect against bullets and shell fragments, the prisms were covered from the outside with hinged armor covers, the so-called “cilia.”

On the right side of the driver's hatch in the armored cap there was a ball mount for a DT machine gun. Beginning in 1942, an armored mask was placed on the barrel of the machine gun (with the exception of vehicles produced by STZ).

The sides of the hull consisted of lower and upper parts connected by welding. The lower one was a vertical armor plate that had five holes for the passage of the balancer axes, four cutouts for the balancer axles, and five brackets with platforms for attaching rubber buffers that limited the rotation of the balancers. The casing of the track tension mechanism was welded in the front part of the vertical side plate, and the final drive casing was welded in the rear part. The upper part of the side was a fender liner with a horizontal bottom and an inclined side sheet. On the inside, eight boxes were welded to the sides (four on each side), in which inclined spring suspensions of the rollers were installed. Tanks for fuel and oil were mounted in the space between the boxes.

The hull stern consisted of an upper inclined sheet, a lower inclined trough-shaped sheet and two final drive housings. The upper inclined trapezoidal sheet was fastened with hinges and screws to the lower and side sheets. It had a quadrangular hatch (since 1942 - round, with the exception of tanks produced at STZ), providing access to units installed in the rear of the transmission compartment, and two oval holes for exhaust pipes (these holes were protected from the outside by armored caps).

The roof over the fighting compartment was an armor plate, in which there was a large round cutout for installing the turret and four cutouts for access to the upper part of the roller suspensions, which were closed on top with covers. The roof over the engine compartment consisted of a middle longitudinal sheet with a hatch for access to the engine, two side sheets over the radiators, two longitudinal sheets of louvers and caps over the radiators.

The roof over the transmission compartment consisted of two armor plates over the fuel tanks, two louvre armor plates, a narrow end cross plate and a mesh over the roof.

Compared to the T-34, the hull of the T-34-85 tank has not undergone any fundamental changes. All of them basically boiled down to simplifying the design. In 1945, the front beam was removed from the bow, and the upper and lower frontal plates were joined end-to-end. Bonnets were welded to the upper frontal sheet for attaching spare tracks. The hole for inserting the antenna in the right upper side sheet was eliminated. In the aft part of the upper side plates, fastenings for external oil and fuel tanks were welded, and protective strips were welded to the upper edges, protecting the turret ring from damage by bullets and shell fragments. Brackets for attaching MDS smoke bombs were installed on the upper stern sheet.

The turret was welded, oval, streamlined, mounted on a ball bearing above the fighting compartment of the hull.

There were three cutouts in its front frontal plate: the central one for mounting a cannon; right - for a coaxial machine gun; left - for telescopic sight. In the side sheets of the turret there were cutouts for welding the bases of the viewing devices, and under them there were holes for firing from a revolver.

T-34 tank armor scheme

Roof over engine:

1 — middle sheet: 2 — side sheets: 3 — armor covers over the suspension shafts: 4 — armor covers for oil tank filler necks: 5 — armor plate of the shutters; 6 — hatch cover above the engine: 7 — armor strip: 8 — air supply hood; 9 — grille of the air supply hood: 10 — hatch cover for oil filling

In the rear sheet of the turret niche there was a hatch for dismantling the gun; its cover was secured with four and then six bolts. For tanks produced by STZ in 1942, the entire rear turret plate was removable (fastened with eight bolts). Sormovo cars did not have this hatch at all.

In the roof of the tower there was a trapezoidal hatch, closed with a hinged lid, in which there were two holes: the left one - for installing an all-round viewing device; the right one is for signaling. Since the fall of 1941, the all-round viewing device has not been installed, and its hole has been welded shut. This hole was no longer present on tanks produced in 1942.

There were two holes in the front sheet of the turret roof: on the left - for installing a periscope sight; on the right, on the longitudinal axis of the tower, covered with a cap, for ventilation. Since the end of 1941, there were two holes for sights - to the left and to the right of the fan.

On the first production tanks, there was a hole in the rear turret roof plate for inserting an antenna with welded armor. In vehicles of subsequent production, this hole was welded, but later it was simply not made, since the radio equipment, along with the antenna input, was moved from the turret niche to the bow of the hull (on the right side along the tank).

In addition to welded ones, cast towers were produced, in which the roof and bottom of the niche were welded after preliminary machining. The bases of the side viewing devices were cast integrally with the turret body. Otherwise, the cast tower was no different from the welded one.

In 1942, a tower of the so-called “improved” shape was introduced, closer in its outline to a regular hexagon. This tower was made both cast and stamped.

The front inclined wall of the turret had a rectangular cutout for mounting weapons. From the outside, the cutout was covered with an armored frontal shield, which was bolted to the turret.

Two viewing slots equipped with viewing devices were cut on the side walls of the tower. In the rear wall of the niche there was a hole for attaching a device for checking the rollback and roll-up of the gun compressor. The hole was closed with a plug, which was secured with a nut from the inside of the tower.

Some tanks produced in 1943 had holes under the viewing slots for firing from a revolver, which were closed with plugs.

The roof of the tower was a flat armor plate. In the front left part of the roof there was a hole for a periscope sight. On command tanks, there was a hole in the front right side of the roof for a commander's panorama. In the middle part of the roof there were two round hatches for the entry and exit of the crew. Between them there was a removable jumper, which made it possible to remove the onboard fuel tanks through the hatches without removing the turret. At the rear of the roof there was a ventilation hatch covered with an armored cap.

Since the summer of 1943, a number of tanks had a cylindrical commander's cupola with five viewing slits with protective glass installed on the left hatch. The turret roof, which rotated on a ball bearing, had a hatch that was closed with a double-leaf lid with a hole for a viewing device in one of the doors. Tanks with a commander's cupola did not have a removable lintel in the turret roof.

T-34-85 tank armor scheme

Sight armor PT-4-7

Reservation of the viewing device. On tanks of early releases, the top cover was fastened with screws, on later ones (this is clearly visible in the next photo) it was welded

Cast turret of the T-34 tank produced in 1942. Plant No. 183

The turret of the T-34-85 tank was a shaped steel casting. In the front part there were embrasures for installing a cannon, a coaxial machine gun and a sight. From the outside, four eyes and three handrails were welded to the side walls of the tower, and six brackets for fastening the tarpaulin were welded on the rear wall.

In the side walls of the tower on each side there was one hole for firing from personal weapons, which were closed with armored plugs and latches. Tanks of early production with the D-5T gun had inspection slits above these openings; vehicles produced in 1944-1945 retained a viewing slit only on the right side of the turret, near the loader's position. The T-34-85 post-war production did not have viewing slots in the turret.

A cast cylindrical commander's cupola was installed in the roof of the tower on the left side. For all-round observation, five viewing slots were cut in the walls of the turret and covered with protective glass. In the turret roof, which rotated on a ball bearing, there was a hatch with a double-leaf lid and a hole for a viewing device in one of the doors.

T-34 produced in 1943, Chelyabinsk Kirov Plant

For tanks produced in 1945-1946 with a turret with a single-leaf lid, the viewing device was installed in the non-retractable part of the turret roof.

To the right of the turret there was a round loader's hatch, closed with a lid. In addition, in the roof of the turret there were two holes for installing MK-4 surveillance devices for the gunner and loader and two ventilation hatches, closed by armored caps welded to the roof, under which fans of the fighting compartment were installed.

The towers of all variants were driven by an electric turning mechanism or manually. When the electric drive was operating, the maximum rotation speed of the tower reached 4.2 rpm.

WEAPONS. Early T-34 tanks were equipped with a 76-mm cannon mod. 1938/39 L-11 with a barrel length of 30.5 calibers and an initial armor-piercing projectile speed of 612 m/s. Vertical aiming - from -5° to +25°. The practical rate of fire in a tank is 1-2 rounds/min. The gun had a vertical wedge semi-automatic breech with a device for disabling semi-automatic action, since in the pre-war years the GABTU leadership believed that there should not be semi-automatic equipment in tank guns (due to gas contamination in the fighting compartment). A special feature of the L-11 gun was its original recoil devices, in which the compressor fluid was in direct contact with the air in the knurl.

Since March 1941, the T-34 was equipped with a 76-mm gun mod. 1940 F-34 with a barrel length of 41.5 calibers. Gun weight 1155 kg. The maximum rollback length is 390 mm, vertical guidance from - 5°30′ to +26°48′. The shutter is wedge, with semi-automatic mechanical copy type. The gun's recoil devices consisted of a hydraulic recoil brake and a knurler and were located under the barrel. The cannon was fired using foot and manual mechanical triggers.

Post-war tank turret:

1 — loader hatch cover; 2 — caps over the fans: 3 — hole for installing the commander’s observation device: 4 — commander’s cupola hatch cover: 5 — commander’s cupola: 6 — viewing slot; 7 — antenna input glass; 8 - handrail; 9 — hole for installing the gunner’s observation device; 10 — hole for firing from personal weapons; 11 - eye; 12 — sight embrasure; 13 — visor; 14 — axle tide; 15 — machine gun embrasure; 16 - hole for installing a loader observation device

Location of fans on the roof of the turret of the T-34-85 wartime tank

L-11 gun:

1 - trunk; 2 — mask installation; 3 - axle; 4 — gun travel position stopper; 5 — gear sector; 6 — sight forehead; 7 - pillow; 8 — sleeve, catcher; 9 — DT machine gun

The F-34 gun has been modernized twice. During the first improvement, the bolt and semi-automatic mechanism with a copying device, the trigger mechanisms were changed, the compensator in the recoil brake, the safety lock for locking the bolt in the stowed position and the bracket with the buffer were eliminated. In the second case, instead of a barrel with a free pipe, they installed a monoblock barrel with a breech, connected to the pipe using a coupling.

Early T-34-85 tanks were equipped with an 85-mm D-5T (or D-5-T85) cannon with a barrel length of 51.6 calibers. Gun weight 1530 kg. The maximum rollback length is 320 mm. The gun had a wedge breech, similar in design to the breech of the F-34 cannon, and a semi-automatic copy type. The recoil devices consisted of a hydraulic recoil brake and a hydropneumatic knurl and were located above the barrel: on the right side there was a knurl, on the left there was a recoil brake.

Since March 1944, the T-34-85 tank was equipped with an 85-mm S-53 (and then ZIS-S-53) gun mod. 1944 with a barrel length of 54.6 calibers. The mass of the swinging part of the gun without armor is 1150 kg. The maximum rollback length is 330 mm. Vertical aiming from -5° to +22°. The gun bolt is a vertical wedge with a semi-automatic copy type. The gun's trigger mechanism consisted of electric and mechanical (manual) triggers. The electric release lever was located on the handle of the lifting mechanism flywheel, and the manual release lever was located on the left shield of the gun fence.

The tank was armed with two 7.62-mm DT machine guns, one of them was coaxial with a cannon, the other was mounted in a ball mount in the front hull plate.

To fire from the L-11 cannon, the TOD-6 telescopic sight and the PT-6 periscopic panoramic sight were used; for firing from the F-34 cannon - the TOD-7 telescopic sight and the PT-7 periscopic panoramic sight, later replaced by the TMFD-7 telescopic sight and the PT-4-7 periscopic panoramic sight. In addition to the standard periscope sight, some tanks were equipped with a PT-K commander's panorama.

For firing from closed positions, since 1943, the F-34 cannon was produced with a side level mounted on a cradle.

For direct fire from the D-5T cannon, the TSh-15 telescopic sight and the PTK-5 periscopic sight were used, and from the S-53 and ZIS-S-53 cannons, the TSh-16 telescopic sight was used. For shooting from closed positions - a side level and a turret inclinometer.

For firing from the L-11 and F-34 guns, unitary cartridges from divisional guns mod. 1902/30 and model 1939 and from the regimental gun model. 1927;

- with a high-explosive long-range fragmentation grenade (steel OF-350 and steel cast iron OF-350A) and a KTM-1 fuse;

The swinging part of the F-34 cannon with a telescopic sight:

1 - calyx; 2 - trailer; 3 — telescope holders; 4 — rollback indicator line; 5 — frontal stop; 6 — eyecup; 7 — lateral correction handwheel; 8 — aiming angle handwheel; 9 — release lever; 10 — sector of the lifting mechanism; 11 - handwheel handle

T-34 and T-34-85 tanks before the parade in Leningrad, 1945. In the foreground is the turret of a tank made in 1944 with a double-leaf hatch cover for the commander's cupola, MK-4 surveillance devices without armor covers and an S-53 cannon. The second car in this series is produced in 1945

- with a high-explosive grenade of the old Russian model (F-354) and fuses KT-3, KTM-3 or ZGT;

— with an armor-piercing tracer projectile (BR-350A, BR-350B, R-350SP) and an MD-5 fuse;

— with an armor-burning projectile (BP-353A) and a BM fuse;

- with bullet shrapnel (111-354 and Sh-354T) and Hartz shrapnel (Sh-354G), with tubes - 22-second or T-6;

— with rod shrapnel (Sh-361) and T-ZUG tube;

- with buckshot (Sh-350).

In October 1943, a unitary cartridge with a sub-caliber armor-piercing tracer projectile (BR-354P) was put into service and began to be included in the ammunition load of the T-34 tank.

In tanks produced in 1940-1942, the ammunition consisted of 77 rounds, which were placed on the floor of the fighting compartment and on its walls. 20 high (for 3 shots) and 4 low (for 2 shots) suitcases were installed on the floor of the tank - a total of 68 shells. There were 9 shots placed on the walls of the fighting compartment: on the right side - 3, in a common horizontal stacking, and on the left - 6, in two horizontal stacks, 3 shots each.

In tanks produced in 1942-1944 with an “improved” turret, the ammunition load consisted of 100 rounds (armor-piercing - 21, high-explosive fragmentation - 75, sub-caliber - 4). To store shots on the floor of the fighting compartment, 8 boxes for 86 shots were equipped. The remaining 14 rounds were placed as follows: 2 armor-piercing tracers - in cassettes on the lid of the box in the right rear corner of the fighting compartment, 8 high-explosive fragmentation rounds - on the left side of the fighting compartment, and 4 sub-caliber ones - in cassettes on the right side.

Internal view of the T-34-85 tank turret (front side):

1 — loader’s seat: 2 — cartridge case catcher; 3 — gunner's seat; 4 — turret rotation mechanism; 5 — capture of the turret ring; 6 — locking device for the opening for firing from personal weapons; 7 — button for turning on the backlight of the protractor; 8 — electrical panel of tower equipment; 9 — sight suspension; 10 — MK-4 observation devices; 11 — sight TSh-16; 12 — sight lighting shield; 13 — cannon; 14 — tower lighting lamp; 15 — coaxial machine gun; 16—stack of machine gun magazines on the right side of the turret; 17 — turret stopper; 18 — device No. 1 TPU

Characteristics of projectiles

| Brand | OF-350 | BR-350A | BR-354P |

| Projectile weight, kg | 6,23 | 6,5 | 3,05 |

| Initial speed, m/s | 680 | 662 | 950 |

| Armor penetration normal, mm at a distance: 500 m | — | 70 | 90 |

| 1000 m | — | 60 | — |

For firing from 85-mm tank guns, standard ammunition from an 85-mm anti-aircraft gun model 1939 was used:

— a unitary cartridge with an armor-piercing blunt-head tracer projectile (BR-365) with a ballistic tip with MD-5 and MD-7 fuses;

— a unitary cartridge with an armor-piercing tracer sharp-headed projectile (BR-365K) with an MD-8 fuse;

— unitary cartridge with a fragmentation steel grenade (0-365K) with a KTM-1 fuse;

— a unitary cartridge with a sub-caliber armor-piercing tracer projectile BR-365P (put into service in February 1944).

The gun's ammunition consisted of 55 artillery rounds (fragmentation rounds - 36, armor-piercing rounds - 14, sub-caliber rounds - 5) and was placed in the hull and turret of the tank in three types of stowage: rack, clamp and box.

The rack for 12 shots was located in the niche of the tower. It included fragmentation grenade shots.

The clamp racks were located: on the right side of the turret - for 4 artillery rounds; in the control compartment on the starboard side of the hull - for 2 artillery rounds; in the right rear corner of the fighting compartment - for 2 artillery rounds. On the right side of the turret shots with armor-piercing shells were stacked, and in the control and combat compartments - with sub-caliber shells.

Six boxes located on the bottom of the fighting compartment contained 35 rounds, of which: 24 with a fragmentation grenade, 10 with an armor-piercing projectile and 1 with a sub-caliber one.

The machine guns' ammunition initially consisted of 2898 rounds of ammunition (46 discs). For tanks of early production that did not have a radio station, it included 4,725 rounds of ammunition (75 discs). The T-34 with an “improved” turret carried 3,150 rounds of machine gun ammunition (50 discs), while the T-34-85 carried 1,953 rounds of ammunition (31 discs). The fighting compartment contained one PPSh submachine gun, 4 magazines for it and 25 F-1 hand grenades.

ENGINE AND TRANSMISSION. The T-34 and T-34-85 tanks were equipped with the V-2-34 12-cylinder four-stroke uncompressor diesel engine. Rated engine power - 450 hp. at 1750 rpm, operational - 400 hp. at 1700 rpm, maximum - 500 hp. at 1800 rpm. Cylinder diameter 150 mm. The cylinders were arranged in a V-shape at an angle of 60°. Compression ratio 14-15. The piston stroke of the left group is 180 mm, the right one is 186.7 mm. The weight of a dry engine with an electric generator without exhaust manifolds is 750 kg.

Fuel - diesel, DT grade or gas oil, grade "E" according to OST 8842; it was supplied forcibly using a twelve-plunger fuel pump NK-1.

Early T-34 tanks had six internal fuel tanks with a total capacity of 460 liters and four external fuel tanks with a total capacity of 134 liters. By the end of the summer of 1943, the number of fuel tanks was increased to eight, and their capacity increased to 545 liters. Instead of four side tanks, two rectangular stern tanks were installed, and since 1943, two cylindrical tanks with a capacity of 90 liters were installed on each side. External fuel tanks were not connected to the engine power system. The power system was preserved in this form on the T-34-85.

View of the engine of the T-34 tank from the side of the turret. Behind the “pancake” of the air cleaner you can see a filler tee with a steam-air valve, designed for pouring water into the cooling system. On the sides, between the shafts for the weights, oil tanks are visible

View of the transmission of the T-34 tank. An electric starter is installed on top of the gearbox, and side clutches are installed on the sides.

Options for aft fuel tanks of the T-34 tank

The lubrication system is circulating, under pressure. Oil circulation was provided by a three-section gear oil pump. The capacity of the internal oil tanks is 76 l, the external one (for T-34-85) is 90 l.

The cooling system is liquid, closed, with forced circulation. There are two tubular radiators, installed on both sides of the engine, tilted towards it, with a total capacity of 90-95 liters.

To clean the air entering the engine cylinders, an air cleaner of the Pomon type was installed on the T-34 tank, and from January 1943, two air cleaners of the Cyclone type were installed, and on the T-34-85, a Multicyclone was installed.

The engine was started by an ST-700 electric starter with a power of 15 hp. or compressed air (two cylinders were located in the control compartment).

The transmission consisted of a multi-disc main dry friction clutch (steel on steel), a gearbox, final clutches, brakes and final drives.

The gearbox is three-way, four-speed with sliding gears (since March 1942 - five-speed, with constant gear meshing). Onboard clutches are multi-disc, dry (steel on steel); The brakes are floating, band, with ferrodo lining. Final drives are single-stage.

The tank's chassis, applied to one side, consisted of five double road wheels with a diameter of 830 mm. The track rollers produced by different factories differed significantly in design and appearance: cast or stamped, with rubber bands or with internal shock absorption (in the summer of 1942, STZ produced rollers without any shock absorption at all).

Transmission compartment of the T-34-85 tank:

1 — side clutch with brake band; 2 — gearbox; 3 - main clutch; 4 - electric starter; 5 - starting relay; 6 — final drive; 7 — left aft fuel tank; 8 — left air cleaner; 9 — air duct; 10 — heater; 11 — fan; 12 — exhaust pipe; 13 — right air cleaner; 14 — right aft fuel tank

Top view of the Multicyclone air purifier installed in the transmission compartment of the T-34-85 tank

General view of a four-speed gearbox without the upper half of the crankcase:

1 - lower half of the crankcase; 2 - main shaft; 3 — main shaft bearing race; 4 - fixed gear of 2nd gear; 5,7,13 - spacer sleeve; 6 — fixed gear of 1st gear; 8 — cage of tapered roller bearings of the middle support; 9 — movable carriage of gears of the 3rd and 4th gears; 10 — roller bearing race of the outer support; 11 — roller bearing of the outer support; 12 — fixed gear of 3rd gear; 14—fixed gear of 4th gear; 15 — driven bevel gear; 16 — intermediate shaft roller bearing race; 17 — intermediate shaft; 18 — movable carriage of gears of 1st and 2nd gears; 19 — drive roller cage; 20 — coupling teeth

General view of a five-speed gearbox without a housing:

1 - drive shaft: 2 - intermediate shaft; 3—main shaft; 4 - 1st gear drive gear; 5 - 1st gear driven gear; 6 - 2nd gear drive gear; 7 - 2nd gear driven gear; 8 - 3rd gear drive gear; 9 — 3rd gear driven gear; 10 - 4th gear drive gear; 11 — 4th gear driven gear; 12 - 5th gear drive gear; 13 — 5th gear driven gear; 14.15 — reverse block gear; 16 — reverse drive gear; 17 — shaft bearings; 18 — driven bevel gear; 19 — carriage of 4th and 5th gears; 20 — carriage of 2nd and 3rd gears; 21 — collar for shift fork for 1st and reverse gears; 22 — drive shaft bearing race; 23 - drive bevel gear

Tactical and technical characteristics of tanks T-34 and T-34-85

| Year of issue | 1940 | 1943 | 1944 |

| Combat weight, t | 26,8 | 30,9 | 32 |

| Crew, people | 4 | 4 | 5 |

| Overall dimensions, mm: | |||

| length | 5920 | 6620 | 8100 |

| width | 3000 | 3000 | 3000 |

| height | 2400 | 2520 | 2720 |

| clearance | 400 | 400 | 400 |

| Armor thickness, mm/tilt angle: | |||

| front hull sheet | 45/60° | ||

| side sheets | 45/0° | ||

| fender liner sheets | 40/40° | ||

| top sheet of stern | 40/47°32′ | 45/47°32′ | 45/47°32′ |

| bottom sheet of stern | 40/45° | ||

| front roof sheet | 16/90° | ||

| removable roof sheets | 16/90° | ||

| front bottom sheet | 16/90° | 20/90° | 20/90° |

| rear bottom sheet | 13/90° | ||

| turret front plate | 45/— | 45/— | 90/— |

| tower side sheets | 45/30° | 45/30° | 75/20° |

| tower roof | 15/90° | 15/90° | 20/90° |

| gun mask | 25/— | 25/— | |

| Max, speed, km/h | 55 | ||

| Average speed, km/h: | |||

| along the highway | 30 | ||

| by area | 25 | ||

| Power reserve, km: | |||

| along the highway | 300 | 300 | 300+100 |

| along the country road | 227 | 250 | 230—320 |

| Support surface length, mm | 3840 | 3840 | 3850 |

| Specific pressure, kg/cm2 | 0,62 | 0,79 | 0,83 |

| Specific power, hp/t | 18,65 | 16,2 | 15,6 |

Individual suspension, spring.

The rear drive wheels had six rollers for engagement with the ridges of the track tracks. In 1942, some tanks were produced with solid drive wheels without rollers. The early T-34s had rubber and then steel tires on the drive wheels.

The guide wheels are cast, with a crank mechanism for tensioning the tracks. Early tanks had rubber-coated guide wheels.

The tracks are steel, with cast or stamped tracks, with ridge gearing. For tanks of early production they consisted of 74 tracks (37 ridge and 37 flat) with a width of 550 mm. For vehicles produced in 1942-1946, the tracks consisted of 72 tracks, 500 mm wide, with a track pitch of 172 mm. The weight of one caterpillar is 1150 kg.

ELECTRICAL EQUIPMENT was made according to a single-wire circuit. Voltage 24 and 12 V. Sources: GT-4563A generator with a power of 1 kW, four 6-STE-128 batteries with a capacity of 128 Ah each. Consumers: electric starter ST-700, electric motor of the turret turning mechanism, electric fan motor (T-34-85 has two), control devices, external and internal lighting equipment, electric signal, radio station umformer and TPU lamps.

MEANS OF COMMUNICATION. The T-34 was equipped with a short-wave transmitting and receiving simplex telephone radio station 9-R (on the first production tanks 71-TK-Z), which had the ability to receive unmodulated telegraph signals. Since 1943, the T-34, and later the T-34-85, began to be equipped with modernized 9-RM and 9-RS radio stations with an extended range.

On early production tanks, internal communication was provided by a pre-war TPU-2 or TPU-3 tank intercom. Later, all T-34 and T-34-85 tanks were equipped with the TPU-Z-bisF intercom.

Combat use of the T-34

The T-34 received its first combat experience in the Great Patriotic War. By the beginning of the war, a little more than a thousand vehicles had been produced, and there were 926 Thirty-Fours in the border districts.

The meeting with new Soviet tanks (T-34 and KV) was a real surprise for the German troops. In terms of its combat characteristics, the T-34 was superior to almost all Wehrmacht tanks available at that time, but the crews’ poor knowledge of new equipment, tactical miscalculations in the use of tanks, and a shortage of ammunition, fuel and repair and maintenance equipment negated all advantages.

In the chaos of the first months of the war, most of the vehicles were simply abandoned due to breakdowns or lack of fuel. And in general, the share of “thirty-fours” compared to the BT-7 and T-26 was very low.

The situation changed in the fall of 1941, when the number of T-34s in the troops increased significantly and they began to pose a much more serious threat to German tanks, as evidenced by numerous evidence from the opposite side.

By the end of 1941, the T-34 had already become the main Soviet tank, playing a key role in all major battles. Since 1942, more T-34s have been produced than all other Soviet tanks combined. Such recognized tank aces as D.F. fought on the T-34. Lavrinenko (52 destroyed German tanks in 2.5 months - the best result among Soviet tankers), V.A. Bochkovsky, N.D. Moiseev, K.M. Samokhin, A.F. Burda and others.

Up until the Battle of Kursk, the T-34 continued to outperform almost all German tanks, but in the summer of 1943 the situation changed. The appearance of new German tanks and tank destroyers significantly weakened the position of the T-34, which ultimately led to the appearance of the T-34-85 modification, which gradually began to displace the T-34 with a 76-mm cannon from the troops. By the beginning of 1945, there were practically no T-34-76s left in the army. A number of them took part in the defeat of the Japanese army.

Start of production.

In the winter of 1940, three production T-34s went on a Kharkov-Kubinka-Smolensk run to identify design flaws. The officers of the BT Research Institute who carried out the tests found so many shortcomings that the report they submitted was not left to the Deputy People's Commissar of Defense Marshal G.K. Kulik has no choice but to give the order to stop the production and acceptance of the T-34. In return, it was decided to speed up the development of a new medium tank, the A-43, with torsion bar suspension and improved armor.

Head of ABTU Ya. Fedorov, with whom G.K. agreed. Kulik proposed to leave the BT-7M in production and speed up work on the T-50. The management of the Kharkov plant did not agree with such an unforestable assessment and the proposal to put an end to their brainchild and insisted on continuing production, proposing to temporarily reduce the warranty mileage of the car, which was supposed to be a thousand kilometers, by three times. The dispute was stopped by Voroshilov, who, although at that time he lost the high position of People's Commissar, but as a member of the Politburo of the Central Committee and as an old Bolshevik, he did not lose his influence, both on Stalin and on the chairman of the Council of People's Commissars, Molotov. It was his recommendation that allowed the continuation of production of the T-34 until it was replaced in production by the T-43M.

Less than six months later, the Second World War showed the correctness of this decision. T-34, the production of which was launched in Stalingrad and Kharkov, made it possible to quickly organize their production at enterprises in rear areas during the war period. From the moment it was put into production until the start of the war, the new T-34 was manufactured in quantities of about 1,225 units. With the beginning of the mobilization of industry, Gorky (manufacturer No. 112) joined the production of the tank.

T-34 in the cinema

Despite the very large number of T-34-76 produced, few copies of this tank survived after the war. Therefore, in films, this tank is almost always replaced by the T-34-85 modification, as was the case, for example, in the famous series “4 Tankers and a Dog” or in the film “Hot Snow.”

Authentic copies of the T-34-76 are present in the following films:

• “Two Soldiers” • “Ivan Nikulin - Russian Sailor”; • “The Great Turning Point” (T-34-76 model 1942 was shown with and without a commander’s cupola); • “Lark” (for this film the T-34-76 was specially reconstructed at the Lenfilm studio).

5/ New tank – in one month

The history of the T-34 has many impressive feats. One of them was the record launch of production at the Chelyabinsk Tractor Plant (today part of the UVZ corporation), which with the beginning of the war turned into the world's largest tank conveyor, or, as it was popularly called, Tankograd. At the height of the war, the plant underwent reconstruction and quickly mastered the production of the T-34: the workers received the drawings on July 22, 1942, and just a month later the first Chelyabinsk “thirty-four” was ready. By the end of 1943, the plant was assembling 25 tanks daily.