Sixty is an age that deserves respect. Even in a human life, this is a considerable period of time, let alone the much shorter automobile age. Collectible elite supercars and executive cars of important people and celebrities mostly survive to this age. But there are exceptions to this rule!

Daniil Minaev, photo by the author

Early on Saturday morning I went to the southeast of the Moscow region, in the direction of that famous Meshchera, glorified by the writer Paustovsky. My colleague told me that a ZIS-151 veteran is still working in a small private farm. And this turned out to be absolutely true. When we were returning home after the retrotest of the ZIS, we met a dump truck on a GAZ-51 chassis. Absolutely serviceable, ready to deliver bulk cargo to your dacha at any moment... Mysticism, and that’s all!

The mystical series of events of that day was a foregone conclusion. No matter how much I test old cars, none of their stories repeat themselves. The only thing that makes automobile biographies similar is their typical youth in Soviet automobile fleets or the garages of private vehicle owners who were rare at that time. But even here the fate of this “151st” ZIS is atypical.

At the development stage

The automaker produced military equipment during the war. During the war years, about one million ZIS-5 models were produced. In parallel with this, the designers were developing a new model with two drive axles. So, in 1944, the first sample of the ZIS-150 car was assembled. Due to its excessive weight, this development did not meet the requirements of the country's Ministry of Defense. Therefore, it was decided to produce three-axis models. Development of the new model began in the winter of 1945. From this moment the history of the creation of the ZIS-151 begins.

A year later, two versions of the car were developed. The first appeared in May. It was distinguished by gable wheels at the rear. The second version was compiled a little later (in the fall of this year). This version had a cab from the ZIS-150 and single wheels at the rear.

In the summer of 1947, tests of the ZIS-151 vehicle were carried out. There he showed his best side. The tires ran very smoothly. It took less fuel to lay the path than competitors. In 1948, production of serial cars began.

All-wheel drive ZIS-32 1940

ZIS-32

- serial

all-wheel

drive Soviet truck.

Production began in 1940 at the Stalin Automobile Plant. The prototype of the ZiS-32 was the NATI-K2 (NATI-ZIS-K2), developed and tested in 1939 at the Scientific Automotive and Tractor Institute and was a modification of the serial rear-wheel drive three-axle truck ZiS-6, redesigned for all-wheel drive. Despite the fact that, in fact, at the end of winter 1939, the NATI-2K was put into service as an all-wheel drive truck for the army, quite a lot of problems lay ahead. The biggest dependence was on another automobile plant, GAZ, which produced some of the ZiS-32 components, in particular, the main gear. It was not possible to produce the same unit on the ZiS, and according to the technical standards of that time it was impossible to install the final drive from the GAZ-AA on the ZiS-5 axle on a production car. As a result, it was necessary to install on the front axle

of the ZiS-32 the main gear from the ZiS-5, which was originally intended for the rear, loaded axle and therefore weighed more than the lightweight “front” one from the GAZ-AA. And this, as you understand, increased the weight of the car, and this weight was useless - tens of kilograms of iron.

Power 73 hp. s., which the ZiS-32 retained from experimental models, was clearly insufficient. But this was not the only thing that slowed down the acceptance: the ZiS-32 did not have tow hooks, and yet a military truck was required to have them. There were a few other “parts” missing, too, but the most difficult one was the lack of power. In 1940, a forced ZiS-16 engine

, but their quantity was not enough to equip all ZiSs, and it was impossible to quickly increase their production capacity.

Meanwhile, the Great Patriotic War was approaching, and the war with Finland was already underway. In the fall of 1940, two intermediate models ZiS-32R and ZiS-32S were created and tested (the first with Rtseppa CV joints, and the second with Spicer CV joints and a raised platform). The commissions recognized that the experimental ZiS-32R and half-track transporter ZiS-22-52 (a modified ZiS-22, which by that time had already been produced in the amount of 200 units) were suitable for serial production. It was decided to start mass production in 1941, but the plant did not have enough production capacity for this, since they were occupied by the serial ZiS-22 and ZiS-33

. The main problem was the lack of equipment for the production of Rtseppa type CV joints. Under the pressure of all these circumstances, production of the ZiS-32 was postponed until the end of the Finnish War, then it was resumed, and at an accelerated pace. As the builds progressed, problems constantly arose and various shortcomings had to be eliminated. To increase production, bonuses were paid to the staff for each machine assembled. But at the end of July, the war began, and the plant received military orders - there was no time to modify the car. Therefore, the 197 ZiS-32 trucks produced were sent to the front, and production was closed. In mid-October, the evacuation of the plant began - Hitler’s troops were steadily approaching Moscow.

Power unit

The car was originally equipped with ZIS-120 engines. This engine had a volume of five and a half liters.

Since 1950, they were replaced by the ZIS-121 engine. This is a four-stroke gasoline carburetor with six cylinders. The ZIS-151 engine had a power of ninety-two horsepower. Liquid cooling. For fuel, two tanks were installed on the truck. Each of them had a volume of one hundred and fifty liters. They were hiding on both sides under the loading platform.

The installed engine allowed the car to accelerate to fifty-five kilometers per hour. At the same time, fuel consumption was forty-two liters per hundred kilometers.

Finalization

The first years of operation of military trucks showed that the vehicle needed fine-tuning. The gable wheels could not pass through the mud; sticky soil wrapped around the treads, and the car stopped. I had to clean the tires with improvised means. Gradually, all the trucks were converted, single wheels were installed, and cross-country ability increased.

In addition, the engine had to be modified; the rated power of 92 horsepower was insufficient. By boring the cylinders and increasing the compression ratio, it was possible to increase the engine power by 12 hp. s., but this was not enough. Engine thrust became optimal after changing transmission ratios.

Transmission and chassis

The ZIS-151 model was equipped with a non-synchronized gearbox with five speeds. The last speed is accelerating. The clutch is a dry type with two discs.

The suspension springs are supplemented with double-acting hydraulic shock absorbers. Drum brakes equipped with a pneumatic drive.

The wheel formula is 6 x 6. ZIS-151 is a vehicle with all-wheel drive. It was complemented by a two-speed transfer case. This made it possible to disable the front axle drive. The transmission included five driveshafts on which ten hinges were installed. The housings of the two rear axles were shifted in different directions. The bridges themselves were suspended by a balancer suspension and had two longitudinal springs. The two rear wheel axles were equipped with three driveshafts, complemented by needle-type bearings. A separate drive has been developed for each of them.

The old horse doesn't spoil the furrows

These are the associations that come when you look at the components and assemblies of the “151st”. The engine, a low-valve in-line six, idles almost silently, while at the same time emitting a pleasant low-frequency rumble that caresses the ear, which creates the impression of monumentality, strength and durability. There is nothing disposable or quick-removable in the design: the only consumables that occasionally need to be replaced are spark plugs and high-voltage wires. The oil filter is centrifugal type, the air cleaner is inertia-oil. It is periodically sorted out, washed and filled with fresh oil. There are an abundance of lubrication points in the chassis, air brakes work reliably, but it is regularly necessary to drain condensate from the receivers and refill the brake pads in the drum mechanisms. With proper (read, daily) care, this entire facility can work for a very long time, which it has been doing for almost 60 years.

Appearance

ZIS-151 “Zvezda” was a universal flatbed truck. The sides are made in the form of a lattice. The body is complemented by benches located longitudinally and an awning.

The first models (before 1950) had a wooden cabin with metal elements, which could accommodate three people. The cladding was made of plywood. The footrests were also wooden. The front wall was made of metal. The windshield is folding. After 1950, a cabin made entirely of metal was installed.

A short bumper was installed on the spar frame at the rear of the car. It allowed you to push the car in front. This was relevant given the difficult road conditions.

Where to begin?

In the newly formed USSR on September 1, 1923, the engineering units of the Red Army included 39 motorized detachments of rifle divisions, 27 motorized cargo detachments, as well as the Petrograd motor transport battalion (4 detachments) and a training motorized brigade. Of course, all these units were equipped with foreign-made cars and motorcycles, so in fact we are talking about automobile troops, but until the early 1930s, all wheeled vehicles were under the control of military engineers.

The AMO F-15 managed to take part in early experiments in using domestic vehicles for engineering needs. On the chassis of this truck there was a modification (at least in a single copy) “F-15 searchlight vehicle with a searchlight 015-2 mounted on the platform.” This car was not new; Anti-aircraft fire searchlights installed on cargo platforms, receiving electricity from a generator installed on the same vehicle and driven by a car engine, were used in the tsarist army.

Due to the specific nature of the tasks solved by engineering units, tracked vehicles - tractors and tanks - turned out to be much more in demand at the turn of the twenties and thirties. The former were used for towing heavy loads (from cannons to pontoons) and laying roads, the latter were equipped with trawls for mine clearance. By the 1930s, military formations began to receive motorized drills, sawmills, boats, scrapers, and graders (including horse-drawn ones).

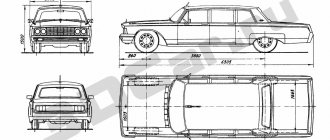

Specifications

The length of the car is 6930 millimeters. Its width is 2320 millimeters. The cabin height is 2310 millimeters. If measurements are taken along the awning, the height will increase to 2740 millimeters. The wheelbase is 3665 + 1120 millimeters. The rear wheel track is 1720 millimeters. Front - 1590 millimeters. Ground clearance - 260 millimeters.

The curb weight of the car is 5580 kilograms. The carrying capacity varied from two and a half thousand to four and a half thousand kilograms. A lower value is typical for driving on unpaved roads. The permissible gross weight of the truck is 10,100 kilograms.

If we talk about the standard modification, the truck was equipped with wooden sides, which were installed on a universal platform. The tailgate opened. In total, the car had ten wheels measuring 8.25-20. Spare tires (two of them) were attached between the cab and the body.

On dirt and country roads, the car is capable of transporting loads weighing two and a half tons. On the highway, this value almost doubles and amounts to four and a half tons. The permissible weight of a trailer that can be towed by a car is considered to be 3.6 tons.

The truck is capable of climbing mountains with a steepness of up to twenty-eight degrees. The lateral roll of the car should not exceed twenty-five degrees. A car can also cross a ford, the depth of which does not exceed eighty centimeters.

ZIS-151 Soviet truck analogue of Studebaker.

ZIS-151

. Experimental samples were ready and began testing in May 1946. Two cars were prepared for comparative tests. The first one had a gable tire for the rear wheels (ZIS-151-2). The tests were successful, but the commission recommended replacing the busbar with a single-pitch one (ZIS-151-1), and in November 1946 the second model was already being tested. Tests have shown higher cross-country ability of the single-slope version, and this option also turned out to be fuel efficient. But it's not that simple. For mass production, we chose a car with a gable tire. As in many respects, the final word was with military customers and the inability to produce wide-profile tires in the required volume. The gable tires reduced the specific pressure of the machine on the ground. When creating and preparing for production of the ZIS-151, Moscow engineers used the developments of GAZ designers, who by 1946 had developed their own version of the GAZ-33 three-axle vehicle within the GAZ-51 family. The main problem of the GAZ-33 was its weak engine for such a heavy vehicle. Ultimately, by decision of the People's Commissariat of Medium Engineering, work on the triaxle at GAZ was stopped, and the prototype and all technical documentation were transferred to ZIS for modification and unification with serial products of existing production.

Modifications

Several versions of the ZIS-151 were produced. The autohistory also includes information about several models produced on its basis.

In the spring of 1946, an experimental model ZIS-151-2 was released, which was distinguished by the presence of dual-pitch rear wheels. A few months later, in the fall of the same year, the car appeared in its second version - ZIS-151-1. Unlike the previous version, it had single wheels at the rear. A cabin from a ZIS-150 was installed on it.

The modification equipped with a winch was called ZIS-151A. Its traction force was 4.5 tf. The winch cable was one hundred meters long. The model was equipped with a three-stage power take-off. It also served to transmit torque to mounted units.

They even produced the ZIS-121 truck tractor and the ZIS-153 car, which featured a half-track chassis. There was a prototype ZIS-151G, also known as ZIL-E157. The tire inflation system was tested on it.

Born in the crucible of war

The military hardships of World War II were not in vain for the designers. The appearance of all-wheel drive and half-track chassis in the armies of the warring powers made it possible to use equipment in the engineering forces more effectively and on a larger scale. This also led to a hitherto unprecedented theater of military operations. The departure from the doctrine of positional battles and the transience of attacks required high-performance vehicles.

And here we should note an interesting pattern.

Many of the American designs of special vehicles and tractors Le Tourneau, Oshkosh, Mack, Caterpillar, Autocar, Walter, Dart, Coleman, Diamond, John Deere, International Harvester represented the most rational attempts to use equipment in military affairs, and after the war their layout became exemplary for imitation.

In contrast, the Wehrmacht used structures and chassis that were practically not used after the war. Here we can mention special equipment on half-track chassis and completely unique attempts to create engineering vehicles by Faun, Lauster, Kaelble, etc.

The transience of battles and the transfer of troops from one theater of operations to another made amphibians extremely popular. The most common were the Ford GPA and GMC DUKW-353, produced in tens of thousands. It is interesting that until the 1960s, captured half-track vehicles were widely used in engineering units, especially during the construction of the launch pad at Baikonur, the Semipalatinsk test site, etc. However, half-track vehicles were not borrowed from the USSR and there is a logical explanation for this: war and the intensification of developments in the military the field was allowed to develop new mass technologies that made palliatives completely unnecessary. Wheels were replaced by caterpillar tracks, and the mechanical drive of working parts was gradually replaced by hydraulic systems.

Military equipment

Several variants of military equipment were produced on the basis of the ZIS-151. Among them are:

- ZIS-485 BAV. Able to move on water.

- BM-13-16, designed for rocket artillery.

- BM-14-16 (8U32) is another combat vehicle. It was equipped with a 140-mm rocket system, allowing it to fire in one gulp.

- BMD-20 (8U33) with a two-hundred-millimeter rocket system installed on it, capable of sending charges over long distances. She worked with salvo fires of the MD-20 “Storm-1” type.

- The BM-24 (8U31) was equipped with the M-24 multiple launch rocket system.

- BTR-152 (or ZIS-152) is an armored personnel carrier.

Floats

If the GAZ-46 was dubbed a “small aquatic car,” then there had to be a “big one.” And indeed, there was such a car. An analogue of the heavy American amphibian DUKW-353 was developed by the leading pre-war specialist of the Gorky Automobile Plant on all-wheel drive vehicles, Vitaly Grachev, during his work at the Dnepropetrovsk Automobile Plant. Initially the project was designated DAZ-485. In July 1951, Grachev was transferred to the ZIS, where the project was materialized. The amphibian, created on the modular base of the ZIS-151, was naturally renamed the ZIS-485, or “BAV” - a large waterfowl vehicle. It served to transport cargo weighing up to 2.5 tons and could not only move over rough terrain, but also cross small rivers, lakes and other water obstacles on the move, delivering up to 3.5 tons of cargo with waves up to 4 points. Since 1958, the heavy amphibian has updated its aggregate base. On the ZIL-157 platform, the “amphibious” ZIL-458A, or BAV-A, was produced. However, the life of these machines was short-lived. With the development of reliable tracked vehicles and the expansion of the range of use of amphibious vehicles since the 1960s, the army has been replenished with more practical tracked vehicles. Among them are the tracked floating transporter PTG K-61 and the tracked all-terrain vehicles GT-T and GT-S (GAZ-47). Now the army widely uses floating all-terrain vehicles GAZ-34037 (development of GT-SM), MT-LB, PTS and PTS-2 transporters.

Specialized peacetime equipment

Based on the ZIS-151 truck, several versions of trucks were developed, designed to perform one specific function. These were the ARS-12D filling station, the PMZ-27 tank truck, and the PMR-43 hose truck.

Several versions of fire trucks were produced on the ZIS-151 chassis:

- PMZM-3 – tank truck for fire extinguishing ATs-40. It was produced from 1952 to 1954 at the fire truck plant in Moscow.

- PMZ-13, which replaced the previous version. Produced from 1954 to 1959 by the Priluki plant. This is an ADC-25 fire tanker.

- PMZ-15, produced between 1952 and 1959. This was the first fire-fighting vehicle in the Soviet Union intended for airfield service.

- PMZ-16, intended for chemical foam extinguishing. It was collected from 1956 to 1959.

Beginning of motorization

By the beginning of the twentieth century, mechanization was used only in military road construction, where the main contractor was the Ministry of Railways. The first self-propelled steam rollers arrived at the Ministry of Railways back in the second half of the 19th century. By 1990, they were supplied by Simeon & Porter, Aveling & Porter, Fowler, Marshall, and Albare. Then the fleet was replenished with machines from the Mechanical, Bryansk Machine-Building Plant, Warsaw, Kolomna Machine-Building Plant, Mechanical and Iron Foundry in Bialystok and the Votkinsk State Plant. At the same time, artillery units of the Russian army were actively supplied with steam routers and tractors.

As soon as cars became an integral technical means of the armed forces, wheeled vehicles began to be used in engineering. During the III International Automobile Exhibition in May 1910, the Main Engineering Directorate of the Russian Imperial Army tested 16 trucks and 2 tractors with trailed carts on the highway between St. Petersburg and Moscow. The commission's findings on the use of mechanical transport for the transport of heavy loads were positive. However, large-scale equipment of engineering units with cars began only in 1914, and they were used mainly for transporting building materials.

By 1917, in terms of motorization of troops and mechanization, the Russian army looked quite respectable among the leading powers. Moreover, in the First World War, the engineering units of Austria-Hungary and Germany looked more than modest compared to the equipment of the Entente.

Disadvantages of the car

During operation, the ZIS-151 car showed several of its shortcomings. During the first tests, the cross-country ability of this model was significantly lower than that of other participants. The ZIS-151 often had to be pulled out of the mud or snow by the forces of “competitors”. This was due to several factors. Thus, the representative of the domestic automobile industry was heavier than the American Studebaker, which he compared to during production, by a whole ton. Small wheels, low ground clearance.

The engine lacked power. Due to the dual-slope wheels, this was felt especially acutely. The second pair of wheels had to make its own way. For example, on the same GAZ-63, the rear wheels did not expend additional forces (they followed the track of the front ones).

ZIS-151 was nicknamed “iron”. Judging by the reviews, the rear wheels regularly became clogged with mud, thereby losing the ability to move. They were just spinning helplessly in the mud. We had to use a crowbar and other available means to clean the wheels so that we could move on.

View from the cockpit

I was surprised many times that day. Another revelation was the fact that I was able to sit comfortably behind the wheel, which I never expected from this cabin. In this matter, I am, frankly, very picky. And here we had slightly outstretched arms behind a huge steering wheel, and we didn’t have to bend our knees much. It’s not often possible to get so comfortable in trucks and even cars that are half a century old. Visibility from the tiny windows of the high cabin is, as expected, unimportant, but is it so important in a field or on a forest path? Under the alligator hood there are only 92 “horses” and a torque of 343 N∙m, but from the very bottom they allow you to confidently move through a snowy field and a muddy clearing. On the floor in the cabin there is a whole “bush” of four levers: gearbox, transfer case, locking, parking brake. Everything turns on clearly, even the strokes are not too large, but the floor pedals are of course “cotton”. The speed of 30 km/h when driving on a snow field seems high, this feeling is complemented by the constant bounces and jumps of an unloaded car, even on large bumps. The maximum, according to the passport data, can be accelerated to 55 km/h. To be honest, I don’t want to go faster with this car, its main value is precisely in moving “on the ground”, and not on roads, and with this task our The “151st” ZIS copes effortlessly! Sometimes I also take with me three or four cubic meters of water in my own tank, but this is in the summer.

BM-13-16 installations on the ZIS-6 chassis

Accordingly, the first 5 experimental BM-13-16 units were manufactured on the ZIS-6 chassis. On June 21, 1941, the Red Army had 10 experimental BM-13 installations. With the beginning of the Second World War, in the summer-autumn of 1941, serial production of guards mortars (multiple rocket launcher) BM-13-16 (M-13), later known as “Katyusha”, was organized on the ZIS-6 chassis. To equip the M-13 guards mortars in the fall of 1941, ZIS-6 vehicles had to be requisitioned (including those with onboard platforms and other bodies, which were then dismantled) from the fleets of various civilian organizations and military units according to a special mobilization order. Due to the approach of the front to Moscow in October 1941 and the evacuation of most of the ZiS capacity to the east of the country, the production of the much-needed ZIS-6 chassis was forced to curtail - the installation of the BM-13-16 on the ZIS-6 chassis was discontinued by order of the State Defense Committee in November 1941.

photo ZIS-6 Katyusha rocket launcher

In the winter of 1941/42, the last ZIS-6s were removed from motor vehicles and used for the installation of less powerful rocket launchers

M-8-36 and M-8-48. Subsequently, Guards Katyusha rocket mortars were installed on the STZ-5-NATI tracked tractor and the T-60 light tank, and from the spring of 1942, mainly on English and American all-wheel drive chassis imported under Lend-Lease. The most famous among them was the Studebaker US-6. Therefore, at present, almost all “Katyushas” on the ZIS-6 chassis on display in various museums, equipped with angular wings, are not auto-identical - such wings were not serially installed on the ZIS-6 and could only appear as a result of subsequent overhauls. In addition, equipped with a completely wooden cabin and similar bent wings made of low-quality roofing iron, the ersatz version of the ZIS-5V was produced in 1942-1944. only with rear brakes and a single headlight, and received a second one only in 1945.

Mechanized installation of the first MU-1 sample on the ZIS-6 chassis (before this there was a development of a similar type, on the ZIS-5 chassis). 24 short guides, for launching 132mm caliber rockets, were located perpendicular to the axis of the vehicle. Declared unsuccessful. The MU-2 installation (with 8 longitudinal elongated guides and two jacks in the rear, which became the prototype of the BM-13 (39-40), was produced only on the basis of the ZIS-6. Until August 12, 1941 (by two factories in Voronezh “named after the Comintern” and Moscow "Kompressor" 53 BM-13-16 installations were built. By November 1941 (three plants named after the Comintern, Compressor and Krasnaya Presnya) 456 BM-13 installations were built. In the fall of 1941, 45 mortar divisions were formed, 12 vehicles each The last ZIS-6 were used for mounting the BM-13 in the winter of 1942. On the ZIS-5 chassis in the fall of 1941, 15 BM-13 launchers were mounted, which turned out to be unsuitable for moving across terrain and carrying sufficiently heavy weapons.