During the Great Patriotic War, Sudaev's submachine gun became No. 2 among the samples of automatic small arms of the Red Army

Typically, small arms that appear in the midst of a war are successful, since they are created to meet specified and clearly formulated tactical and technical requirements. This is what happened with our today's hero. Easy to manufacture and operate, extremely reliable and very convenient in daily use, the Sudaev submachine gun greatly helped the Soviet troops in the second stage of the Great Patriotic War. Today we will compare it with its “big brother” - PPSh, we will find out why the PPS was so good that it deserves a special mention.

German MP-34/35

Production of the MP-34/35 began in Germany in 1934. The bulk of the submachine guns produced in the city of Karlsruhe were sent to arm selected units - the SS troops. The MP-34/35's trigger was designed in a unique way: partial pressing produced a single shot, and a fully depressed trigger provided automatic fire. The most distinctive external feature was the adjacent store to the right. In automatic fire mode, the rate of fire was 650 rounds per minute.

MP-34 submachine gun, designed in Germany by Theodor Bergman. An experimental batch was produced in Denmark in 1932, and under the designation BMK-32, the MP-34 submachine gun was adopted by the Danish army

Erma

The 9mm Erma (or EMP) submachine gun was developed by Heinrich Vollmer and Berthold Gipel based on a 1920s model designed by Heinrich Vollmer. It was used on the fronts until 1942. An EMP version with a silencer was produced to arm the French police. The Erma submachine gun unfairly became known as the "Schmeisser", after the name of the chief designer in the city of Suhl. only produced these weapons, but MP-38, MP-38/40 and MP-40 still continue to be called “Schmeisser”.

The MP-38 submachine gun, first produced in Erfurt, was equipped with a folding metal stock and had plastic parts, which was then unusual

It was the first submachine gun with a folding metal stock, which reduced the length from 833 to 630 mm and made it an ideal weapon for paratroopers and combat vehicle crews. Under the front sight, this submachine gun had a characteristic stop, thanks to which the barrel could be hooked onto the embrasure of an armored personnel carrier or over the side of a truck and fire automatically without fear that the weapon would slip inside.

A cooling fin ran from the stop to the receiver. The idea of combining a pistol grip with a trigger was borrowed from the American Thompson

M1928 - before this, the butts of submachine guns were the same as those of carbines. It was the first submachine gun to use plastic (bakelite) in its construction.

The MP-38 went into mass production, but during the military campaign in Poland (1939), one dangerous flaw was revealed. If the weapon was cocked, a slight push was enough for the bolt to fall forward and an accidental shot to occur. A leather ring was used as an improvised safety, which was placed on the barrel to hold the charging handle. Subsequent releases began to be equipped with a fuse at the factory, and this modification was designated MP-38/40.

Propaganda poster depicting a German officer with decorations on his chest leading an attack with an MP-38 submachine gun in his hands

The desire to reduce production costs and speed up product release led to the appearance of the MP-40 model. This weapon retained many of the external features of the MP-38/40, but machining of parts was kept to a minimum and stamping and spot welding were used wherever possible. In Russia, German soldiers armed with the MP-40 discovered the fire superiority of the Soviet PPSh-41 submachine guns with 71-round magazines. To cope with this problem, at the end of 1943, Erma released the MP-40/1 modification. The MP-40/1 had a receiver adapted to install two magazines side by side. This increased the readily available ammunition to 60 rounds, but increased the weight to 5402 grams.

Until the end of World War II, about 1,047,000 MP-40 submachine guns were produced. As reported, communist partisans who captured the leader of fascist Italy Benito Mussolini shot him with an MP-40. After the war, this weapon was used by the French, and in the arsenal of the Norwegian army it remained until the 1980s under the designation “Maskin M40 caliber 9 millimeters”.

"Schmeisser"

The MP-38 and MP-40 submachine guns, which the Allies vaguely called "Schmeissers" during World War II, were armed with German non-commissioned officers who commanded the crews of the MG-34 and MG-42 machine guns. If a machine gun crew suddenly found itself dangerously close to the enemy, he had a weapon that had high firepower at a short distance. In a confined space, it was difficult to control a powerful machine gun, unlike a compact submachine gun. Non-commissioned officers were also equipped with binoculars to help correct machine gun fire.

German non-commissioned officer with a Schmeisser and binoculars. Six spare magazines had enough ammunition to survive the fight

Beretta, model 1938A

This model, which turned out to be quite successful, was based on a self-loading carbine produced in 1935. The submachine gun is built according to the usual blowback design and has two triggers - the first for single fire, the second for continuous fire. Various versions of this model were produced, the differences between which were minor. For example, weapons of early releases consisted mainly of machined parts, while weapons of later releases had an increased proportion of stamped parts. Model 1938A was in service with the Italian and German armies and was intensively used in combat. Subsequent improvements led to the introduction of the 38/42, 38/44, 38/49 and Beretta 5 models.

Italian MAB 38

The Italian MAB 38 submachine gun was produced by the Beretta factory in Brescia. Until 1943, only airborne paratroopers, carabinieri and police officers in Italian Africa were armed with it. Over time, it became a common weapon in the Republic of Salo (a fascist state in Northern Italy that existed from 1943 to 1945), among partisans and in Italian units fighting under Allied command. The modified version of the MAB 38/42 was lighter, shorter and had a higher rate of fire. It remained in service with the police and carabinieri until the 1970s.

The Italian Beretta MAB 38/42 submachine gun was equipped with magazines for 20 or 40 rounds. The rate of fire was 550 rounds per minute

Beretta, model 1938/42

This weapon is a modified version of the Model 1938A submachine gun, which is easily distinguished from the prototype by its shortened barrel. The wooden stock is shorter and ends immediately at the store. To reduce the contamination of the weapon, the charging handle is equipped with a protective casing. Like the previous Model 1938A, the Model 1938/42 turned out to be very successful, and was purchased in large quantities by the German army, as well as the Romanian army.

Submachine gun "Marlin"

The American 9 mm submachine gun, which became widely known as the Marlin, but was officially designated the United Defense M42, was developed in 1941-1942. Carl J. Suibilius, designer of the High Standard Manufacturing Company. The first YUD M42 submachine guns were manufactured by this company to order from Holland and most of them were sent to the Dutch East Indies just before the Japanese invasion. The remaining 15,000 submachine guns were purchased by the US government and were used primarily by operatives of the Office of Strategic Services (OSS) and were also sent to the Resistance movement, especially on the island of Crete. The YuD M42 was a fairly complex but well-made weapon with a twenty-round magazine. For quick reloading, magazines, unusual for that time, were issued, fastened with a “jack”.

The YuD M42 submachine gun, also called “Marlin,” was equipped with 20-round magazines that could be connected in pairs. The rate of fire was the same as that of the Thompson Ml and M1A1 - 700 rounds per minute

M3 "Oil Can"

The American M3 submachine gun was developed in 1943 as a cheap replacement for the Thompson; soon modified versions of it appeared. Accessories to the weapon included an oiler in the pistol grip and an ingenious retractable steel wire stock. Separate parts of the butt could serve as a screwdriver, a wrench for separating the barrel, a cleaning rod and a device for equipping a magazine. Although the M3 did not have a single-fire mode, the rate of fire was exceptionally low, amounting to only 450 rounds per minute, and the placement of the barrel in line with the buttstock made it easier to control recoil. A trained soldier could also fire single shots. Before opening fire, the cover of the window for spent cartridges had to be manually opened, which also served as a fuse.

The American M3, or "Oil Can" submachine gun, .45 caliber, which appeared in 1943, was the embodiment of a number of innovative solutions

The M3 body was made of two stamped metal parts connected by welding; the barrel was secured with a simple nut, and the bolt moved along two guide rods inside the receiver. This provided clearance between the bolt and the receiver so that contamination of the weapon did not cause it to jam. The only design flaw was the unreliable fixation of the magazine in the receiver. This submachine gun received its nickname due to its unusual appearance, which resembled a car oil syringe.

The M3 magazine held 30 rounds of .45 AKP ammunition, which was also used in the M1911A1 pistol and the Thompson submachine gun. The weapon remained in service with American infantry through the Korean and Vietnam wars, and some units were armed with it even during the first Gulf War in 1990-1991.

Spectrum M-4

Introduced in 1984, this weapon fires from a closed bolt and features a double-action trigger mechanism that includes a safety release lever. Pulling the trigger cocks the hammer and fires a cartridge into the chamber. In this form, the weapon can be carried safely. The cartridges in the magazine are arranged in four rows, which allows you to have more ammunition in a shortened magazine. In the mid-1980s, the Specter was the only double-action submachine gun on the market.

Thompson submachine gun

At the beginning of 1920, it released a prototype, the rate of fire of which was 800 rounds per minute.

Despite the good test results, neither the US Army nor the Marine Corps accepted the Thompson for service. However, Thompson was able to secure a contract to produce 15,000 “Thompson Model 1921 submachine guns.”

"Thompson" М1928А1 with a twenty-round magazine. Although the weapon, weighing 4880 g, was heavy, it was reliable and survivable and was popular with US and Allied forces, especially among British commandos

There were no further orders for the submachine gun until the United States entered World War II. Since 1942, the volume of orders has increased sharply. The Thompsons were superior to other submachine guns in terms of reliability and survivability. The British commandos did not abandon their Thompsons even after the British Sten became an affordable weapon, and on the day of the Normandy invasion in 1944 they were armed with them. The main disadvantages were its heavy weight, the inability to shoot accurately at distances greater than 45 m, and low penetrating power. However, in close combat this weapon was extremely effective.

MG 42

The most famous Wehrmacht machine gun.

During World War II, Germany used many different machine guns, but it was the MG 42 that became one of the symbols of the aggressor in the yard with the MP 38/40 submachine gun. This machine gun was created in 1942 and partially replaced the not very reliable MG 34. Despite the fact that the new machine gun was incredibly effective, it had two important drawbacks. Firstly, the MG 42 was very sensitive to contamination. Secondly, it had an expensive and labor-intensive production technology.

Australian Owen submachine gun

By 1939, Australian designer Evelyn Owen had developed his first automatic weapon chambered for the .22 LR cartridge and offered it to the Australian Army, which rejected the unusual-looking design. However, Owen insisted on his own, and by 1941 in New South Wales he had released several experimental models of various calibers, including chambered for .45 AKP, 9 mm Parabellum and even chambered for the .38 Special revolver cartridge.

An Australian soldier armed with an Owen Mk 1 submachine gun. The workmanship of this weapon was high, it was reliable, and the bolt was well protected from dirt and dust. The 33-round magazine located on top ensured their reliable supply under the simultaneous influence of gravity and spring, which distinguished it favorably from the Thompson.

The 9 mm caliber model successfully withstood comparison with the Thompson and Sten submachine guns. In 1942, the Owen submachine gun was adopted into service and was produced until 1945 in three main versions: Mk 1-42, Mk 1-43 (or "Mk 1 with a wooden stock") and Mk 2. About 45,000 were produced. Owen submachine guns, which remained in service with the Australian armed forces until the 1960s and saw the Second World War, the Korean and Vietnam wars. Australian soldiers greatly appreciated the reliable, simple and unpretentious, although heavy, Owen.

Jandoso TC-45

Developed at the very end of World War II, the TC-45 submachine gun had a simple design and was cheap to produce. It is equipped with a retractable metal stock and an automatic safety on the handle. Although a number of these weapons were exported, neither the workmanship nor the performance characteristics made much of an impression, and soon production of the TC-45 in Italy was discontinued.

British Sten submachine gun

Following the French surrender and evacuation from Dunkirk in 1940, the British faced the looming threat of a heavily armed German army invading the islands. There was an urgent need for automatic weapons. The answer to the challenge was the British submachine gun, developed by Major R. W. Shepherd and H. J. Turpin at the Government Small Arms Factory in Enfield. “Sten” (STEN) received its name by adding the first letters of the names of the designers (RV Shepherd and N. J. Turpin) and the name of the weapons company (Enfield).

The Sten Mk I submachine gun entered service in the summer of 1941, but due to its rough finish and awkward appearance, it was received rather coolly by the troops.

"Sten" was produced in huge quantities in Britain and Canada, and by the end of the war, about 3.25 million units were manufactured. This submachine gun was cheap and easy to manufacture. The weight of the weapon was about 3500 g, all modifications worked on the principle of a free shutter, the rate of fire was 540 rounds per minute, and the initial bullet speed was 366 m/s. The magazine capacity is 32 rounds, however, due to problems with the spring, the magazine was usually equipped with only 30 rounds. In the period 1940-1945. The Sten was repeatedly modified and improved, so that several models existed.

The Sten Mk I, which was equipped with a flash suppressor, a wooden fore-end and a folding front handle, quickly gave way to the Sten Mk II, which was produced in mass quantities. The Mk II was more compact and easily disassembled, the weapon could be concealed, and it became the weapon of choice for many European Resistance units. The magazines of the German MP-40 approached the “Sten”, which was very convenient, since it was possible to use captured ammunition. The weak point of this weapon, like the German MP-40, was the magazine fastening, due to the distortion of which there were delays when firing. The weapon was as simple as possible and consisted of 47 steel parts, which were connected to each other by welding and riveting. The only components that required machining were the bolt and barrel. A total of 2 million Sten Mk II were produced.

Women's military training in Britain in 1941. In the foreground is a Sten Mk III, in the background is a Mk I. Submachine guns are not cocked as the women practice basic weapon holding and aiming techniques

One of the requirements for the developers was the ability to produce a submachine gun at non-specialized enterprises. An example of such a weapon was the “Sten” Mk III with a barrel tightly connected to the body, and a bolt box and barrel casing made in one piece by welding. It was produced by , which usually produced children's toys. The Mk III was in service with troops during the Normandy invasion in 1944. Surprisingly, this superior variant of the "Wall" was not produced in large numbers.

Although "Walls" were intended to arm the crews of combat vehicles, reconnaissance groups and anyone who did not need long-range weapons, they were mainly used by infantry, especially platoon commanders, sergeants and squad leaders. Pistols were the personal weapons of senior officers, but many preferred the Sten due to its greater combat power.

The silent "Sten" Mk II (C) was developed in 1943. This modification, which allows firing single shots, was popular with Resistance fighters. It was possible to fire bursts from it, but at a rate of fire of 450 rounds per minute, the muffler quickly burned out

Among the troops, the “Sten” caused a lot of complaints due to frequent jamming in case of contamination or spontaneous firing when dropped. This happened to Corporal Proctor of the Somerset Light Infantry during an operation in Holland in 1944. The soldier slipped, dropped his Sten, the weapon hit the ground and fired, wounding Proctor in the groin. The platoon commander, Lieutenant Djari, cursed this weapon with the following words: “... In the minds of these designers there was only one thing - how to reduce the cost of mass production... It did not have a safety lock, and with strong shaking the bolt could move back, making room for a cartridge from the magazine, and then this cartridge would go into the chamber and fire.”

"Walls" in war

The Sten was first used in combat during the disastrous raid on Dieppe in August 1942. Before the raid, Canadian soldiers spent several weeks adjusting and testing their Sten to ensure trouble-free operation. But the first raid, codenamed "Jubilee" in July, was called off. The day before the start of Operation Pilot, the soldiers received completely new “Walls”, still in boxes and in factory lubricant.

Captain Brian Priday, second-in-command of the 2nd Battalion, Light Infantry, armed with a Sten Mk V with bayonet (Normandy, 6 June 1944). Two key bridges over the Orne River and the Orne Canal have just been captured.

German copies of "The Wall"

Despite its shortcomings, the simplicity and low cost of production of the "Wall" allowed the Germans in 1944-1945. release copies of it under several designations: “9 mm Maschinenpistole 3008”, “Volksmaschinenpistole”, “Geret Potsdam” and “Maschinenpistole 749 (e)”. Since it was manufactured by all and sundry, this submachine gun was used for many years after 1945. The American technical reference Unusual Military Devices and Techniques describes a copy of the Sten Mk II captured from the Viet Cong in 1964 during the Vietnam War.

Tenacity Worth Better Use

Until the surrender of the Japanese Empire in 1945, Japanese infantrymen fought with repeating rifles in their hands. The adoption of a mass-produced reliable self-loading rifle did not take place. The descendants of the samurai did not receive a submachine gun produced in sufficient quantities. What prevented the Japanese from saturating their army with these weapons?

Model of the Tokyo Arsenal arr. 1927 and 1928

Contrary to established opinion, the Japanese military was actively interested in the latest foreign developments of automatic weapons. The introduction of our own promising models was hampered by a number of factors - the workload of arsenals with the production of rifles and machine guns, a chronic lack of resources, which especially worsened in 1943, and insufficient production of 8-mm pistol cartridges.

Japanese Marines in Shanghai, January

1932

Back in 1927–1930. The scope and tactics of using submachine guns were unclear to the Japanese: they were supposed to be used in limited quantities as a temporary replacement for light machine guns. However, after the use of submachine guns by the Japanese Marines in street battles in Shanghai in January 1932, interest in these weapons increased significantly. Assault squads of 10–12 people, reinforced with one or two submachine guns, had a significant advantage in firepower during quick firefights at short distances with Chinese soldiers armed with rifles and pistols.

The Chinese nationalists began to acquire rapid-fire weapons - Mauser C96 pistols, Bergmann and Thompson submachine guns, both original and copies of their own production. This could not pass by the technical department of the imperial army headquarters. In addition, the Japanese Imperial Navy, realizing that it would not be possible to receive its own submachine gun soon, began urgently purchasing batches of automatic weapons in Europe. In 1931, the Marine Corps began purchasing Swiss Bergmann SIG 1920 submachine guns, which were given the Japanese name Type BE.

By order of the technical department of the army headquarters, the Tokyo Arsenal in 1927 produced an experimental model (Shisei Jidou Tanjuu) chambered for the 8x22 mm Nambu cartridge. It is reliably known about Kijiro Nambu’s direct participation in the design of this submachine gun.

Features of the automatic operation were a short barrel stroke and locking the bolt with a swinging wedge. A similar locking design was implemented in the subsequent Model 94 pistol of 1934. The magazine supply was very unique - curved cassettes for 10 rounds, similar to cassette clips for Hotchkiss machine guns. The cassettes were combined into a tape of five pieces and placed in a drum, the capacity of which was thus 50 rounds. An alternative method of feeding was a box magazine with a capacity, according to various sources, of 25 or 30 rounds, staggered and arranged in one row.

During comparative tests together with the Bergmann MP-18/I submachine gun chambered for 9x19 mm with a 32-round magazine in 1928, the Japanese experimental model of 1927 showed a large number of delays in the supply of cartridges, the rate of fire was too high - up to 1200 rounds per minute - and rapid wear of parts.

The 1927 model was modernized in 1928. A pneumatic shock absorber was added to its design, which significantly reduced the rate of fire, which was now regulated in the range of 300–600 rounds per minute. The rate of fire was adjusted by changing the diameter of the hole in the exhaust valve of the compression chamber of the pneumatic shock absorber.

Bergmann SIG 1920 submachine gun, also known as the Japanese Type

BE

. In the modernized experimental model of 1928, 6.5 mm caliber cartridges were tested (corresponding to the designations of .25ACP or 6.35x16 mm HR Browning cartridges accepted in Japan at that time), 7, 7mm (corresponding to .32ACP or 7.65x17mm HR Browning) and 7x20mm Nambu. Food was supplied from box magazines, according to some information - single-row, with a capacity of 20-25 rounds.

During repeated testing, the 1928 sample failed due to a breakdown, was no longer tested and did not receive recommendations for improvement. Despite the fact that only a few copies were made, the Tokyo Arsenal submachine guns are the first Japanese designs.

Based on the test results, it was decided to carry out further developments chambered for the 8×22 mm Nambu cartridge, as standard and accepted for supply. The air shock absorber was later used in the experimental development of Type I, Type II and Type III submachine guns.

Experimental submachine gun of the Tokyo Arsenal, 1927

Tactical and technical characteristics of the experimental submachine gun of the Tokyo Arsenal of the 1927 model (in brackets - the 1928 model): caliber 8x22 mm Nambu (6.35x16 mm HR, 7.65x17 mm HR, and 7x20 mm Nambu), drum magazine for 50 rounds or box magazine for 30 (20-25) rounds, total length - 690 mm, barrel length - 230 mm, rate of fire - 1200 (300-600) rounds per minute, weight - about 3.2 kg, sector sight (graduation unknown).

Original Japanese designs

The cessation of work on the Tokyo Arsenal submachine gun gave rise to the search for the appearance of new experimental “short machine guns” of an original design. By 1930, the design department of the Kijiro Nambu company in Tokyo and military representatives from the technical department of the army headquarters formulated requirements for the newly developed models of the “short machine gun”. They were derived from the specifics of the use of light machine guns in maneuverable military branches and concerned the effectiveness of automatic fire.

Thus, the “large automatic pistol,” which later received the name Type I, was intended for armored vehicle crews and was supposed to use a standard 8x22 mm Nambu cartridge, a 50-round magazine, a weight of 2.0 kg, while having maximum compactness and an effective range fire at targets in winter uniform up to 500 meters. One of the requirements was the ability to fire through viewing slits.

Experimental submachine gun Type

I model 1930, general view

The sample, called Type II, was designed for mobile units that required weapons to increase fire during short-term clashes - namely, oddly enough, for cavalry. It was designed for magazines of 30 rounds and a weight of 3.0 kg. For this sample, an experimental 6.5 mm Type 95 cartridge was developed based on a cartridge case extended to 30 mm from the 8x22 mm Nambu caliber cartridge, a 6.5 mm bullet weighing 7.0–7.5 grams and a speed of 550–600 m /s (data are approximate). The Type 95 cartridge was supposed to ensure reliable destruction of targets in winter uniform up to 700 meters. Ammunition with 7.7 mm and 8.65 mm bullets was tested on the basis of the same cartridge case, but they did not find use outside the test benches. The Type 95 cartridge was planned as an exclusively automatic cartridge for “short machine guns”, and only the decision of the technical department about the inexpediency of adopting another pistol cartridge into service finally stopped the project in 1938.

The specifications for the Type III submachine gun were drawn up at the request of the military much later, by 1939, and were implemented in the form of the Type 100 submachine gun.

Submachine gun Type I model 1930

In 1930, the design department of Kijiro Nambu presented the design of a submachine gun of an unusual design for that time. The first thing that caught your eye was the placement of the magazine receiver in the fire control handle. The sector magazine had a capacity of 50 rounds; a folding hook was attached to the heel of the magazine for stable shooting from an emphasis on the parapet of a trench, wall, etc.

The weapon's automatic operation was based on the recoil of the free shutter. In this case, the bolt was not located inside the receiver, as in the classic models of first-generation submachine guns (Bergmann, Schmeisser, Thompson), but in the form of a casing moved during the reloading cycle, like in automatic pistols, along the external frame guides. The recoil spring was not located behind the bolt on the guide rod, as in the MP-18/I, for example, but around the barrel, “pistol-style.”

Submachine gun Type

I model 1930, the bolt is on the slide stop.

For compactness, the butt could be unfastened when removing the turning pin on the right side, or when turning the same pin, it could be folded down along the fire control handle and magazine, thereby reducing the dimensions of the weapon.

The sight was installed with an aperture (ring), with a sector strip marked up to 500 meters, sometimes indicated on a reversible rear sight with distances of 100 and 200 meters. Shooting was carried out from an open bolt, the firing pin was stationary, mounted on the bolt mirror. The fire mode is automatic only. The safety lever, also known as the fire switch, is on the left side in front of the trigger guard and blocks both the sear and the bolt.

The rate of fire could be adjusted between 300 and 600 rounds per minute. To regulate the rate of fire, a pneumatic buffer in the rear of the receiver served. It consisted of an expansion chamber, which was acted upon by a piston with a rod connected to a shutter casing. The volume of air entering the expansion chamber, and, consequently, the rate of operation of the automation cycle, could be adjusted by rotating the end screw-valve mounted directly on the piston disk. When firing a shot, the shutter, moving backward, was slowed down, acting through the rod on a system based on creating a vacuum in the chamber.

Finnish submachine gun

"Suomi" m/26 chambered for 7.65x22 Parabellum.

Almost a similar idea was used in his early design of 1926 by Aimo Johannes Lahti for the 7.65mm Konepistooli KP/-26 submachine gun. The Finnish gunsmith offered this design to various military departments in Europe, but was unable to implement such a complex weapon. Whether the Japanese borrowed the idea of Lahti or developed their own weapons ideas is difficult to say. In any case, in Japanese patent documents for 1930 and 1935 there are drawings showing a completely different approach to the design of air shock absorbers for braking the breech of a submachine gun.

The Type I submachine gun was tested in 1930 and 1934 and was rejected due to unstable automatic operation, problems with feeding cartridges and a tendency to jam the bolt due to clogging of the compression chamber of the air shock absorber with dust, particles of gunpowder and lubricant. Only a few samples were produced for testing - for example, reports at the end of 1936 indicate no more than four copies.

Tactical and technical characteristics of the submachine gun Type I (Shisei Is-Gata Kikauu Tanjuu) model 1930: caliber 8x22 mm Nambu, sector magazine for 50 rounds, total length - 620 mm, barrel length - 230 mm, rate of fire - 300- 600 rounds per minute, weight - 2.8 kg.

Submachine gun Type I model 1934

The unstable operation of the automatic operation of the Type I submachine gun of the 1930 model confronted Japanese gunsmiths with the need to rework the design. But instead of abandoning the problematic air shock absorber, moving to a simpler and more reliable design, Nambu engineers continued their experiments.

In the 1934 model, shock absorption was also carried out using pneumatics with adjustable air release through five holes with a diameter of 0.25 to 1.75 mm. Instead of a control screw, a rear cover of the receiver with holes on the side surface was used; instead of a disc-shaped piston, a spring-loaded rod connected to a movable bolt casing, a piston in the form of a cylindrical sleeve was used. By means of a short spring inserted onto this sleeve during recoil, the recoil force of the bolt casing was received. By turning the rear cover of the receiver, the air release hole from the pneumatic compressor was selected and the automatic operation rate was set in the range of 400–600 rounds per minute.

As in the 1930 model, shooting was carried out from an open bolt, the firing pin was stationary, mounted on the bolt mirror. The fire mode is automatic only.

Experimental submachine gun Type

I model 1934, general view

For cocking, a special cocking lever was used on the left side, moved by the reloading handle back and forth in a special guide frame. When firing, the reloading handle remained motionless. It was also possible to cock the bolt using the massive base of the front sight.

Cartridge feeding was provided from double-row magazines with 50 rounds of ammunition with a double-row exit, a longitudinal slot for visual control of the number of cartridges and ease of loading, as well as a folding spur hook on the heel of the magazine. For ease of holding when shooting, the Type I model of 1934 was equipped with an all-metal forearm. Surviving submachine guns are equipped with a permanent stock, but reference literature also indicates models with folding and removable stock options.

An interesting fact is the attempt to offer this model in 1936... to Great Britain for arming tank crews! In January 1936, the British military mission in Japan concluded an agreement to purchase two units of experimental submachine guns and 1000 rounds of ammunition for them. The British army commission, after comparative tests with other imported models, rejected the Japanese submachine gun due to delays, an unstable rate of fire due to contamination of the pneumatic shock absorber and deformation of the recoil spring from prolonged heating when firing, as well as a non-standard cartridge for the British. On February 7, 1938, the British ambassador in Tokyo made a request to purchase several units of a Japanese submachine gun for repeated testing, but was refused, justified by the cessation of production of this weapon.

Submachine gun Type

I model 1934, left view

The Imperial Japanese Army tested the submachine gun since February 1935 and in September of the same year received a number of complaints about the survivability of parts and automatic failures. After 1937, the submachine gun allegedly underwent military testing in southern China. The number of produced Type I submachine guns of the 1934 model in the reference literature is estimated at no more than 50 pieces, but according to Japanese reports, in August 1938 there were only six units available. Information about testing and use in the Imperial Navy, given in popular reference books, is not confirmed.

From June 9 to June 23, 1938, at the Futsu training ground, the Type I submachine gun of the 1934 model was tested as a defensive weapon for armored vehicles of the Japanese army. General testing as a close-combat weapon was resumed on August 6, 1938, and continued until December. For comparative tests, the Type II submachine gun in versions chambered for 8 mm and 6.5 mm cartridges, as well as the new Type 96 light machine gun, were also used.

Tactical and technical characteristics of the submachine gun Type I (Shisei Is-Gata Kikauu Tanjuu) model 1934: caliber 8x22 mm Nambu, sector magazine for 50 rounds, total length - 638 mm, barrel length - 229 mm, rate of fire - 400- 600 rounds per minute, weight - 2.95 kg, sector sight, marked up to 500 meters.

Type II submachine gun and its variants

It is often stated in the weapons literature that experimental Type I and II submachine guns were transferred for military testing to both the army and the navy, and the first use of the experimental Nambu "short machine guns" is associated with events in Shanghai - it is not said, in 1932 or 1937. Now we can say for sure that the Marines were the first to use submachine guns in Shanghai in 1932, and these were purchased Type BE (SIG 1920). Experimental submachine guns did not participate in these events; the army made do with standard Arisaka Type 38 rifles, Type 11 and Type 3 light machine guns.

Experimental submachine gun Type

II A model 1934 with Type 2 bayonet

It is important to point out that Kijiro Nambu, from the beginning of his service with the rank of lieutenant, worked on orders from the army. In 1927, Lieutenant General Nambu organized the Namby Arms Manufacturing Company Limited to manufacture ammunition under contract and technical supervision of the Imperial Japanese Army. To increase the production of ammunition for the increased volume of military contracts in December 1936, he merged with Taisei Kogyo K.K. In fact, there was a monopolization of the development and production of weapons for the army: Nambu companies received a general order from the army and themselves placed it with subcontractors.

The Imperial Navy was forced to independently place its orders from other manufacturers of small arms or, having purchased blank components, assemble them using naval arsenals - for example, the Yokosuka Arsenal produced “naval” Arisaka Type 99 rifles. As a last resort, weapons were purchased from Italy and Germany and Switzerland.

Prototypes of small arms from companies headed by Kijiro Nambu entered the imperial army. Experimental submachine guns were also designed at the request of the army, where they were subsequently tested. Experimental submachine guns were never supplied to the Imperial Japanese Navy.

Model 1934 Type IIA submachine gun

This submachine gun was first written about in Gun Magazine in August 1976. In 1934, the Japanese gunsmiths of the Nambu company, in addition to the improved version of Type I of the 1934 model chambered for the 8x22 mm Nambu cartridge, presented to the technical department of the army a modification of the Type IIA submachine gun (Shisei Ni-Gata Kikauu Tanjuu) chambered for a special cartridge Type 95 6.5 ×30 mm.

The Type IIA submachine gun was intended for Army cavalry units that needed a portable automatic weapon that was more reliable and lighter than the Type 11 machine gun of 1922, which weighed 10.2 kg. This 6.5 mm model was tested at the Futzu training ground for power and ability to hit targets in winter clothing at distances of up to 700 meters. Different sources indicate different parameters for the weight, length and capacity of the Type II submachine gun magazine for a special 6.5 mm cartridge: from 2.8 to 3.8 kg, from 638 to 700 mm, 30 or 35 rounds. In total, no more than four copies of this model were made.

II

A submachine gun , model 1934, with the stock removed.

Specially designed cartridges of 7.7×30 and 8.65×30 mm did not go beyond the Nambu laboratory, and on September 17, 1938, models for those already adopted for service were sent for testing. and supply of ammunition. They showed the unreliability of automation and the sensitivity to rust and dust of experienced Type I and Type II submachine guns. The conclusion pointed out the lack of advantages in power and reliability compared to the new Type 96 machine gun. Survival tests of the submachine gun parts were limited to the consumption of 3,000 special 6.5 mm cartridges, while the Type 96 machine gun reached a consumption of 80,000 cartridges - of course , with the replacement of some non-essential parts and when firing new Type 38G cartridges with reduced flash.

The Model 1934 Type IIA submachine gun was an improved and modified design of the 1934 Type I submachine gun chambered for the 8x22mm Nambu cartridge. The changes affected the stock and the bolt cocking device. According to military requirements, a solid wooden rifle-type stock was designed with a device for mounting a Type 30 bayonet (later a short Type 2 bayonet was installed).

The trigger guard was missing; instead, a hole was made in the stock for the index finger. The cocking lever was abolished; cocking was carried out using the protrusion on the bolt casing. The fuse was located on the left rear, closer to the rear cover of the receiver. The fire mode switch was located to the left in front, above the trigger. The magazine release button was located on the left in the recess of the stock. Two types of magazines were used - 30 and 50 rounds.

II

A submachine gun , model 1934, with a 50-round magazine

. Sector sight, with aperture rear sight. The air shock absorber system is similar to the 1934 Type I submachine gun with selectable automatic fire rates. Shooting was carried out from an open bolt, the firing pin was stationary and mounted on the bolt mirror. The fire mode is automatic only. This 8-mm model, produced in 50–60 copies, was used to a limited extent by the Japanese army in Burma, where it was captured by the British as a trophy.

Tactical and technical characteristics of the submachine gun Type IIA (Shisei Ni-Gata Kikauu Tanjuu) model 1934: caliber 8x22 mm Nambu, sector magazine for 30 or 50 rounds, total length - 709 mm (1090 mm with Type 30 bayonet), barrel length - 229 mm, rate of fire - 400–600 rounds per minute. Weight - 2.85 kg without magazine and cartridges, 3.09 kg with an empty 30-round magazine, 3.15 kg with an empty 50-round magazine, 3.435 kg with a full 30-round magazine, 3.725 kg with a full 50-round magazine . Sector sight, marked up to 500 meters.

Model 1942 Type IIA submachine gun

Thanks to a British technical report compiled in February 1946, you can study the description of the Type IIA modification of the 1942 model chambered for the 8x22 mm Nambu cartridge (serial number 37). This model may sometimes be referred to as Type IIB or Type IIA version 1 in reference literature.

II

A submachine gun, model 1942, general view

This submachine gun was discovered by representatives of the British Army among the captured weapons of the Imperial Japanese Army in Singapore. In practice, the model corresponded to the Type IIA model of 1934 previously found in Burma, but had some differences.

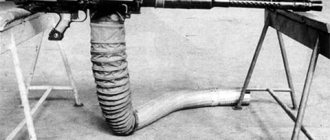

The Model 1942 Type IIA submachine gun was slightly shorter than the 1934 Model and did not have a bayonet mount. Instead of guides for its installation, a massive adapter was mounted for fastening using a pivot on a vehicle or armored vehicle. On the right side of the stock, opposite the window for ejecting spent cartridges, a metal plate was installed for mounting a canvas bag-casing collector so that spent cartridges would not scatter on the floor of an armored personnel carrier or tank and would not fall into the mechanisms.

The trigger mechanism, bolt housing design, and air spring system were found to be similar to the 1934 Type IIA model. To cock the firing pin and chamber the first cartridge, a protrusion on the left side of the bolt casing was also used; cartridges were fed from sector magazines with a double-row output for 30 or 50 rounds. When the cartridges in the magazine ran out, the bolt in the rear position became a bolt stop, signaling the need to replace the magazine.

Experimental Type IIA submachine gun model 1942, right view

Shooting was carried out from the front position of the bolt, the fire mode was only continuous. The outer surface of the barrel had segmental longitudinal valleys to improve heat dissipation during long-term shooting. The sighting devices were an aperture rear sight with height adjustment and markings up to 600 meters and a rail front sight protected by V-shaped side wings.

When testing a modification of the Type IIA submachine gun of the 1942 model, the British noted excellent performance in automatic fire. The weapon was characterized as easy to control and accurate, lightweight, with minimal barrel drift and low recoil. At the same time, sensitivity was noted to both insufficient and excessive lubrication, contamination by dust or carbon deposits, and overheating of the recoil spring, which affects the operating cycle of the automation and, accordingly, the rate of fire.

This submachine gun was supplied for testing to the Japanese army, the number of copies produced is estimated at a maximum of 50. There is a version that some of the experimental Type IIA submachine guns of the 1934 model were simply converted in 1942 for use on vehicles.

Experimental submachine gun Type

II A model 1942 with a magazine for 30 rounds

Tactical and technical characteristics of a submachine gun Type IIA (Shisei Ni-Gata Kikauu Tanjuu) model 1942: caliber 8 × 22 mm Nambu, sector magazine for 30 or 50 rounds , total length - 660 mm, barrel length - 220 mm, rate of fire - 600–820 rounds per minute, weight - 2.85 kg without magazine and cartridges.

Chinese copy of Type II submachine gun

Even less is known about this model of the Type II submachine gun than about the Japanese prototypes. According to available information, this submachine gun was produced in 1946–1947. at the arsenal in Mukden (formerly the Japanese Hoten Arsenal) after coming under the control of the Kuomintang. In the archives of the arsenal's design department, Chinese gunsmiths discovered drawings of a Japanese experimental Type II submachine gun of the 1934 model.

The purpose for which these drawings were transferred from Japan to mainland China - for familiarization or deployment of production - has not yet been established. Due to the need of the Nationalist Army of China for any automatic weapon, the submachine gun was put into production by the Chinese, the approximate quantitative estimate is no more than 400–500 copies produced.

The Chinese copy has significant simplifications in design compared to the original Japanese design. The caliber was changed to .45ACP (11.43x23 mm), box magazines with 20 or 30 rounds were used, similar to the magazines from the Thompson submachine gun, attached from below through a guide neck. The magazine release button was located on the left side of the metal frame. The stock was also simplified and consisted of a butt with a weakly defined pistol grip and a short fore-end, with a metal butt plate.

Mukden Arsenal submachine gun Type II

Automation was still based on the recoil of a free bolt casing, spring-loaded by a return spring placed “pistol-style” around the barrel. Cocking was carried out using a handle welded to the casing, similar in shape to the bolt handle of the Thompson M1921 submachine gun. A muzzle compensator with four holes or transverse slits located on top was mounted on the casing. The air shock absorber was replaced with a hard rubber buffer insert to soften the shock of the bolt in the rear position. The rate of operation of the automation is constant, 500-550 rounds per minute. The firing mode is automatic only. The rear sight is non-adjustable, permanent annular, designed for a distance of 100 meters. The safety is pin-type, on the left side above the trigger.

After the victory of the Chinese Communists over the Kuomintang in 1949, surviving examples of the Type II submachine gun from the Mukden Arsenal were used by “Chinese volunteers” during the Korean War of 1950–1953, where some examples ended up as trophies to the Americans.

Tactical-technical Type II Mukden Arsenal model 1946: caliber .45ACP (11.43x23 mm), direct magazine for 20 or 30 rounds, total length - 702 mm, barrel length - 230 mm, rate of fire - 500–550 rounds per minute, weight - 3.47 kg without cartridges.

Type III submachine gun and its versions

After final testing of the Model 1934 Type IIA submachine gun in December 1938, unsatisfactory results were obtained for single-fire accuracy at all ranges, with good automatic fire at short ranges. The reliability of the automation was low during prolonged firing and increased contamination of the mechanisms, overheating of the return spring and clogging of the air shock absorber. As a result, the requirements for the designed “short machine guns” were revised.

New requirements were formulated by the technical department of the army headquarters already in August 1937. The basic concept in the form of a “large automatic pistol” with a movable bolt casing was revised in terms of simplification and a return to design based on classic first-generation submachine guns such as the Bergmann-Schmeisser systems.

Training 6.5 mm machine gun, right view

Model Type IIIA (Shisei San-Gata Kikauu Tanjuu), designed by 1938, was based on ideas close to the design of the Bergmann MP-18/I submachine gun, to which numerous changes were made by the design department of the Chuo Kogyo company K.K. under the leadership of Colonel Sadamitsu Toguchi.

One of the types of products manufactured by Chuo Kogyo K.K. were training Nambu machine guns chambered for blank or 6.5 mm practical cartridges for firing a short bullet, intended for training schoolchildren and students in handling automatic weapons. Experience in the production of receivers and trigger mechanisms for training machine guns with automatic action based on blowback recoil was used to master the production of the Type III submachine gun.

The original prototype of the Type IIIA submachine gun was a Nambu training machine gun, chambered for 8x22mm Nambu pistol cartridges instead of the short lead bullet cartridges intended for training. Also, instead of a barrel with a smooth bore, a rifled barrel was installed on the prototype.

Reconstruction of the appearance of a Type IIIB submachine gun

The 228 mm long barrel with six right-hand rifling was removable and attached to the receiver using a transverse wedge bolt; the inner surface of the barrel, including the chamber, was chrome-plated to increase resistance to corrosion and wear. To supply ammunition to the submachine gun, a 30-round magazine with a double-row exit from the 1934 model was used. The magazine was attached through a milled neck on the left. Shooting was carried out from the rear position of the bolt; the firing pin was attached to the bolt as a separate part and could be replaced if broken.

The firing mode is only continuous. The rate of fire was not regulated, but varied between 400–600 rounds per minute depending on the quality of the cartridges, heating of the return spring and the degree of contamination of the bolt channel. The safety is made in the form of a switch in front of the trigger guard. A carbine-type stock made of solid wood with a semi-pistol neck butt. Sector sight with aperture (ring) rear sight with graduation up to 600 meters.

Mounted underbarrel bayonet block on a Type IIIC submachine gun

During factory testing, the Type IIIA prototype showed low accuracy when firing, and the angle of the magazine neck did not ensure reliable supply of cartridges to the chambering line.

By January 1938, the following changes were successively made to the design of the Type IIIA prototype: a shortened guide for the recoil spring was installed, the length of the bolt box was reduced and the weight of the bolt was increased due to elongation; by selecting the stiffness of the spring, a constant rate of fire was set at 450 rounds per minute. We also redesigned the magazine fastening point in the neck and the shape of the magazine feeder, and added a barrel protective casing.

The modified model, designated Type IIIB, was tested at the technical department of Army Headquarters in Tokyo in April 1939 and received generally positive reviews. The mediocre accuracy during automatic firing compared to the MP-18/I caused criticism. It was recommended to produce a batch of 200 units for military testing in infantry, cavalry and artillery units, as well as in army reserve schools.

Type IIIC submachine gun with bipod and folding stock

During the production of a test batch, the army received additional demands to increase the accuracy of fire, to equip the submachine gun with a special under-barrel device for mounting a Type 30 bayonet (later special shortened Type 100 or Type 2 bayonets). According to the requirements from the cavalry school, some Type IIIC submachine guns were equipped with a bipod similar to the Type 11 machine gun, and a sight with an aperture rear sight, graduated to 1500 meters, was mounted. This was done to assess the possibility of hitting targets as a light machine gun.

For parachute units of the army, some of the Type IIIC submachine guns were equipped with a folding stock on the right side with a unit similar in design to the special 6.5 mm Type 01 carbine for paratroopers, created on the basis of the Type 38 carbine.

There is a photograph of one version of the experimental Type IIIC submachine gun, equipped with a special extended block for mounting a Type 30 bayonet. This single example was modified for use in bayonet combat. In this version, the total length of the submachine gun reached 1360 mm - the minimum length, similar to the Type 38 carbine with a fixed bayonet, ensuring effective use in combat.

Submachine gun Type 100 model 1940

To increase the effectiveness of automatic fire, in November 1939, a double-slit muzzle brake-compensator was installed on some of the previously released Type IIIC test submachine guns. Almost before the completion of the full cycle of military tests in the summer of 1940, the Type IIIC submachine gun model with a muzzle brake-compensator was adopted by the army under the name Type 100 (Hyaku-Shiki Kikan-Tanjū) and was finally sent into mass production. However, the Type 100 did not become a truly mass-produced weapon for the Japanese infantry. The initial reliance on technically complex prototypes, the development of which was delayed, the monopoly of arms companies and the general weakness of the industry left the Japanese soldier to fight with a repeating rifle in his hands.

Tactical and technical characteristics of Type III model 1937-1939: caliber 8x22 mm Nambu, sector magazine for 30 rounds, total length - 872 mm, barrel length - 228 mm, rate of fire - 400-600 rounds per minute, weight - 3, 73 kg.

Finnish submachine gun "Suomi"

The Finnish submachine gun "Suomi-KP M/31" was distinguished by very high quality workmanship. It weighed 4676 g, as many parts were all metal. As a result, the weapon was very reliable and remained in use for many years.

The Finnish Suomi-KP submachine gun model 1931 was produced in Finland and under license in Denmark, Sweden and Switzerland and was widely exported. It was developed by Finnish gunsmith Aimo Lahti between 1920 and 1930. Suomi proved its very high combat effectiveness during the Winter War of 1939-1940, when Finland was attacked by the Soviet Union. The fire of submachine guns with 71-round magazines often prevented Soviet soldiers from raising their heads. In 1944, production of the Suomi was discontinued in Finland, but the weapon continued to be used until the 1990s, when it was replaced by an assault rifle.

A Finnish soldier in a trench on the Eastern Front holds a Suomi with a 20-round magazine in his hand.

Soviet PPSh-41

After the German invasion of the Soviet Union in 1941, the Russians lost a huge amount of small arms and a significant part of their weapons factories, which created an urgent need for light and simple weapons with great combat power. The result was a reliable and very effective Shpagin submachine gun model 1941 (PPSh-41) of 7.62 mm caliber, developed by Georgy Shpagin. The PPSh-41 was much cheaper and simpler than previous Soviet submachine guns, since it had no screw connections at all, and all metal parts were made by stamping and welding. It weighed 3500 g and was used with either a 71-round drum magazine (like the Suomi magazine) or a 35-round box magazine. The rate of fire was 900 rounds per minute.

The Soviet PPSh-41 submachine gun of 7.62 mm caliber, mass produced in the USSR during World War II, was ideal for arming tank landing forces on the Eastern Front

During the war, Soviet soldiers respectfully called this weapon “Daddy” or “Shpagin.” It used a chrome-plated barrel, like the 1891/30 Mosin-Nagant rifle, for better corrosion resistance and longer service life. The weapon was very easy to disassemble: the receiver cover was hinged, opening access to the bolt and return spring. Some late models only allowed automatic fire, so they did not have a translator.

A simple compensator and muzzle brake reduced the upward thrust of the muzzle of the barrel as a result of recoil. The PPSh-41 had several disadvantages: an accidental discharge could occur when dropped, reloading was difficult, and drum magazines were prone to jamming, which did not happen with box magazines.

The Soviet PPSh-41 was created based on the design of the Finnish Suomi submachine gun (Finland).

About five million PPSh-41s were produced before 1945, and infantry tactics were changed to take full advantage of the new weapon. Often military units, especially tank landings, were entirely armed with submachine guns. The standard ammunition load probably consisted of one drum and five to six box magazines. Before the advent of box magazines, ammunition apparently consisted of two drum magazines. The short range of actual fire meant that units had to come into direct contact with the enemy. Such tactics, somewhat reminiscent of bayonet fighting tactics, had a terrifying effect on the enemy on the Eastern Front.

MP-717(r)

The Germans also highly appreciated the PPSh-41 and used it whenever they managed to capture this weapon.

Since Soviet 7.62 mm cartridges and Parabellum cartridges were similar in size, to adapt the PPSh-41 to the MP-38/40 magazines, one only had to change the barrel and use an adapter for the magazine. The Wehrmacht officially adopted the converted PPSh-41 under the designation MP-717 (r). During World War II, the Finns captured just over 4,000 Soviet 7.62 mm submachine guns. Such a quantity was too small to convert production to produce Soviet 7.62 mm ammunition and create additional difficulties for the supply system of Finnish troops. However, although the need for submachine guns was very great and the command of the Finnish army studied the possibility of converting weapons for Finnish 9 mm caliber cartridges and magazines for the Suomi submachine gun, production of the modified PPSh-41 was never started.

Leningrad weapons

During the siege of Leningrad in 1941-1944. In the city, despite the shortage of materials, weapons factories continued to operate. Under these conditions, A.I. Sudaev designed PPS-42. After modification, the Sudaev submachine gun model 1943 (PPS-43), an all-metal weapon with a folding stock and a compact curved magazine for 35 rounds, was adopted for service. Production of PPS-43 continued after the war. The folding stock reduced the size of the weapon and made it ideal for tank crews, paratroopers and reconnaissance units. Although the rate of fire was relatively low (700 rounds per minute), this was more than compensated by its low weight, small size and high manufacturability. About 500,000 were produced. Captured PPS-43s were used by the Germans under the designation MP-719 (r).

The folding stock of the PPS-43 reduced its length to 622 mm and made the weapon ideal for armored vehicle crews and paratroopers

Share link

Special weapons

In addition to the main small arms, the warring parties used all kinds of grenades, machine guns, anti-tank rifles and other means to fight the enemy. In particular, the following were widely used:

- grenades - F-1 and Stielhandgranate;

- machine guns - MG-42, DP-27 and Maxim;

- anti-tank rifles - PTRS, PTRD and PzB-38;

- "Molotov cocktails".

Stielhandgranate - an anti-personnel hand grenade, a symbol of the Wehrmacht, was a favorite trophy of both the Allies and Soviet soldiers, as it was very safe and convenient. At the time of the war, it was the only explosive completely protected from self-detonation. However, it also had disadvantages, for example, frequent leakage, which made it impossible to use.

The Soviet F-1 hand-held defensive anti-personnel grenade has been in service for about 70 years. And it will be used for a long time, since it has a wide range of advantages - high explosion power, reliability and simplicity, low cost of production. The negative aspects include a weak fragmentation effect, a remote fuse and too much weight.

Contrary to popular belief, the Molotov Cocktail was not invented by Soviet soldiers. For the first time, a similar bottle filled with an incendiary mixture was used during the Cuban War of Independence. And in the Red Army it was used by the 100th Rifle Division of the Red Army in 1941 during the defense of Minsk.

Machine guns, Soviet and German: the famous MG-42, the reliable DP-27 and the old Maxim were indispensable in supporting infantry and performing a variety of combat missions. They were heavy, but this drawback was more than compensated by their rate of fire and relative simplicity.

Anti-tank rifles were also very useful when fighting against vehicles. With their help it was possible to destroy light and medium tanks, and, with the proper skill, aircraft. Guns made it possible to shoot even strong fortifications. Despite the complexity of operation, in many cases they remained the only possible method of destroying equipment.

Each weapon contributed to the way war was fought. And no matter how bad the fact of the conflict was, it gave a huge impetus to improving the production technologies of a wide variety of weapons. The transition from the old single-shot rifles to automatic carbines, which are still used today, is a major milestone in the history of weapons development.