GOST 7840-78

Group U65

STATE STANDARD OF THE USSR UNION

SPORTING CARTRIDGES 12 GAUGE AND HUNTING CARTRIDGES 12, 16, 20 AND 28 GAUGE WITH PAPER CASES

Specifications

Sport cartridges caliber 12 and hunting cartridges caliber 12, 16, 20 and 28 with papes case. Specifications

OKP 72 7220, OKSTU 7272

Date of introduction 1979-01-01

INFORMATION DATA

1. APPROVED AND ENTERED INTO EFFECT by Resolution of the USSR State Committee on Standards dated January 31, 1978 N 309

2. Instead of GOST 7840-68, GOST 5.1857-73

3. REFERENCE REGULATIVE AND TECHNICAL DOCUMENTS

| Designation of the referenced technical document | Number of clause, subclause, enumeration, appendix |

| GOST 15.009-91 | 2.2 |

| GOST 1028-79 | 2.4 |

| GOST 1760-86 | 5.10 |

| GOST 2488-79 | 5.10 |

| GOST 3282-74 | 5.13 |

| GOST 7574-71 | 2.4 |

| GOST 7837-76 | 2.4 |

| GOST 7933-89 | 2.4 |

| GOST 9569-79 | 5.10 |

| GOST 10354-82 | 5.10, 5.13a |

| GOST 14192-77 | 5.6 |

| GOST 19433-88 | 5.6 |

| GOST 22781-77 | 2.4 |

| GOST 23683-89 | 5.10 |

| GOST 24579-81 | 2.4 |

| GOST 26319-84 | 5.14 |

4. The validity period was removed by Decree of the State Standard of the USSR dated July 25, 1991 N 1297

5. REISSUE (October 1995) with Amendments 1, 2, 3, 4, approved in February 1980, February 1984, March 1987, February 1990 (IUS 4-80, 5-84, 6-87, 5-90)

This standard applies to cartridges with paper sleeves intended for shooting from sporting and hunting shotguns, used for the needs of the national economy and for export.

(Changed edition, Amendment No. 3).

TYPES, MAIN PARAMETERS AND DIMENSIONS

1. TYPES, MAIN PARAMETERS AND DIMENSIONS

1.1. Hunting cartridges must be made of three types:

ODC - with black powder and a central firing primer;

OBZH - with smokeless powder and primer-igniter "Zhevelo".

Baikal-OBZH for self-loading shotguns 12 gauge.

Sports cartridges must be made of two types:

SP-T - sports cartridge for a trench stand;

SP-K is a sports cartridge for a round stand.

Hunting cartridges of the OBZh type are available in two brands:

grade A - for export or for the needs of the national economy;

grade B - for the needs of the national economy.

Sports cartridges are available in two brands:

grades M - to improve sportsmanship, intended for export or for the needs of the national economy;

grade O - for initial shooting training, intended for the needs of the national economy.

(Changed edition, Amendment No. 1, 3).

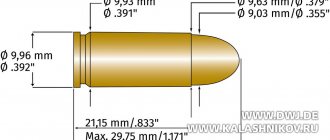

1.2. The dimensions of the cartridges must correspond to those indicated in the drawing and in Table 1 and ensure that the cartridge fits into the chamber of the gun with minimum dimensions.

_______________ * Dimensions for reference

Table 1

Dimensions, mm

| Cartridge caliber | Max. | Max. | Max. | Max. | ||||||||

| For chamber length | ||||||||||||

| 70 | 65 | 70 | 65 | |||||||||

| Sealing type "Rolling" | Sunset "Star" type | |||||||||||

| Nom. | Prev. off | Nom. | Prev. off | Nom. | Prev. off | Nom. | Prev. off | |||||

| 12 | 20,20 | 22,45 | 20,60 | 1,85 | 65 | ±1,0 | 60 | ±1,0 | 60 | ±1,0 | 55 | ±1,0 |

| 16 | 18,55 | 20,65 | 18,90 | 1,65 | ||||||||

| 20 | 17,35 | 19,40 | 17,70 | 1,55 | ||||||||

| 28 | 15,55 | 17,40 | 15,85 | 1,55 | ||||||||

| 12 "Baikal" | 20,20 | 22,45 | 20,60 | 1,85 | -1,0 | -1,0 | ±1,0 | ±1,0 | ||||

| Note. Lots of cartridges with a length of 59±1.0 mm are allowed. | ||||||||||||

Examples of symbols

12-gauge hunting cartridges with a 70 mm long case, central firing primer, filled with black powder and OM-3 shot:

ODC 12x70 OM-3 cartridges

GOST 7840-78

Hunting cartridges of grade A 20 caliber with a 65 mm long sleeve, a Zhevelo igniter primer, filled with smokeless powder and ST-7 shot:

Cartridges OBZH-A 20×65 ST-7

GOST 7840-78

Hunting cartridges "Baikal" with a sleeve 65 mm long, with ST-7 shot:

Cartridges "Baikal" 12×65 ST-7

GOST 7840-78

Sports cartridges for a trench stand, brand M 12 gauge with a 70 mm long sleeve, a Zhevelo igniter primer, filled with smokeless powder and ST-7 shot:

SP-T-M 12×70 ST-7 cartridges

GOST 7840-78

The same for a round stand with ST-9 shot:

SP-K-M 12x70 ST-9 cartridges

GOST 7840-78

(Changed edition, Amendment No. 1, 3, 4).

There are bullets

Bullets are: round (ball), arrow with a tail stabilizer, using the principle of arrow stabilization for the correct orientation of the bullet in flight; turbine, using a counter flow of air to rotate the bullet during flight; switch-turbine.

All shotgun cartridges can have paper, plastic or metal casings; various types of wads: felt, wood-fiber, cardboard, plastic (sometimes with containers for shot); various capsules - such as “Zhevelo” and “Tsentroboy” (TsBO); equip yourself with smokeless and smoky (black) powder. Cartridges for weapons with paradox drill barrels are divided into shot, buckshot and bullet.

TECHNICAL REQUIREMENTS

2.1. Cartridges must be manufactured in accordance with the requirements of this standard according to regulatory and technical documentation. (Changed edition, Amendment No. 3).

2.2. The appearance of the cartridges must correspond to standard samples approved in accordance with GOST 15.009-89*. ________________ * The document is not valid on the territory of the Russian Federation. GOST 15.009-91 is in force. — Note from the database manufacturer.

The appearance and quality of the design and inscriptions on cartridge cases must comply with the requirements of the regulatory and technical documentation for cartridge cases, approved in the prescribed manner, and standard samples.

Cartridges intended for the national economy may have cartridge cases with or without inscriptions, drawings, and cartridges intended for export must be issued in accordance with the requirements of the work order. Cartridges must contain information about the shot number. The design and inscriptions of sports cartridges must reflect their intended purpose.

(Changed edition, Amendment No. 4).

2.3. The quality of materials and components from which cartridges are made must comply with regulatory and technical documentation.

2.4. To equip cartridges of calibers 12, 16, 20 and 28, the following components must be used:

paper sleeves according to NTD;

central firing primers - in accordance with GOST 7574-71, Zhevelo igniter primers - in accordance with GOST 24579-81 or according to technical documentation approved in the prescribed manner. For sports cartridges, “Zhevelo-non-rusting” igniter primers are not allowed;

hunting smokeless gunpowder "Falcon" in accordance with GOST 22781-77 or smokeless gunpowder manufactured according to technical documentation approved in the prescribed manner, or smokeless gunpowder for commercial hunting in accordance with GOST 1028-79 grade DPO;

shot or buckshot according to GOST 7837-76, for sports cartridges for trench stand N 7; 7.5; 8, for a round stand - N 9 from one manufacturer;

wads and gaskets according to technical documentation or felt and polymer wads and gaskets according to regulatory and technical documentation.

For “Baikal-OBZh” cartridges and cartridges supplied for export, shot gaskets must be made from boxboard of chrome-ersatz grades: M, NM according to GOST 7933-89.

(Changed edition, Amendment No. 1, 2, 3, 4).

2.4a. To equip a batch of cartridges, components of no more than two batches should be used. When loading a batch of cartridges from two batches of gunpowder, a propellant charge must be selected for each of them.

(Introduced additionally, Amendment No. 3).

2.5. The igniter primer must be seated flush with the end surface of the cartridge case base. The capsule may be sunk to a depth of no more than 0.4 mm.

2.6. The number and height of wads are selected to achieve a dense load depending on the length of the cartridge case, the mass of gunpowder and shot.

2.7. The ends of the wads and gaskets in the cartridge must be perpendicular to the axis of the sleeve. Distortions of wads and gaskets are not allowed.

2.8. The cut of the cartridge case of a loaded hunting cartridge must be rolled using the “rolling” or “star” method, and for sporting cartridges - using the “star” method.

The cartridge's loading and rolling must be tight.

(Changed edition, Amendment No. 4).

2.9. The cartridges must function flawlessly when fired from a ballistic or sports rifle, and 12-gauge hunting cartridges must also function from a self-loading rifle.

(Changed edition, Amendment No. 3).

2.10. When shooting from ballistic, sports, or hunting weapons, including self-loading weapons, the following are not allowed:

misfires due to the cartridge case, failure to fit the igniter primer into the cartridge case, failure to load the cartridges;

rupture of the base of the sleeve;

the pallet extends beyond the length of the sleeve;

more than one case of displacement of the pallet within the length of the cartridge case for cartridges supplied for the national economy;

disconnecting the base of the sleeve from the tube;

violations of the integrity of the paper tube of the cartridge case, preventing the cartridge case from being removed from the chamber by the mechanisms of ballistic, sports, self-loading and non-automatic shotguns;

breakthrough of powder gases through the primer socket of the cartridge case;

failures due to the fault of the igniter primer exceed the standards established by the regulatory and technical documentation for igniter primers.

(Changed edition, Amendment No. 4).

2.11. (Deleted, Amendment No. 4).

2.12. In terms of ballistic indicators, cartridges of the ODC type must comply with the standards specified in Table 2, cartridges of the OBZh type - in Table 3, and cartridges of the SP type - in Table 3.

table 2

| Indicator name | Standard for cartridge type ODC caliber | ||

| 12 | 16 | 20 | |

| Maximum pressure of powder gases in the barrel chamber, Pa (kgf/cm), no more | 64·10 (650) | 64·10 (650) | 64·10 (650) |

| Average flight speed of a shot shell at a distance of 10 m from the muzzle of the barrel, m/s, not less | 300 | 300 | 300 |

| Average accuracy of fire for choke N 05 at a firing range of 35 m, %, not less | 50 | 50 | 50 |

| Shot projectile mass, g | From 31 to 34 | From 26 to 28 | From 23 to 25 |

Table 3

| Indicator name | Standard for cartridges of OBZh type caliber | |||||||

| 12 | 16 | 20 | 28 | |||||

| brand A "Baikal" | brand B | grade A | brand B | grade A | brand B | grade A | brand B | |

| Powder gas pressure in the barrel chamber, MPa (kgf/cm), not more than: | ||||||||

| average | 65 (663) | 68 (694) | 72 (734) | 72 (734) | ||||

| greatest | 70 (714) | 74 (755) | 79 (806) | 79 (806) | ||||

| Average flight speed of a shot shell at a distance of 10 m from the muzzle of the barrel, m/s, not less: | ||||||||

| for shot with a diameter of no more than 2.0 mm (shot N 9 and less) | 315 | 310 | 315 | 310 | 315 | 310 | 310 | 305 |

| for shot with a diameter from 2.25 to 3.0 mm (shot from N 8 to N 5) | 325 | 320 | 325 | 320 | 325 | 320 | 320 | 315 |

| for shot with a diameter of 3.25 mm or more (shot N 4 or more) | 330 | 325 | 330 | 325 | 330 | 325 | 325 | 320 |

| Average accuracy of fire for choke N 05 at a firing range of 35 m, %, not less | 55 | 50 | 55 | 50 | 55 | 50 | 45 | 40 |

| Shot projectile mass, g | From 30 to 36 | From 26 to 30 | From 23 to 27 | From 16 to 20 | ||||

Table 3a

| Type, caliber of cartridge | Maximum pressure of powder gases, MPa, kgf/cm, no more | Average speed of a shot projectile at a distance of 10 m from the muzzle of the barrel, m/s, no less, for brand cartridges | Average accuracy of fire, ,%, not less | Average uniformity of holes location, %, not less | Average accuracy of fire, ,%, not less | Average uniformity of holes location, %, not less | Shot projectile mass, g | ||||||

| For a barrel with a choke of at least 0.7 mm and a firing range of 35 mm, a target with a diameter of 750 mm for brand cartridges | For a bell or cylinder type barrel at a range of 20 m, targets with a diameter of 750 mm for brand cartridges | ||||||||||||

| M | ABOUT | M | ABOUT | M | ABOUT | M | ABOUT | M | ABOUT | Nom. | Prev. off | ||

SP-T 12 (N 7; 7.5;  | 90 (918) | 328 | 318 | 65 | 60 | 85 | 80 | — | — | — | — | 28 | +0,5 -1,0 |

| SP-K 12 (N 9) | 320 | 310 | — | — | — | — | 65 | 60 | 90 | 85 | |||

Cartridges manufactured for export according to specified parameters: the mass of the propellant charge and shot projectile (buckshot) or the mass of one of them, or according to one of the ballistic indicators, must be accepted according to the specified parameters; for other indicators, depending on the specified parameters, cartridges should be accepted based on actual results.

Cartridges manufactured for export according to specified parameters belong to the brand to which they comply with other requirements.

(Changed edition, Amendment No. 3, 4).

2.13. The minimum flight speed of a shot shell (buckshot) of 10 shots should not differ from the average speed indicated in Tables 2 and 3 by more than 15 m/s for hunting cartridges, and by more than 10 m/s from that indicated in Table 3 for sporting cartridges cartridges, and for Baikal-OBZh cartridges it must be at least 305 m/s.

(Changed edition, Amendment No. 1, 3).

2.14. The average accuracy of cartridges with shot with a diameter of no more than 2.25 mm can be 10% less than that indicated in Table 3.

(Changed edition, Amendment No. 4).

2.15. The mass of the propellant charge and shot shell (buckshot) must be selected before equipping the cartridges with a new batch of gunpowder and each shot number to obtain the ballistic indicators indicated in Tables 2 and 3.

2.16. The permissible deviation for the selected mass of a shot shell for hunting cartridges equipped with shot sizes of no more than 2.75 mm should be ±1.0 g, for shots larger than 2.75 mm - ±2.0 g, and for "Baikal-OBZh" cartridges with shot with a size of no more than 2.75 mm - ±0.5 g and more than 2.75 mm - ±1.0 g.

For cartridges loaded with buckshot, the weight tolerance should not exceed the mass of one ball of buckshot.

(Changed edition, Amendment No. 1, 3).

2.17. (Deleted, Amendment No. 4).

Bullets for "paradoxes"

Bullets for “paradoxes” (Fig. 1) differ in design from bullets for smooth-bore and rifled weapons. All of them have two leading belts, which, cutting into the rifling, give the bullet a rotational movement. The bullet for the Deer gun consists of 85% lead, 10% tin and 5% antimony.

Rice. 2.

Shot cartridge for smoothbore weapons:

1 — pressing with an “asterisk”; 2 — container (concentrator); 3 - fraction; 4, 6, 14, 15 — wads and gaskets; 5 — plastic sleeve body; 7 - gunpowder; 8; - base of the sleeve; 9 - pallet; 10 — sleeve flange; 11 - primer - igniter; 12 — ignition hole; 13—salting of the main wad.

Currently, most hunters use smooth-bore weapons, shooting shot, buckshot and bullets of various systems (Brenneke, Yakan, Vyatka, Sputnik, etc.).

ACCEPTANCE

3.1. To check the compliance of cartridges with the requirements of this standard, presentation and acceptance tests are carried out.

3.2. In the absence of State acceptance, the quality control department of the manufacturer carries out acceptance tests of batches of cartridges in the volume and sequence indicated in table 4, and if the enterprise has state acceptance, the quality control department conducts presentation tests, and the state acceptance department carries out acceptance tests according to subparagraphs 1-5 of table .4; according to subparagraphs 6, 7 of Table 4, tests are carried out jointly.

Table 4

| Controlled parameter | Item number | Sample size | ||

| technical requirements | test methods | for the national economy | for export delivery | |

| 1. Quality of marking and sealing of boxes, stacked pallets | 5.5-5.8, 5.13, 5.13a | 4.1 | At least three boxes of ammunition or all bagged pallets | At least five boxes of ammunition or all bagged pallets |

| 2. Appearance of packaging: boxes, bags or bundles, boxes, stacked pallets | 5.3-5.12, 5.13a | 4.1 | At least one box, 5 bags or 5 bundles and 10 cartons or all bagged pallets, 5 cartons; 5 bags of cartridges, 250 pcs. and 10 boxes | At least one box, 10 bags or 10 bundles and 20 cartons or all bagged pallets, 10 cartons, 10 bags of 250 pcs cartridges. and 20 boxes |

| 3. Appearance of cartridges | 2.2, 2.8, 5.1, 5.2 | 4.2 | At least 200 pieces, taken from different places | |

| 4. Chuck sizes: | 1.2, 2.5 | 4.3 | At least 200 pieces selected for inspection based on appearance | |

| , 0.4 max. and chamber entry | ||||

| 5. Quality of equipment, weight of propellant charge and shot shell | 2.4-2.8, 2.15, 2.16 | 4.4, 4.5 | At least 10 pcs. of those selected for inspection based on appearance | At least 20 pcs. of those selected for inspection based on appearance |

| 6. Ballistic indicators: | 2.12, 2.13 | 4.6, 4.7 | 10 pieces. (20 pcs. with separate tests for speed and pressure) from those selected for verification by appearance and geometric dimensions | |

| Pressure of powder gases and flight speed of a shot shell, buckshot | ||||

| Accuracy of fire for hunting cartridges | 2.14 | 4.7, 4.8 | 10 pieces. from those selected for inspection by appearance and geometric dimensions from each batch of cartridges | |

| Accuracy of fire and uniformity of holes for sports cartridges | 2.14 | 4.7 | 10 pieces. from those selected for inspection by appearance and geometric dimensions from each batch of cartridges | |

| 7. Durability and trouble-free operation of cartridges when firing from a ballistic or sports gun | 2.9, 2.10 | 4.10, 4.11 | 20 (30) pcs. from those selected for inspection based on appearance and geometric dimensions | |

| when shooting from a self-loading gun | 2.9, 2.10 | 4.10, 4.11 | 25 pcs. from each batch of 12-gauge cartridges selected for inspection based on appearance and geometric dimensions | 25 pcs. from each batch of 12-gauge cartridges selected for inspection based on appearance and geometric dimensions |

| Note. For warm-up shots, before testing cartridges for speed, pressure and accuracy, an additional cartridge is selected for each indicator. When testing speed and pressure simultaneously, one less cartridge is selected. | ||||

3.3. After positive results of the presentation tests, the Quality Control Department presents the cartridges in finally packaged form to the State Acceptance Department in batches.

A batch is taken of cartridges of the same type, brand, caliber, the same length of cartridge cases, the same size of shot or buckshot, manufactured on the same type of equipment, according to the same technical documentation during one or several shifts in a row, necessary for the manufacture of a batch of cartridges.

The lot must contain no more than 105,000 rounds of ammunition. Each shipment for export is equipped with cartridges of the same color or shades of this color or according to the terms of the order, and for the national economy cartridges of different colors and shades are allowed, unless the color is specified by the consumer.

If the number of cartridges on the order is not a multiple of the number of cartridges on the pallet, it is allowed to replenish the cartridges on the pallet with shot of a different number according to the same order, indicating on the labels the number of cartridges with each shot number.

3.4. The following cartridges are not allowed in the sample:

with non-entry into the caliber chamber, built according to the minimum dimensions of the chamber;

with deviations in appearance from the standard samples obtained during equipment, more than 2.5% of the sample volume;

with deviations in geometric dimensions of more than 2.5% of the sample volume:

in size (in excess of the length tolerance established in Table 1, but not more than ±0.5 mm)

in size 0.4 max. up to 0.5 mm;

more than one cartridge with a shot shell mass that differs by up to 1 g from the established maximum deviations (for hunting cartridges supplied to the domestic market);

more than 2% of pellets in the cartridge deformed by dosing devices.

Control samples approved by the State Acceptance Committee are approved for permissible deviations.

Lots of cartridges manufactured for export may be used for the national economy if their characteristics comply with the requirements of this standard or the terms of contracts with consumers, and the manufacturer’s trademark is affixed to the box (pallet). For cartridges supplied to trade organizations, the individual packaging must indicate the retail price and designation of this standard. For cartridges supplied to sports organizations, the wholesale price and designation of this standard must be indicated on the box (pallet).

3.5. If unsatisfactory results of quality control of markings and the appearance of packaging, the appearance and dimensions of cartridges are received (subparagraphs 1-4 of Table 4), the batch is returned for review and correction, after which it is presented again.

Repeated presentation is made with a certificate of analysis and elimination of defects. Repeated tests are carried out on a double sample.

The results of re-inspection are considered satisfactory if the percentage of deviations during re-inspection does not exceed the standards established in clause 3.5.

If the results of the re-inspection are unsatisfactory, the batch is rejected.

3.6. If unsatisfactory quality control results are obtained for the equipment, the mass of the propellant charge and the shot shell (subparagraph 5 of Table 4), the batch is returned for analysis and identification of the reasons for non-compliance with the requirements of this standard. Repeated tests are carried out on a double sample with an analysis report, and defects are not allowed.

If the results of the re-inspection are unsatisfactory, the batch is rejected.

3.7. If unsatisfactory test results are obtained for at least one of the ballistic indicators, repeated tests are carried out on a double sample for the indicator for which the unsatisfactory result was obtained; for the remaining indicators, the sample size is in accordance with Table 4, and the test results must meet the requirements of this standard.

If the results of repeated tests are unsatisfactory, the batch is rejected.

If unsatisfactory results in terms of shooting accuracy are obtained after repeated tests, the suitability of the ballistic or sports gun is checked and further tests are carried out in accordance with the requirements of regulatory and technical documentation.

3.8. If during the initial tests of cartridges for strength and trouble-free operation by shooting from a ballistic or sports or self-loading weapon (subparagraph 7 of Table 4), more than one, but not more than two cases of displacement of the pan within the length of the cartridge case, as well as one misfire due to the cartridge case, were obtained For cartridges intended for the national economy, repeated tests of a double sample are carried out on the type of weapon on which unsatisfactory results were obtained, and defects are not allowed. If the results of repeated tests are unsatisfactory, the batch is rejected.

If during the initial tests one of the following defects is obtained on at least one shot: the pallet extends beyond the length of the cartridge case, the base of the cartridge case is disconnected from the tube, the integrity of the paper tube of the cartridge case is damaged, preventing the cartridge case from being removed from the chamber by the mechanisms of ballistic, sports, self-loading and non-automatic shotguns, breakthrough powder gases through the primer socket of the cartridge case, misfire due to the loading of cartridges - the batch is rejected.

Note. If failures are received due to the igniter primer, further firing is carried out until the defect levels established by the regulatory and technical documentation for the igniter primers are confirmed.

3.9. For established mass production, after positive test results on five batches in a row in terms of “firing accuracy of hunting cartridges”, except for cartridges with shot with a diameter of 2.5 mm or less and “strength and trouble-free operation of cartridges”, tests for these indicators are carried out on one batch of five.

In the event of a batch of hunting cartridges being rejected for accuracy of fire, strength and trouble-free operation when firing from a self-loading gun, each batch is tested. If positive results are obtained on five batches in a row, they again switch to testing one batch out of five, but at least once a quarter.

In case of unsatisfactory test results for accuracy of fire and trouble-free operation of products manufactured and shipped during the controlled period, a decision is made.

3.10. Testing and acceptance of batches of cartridges are suspended.

The decision to resume testing and accept batches of cartridges is made by the head of the State Acceptance Committee.

Section 3. (Changed edition, Amendment No. 4).

TEST METHODS

4.1. Quality control of cartridge packaging, marking and sealing is carried out by visual inspection.

4.2. The appearance of cartridges is checked by visual inspection with a reference sample.

4.3. The dimensions of the cartridges are checked with a special testing and measuring tool, manufactured according to regulatory and technical documentation.

The fit of cartridges into the chamber of a gun is checked using a chamber caliber, the maximum dimensions of which do not exceed the minimum dimensions of the chamber.

4.1-4.3. (Changed edition, Amendment No. 2, 3).

4.4. The quality of cartridge equipment is checked by external inspection of the components of the equipment.

To check the quality of the equipment, the cartridges must be unloaded.

4.5. The mass of the propellant charge is checked by weighing with an error of no more than 0.01 g, the shot shell with an error of 0.1 g.

4.6. The preparation of cartridges and guns for ballistic tests is carried out in sequence and in accordance with the requirements of technical documentation approved in the prescribed manner.

4.7. The flight speed of a shot projectile, the pressure of powder gases, the accuracy of fire and the uniformity of the location of holes are determined according to regulatory and technical documentation. Powder gas pressure is measured at a distance of 25 mm from the breech end of the barrel.

Accuracy of fire is determined from sporting weapons:

sports cartridges for a trench stand - with a barrel length of 750 mm, having a muzzle narrowing of the channel of 0.7 mm;

sports cartridges for a round stand - with a barrel length of 675 mm, having a muzzle expansion of the “Fall” type channel or a cylinder 700 mm long.

The flight speed of a shot projectile is determined from a ballistic (or sports and hunting) weapon manufactured according to regulatory and technical documentation.

(Changed edition, Amendment No. 4).

4.8. (Deleted, Amendment No. 4).

4.9. When determining the speed, pressure, accuracy and uniformity of the distribution of holes, it is possible to exclude an abnormal shot. An abnormality assessment is carried out according to regulatory and technical documentation.

(Changed edition, Amendment No. 4).

4.10. Testing of cartridges for strength and trouble-free functioning is carried out by shooting from a ballistic or sports gun simultaneously with determining the ballistic characteristics of the cartridges and, additionally, from a self-loading rifle with 12-gauge hunting cartridges.

(Changed edition, Amendment No. 3, 4).

4.11. After firing, the cartridges are checked visually for compliance with the requirements of clause 2.10.

(Changed edition, Amendment No. 4).

Brass sleeves are the most economical

Brass sleeves are the most economical; they work at any temperature and in any weather, but the quality of combat when using them is lower than with paper and plastic ones, since the internal diameter of the metal sleeve is larger than the internal diameter of the bore of most modern guns, which are made for a paper sleeve. In addition, the brass sleeve weighs 23 g, while the plastic sleeve weighs 8, the paper with a low metal head weighs 8, and the paper with a high metal head weighs 9.5 g.

SAFETY REQUIREMENTS

6.1. Sports cartridges of 12 gauge and hunting cartridges of 12, 16, 20 and 28 gauges belong to class I, subclass 1.4, compatibility group S according to the classification according to GOST 19433-88.

Safety measures in the event of an accident on a vehicle and methods for eliminating its consequences must be provided for in emergency card N 710.

6.2. All work related to the manufacture, testing, use and destruction of cartridges must be carried out in accordance with the current operating rules of production, agreed upon and approved in the prescribed manner, and the requirements of the “Unified Safety Rules for Blasting Works”, approved by the USSR State Mining and Technical Supervision.

(Changed edition, Amendment No. 4).