Due to the technological simplicity of manufacturing, the dovetail mount is perhaps the first way to install sights on weapons. In the simplest case, the sight rings were installed in grooves cut with a milling cutter on the body of the gun. At the same time, the ease of mounting allows manufacturers not to adhere to any standards (unlike, for example, Weaver or Picatinny rails) and set their own rules. In this article, I summarized my experience of installing scopes (using ring stands or brackets) on dovetails, which is what I do consulting hunters literally every day.

- Retaining "wall"

- Rifle "Diana"

The very first mount

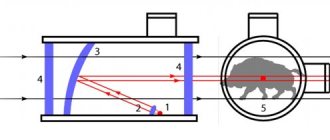

Let's start with the history of this mount. The receivers of the first guns had the simplest form, designed mainly for the simplicity of the mechanisms for feeding a bullet into the barrel, but not for the installation of sights. Many guns with a long history still force amateurs to come up with different solutions for installing sights. In general, the sight body also has the shape of a cylinder. That is, we need to connect the cylindrical shape of the sight and the receiver. This is how small grooves appeared on the first guns, which when cut looked like a trapezoid. This figure was very similar to that same swallowtail. Such a fastening is not an innovation, since something similar exists in the connection of logs.

Content

- 1 Sights for rail mounting 1.1 Zeiss rail

- 1.2 Swarovski SR rail

- 1.3 S&B Convex rail

- 1.4 Prism 70 degrees

- 2.1 Dimensions

- 3.1 Bases

- 4.1 Quick release

What types of dovetail are there?

The dovetail mount is the simplest mounting design for most shotguns from various gun manufacturers. So, we list the main options for this mount:

Dovetail with a rounded shape

The upper part of the seat is a continuation of the circumference of the receiver. To produce such a fastener, it was necessary to simply mill small grooves from two edges. The ease of manufacture brought with it an installation problem, as many scope rings or red dot sights themselves have a straight base.

Dovetail with straight base

A straight base, as can be seen in the cut, requires sanding the upper part of the seat. There are currently various mounting options available for this mount.

External dovetail strip

For many rifles, the manufacturer did not initially install any rails, and the previous two methods involve precise and significant mechanical impact on the body of the weapon. In addition, this method is not available for all guns, for example, if the thickness of the receiver does not allow it. Therefore, for some types of weapons, the installation of an external dovetail and weaver strap is used. Weaver is used more often due to the presence of a standard and greater distribution among imported sights and brackets. The most common method is to install the rail directly on the receiver body. Usually in this case you need to contact a gunsmith, but if you are confident in your abilities, below we explain in detail how to install such a bar on a weapon.

Below are the most common external dovetail trims:

Quite a popular dovetail rail for small-caliber TOZ rifles. The plank has a straight base with reduced grooves. Stoppers are bearings installed at the end.

A version of the dovetail strip with a straight shape and a locking “wall” from the Novosibirsk TochPribor. Read more…

Transition strip with ventilated strip and Weaver

For some shotguns with vertical barrels, the sight can only be mounted on a ventilated rail, which is reinforced with transitional universal dovetail or Weaver rails. For example, for “IZH-27” (MR-27) and “TOZ-34”. In addition to creating a seat, such an adapter bar allows you to adjust the alignment of the sight relative to the axis of the shot, and also, unlike rings, distributes the shock load onto the ventilated bar and allows you to install more massive sights.

Side dovetail strap

The use of a dovetail strap on the side surface of the receiver has become widespread - on weapons where it is impossible to use the upper part of the weapon body. Here are just a few of them (with links to relevant articles):

- Kalashnikov and its civilian modifications (“Vepr”, “Saiga”)

- SVD and "Tiger"

- Mosin and KO-44

- SCS

- SVT

- MC 20-01, MC 20-07, TOZ-106

On some shotguns, the side mount is due to the top feed of cartridges or ejection of cartridges, a rotary bolt, or a non-rigidly fixed receiver cover (as on an AK).

All possible dovetail side strips and brackets for them are collected in this section of the catalog. There's plenty to choose from

The uniqueness of the side mount is that it is quick-detachable, and most importantly, without loss of sighting after removal and subsequent installation of the optics.

The presence of runners allows you to push-mount the brackets. But the main thing for side fastening is the presence of stoppers. Different types of weapons have different stoppers. This is due to the butt pull. For example, it is typical for the Tiger to have a stopper on the far edge of the bar relative to the shooter’s eye, for the Saiga - on the near one.

To mount sights, there are a large number of side brackets for both rings and Weaver rails. Many manufacturers produce side brackets for mounting night sights. When choosing such brackets, it is necessary to take into account the drawback of the sight (depending on the eye relief), the installation height of the mounting bar, and the correct position along the axis of the gun.

Installing the side dovetail strip is similar to the top one and is described at the end of this article.

Other features[edit]

Quick release [edit]

Picatinny ring mount with two quick release levers.

Quick Release (QR) can refer to several different scope mounting options that can be quickly installed and disassembled without tools.

Tilt[edit]

Main article: Milliradian § Adjustment range and base slope

In some cases, it may be appropriate to add additional tilt to the scope to be able to shoot at a greater (or shorter) distance. For example, it is popular for long-range shooting, where a 6 mrad (20 MOA) cant angle is commonly used. Additional tilt can be achieved in several ways, such as using a tilted Picatinny rail (eg 6 mrad tilt), using bases or rings (eg 6 mrad tilt) or using special insert rings (eg Burris Pos-Align). [21]

Dovetail strip width

As mentioned above, due to the lack of a unified dovetail standard, almost every gun manufacturer offers its own options. First of all, this concerns the width of the strap: starting with Turkish guns, in which the width is about 6 mm at the top edge, ending with Czech ones, in which the dovetail width is 19 mm. Domestic production is still characterized by 11 mm rails, which are most widely used on air and small-caliber rifles.

The most painful example of a non-standard rib width is the Czech CZ shotguns, popular in Russia and the CIS. So, the width of the dovetail strip is:

- 11 mm for CZ 452, CZ 455, CZ 512, BRNO;

- 16 mm for CZ 527, BRNO;

- 19 mm for CZ 550, CZ 557, CZ 555;

which, in combination with the length of the cartridge (the distance between the front and rear straps), as well as with the reach of the sight forward (from the shooter) and back (to the shooter), leads to a huge number of options for rings, brackets (monoblocks) and adapter strips. The Czech manufacturer Kozap coped best with the task of covering the entire range of brackets for CZ, and we examined the entire variety of brackets and rings for CZ in a separate article.

But “ours” also have their own jokes, for example, in seemingly one model IZH-94 (MR-94, Taiga and Sever) the dovetail strap can be from 5.6 to 11 mm! Below is a little more detail about this. Therefore, before ordering rings, an adapter bar or a dovetail dovetail sight, be sure to measure the width of the bar on your weapon and pay attention to this parameter in the product you are ordering!

There are also quite “amazing” cases (it’s difficult to find a decent word). For some reason, the 11 mm wide dovetail grooves on the receiver on some MP-155 samples are made at different angles. If a collimator sight for a standard dovetail fits on them, it will be shifted to the side and slightly tilted. Therefore, on such MP-155s they first install a Weaver adapter bar, on which the sight is already installed. Read more about creating a mounting location for a sight on the MP-155 here.

Price range

The cost of the bracket is determined by a number of factors. The final price tag is influenced by the following points:

- fastening strip material;

- manufacturer;

- Manufacturer country;

- design features.

The most popular are optics mounts created by EAW and Leupold. Their price, accordingly, is not small. But reliability is also extremely high, which indicates maximum service life. But, of course, the choice of manufacturers is quite wide.

Types of stoppers used

A rather important nuance of dovetail fastening is the presence of stoppers. Many air rifles boast zero recoil, but what about firearms? When recoil occurs, the gun moves in the direction of the shooter, if you remember Newton's law, it will become clear that the reverse force moves the sights in the opposite direction. With fairly large recoil, the sight can move along the bar, thereby disrupting zeroing. To prevent the sight from coming off, there are several options:

- Retaining "wall". It represents a small barrier to prevent the sight from “walking.” It is located mainly at the end of the bar relative to the shooter's eye. When installing optics, you must move the bracket close to the stopper.

- Locking pins. Designed for recesses in the bracket for mounting optical sights or collimators. Can be located anywhere on the landing strip.

- Stopper holes. Designed for the presence of retractable bracket stops. Possible location in any part of the landing strip.

There is another way - limiting the grooves. A fairly common option for ensuring installation strength. The edges of the seat go to zero; during installation, the brackets move towards the end of the grooves, thereby locking. Most often found on planks with a rounded shape.

Examples of use on weapons

When approaching the most important thing - installation, you need to clarify what type of seat your seat is. To select brackets, OpticsTrade consultants will always come to the rescue. We can suggest considering the types of “dovetail” using the example of some guns:

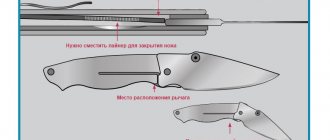

Straight shape with locking holes as exemplified by Diana rifles

These rifles have a simple dovetail seat. Made in the form of a longitudinal place with a straight base. It must be taken into account that these air rifles have significant recoil in relation to sights. By the way, when installing sights, we recommend considering Hawke Airmax air sights, as they can withstand double recoil with a reinforced spring.

Other recommendations for choosing a sight for pneumatics are in this article.

To ensure installation strength, the seat has a locking hole. The two most popular Diana brackets for installing optical sights are manufactured by the Tula company EST (Bracket “Diana” EST) and the Novosibirsk Central Design Bureau “Tochpribor” (Bracket “Diana” Tochpribor). EST offers two bracket options for mounting rings 25.4 and 30 mm, Tochpribor only 25.4 mm. Brackets from both manufacturers are designed for installation along the entire length of the seat, and also have retractable stops. If the Diana bracket from Tochpribor has a standard stopper, which is pulled out into the hole with a screwdriver, then EST has made a convenient spring fixation. The latter has two clamps, and Tochpriborovsky tightens it with a solid bar. The difference between the brackets is the height. The Diana bracket (ECT) has the ability to view an open sight with an optical sight installed (the diameter of the lens must be taken into account). The Diana bracket (Tochpribor) provides a lower landing.

Bracket "Diana" from EST with a unique spring fixation system. Read more…

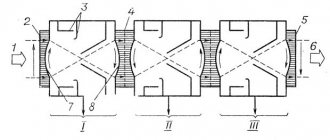

Rounded shape of separate bases with locking pins using the example of the Los and Bars carbines

A distinctive feature of the dovetail is its separate bases. It is important to take into account during installation that the brackets will not “drive” onto the bar. To install, you need to fold the bracket from the side. The difference between the seemingly identical seats of the Los-7 and Los-9 carbines lies in the distance between the separate bases. It is common for many manufacturers of night vision scopes to name the bracket “Los”, but in fact it can be clarified that it will be Los-7 and its analogues. The protruding stoppers are clearly visible in the photo. To install optics, the brackets must have a corresponding opening, as can be seen in the version of the universal adapter bracket from dovetail to Weaver for Los-7, Los-9, Bars carbines:

Bracket Base Weaver-U (Europrism) + power line racks is a universal bracket, as it has the ability to move the racks along the bar, while the width of the dovetail bar can be in the range from 8 to 12 mm. Read more…

Straight shape with limited grooves using the example of the combined gun IZH-94 (MR-94)

I would like to consider these guns separately, since the dovetail has a short installation length. In this case, there are two width options - 5.4 and 9.5 mm at the base of the bar. With such a rather non-standard bar, there are still bracket options. Basically, this is the same Tula manufacturer of ECT, but Belarusian engineers have proposed a transitional version from the “dovetail” to the Weaver with both a width of 5.4 mm and 9.5 mm. Adapter brackets are a fairly common solution, since many scopes are more adapted to the Weaver rail (night vision scopes), which allows you to create a universal mounting position.

We have combined all rings, brackets and adapter strips for MP-94 (IZH-94) in this section of the catalog.

A variant of the bracket for an optical sight designed to be installed on a small dovetail rail, 9.6 mm wide (for IZH-94 “North”). Read more..

Option to switch from a dovetail, 5.4 mm wide, to a standard weaver strip from Belarusian.

Straight form of split bases with locking recess, exemplified by the CZ 550

The use of the Czech 550 rifle is quite popular among hunters. As a consideration for the dovetail, we cannot pass it up. The mount consists of two separate places with a straight base. But what is non-standard is the width of the strip - 19 mm. Since the width of the Weaver strip is 21 mm, many people confuse these fastenings. Individual brackets are used to install scopes on the 550. This is typical for many foreign guns. But in this review it is interesting to consider the original solution of the stopper on the 550. On the closest (relative to the shooter’s eye) seat, on the left side there is a recess for the stopper. Brackets for the 550 must take this fact into account. The most popular solution when choosing a bracket involves the transition from such a non-standard “dovetail” to a Weaver bar. There are many such brackets, here are some of them:

The counter part of the CZ 550 bracket from the Vologda Optical-Mechanical Plant. The photo clearly shows the protruding stopper on the left side of the bracket. Read more…

The bracket for the CZ 550 from Izhevsk, updated in 2016, does not have the characteristic stopper for the CZ 550. At the same time, the designers have developed a unique system for rigidly fixing the bracket on the dovetail bar. Read more…

It is worth noting that not only the CZ 550 has a non-standard dovetail, for example, the CZ 527 model has a width of 16 mm, and the CZ 455 is 12 mm wide. We presented an overview of these brackets in a separate article - Selecting a scope for CZ.

Sight height[edit]

Scope sight height can be important for cheek support (often called cheek weld

) to obtain correct eye placement and also for ballistics calculations (such as a ballistic table). The latter is especially true at very close ranges (such as 15 meters [50 ft]), whereas at longer ranges, such as long range shooting, sight height has less of an impact on ballistic calculations.

Scope height can be measured in a variety of ways. As for ballistic calculations, it is usually measured only from the center of the bore axis to the center of the sight (line of sight). When it comes to cheek support, several methods are used: On firearms with a Picatinny rail, the height is measured from the top of the Picatinny rail on the firearm. On most other types of bases, it is customary to measure from the upper radius of the receiving jumper. Once the low measurement point is determined, the height is measured to either the optical center or the bottom of the scope tube (on ring mount scopes). The difference between the two measurement methods is the distance from the optical center to the bottom of the scope's tube, which usually corresponds to half the diameter of the scope (for example, 15 mm in binoculars with a 30 mm tube).

Installing the strip

Due to the wide distribution of brackets and sights for the dovetail rail, it is this one that is most often chosen to create a seat on a weapon - models that, for various reasons, do not have it installed at the factory. On most shotguns and carbines, the rail is attached directly to the receiver: top or side position.

Typically, installing the rail, this simple plumbing work, is done in gunsmith shops, but you can install it yourself if you are sure that the internal mechanisms of the gun allow you to install screws or rivets.

The installation sequence is the same for all strips. We have prepared the instructions described below based on the experience of user impeller from the Guns.ru forum for the “EST” side bracket. The point is that to install you must already have a set of scope + rings + dovetail rail.

- Before drilling the receiver.

- Degrease the sight rail. Degrease the box.

- We glue the strip to the box with cyanoacrylate glue, for example, “Super MOMENT”.

- Let the glue harden.

- We install the crowns with a sight on the bar.

- We lean in, we look, we try. Hereinafter, we recommend using a cold zeroed cartridge for the appropriate caliber: just make sure that the laser dot matches or is close to the sight's reticle set to zero.

- If you don't like it.

- We remove the crown with a sight. By lightly tapping with a mallet or a suitable piece of wood, we knock down the plank (the glue is fragile to impact loads).

- Wash off any remaining glue with acetone.

- We repeat the “glued, figured” operation. Until we achieve the desired result.

- If you like it.

- Carefully tilt the box. Along the centers of the holes in the plank.

- We knock down the bar as described above and clean the surfaces.

- Carefully drill holes with a thin drill.

- We take a drill of a slightly larger diameter - for cutting threads.

- We cut the thread.

- We glue the surfaces with two-component glue.

- Screw the bar.

- If the bracket still fits onto the box a little crookedly, we correct it with spacers of different thicknesses in the rings of the bracket.

Bracket Materials

The metal alloy used in the process of creating the fastening strip affects the strength of the part and other performance indicators. The bracket is based on steel and aluminum-based alloys (duralumin, silumin). More expensive solutions can even be cast from titanium alloy.

The steel structure is characterized by maximum reliability. The only disadvantage worth noting is the increased susceptibility to corrosion, but this disadvantage is offset by careful handling of the bracket and regular lubrication of all key fastener components with gun oil.

Anodized aluminum is no less popular due to its high strength characteristics. It also benefits from its low weight, which will subsequently affect the operation of the weapon. And the cost of “winged” metal is somewhat lower. The disadvantage is the inability to withstand the load from shots from large-caliber rifles.