Gun stamps are needed to inform each gun owner about the manufacturer, model, year of manufacture and some other characteristics.

To put it simply, gun marks are a certain set of signs and inscriptions that are stamped on the metal parts of the weapon.

In most cases, brands are applied to under-barrel pads, hooks, and metal blocks. When a manufacturer affixes marks and signs, he thereby confirms the quality of his products and takes responsibility.

Each specific enterprise uses exclusively its own branding system, but it is still possible to identify several common features that characterize them all.

Online club

By the end of the 16th century, the small-scale production of weapons in Russia was concentrated in several historically established points: in Moscow (Moscow Armory Chamber in the Kremlin), Tula (“state-owned” blacksmiths-outworkers), in the armories of the Trinity-Sergius Lavra and the Solovetsky Monastery (at Solovetsky Islands). Military weapons were forged here, and the most talented craftsmen (Ivan Boltyrev and others) worked “on the hunt” to make ceremonial, “hunting” weapons (Fig. 1).

Until the end of the 18th century, firearms from state-owned factories usually indicated the year and place of their production - Olonez (Olonets plant), Susterbeck (Sestroretsk), Tula, Izhevsk (Fig. 2). From the same time, personal marks of Tula craftsmen began to be found on hunting rifles: gunsmith Ivan Pushkin, Jvan Lialin, etc.

In 1850-1870 hunting rifles were made primarily by artisan gunsmiths. Some of them (Petr Goltyakov in Tula and others) used barrel blanks from a state-owned plant for their products, tested by a factory test for strength and marked with a factory mark. Such gunsmiths put their personal mark and surname on their guns (Fig. 3). Double-headed eagle - state

Rice. 1. 17th century matchlock by an unknown artist. The gun has a diopter sight - with a hole in the sighting shield.

The development of the arms industry began during the reign of Peter I, who reorganized the entire military system of the Russian state. At the beginning of the 18th century, he founded the Tula, Sestroretsk, Nevyansky, Olonetsky, Lipetsk and other factories of the state-owned arms manufactory; somewhat later (in 1760), the production of weapons began at the Izhevsk state-owned factory.

Rice. 2. Marks of Russian hunting rifles of the 18th century.

Rice. 3. Sighting bar on a gun made by Tula resident Pyotr Goltyakov.

Only factories and, in rare cases, artisans put the coat of arms of Russia on their guns. This coat of arms can be found on the guns of Tula factory gunsmiths until 1917. At the same time, many ramrod piston single-barreled guns were produced, converted from soldiers’ guns that had been withdrawn from service. After the Berdan and Krnka center-fire rifles were removed from army service in the 1870s, state-owned factories and private enterprises began converting them into single-barreled hunting rifles, which were in great demand due to their low cost. Single-barreled rifles converted from the 2nd Berdan model rifles, which were withdrawn from service in 1891, were no less in demand among the wide mass of hunters. All these “alterations” had a state mark (eagle) and the name of the enterprise that carried out the alteration (Fig. 4). Along with state factories, the best conversion weapons were produced by the Averin and Liventsev arms factories in Tula and the Evdokimov factory in Izhevsk. The rifles remade by artisans were inferior in quality to factory ones and had neither marks nor the names of the craftsmen who produced them.

Rice. 4. Factory mark on a converted Berdan rifle.

Mass production of specially hunting single- and double-barreled shotguns (hammer and hammerless) began at the Tula plant in the 1880s. The factory mark of that period sounded ornate: “Tula Arms Factory of Emperor Peter the Great.” On the breech of the barrels, a double-headed eagle was minted on top (sometimes in gold), and on the bottom - the serial number of the barrels (guns) and a strength test mark (Fig. 5).

Rice. 5. Test marks on Tula hunting rifles from the mid-19th and early 20th centuries.

Many hunting rifles at the end of the 19th and beginning of our centuries were produced by private factories and craftsmen, among whom Artari Colombo, Dokin, Pavlov, Shishkov enjoyed well-deserved fame - in Moscow; I. Aleshkin, Vishnevsky, Gono, Lardere, the Lejeune brothers, F. Matska and his successor K. Maslov, B. Ruzicka, Skala - in St. Petersburg; A. Evdokimov, Petrov - in Izhevsk; M. Averin, brothers Goltyakov, Gryaznov, I. Kuznetsov, I. Liventsev, Makarishchev, Nevernov, Porokhov - in Tula; Jench - in Odessa; Passup - in Revel (Tallinn); Bartelmeis, Niklas - in Riga; Becker, Sosnowski, Stapf, Ziegler, J. Spect, Jachimek - in Warsaw; Hegel, Kurtz, Shpagin brothers - in Tiflis; Prusha - in Rostov-on-Don; Vorobyov, Ohnesorge, Rush - in Saratov. The Urals and Siberia had their own celebrities.

In the book “Hunting Goods” (Gostorgizdat, Moscow, 1937), the famous Soviet game expert V.N. Satinsky wrote: “In pre-revolutionary Russia there was not even a semblance of a government testing station in the true sense of the word. Handicraft weapons (now produced in large quantities by various cooperative associations) went on sale without testing at all, since only the products of the Tula Arms Plant were subjected to the latter at the factory testing station.

The Tula plant had its own brand, depicting two hammers lying crosswise. In addition to these marks, indicating the sample produced, the Tula guns had a factory mark of the letters ITOZ, in an oval. The stamp of the same form is put by the plant even now, only without the letter I - TOZ, which means Tula Arms Plant.”

In the Soviet Union, as in pre-revolutionary Russia, manufactured hunting rifles are not subject to state tests. Each enterprise has its own mandatory technical conditions. In particular, each gun is tested by the factory for strength and accuracy. Branding systems, the very image of factory marks for different models of the same plant are often different. Therefore, it is not surprising that it is not so easy for a hunter, especially one purchasing a used gun (without a passport), to understand the mass of different badges, brands and images embossed in various parts of his gun.

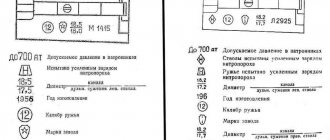

V.N. Satinsky wrote: “On the guns of the Tula plant of Soviet production, initially no marks were placed, except for the gun number; Since 1932, the plant began to brand guns with the number 1517, indicating the year the gun was manufactured. The same mark, but with the addition of an asterisk to the right, was placed during the first 9 months of 1933; from October 1, 1933, instead of an asterisk, the plant began to put the Roman numeral X. In 1934, to the mark of 1932 (1517), Roman numerals were added to the right numbers I, II, III, IV - indications of the quarter in which the gun was released. Since 1935, the last digit of the year of manufacture has been placed at the end of the gun number after the dash, for example 48557-6 means that the gun number is 48557, it was released in 1956.”

Since 1936, TOZ guns, in addition to the factory gun number, have been affixed with a number of mandatory marks, which are a kind of “gun passport”. So, for example, the letters ChP and the numbers following them mean the recommended weight of the black powder charge, DR 32 - a shot shell weighing 32 g, PG-70 - the chambers are drilled for a folder sleeve 70 mm long, MB-16 - model B 16 caliber.

Below are the factory marks and hallmarks of hunting rifles that are most often found among our hunters.

Tula Arms Plant (TOZ)

| factory mark on hammer-fired double-barreled shotguns of models A, B (since 1928), BM (modernized) and TOZ rifles; |

| the same on Model B shotguns in the period 1925-1928; |

| the same on guns mod. B in 1945; |

| the gun has been accepted by the technical inspector (on guns mod. A, B and BM); on models A and B of previous years there is a modified mark: the same combined letters T and K, but in an oval; |

| the gun was tested with an increased charge of gunpowder; |

| tested for accuracy and accuracy. |

CIL - cylindrical drilling of trunks; p/choke — muzzle constriction “receipt”; choke - choke constriction; 16 k or 16×70 - designation of caliber (in this case 16th) or caliber and chamber length (in this case 70 mm);

700 atm - maximum permissible (working) pressure in the chamber;

Boom is a mark indicating that the chamber is drilled for a paper (folder) sleeve.

In addition, Tula guns are marked with the year of manufacture and the serial number of the gun of this model. On model B shotguns produced in 1925-1928, there is a mark indicating the recommended weight of shot in grams (“Dr 32”) and a mark indicating the testing of the barrels (“tested without powder.”).

The factory marks listed above were placed on the barrels of the guns, technical control marks were placed on the stock, and other test and working marks were placed on the cushion of one of the barrels (mostly the right one). The gun number is usually stamped on the left barrel pad and is duplicated on the fore-end hinge and the left platform of the box.

In 1926-1928 TOZ produced a hammerless double-barreled shotgun of the Anson-Dilley type. This gun was marked with only the year of manufacture, the serial number of the gun, the caliber designation (16 k), the gun's smokeless powder test mark (Nitro) and the acceptance inspector's mark (K).

TsKIB in Tula

The Central Design Research Bureau for Hunting and Sporting Weapons (TsKIB) produces piece shotguns of the MTs5, MTs6, MTs7, MTs8, etc. models. On most guns, all marks are applied to the barrel sleeve, and the gun number is duplicated on the receiver. On models MTs9, MTs10, MTs11 and MTsZO, individual marks are stamped on the barrel pads, on the large hook, on the base of the trigger mechanism, etc. The meaning of the marks is given below.

- TsKIB brand;

- gun model;

— tested for accuracy and accuracy;

- tested with enhanced charge

No more than 700 kg/cm2 or 700 atm - long-term firing with cartridges with a gas pressure in the chambers of no more than 700 atmospheres is permissible;

— designation of caliber and choke number (in this case, 16 gauge and choke number 4);

- the same, 12 gauge;

70, or 70 mm - chamber length; 1600 – weight of trunks (in grams);

— barrel steel grade;

— stamp of the technical control department of the bureau (not found on all models).

In addition, all guns indicate the year of manufacture and serial number.

At TsKIB there is a School of Weapons Craftsmanship. The brand of this school is on the Tula cage guns TS-1 and TS-2. In addition to the year of manufacture, the current number of the gun, the caliber designation and the number of the choke, on the guns of both of these models there is a mark for testing the barrels with smokeless and smoky powder, as well as a special mark with which the finally assembled gun was tested.

Izhevsk plant

The hallmarks and even the factory mark of Izhevsk guns have undergone a number of changes over the years.

— brand of the Izhevsk arms factory (pre-revolutionary period);

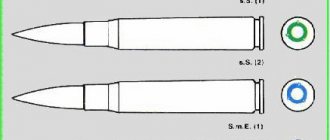

The IZHB-36 and IZHB-47 shotguns have the following signs and marks:

— factory brand;

— serial number and year of manufacture of the gun;

- the caliber of the barrel and the presence of a choke in it (in the right diamond - constriction No. 2);

The length of the chamber (70 mm), its diameter (20.7 mm) and the diameter of the right (18.2) and left (17.4 mm) barrels in the muzzle;

— strength test mark (on the IZHB-47 model);

— test with smokeless or black powder (on the IZHB-36 model);

NITRO - the same on IZHB-47 guns.

On ZK (IZH-K) guns, the factory mark is already a five-pointed star on the shield. The mark indicates the caliber of the gun, the drilling of the barrels and the length of the chamber.

The letter means test of strength

- controller's mark;

- testing the strength of the gun.

On guns of the IZH-49 model, in addition to the factory brand (star on the shield), year of manufacture and gun number, designations are given for the caliber of the barrel and the length of its chamber (for example, 20×65), the drilling of each barrel (for example, i.e. choke constriction = 0.5 mm) and a stamp was affixed (the letter “U” in a trapezoid) to test the strength of the trunks.

Since 1954, the IZH-54, IZH-56, IZH-57 and IZH-58 shotguns, as well as the IZH-K and IZH-KB models, have been marked with the following main marks:

— brand of the plant;

- barrel caliber;

— in the numerator – the diameter of the right (lower) and (in brackets) left (upper) trunk; in the denominator – the diameter of the corresponding barrel in the choke constriction;

— tested with an enhanced charge of nitro powder;

— controller badge (only on IZH-K and IZH-KB guns).

In addition, the guns indicate the year of manufacture, series and serial number of the gun (for example, M.2016), and the maximum permissible pressure in the chamber is indicated (up to 700 atm).

For shotguns of the IZH-54 and other models, most of the marks and the factory mark are located on the barrel pads; for IZH-K and IZH-KB guns - on the barrel, receiver and barrel hook.

Other enterprises

Until recent years, the USSR produced single-barreled guns of the ZK (Kazansky model), ZK-B (same, hammerless), ZKM-1 (same, modernized, type 1), ZKM-2 (same, type 2), ZKMSh- 2 (the same, piece), ZB-1, ZE-2, ZBSH-1 and with a vertically paired pair of barrels, the “Deer” gun. These guns are not currently in production. Their marks are given below.

— letters ZMZ – factory mark;

— caliber, chamber length and year of manufacture (this mark is absent on the “Deer” model);

Deer - gun model (engraved on the sighting bar);

— caliber of the first and second barrels and chamber length (on the “Deer” model);

UK - tested with enhanced charge (U) and accuracy (K);

A3219 - series and number of the gun;

— the gun has been accepted by the technical control department;

- controller's mark.

Most of these marks are applied to the barrel and its hook.

KIEV - a brand of double-barreled shotguns of 16 caliber, produced from 1947 to 1954 by one of the Kiev artels based on barrel blanks and other parts of Izhevsky, was a hammerless type IZH-47, and the model "Kiev-3" (1950-1954) - double-barreled shotgun IZH-49. These guns differed from the corresponding models of the Izhevsk plant in a more varied engraving, since they were manufactured exclusively according to individual orders. The quality of the Kiev shotguns (drilling barrels, fitting parts, etc.) was low, and in 1954 the production of shotguns in Ukraine ceased.

The drawings of the above marks will help the young hunter to easily understand the marks that he will encounter on new models of hunting rifles produced by domestic factories.

A. Zelenkov, V. Kholostov

Magazine "Hunting and Game Management", No. 5, 1960.

img src=

Repair mark

A square divided in half.

1 description option. Near the wooden overlay there is a restoration mark - a rectangle divided in half. Such terminals had been installed for several years since 1928, while revolvers (triggers, springs, sights) worn out in the battles of the imperialist and civil wars were being repaired.

Option 2 description. Small repair marks - a rectangle divided in half (read “overhaul in 1932”, when they began to remake the sighting parts), which were placed since 1932 on revolvers produced earlier, i.e. The revolver with this mark was produced before 1932.

A diamond means a complete overhaul, which in turn means a complete or partial re-sorting of parts of the revolver. During the overhaul, they could change the drum and re-barrel, but this is less likely than simply replacing a worn-out trigger. The diamond sign is less common than a rectangle divided in half. Accordingly, it means a non-standard overhaul, or a special workshop. I think this sign indicates some kind of “fine” work on the revolver.