German single machine gun MG 34 (German: Maschinengewehr 34)

The 7.9 mm MG 34 machine gun was developed by the German company Rheinmetall-Borsig AG for the Wehrmacht. The development of the machine gun was led by Louis Stange, however, when creating the machine gun, the developments of not only Rheinmetall and its subsidiaries, but also other companies, such as Mauser, were used.

The German machine gun was officially adopted by the Wehrmacht in 1934. Until 1942, it was the main machine gun not only for infantry, but also for German tank forces. In 1942, instead of the MG 34, the more advanced MG 42 machine gun was adopted. But even in 1942, production of the MG 34 did not stop, since it was used as a tank machine gun and was more convenient for use in this direction.

Notes[ | ]

- mg-list

- MG 34 and MG 42 Machine Guns - Osprey Publishing, 2012. - pp. 12-13. — ISBN 978 1 78096 008 1

- Louis Stange: Patent GB468913: Improvements in or relating to automatic guns. Angemeldet am 6. Oktober 1936, veröffentlicht am 15. Juni 1937, Anmelder: RHEINMETALL-BORSIG AKT.-GES., Erfinder: Louis Stange.

- ↑ 12

Das Maschinengewehr 34 / Berausgegeben von der Hauptverwaltung Deutsche Volkpolizei im Ministerium des Innern der DDR. - Berlin, 1960. - 10 p. - H.Dv 130/2a Ausbildungsvorschrift für die Infanterie (AVI). Heft 2. Die Schützenkompanie.. - Berlin, 1940.

- Zu H.Dv. 130/2b Merkblatt fuer Gliederung und Einsatz der sMG-Gruppe der Schuetzenkompanie. - Berlin: Verlag "Offene Worte", 1938. - 16 p.

Post-war production

After the war, the MG 34 was produced in huge quantities and was in service for a long time in the following countries:

USA, Germany, East Germany, Yugoslavia, Czechoslovakia, France, Turkey and Switzerland (variant M-53), including for NATO standard ammunition (7.62 and 7.5 mm).

In addition, large quantities (tens of thousands of units) were exported and supplied to the USA, Germany and the USSR (mostly captured and restored) to the countries of the Middle East, as well as China, Iran, Iraq, Egypt and Israel.

German single machine gun MG 34 (German: Maschinengewehr 34), bipod position in anti-aircraft mode

The MG 34 is primarily worthy of mention as the first single machine gun ever adopted. It embodied the concept of a universal machine gun, developed by the Wehrmacht from the experience of the First World War, capable of performing the role of both a light light machine gun used from a bipod and an easel machine gun used from an infantry or anti-aircraft machine gun, as well as a tank gun used in twin and separate installations of tanks and combat cars Such unification simplified the supply and training of troops and ensured high tactical flexibility.

Stock and bipod

Options and modifications

- MG 34/41

- appeared as a result of understanding the experience of the first real battles of the beginning of World War II, when it became clear that an increase in the rate of fire leads to greater dispersion over the area.

The rate of fire for the MG 34/41 was increased to 1,200 rounds per minute (for the MG 34 the rate of fire was 800-900 rounds). The weight of the MG 34/41 has increased slightly (14 kg) compared to the original (12.1 kg). A limited production of this modification was made; 300 copies of the machine gun were sent to the Eastern Front. In field tests, the MG 34/41

performed worse than the MG 39/41, which was later designated MG 42. - MG 34T

- a modification for installation on tanks, the main difference of which was a heavier barrel casing without ventilation holes and the absence of a bipod.

The MG 34 machine gun is built on an automatic basis with a short barrel stroke. The barrel is locked by a bolt with a rotating combat cylinder, on which combat stops are made in the form of screw thread segments.

Literature and sources[ | ]

- Pavel Stolyarov. “Thirty-fourth” // “Master Gun” magazine, No. 61, April 2002. Pp. 12-17

- Chris McNab.

MG 34 and MG 42 Machine Guns. - Osprey Publishing, 2012. - ISBN 9781780960081. - Monetchikov S.

Infantry weapons of the Third Reich. Machine guns (Russian) // Weapons: special issue of the magazine. - 2005. - January (No. 01). - Jim Thompson.

Revolutionary in its Design: 10 facts about the MG34 general purpose machine gun (English) // World of Firepower: magazine. — 2015. — March-April (vol. 03, no. 02). — P. 10-12. - D 124/2 - Maschinengewehr 34. Teil 2. MG Lafette 34 Beschreibung, Handhabung und Behandlung. - 5.3.1943. — 23 s.

Locking

Locking is carried out using a special coupling, rigidly fixed to the breech of the barrel. The rotation of the bolt cylinder is carried out by the interaction of the rollers located on it with shaped grooves made on the inner walls of the box. The axes of the rollers are located perpendicular to the axis of the shutter, on its opposite sides. In addition to controlling locking and unlocking, these same rollers also serve as bolt accelerators, interacting after it is unlocked with special shaped bevels on the barrel coupling.

The role of the flame arrester

To increase the reliability of the automatic operation, the machine gun has a muzzle recoil amplifier, which uses the pressure of powder gases on the muzzle of the barrel to give it additional acceleration during recoil.

This same muzzle amplifier also serves as a flash suppressor.

The barrel casing is cylindrical, with round ventilation holes.

The MG 34 tank version has a solid, reinforced barrel casing. The cylindrical box, milled, is connected to the barrel casing with a longitudinal axis on the right side and a latch on the left. The box can rotate on the mentioned axis relative to the barrel casing up and to the right, opening the breech of the barrel.

Replaceable barrel

Thus, changing the barrel is carried out in a matter of seconds, however, the machine gunner needed heat protection to remove the hot barrel, since he did not have any handles for this purpose, so the machine gun included an asbestos glove. The hot barrel was simply removed from the casing back, a cold one was put in its place, after which the box was rotated to its original position.

Power supply MG 34

The MG34 was fed with machine gun belts from a 150-round box (German: Patronenkasten 36) or from 300-round cartridge boxes (German: Patronenkasten 34 and Patronenkasten 41); early 150-round belts were solid, then consisted of pieces of 25 (until 1938), and later - 50 rounds. In addition to the indicated cartridge boxes, various special cartridge boxes were used for use on various equipment. In the manual version, compact cylindrical boxes for tapes with 50 rounds of ammunition were used (German: Gurttrommel 34), which were attached to the left of the machine gun directly to the tape receiver. In 1938, for anti-aircraft units and in 1939 for tank units, a magazine-fed version of the MG34 was introduced: for machine guns, the box cover with a tape drive mechanism was replaced with a cover with a mount for a 75-round drum magazine (German: Patr.Trommel 34). The magazine consists of two connected drums, from which cartridges are fed alternately. The Patropnentrommel 34 magazine is an almost complete copy of the Doppeltrommel 15 magazine of the MG 15 machine gun and can be used in it (but not vice versa).

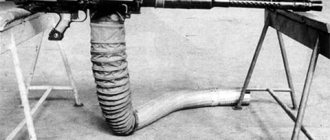

mounting the bipod in the anti-aircraft position

Stories about weapons. MG-34 machine gun

The machine gun (in its modern sense) first appeared at the end of the 19th century through the efforts of Hiram Maxim.

Already the first experience of its use has shown the high effectiveness of this type of weapon. But the real finest hour of the machine gun was the First World War. The machine gun reigned over the battlefields of that time. Machine guns began to be installed on tanks, airplanes, and warships. Most machine guns of that time had a decent weight, they were installed on special machines or turrets.

Work was actively carried out on the creation of a so-called single machine gun, which could perform the functions of both a light infantry machine gun and be installed on a turret, a machine tool or on armored vehicles.

This concept significantly simplified the use of such weapons and reduced the cost of supplying and training personnel. A similar issue was dealt with in many countries of the world, but they were able to achieve success only in Germany.

The German MG-34 can rightfully be considered the first single machine gun.

It was created by Rheinmetall-Borsig AG. During its development, all the experience of using similar weapons in the First World War was taken into account. The machine gun could be used from a bipod, used as an easel gun, or installed in tanks and other armored vehicles. It weighed only 12 kg (for comparison: the Maxim machine gun weighed 60 kg), so this machine gun could be carried and could easily support infantry units with fire.

This machine gun had many advantages, and it was not for nothing that they continued to produce it until the very end of the war, but there were also disadvantages, especially significant and unpleasant in wartime conditions.

The main problem with the MG-34 was its high cost and rather high complexity.

The machine gun contained a large number of milled parts; special types of steel were required. The cost of one machine gun was 327 Reichsmarks, which was very expensive for that time. Disassembling the machine gun and servicing it was quite difficult.

For this reason, a decision was made to modernize the machine gun, which began back in 1938. The outbreak of hostilities in Russia only accelerated this process: the MG-34 was very sensitive to pollution, which was immediately evident during its use on the Eastern Front and in the sands of North Africa.

The machine gun was officially adopted by the Wehrmacht in 1934 and until 1942 it was officially the main machine gun not only of the infantry, but also of the German tank forces.

In 1942, instead of the MG-34, the more advanced MG-42 machine gun was adopted, but production of the MG-34 did not stop until the end of World War II, as it continued to be used as a tank machine gun due to its greater adaptability to this compared to MG-42.

Characteristics:

Weight, kg: 12.1/19.2 (with machine) Length, mm: 1219 Barrel length, mm: 627 Cartridge: 7.92×57 mm Mauser Operating principles: Barrel recoil with short stroke, rotary bolt Rate of fire, rds/ min: 800—900 Initial bullet speed, m/s: 755 Type of ammunition: belt for 50 or 250 rounds or double-disc magazine for 75 rounds

The barrel casing is cylindrical, with round ventilation holes. The tank version of the MG-34 has a solid, reinforced barrel casing.

The cylindrical box, milled, is connected to the barrel casing with a longitudinal axis on the right side and a latch on the left. The box can rotate on the mentioned axis relative to the barrel casing up and to the right, opening the breech of the barrel.

Thus, changing the barrel is carried out in a matter of seconds, however, the machine gunner needed heat protection to remove the hot barrel, since he did not have any handles for this purpose, so the machine gun included an asbestos glove. The hot barrel was simply removed from the casing back, a cold one was put in its place, after which the box was rotated to its original position.

The machine gun came with a case for three spare barrels. It was recommended to change the barrel after 300 shots.

The MG34 was fed with machine gun belts from a 150-round box (Patronenkasten 36) or from a 300-round cartridge box (Patronenkasten 34 and Patronenkasten 41).

Belts for 150 rounds, inherited from the Reichswehr, were solid, then consisted of pieces of 25 (until 1938), and later 50 rounds.

In addition to the indicated cartridge boxes, various special cartridge boxes were used for use on various equipment. In the manual version, compact cylindrical boxes for tapes with 50 rounds of ammunition (Gurttrommel 34) were used, which were attached to the left of the machine gun directly to the tape receiver.

In 1938, for anti-aircraft units and in 1939 for tank units, a magazine-fed version of the MG-34 was introduced: for machine guns, the box cover with a tape drive mechanism was replaced with a cover with a mount for a 75-round drum magazine (Patronentrommel 34). The magazine consists of two connected drums, from which cartridges are fed alternately. The Patronentrommel 34 magazine is an almost complete copy of the Doppeltrommel 15 magazine of the MG-15 machine gun and can be used in it (but not vice versa).

In addition to the infantry version, the MG-34 existed in two other forms.

MG 34T

A modification for installation on tanks, the main difference of which was a heavier barrel casing without ventilation holes.

MG-81

Aviation machine gun. Developed by Mauser on the basis of the MG-34 infantry machine gun in 1939. The development was aimed at reducing the cost of production and the possibility of use on aircraft as a defense weapon mounted on a movable machine.

For these purposes, changes were made to the design to allow the tape to be fed from any side. There was also a modification of the MG-81Z, consisting of two machine guns with a combined trigger.

Anti-aircraft installation of 8(!) MG-81 machine guns.

Overall, the MG-34 played its role as the first single machine gun, and played it well.

Modifications

MG 34/41

MG 34/41 appeared as a result of understanding the experience of the first real battles of the beginning of World War II, when it became clear that an increase in the rate of fire leads to greater dispersion over the area. The rate of fire for the MG 34/41 was increased to 1,200 rounds per minute (for the MG 34 the rate of fire was 800-900 rounds). The weight of the MG 34/41 has increased slightly (14 kg) compared to the original (12.1 kg). A limited production of this modification was made; 300 copies of the machine gun were sent to the Eastern Front. In field tests, the MG 34/41 performed worse than the MG 39/41, which was later designated MG 42.

MG 34T

A modification for installation on tanks, the main difference of which was a heavier non-perforated casing.

MG-81

MG 81 - 7.9 mm aircraft machine gun. Developed by Mauser on the basis of the MG 34 infantry machine gun in 1939. The development was aimed at reducing the cost of production and the possibility of use on aircraft as a defense weapon mounted on a movable machine.

For these purposes, changes were made to the design to allow the tape to be fed from any side. There was also a modification of the MG-81Z, consisting of two machine guns with a combined trigger (the Z index comes from the German zwilling - double).

muzzle cut, flash suppressor unscrewed. a tooth is visible that fits into the groove of the flame arrester, producing fixation.

Expert Vladimir drew attention to the excessively labor-intensive process of cutting notches along the entire perimeter of the flame arrester. It was possible to limit ourselves to one or several grooves for fixation, while making the manufacturing process less labor-intensive.

The device of the MG.42 machine gun

The developers of the MG.42 were given certain tasks: to create the most reliable and cheapest to manufacture single machine gun with a high rate of fire, which would allow them to achieve high combat power. This machine gun used some elements of the MG.34, but we can definitely say that the MG.42 is an original and unique weapon.

Reduced cost and manufacturability were achieved through the use of cold stamping and spot welding. For example, the receiver of a machine gun was produced by stamping from a single blank, whereas the MG.34 had two separate milled parts.

The cost of new weapons has decreased by approximately 30%, and metal consumption by 50%, the total number of parts has decreased to 200 pieces. Except for the bolt, muzzle, clamp and sear, all parts of this machine gun are made by stamping.

MG.42 operates on the principle of recoil with a short stroke barrel. Part of the powder gases is diverted through the muzzle device to enhance the recoil of the barrel after the shot. A special muzzle regulator allows you to change the recoil speed of the moving parts of the machine gun, thereby changing its rate of fire. The shot is fired with the shutter in the rear position (open shutter).

The cycle begins with cocking the bolt using a very large handle. After pressing the trigger, the bolt moves forward, sending the cartridge into the chamber. The barrel is locked using two rollers that are located in the combat cylinder; they fit into special grooves in the breech. After they diverge, a firing pin passes between them and pierces the primer.

The rollers ensure smooth operation of the machine gun mechanics, reduce friction as much as possible, while providing sufficient support surface.

After the shot, the barrel moves back along with the bolt, the rollers in the combat cylinder are brought together by the bevels of the box. The barrel goes even further until it is pulled back by the recoil spring. A special spring-loaded ejector removes the cartridge case. The recoil spring pushes the bolt to the forward position.

The impact mechanism of a striker-type machine gun is located in the bolt. The trigger mechanism is located in the pistol-type handle, and there is also a push-button safety that blocks the trigger sear. The trigger mechanism of the MG.42 allows for exclusively automatic fire.

The sights of the machine gun consist of an open sight and a front sight. The folding front sight is mounted on the barrel casing, the sight is sectorial, has divisions from 200 to 2000 meters with an interval of 100 meters. The sight clamp moved along the bar with a characteristic click, which made it possible to set the distance by ear, in conditions of poor visibility or in the dark.

The length of the sighting line is 430 mm, and the sight slot is located at a considerable distance from the back of the butt (550 mm). A fixed ring-type anti-aircraft sight can be mounted on the machine gun casing.

The butt has a characteristic shape (“fish tail”), is located in line with the axis of the barrel, and can be held with the left hand when shooting from a bipod.

The barrel is air cooled. The barrel casing has characteristic oval holes that improve heat transfer, and on the right side there is a cutout for almost the entire length of the barrel; through this cutout it is replaced. The barrel is relatively light, it can be quickly changed; the process of replacing the barrel on the MG.42 takes 5-8 seconds. To do this, it was necessary to fold forward the latch, which was located on the right side of the casing. Then the barrel was pulled back; one hand was enough to replace it. To carry out this operation, the machine gunner needed a glove or rag, because it was necessary to touch the hot metal.

Reducing the cost of production and increasing the rate of fire led to a reduction in the survivability of the barrel. Later, however, his channel began to be chromed, which somewhat corrected the situation.

According to the rules, it was necessary to change the barrel every 150 shots (that’s three machine gun belts), otherwise the ballistic properties of the weapon would decrease. Spare barrels were stored in a special container near the second number of the machine gun crew. Excessive overheating of the barrel could cause the cartridge to jam in the chamber.

A folding bipod was attached to the front of the barrel casing, the design of which was slightly changed compared to the MG.34. The bipod had a hinged mount, which made it possible to put the machine gun on the ground and quickly raise it. The carrying strap was attached to the barrel casing and to the pistol grip.

The machine gun was powered by flexible metal belts with a semi-closed link, similar to the belt of the MG.34 machine gun. One tape could be attached to another using a cartridge. The length of one belt was 50 rounds. The problem was controlling the consumption of ammunition, because the weapon fired up to 20 rounds per second.

Loading the machine gun was very simple. It was necessary to open the lid by pressing a convenient latch (this could be done with mittens), place the cartridge in the correct position and cock the bolt.

The high rate of fire of the machine gun led to the widespread use of the MG.42 as a light air defense weapon for infantry, as well as an anti-aircraft machine gun for armored vehicles. Based on the MG.42, several anti-aircraft installations were created from several machine guns fastened together. In this case, they had a single trigger and special sighting devices.

For the MG.42, a special machine with three supports, “Carriage-42,” was developed. It was slightly different from the machine for MG.34 and was 3 kilograms lighter.

Bipod

The base of the bipod has quite serious lugs.

Two grooves were provided for attaching the bipod. one groove was located closer to the muzzle.

the second is closer to the receiver. Accordingly, it was possible to fire at infantry and quickly transfer fire to air targets.

Post-war use

After the end of the war, this machine gun in various modifications and for different calibers (.308, 7.5, .30-06, etc.) was produced/converted for their own needs and for export by France (Manuhrin), Switzerland (SIG), Czechoslovakia (CZ ), Italy (Beretta, Fiocchi, Fabarm), USA (Colt's Manufacturing Company and Remington Arms), Norway and Austria (Steyr).

After World War II, the MG 34 machine gun was officially in service with the armies of Egypt, Turkey, Austria, Italy, Greece, France, Spain, Portugal, Argentina, Iran, Pakistan, Czechoslovakia, and for a long time (until the mid-late 1970s). Norway, Switzerland, Israel, Syria, China, Vietnam, USA and Yugoslavia. In the USSR, maintenance and repair of captured weapons, including machine guns located in warehouses, was regularly carried out, and their ammunition was stocked. In the GDR it was in service with the People's Police.

Application of MG.42

MG.42 - the main German machine gun of the final stage of World War II. This weapon was known for its reliability, simplicity and durability. We can confidently say that in this case, simplifying the design only benefited the weapon.

In addition to general simplification, many changes were made to the design of the machine gun due to experience in using the MG.34. The gaps between parts were increased, which made the weapon much more reliable; the large charging handle and lid latch made it possible to operate them even with warm gloves. A special “winter” trigger was developed, which also made it possible to fire while wearing mittens.

MG.42 was less demanding on the quality of lubricant, its disassembly and maintenance were easier. Germany trained a huge number of machine gunners for its armed forces (by the end of the war their number was more than 400 thousand people).

However, the main feature of this weapon was its rate of fire. The machine gun could fire from 1200 to 1500 rounds per minute. Although the dispersion at such a high rate of fire is quite significant, it is not critical. The vibration and recoil of the MG.42 does not interfere with its controllability and does not cause any particular complaints.

As a rule, the crew of a machine gun consisted of the first and second numbers, they were also accompanied by a shooter, as well as an ammunition carrier.

It should be noted that German field tactics of that time were largely built around a single machine gun. If the Americans and the British put the rifleman at the forefront, then in Germany the main thing was the machine gunner. In the German army the number of machine guns was maximum, most of which were MG.42.

The MG.42 crew could create a continuous fire barrier through which the attackers simply could not break through. This leaden rain was interrupted only while the barrel was being replaced. American and British soldiers were specially trained to hide from MG.42 bursts and advance while changing the barrel. The psychological impact of this machine gun's fire on enemy soldiers was very great. The Americans released a special training film on how to cope with shock after being under MG.42 fire.

The Americans and British called this machine gun “Hitler’s circular gun,” and the Soviets called it “lawn mower,” “widowmaker,” and “bone cutter.” The Germans themselves nicknamed the MG.42 “Hitler’s saw.” Based on these names, one can imagine its deadly effectiveness. The characteristic roaring sound of this weapon brought real terror to enemy soldiers.

Another unique feature of the MG.42 was the Tiefenfeuerautomat, or depth-of-fire automat. If the machine gunner assumed that his target was approximately 1,500 meters away, he could adjust the weapon to aim (and fire) from 1,300 to 1,700 meters and back. While the weapon was firing, the fire was conducted precisely in this range.

The MG.42 could not conduct single fire, and for a machine gunner a good indicator was the ability to fire bursts of three to five rounds. The German army had strict regulations on how to shoot the MG.42. It was forbidden to fire more than 250 rounds in one burst; the rate of fire at which 300-350 rounds were fired per minute was considered optimal. Similar instructions were introduced to reduce barrel wear and increase the weapon's accuracy.

To summarize the above, we can conclude that the MG.42 is indeed the best single machine gun of the Second World War. The simplification, which was caused by a lack of resources in Germany, not only did not worsen the characteristics of the machine gun, but on the contrary, made this weapon even more reliable and effective. MG.42 proved this both in the sands of North Africa and in the snows of the Eastern Front. This is precisely what can explain the fact that modifications of the MG.42 are still in service.

MG 34 machine gun characteristics:

| Weight, kg: | 12.1/19.2 (with machine) |

| Length, mm: | 1219 |

| Barrel length, mm: | 627 |

| Cartridge: | 7.92x57mm Mauser |

| Work principles: | Short recoil barrel, rotating bolt |

| Rate of fire, rds/min: | 800—900 |

| Initial bullet speed, m/s: | 755 |

| Type of ammunition: | 50- or 250-round belt or 75-round double-disc magazine |

source: https://ru.wikipedia.org/wiki/MG_34

source: https://smallarms.ru/article?arms=mg34

Specifications[ | ]

Weight and dimensions[4]

| Length of machine gun assembly | 1225 mm |

| Barrel assembly length | 625 mm |

| Barrel caliber | 7.9 mm |

| Rifling pitch | 240 mm |

| Weight of the assembled machine gun (with belt and bipod) | 12 kg |

| Barrel weight | 2 kg |

| Weight of cartridge box with 300 cartridges | 10 kg |

| Aimed shooting range using a mechanical sight | 2000 m |

| Initial bullet speed | 755 m/s |

Penetration[4]

| distance | material | thickness |

| 100 m | dry pine board | up to 85 cm |

| 400 m | dry pine board | up to 65 cm |

| 800 m | dry pine board | up to 45 cm |

| 1800 m | dry pine board | up to 25 cm |

| 300 m | steel sheet | up to 10 mm |

| 550 m | steel sheet | up to 7 mm |

| 100 m | armor plate | up to 5 mm |

| 600 m | armor plate | up to 3 mm |