“Cow” saved “Chinook”: details of the special operation

On Monday, details of a special operation in Afghanistan became known, as a result of which Russian pilots saved NATO troops. Our huge Mi-26 helicopter, which the military calls a “cow,” evacuated a damaged American helicopter with its crew, which was already surrounded by militants. Barack Obama has already thanked Moscow for the brave operation of the Russian pilots , and NATO members took souvenir photos of the car, which easily carried away their multi-ton Chinook from the Taliban.

Russian helicopter pilots took these photographs while flying to rescue the American military. Although the pilots themselves say that nothing special happened that day - “we did the usual work.” Moreover, this is not the first time.

“This is already the third case,” says General Director Vladimir Skurikhin. “The ship’s commander called me and asked for permission. We discussed all the details and decided to help.”

The command of the coalition forces never reported what actually happened in Helmand province. According to the official version, the Chinook helicopter made an emergency landing; according to the unofficial version, it was shot down by the Taliban. Militants began to approach the crash site, two crew members were wounded in the shootout, and the helicopter was so badly damaged that it could no longer take off. At first, the Americans tried to lift the multi-ton vehicle themselves, but it didn’t work out - the helicopter was too heavy and the area was too dusty. And then they remembered about the Russians, who transport cargo under a contract with international forces. Ours, as always, did not refuse help.

“The conditions were difficult - heat, high altitude, dust. The coalition forces, of course, provided reconnaissance and security,” says Vladimir Skurikhin

Risking their lives, the Russian crew worked at the crash site of an American helicopter. Ours deserve to call them all by name: commander Valery Likhachev, co-pilot Valery Chumakov, navigator Roman Volkov, flight operators Sergey Lebedev and Konstantin Izotov and flight engineer Andrey Taranenko.

The Russian crew rescued an American helicopter and wounded military personnel. An Mi-26 on an external sling was dragging a damaged Chinook 110 kilometers above the territory where the Taliban were operating. And now the finale of the flight - the Chinook is lowered onto the runway of the international military base in Kandahar.

Dozens of people came to see the Russian miracle helicopter, which calmly transports multi-ton cargo, primarily, of course, fellow pilots. Some even took pictures in front of the Mi-26. It really is the world's largest transport helicopter.

The work of our pilots was also appreciated by the White House, which, through the embassy in Washington, asked to express gratitude to the Russians for their help. And at the base in Kandahar that day, everyone admired the courage and professionalism of the Russian pilots, who once again did the seemingly impossible, at least no one else could do it.

Short story

Production of the Mi-26 began in the 1980s in the USSR, and since then it has remained the world's highest-capacity production helicopter. In total, the vehicle holds 14 world records and, unlike its American counterpart, it is also used for civilian purposes: for transporting large cargo, for extinguishing fires, installation work and other tasks.

The CH-53K King Stallion is being created to replace the Sikorsky CH-53E and made its first flight in 2015. Initially, the program began as an extension of the life of the CH-53E, but it was soon decided to create a new vehicle.

Compared to its predecessor, it received new blades made of composite materials, more powerful engines and a more spacious cabin.

Commissioning is scheduled for 2022; in total, about 200 vehicles are planned to be delivered to the troops. The use of this helicopter for civilian purposes is doubtful due to its enormous cost.

Design

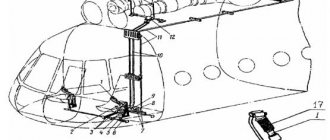

A single-rotor helicopter with a tail rotor, two gas turbine engines and a tricycle landing gear. The structure is made of aluminum-lithium alloys with extensive use of titanium alloys and composite materials.

Fuselage

Semi-monocoque design. In the bow there is a crew cabin, consisting of the first pilot in the front left seat and the second pilot in the right seat. Behind the first pilot is a flight engineer, and behind the second is a navigator-radio operator; Between the pilots, a cargo operator can be located on a folding seat; behind the cockpit there is a separate cabin for four passengers.

On the Mi-26TM crane helicopter, used for transporting cargo on an external sling and for construction and installation work, in the front part of the fuselage behind the front landing gear there is a suspended control cabin facing the rear so that the operator can conveniently control cargo work. The option of a two-seat suspended control cabin, located under the cargo ramp and facing forward, was considered. The cabins were equipped with an electric remote control system.

The cargo cabin has a length of 12 m (with a ramp of 15 m), a width of 3.2 m and a height of 2.95-3.17 m, the volume of the cabin is 121 m3. The cabin is equipped with mechanized loading and unloading facilities, consisting of two hoists with a lifting capacity of 2500 kg and electric winches with a force of 500 kg for moving loads in the cabin, the floor of which is equipped with roller tables and hooks for securing loads. There is a hatch in the floor through which the cable from the cargo winch passes for transporting cargo weighing up to 20 tons on an external sling. The cargo compartment is equipped with a cargo hatch with a lowering cargo ramp with doors opening outward. The cargo ramp is powered by hydraulic boosters and can be fixed in any position, allowing you to transport long loads with the ramp fixed in a horizontal position. In an emergency, the ramp can be moved using a hand pump. The large dimensions of the cargo compartment and cargo hatch ensure the transportation of large-sized civilian and military equipment, such as a crane or two infantry fighting vehicles and standard cargo containers.

In the military transport version, the cargo compartment can accommodate 80 soldiers on folding seats on the sides of the cabin with equipment or 60 wounded on stretchers with 4-5 accompanying persons. In the passenger version, the cabin accommodates 70 passengers, five in a row, on standard seats with reclining backs, lighting and alarm, the cabin has a central aisle and at the end two toilets and a luggage compartment, access to the cabin is through a door on the left side with a folding ladder To ensure comfortable conditions for passengers, thermal and soundproofing finishing was used and an air conditioning system was installed.

Tail boom

Having a flat bottom surface to improve loading and unloading conditions, it turns into a large vertical tail with an asymmetrical profile to create lateral force and unload the tail rotor and an adjustable stabilizer when parked.

Chassis

Fixed, tricycle, with twin wheels and retractable tail support. The front support is self-orienting, the main supports with twin wheels measuring 1120 x 450 mm are small in size, and double-chamber shock-absorbing struts provide a change in ground clearance when parked.

Rotor

Eight-blade, with hinged blades and hydraulic dampers. The blades are rectangular in plan, have improved aerodynamic profiles with a relative thickness of 0.12 at the butt and 0.09 at the tip of the blade and moderate aerodynamic twist. The blades are of mixed construction with a tubular steel spar, to which are attached 26 sections with ribs, fiberglass skin and honeycomb core. The tip of the blade is protected by an anti-corrosion lining made of titanium alloy. The blade chord is 0.835 m, the peripheral speed of the blade tips is 220 m/s.

Tail rotor

Five-bladed, with a diameter of 7.67 m, with rectangular-shaped blades made of fiberglass.

Power point

It consists of two turboshaft gas turbine engines with a free D-136 turbine, installed side by side on top of the fuselage in separate nacelles separated by a titanium firewall. The engine air intakes are equipped with dust protection devices and electrical anti-icing systems. The power plant has a system for automatically maintaining rotor speed; in the event of failure of one engine, the system automatically increases the power of the second to emergency, maintaining constant rotor speed (132 rpm).

Turboshaft gas turbine engine D-136 with a free turbine of modular design. The gas generator is based on the D-36 turbofan gas generator and has a six-stage low-pressure compressor with a rotation speed of 10,950 rpm and a seven-stage high-pressure compressor (14,170 rpm). The two-stage free turbine has a rotation speed of 8300 rpm, adjustable within ±300 rpm. Engine length 57.5 m, width 1.4 m, height 1.13 m, dry weight 1050 kg, extreme engine power 8500 kW/11,400 hp. s., maximum continuous power 6338 kW/8500 l. With. Specific fuel consumption 0.206 kg/l. s.-h.

The auxiliary power unit is located under the cockpit on the left side and provides engine starting and operation of the electrical, hydraulic and air conditioning systems when parked.

The fuel is contained in 8 soft tanks with a total capacity of 12,000 liters, located under the cabin floor, from which it flows into two supply tanks located on top of the engines.

Transmission

It consists of a main gearbox, two freewheels, tail rotor drive shafts, an intermediate gearbox and a tail rotor gearbox. The main gearbox VR-26 is of a modular design, three-stage, and has drives for the cooling fan of the gearbox and oil systems installed above the air intakes of the engines, tail rotor transmission and helicopter units. The gearbox has a length of 2.5 m, a width of 1.95 m and a height of 3.02 m, with a dry weight of 3640 kg.

For servicing the power plant and transmission, the engine fairings have large hinged panels used as work platforms, and the tail boom has a passage for servicing the tail rotor transmission without special ground equipment.

Equipment

Two hydraulic systems with a pressure of 20.6 m Pa / 210 kg/cm2 and a DC electrical system with a voltage of 28 V.

The navigation system for flights day and night, in simple and adverse weather conditions, includes a combined heading system "Crest-2", a flight command device PKM-77M and an attitude indicator AGR-83-15, automatic radio compasses ARK-19 and ARK-UD, a radio engineering system short-range navigation "Veer-M", Doppler speed and drift angle meter DISS-32, antenna-feeder system "Romashka", radio altimeter A-036. The PKV-26-1 flight complex installed on the Mi-26 includes a four-channel autopilot VUAP-1, a trajectory control system, a director control system, and a load oscillation damping system on an external sling. There is a weather radar. Radio communication equipment includes command UK13 radio stations R-863 and R-828, a communications HF radio station "Yadro-1B", an emergency radio station R-861 and an aircraft intercom SPU-8, on-board television equipment BTU-1B with three video cameras and a video control device VK-175 for monitoring the condition of cargo on an external sling. A Tester-UZ magnetic flight data recording system and RI-65 voice communication equipment were installed to alert the crew about in-flight emergencies.

Military transport variants are equipped with LTC ejection devices, IR interference transmitters, and screens for suppressing IR radiation.

Modifications

Mi-26 – Military transport version.

Mi-26A – Improved version.

Mi-26M – Designed for increased performance and equipped with new navigation equipment and a new propeller.

Mi-26MS – Medical version.

Mi-26NEF-M – Experimental anti-submarine variant; it carried a hydroacoustic submarine detection station on an external sling, had a side removable pilot-operator cabin, and was in a semi-disassembled state in the flight museum. On November 16, 2013, it was spotted in the area of Novocherkassk during transportation on an Mi-26T external sling.

Mi-26P – Civil version for 63 passengers.

Mi-26PK - “Flying Crane”.

Mi-26PP – Jammer.

Mi-26T – “Flying Crane”.

Mi-26T2 – 2-3 pilots, the helicopter is capable of night flights, screens have been added in the cockpit instead of analog sensors.

Mi-26TC – Cargo version, certified in China.

Mi-26.

Mi-26TP – Fire variant.

Mi-26TZ – Refueler.

Mi-27 - Air control point for combat operations of combined arms armies. The cargo compartment was divided by transverse partitions into the operational group (OG) cabin, technical and living compartments. There were 6 workplaces in the exhaust cabin; in the next compartment there was a group for managing technical equipment and organizing communications; additional rest areas could be organized there if necessary. The technical compartment contained radio communication equipment. Household equipment included a water supply system, a buffet, a compartment for resting two people and a toilet. Two production helicopters were converted and tested in Leningrad and Evpatoria. One of these vehicles then ended up at the Kharkov Air Force Institute, where it was used as a visual aid and was then disposed of.

Unnecessary weapons

The CH-53K King Stallion helicopter is considered only as a transport and cargo vehicle for the US Air Force, but it is equipped with three 12.7-caliber machine guns, thanks to which it can provide air support to troops. It is difficult to say why this was done: apparently, this was the wish of the military.

There are no weapons on the Mi-26, but its absence is not due to the fact that it is impossible to install it. Experience using a helicopter has shown that it is not necessary, while installing three machine guns requires three more crew members, which means it reduces the payload.