On March 31, a world-famous tank entered service, becoming the most popular vehicle in the history of tank building and, without exaggeration, the best medium tank of the Second World War - the T-34.

Perhaps the book format will not be enough to describe the complex pre-war and no less complex military fate of this tank. In some countries, for example, in Yemen, it is in service and successfully conducts combat operations today.

But for us, the fate of the T-34 is inextricably linked with achieving victory in the Great Patriotic War. With its fire and maneuver, the tank led our infantrymen into the attack, with its armor it held back the blows of confused aces from the Panzerwaffe, and at full speed went into dashing attacks on the fields near Kursk against heavy “Tigers” and “Panthers”. And at the end of the war, winding hundreds of kilometers of Eastern European roads on tracks and shooting the “royal” “Tigers” along the way from a new powerful weapon, he brought our tankers to the squares and streets of Berlin.

Today, on the anniversary of the appearance of the main symbol of our victory, a worker in the daily battle of war, we will remember the main stages of the development and evolution of the T-34 tank - the Tank with a capital “T”.

On the brink of war

By the end of the 30s, the coming world conflict was taking on increasingly clear outlines, and European countries were intensively arming themselves. Since the time of the clumsy “steel monsters” of the First World War, a whole generation of armored vehicles and tanks has already been replaced, and the developments of the early thirties are gradually becoming a thing of the past.

Two "thirty-fours" (on the right) in the company of BT-7M and A-20

Source: pinterest.ru

The country needed an armored fighting vehicle that could confidently operate in a breakthrough and in defense (BT tanks, as it turned out, could no longer provide this). What was needed was a vehicle that was passable and had anti-ballistic armor, reliably withstanding the blow of new and much more powerful anti-tank guns than the German 37-mm “beaters” (which neither the T-26, nor the T-28, nor the T-35 provided). A modern medium tank was required, superior to heavy KVs in mobility, but not inferior to them in firepower and armor protection.

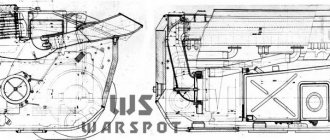

T-34 reservation scheme

Source: pinterest.ru

Work on the new vehicle began at the Kharkov Design Bureau of Plant No. 183 under the leadership of the legendary “father” of the T-34 tank, Mikhail Ilyich Koshkin, you can read his biography on our portal. Already an experienced designer at that time, who had brought, as we usually say, the lightweight BT-7 to perfection, he enthusiastically headed the work on the new tank. In a short time, Kharkov residents offered two options for the future vehicle with the indexes A-20 and A-32. The “Twenty” turned out to be lighter than necessary and had no potential for modernization, but the military liked the “Thirty-second”.

Tank evolution: crew

The crew of the first production tank consisted of 8 people, including a commander, a driver with two assistants, and, depending on the weapon, two gunners and two loaders or 4 machine gunners. Sometimes the ninth was a gunner who defended the rear of the vehicle. There were several communication systems. Carrier pigeons were used to send information over long distances. However, birds often died due to exhaust and powder gases inside the tank. For short-range communications, commanders used a signal flag or a set of signal flares. Among the non-statutory methods was a hand pulled out of a hatch, or a shovel. Neither method was reliable, so sending a messenger was considered the best solution. There were no intercoms inside the combat vehicle at all. Crew members communicated using shouts and gestures.

4 people were responsible for moving the Mark I. In addition to the efforts of the driver and his two assistants, the commander was required to be responsible for the track brakes. The gunner's job was also far from comfortable. He fired while kneeling and aimed the gun using a shoulder rest. In order to observe the battlefield, tankers used viewing slits, however, if a bullet hit the armor, splashes of molten lead flew at the soldiers. On later "Marks" they tried to cover the cracks with glass, but it did not hold up and caused injuries to the crew. For their own protection, tank crews wore glasses with steel plates with slots and mesh, as well as thick leather masks reinforced with metal and chain mail.

The first tanks were created for specific tasks, and practically no thought was given to the comfort of the crew. The engine was located directly in the fighting compartment. Within minutes of launch, it raised the temperature to 40 degrees Celsius and filled the air with exhaust gases. During shooting, powder gases from spent cartridges were mixed with them. Poisoning of tank crews with such a “cocktail” was common. It all started with a headache and ended with delirium, fainting and even death. Sometimes, to catch their breath, crew members jumped out of their vehicles during the battle.

While British technology was inspired by ships, the first German combat vehicle, the A7V, was more reminiscent of a fort. It also became a tank with the largest crew in history - 18 people, including a commander, driver, loader, gunner, two mechanics and twelve machine gunners. The A7V was more comfortable than the British "diamonds". The machine gunners had seats, the gunner had a leather chair, and the commander led the gun crew using a special mechanism. In theory, the driver could control the car independently, but the problem was the visibility, which made it possible to see the terrain further than 9 meters from the tank. Anything closer fell into the blind spot, so in practice the mechanics corrected the movement.

In addition to the main weapons, the crew had at their disposal an MG 08/15 machine gun, ten Mauser carbines, pistols and 20 hand grenades. For some time, the designers thought about a flamethrower, but not a single tank was equipped with it. By the way, the problems of German technology were similar to those of British technology. The A7V was just as hot and noisy inside, but it shook less.

The French found a way to eliminate the main tank shortcomings of that time, creating the small but progressive Renault FT-17. The engine in it was isolated from the crew, did not heat up the car and did not make so much noise. The new layout provided better visibility for the driver, and the rotating turret enabled the commander to effectively observe the battlefield and conduct all-round fire. Besides, the Renault didn't shake as much, and it was cheap.

Renault FT-17 became a trendsetter in tank building. New tanks were built in his image all over the world. As a result, the equipment of the 20–30s inherited similar problems, including a small crew and overloaded with responsibilities. There were only 2 people inside the Renault. The driver drove the tank, but the commander took the rap for the three. In addition to his duties, he was both a loader and a gunner. This uneven distribution of crew labor was typical for all tanks produced between the two world wars.

By the end of the First World War, many innovations had appeared in tanks that made life easier for the crew. For example, in the Mark V, the viewing slots were covered with triplexes for the first time, and in the Mark VIII they installed an internal communication system - first a speaking tube, and then an internal telephone. The functions of the crew members were becoming more and more familiar. Thus, drivers gradually began to engage in equipment maintenance and became mechanical drivers. Later, compact radios appeared. They solved the problem of external communication of tanks, and one of the crew members took on the function of a radio operator.

The Germans put an end to the wide specialization of crews by releasing the Pz.Kpfw. III. The crew of this tank consisted of 5 people - a driver, a gunner-radio operator, a gunner, a loader and a commander. A few years later, the USSR adopted the T-34. Its crew is 4 people: driver, loader, gunner-radio operator and commander. However, during the Second World War, the position of the gunner-radio operator turned out to be an extra link and disappeared. The commanders independently used radio stations. Due to this, the speed of reaction to orders increased, and the number of people in the combat vehicle decreased.

Now most tanks have a crew of 4 people. The exception is the Soviet-style MBT and some French vehicles. In 1967, the T-64 was put into service. Its crew is a commander, gunner and driver. The automatic loader allowed the number of tankers to be reduced. The French were the first to abandon the loader on their AMX 13. The tank fired 10–12 shells per minute, but it needed to leave the battle to reload. A full-fledged automatic loader appeared only in the 80s on the AMX-56 Leclerc. However, all the advantages of automatic systems did not allow them to become a generally accepted solution in tank building. The American M1 Abrams, German Leopard and British Challenger still employ loaders.

The prospects of crews now directly depend on the development of technology. There are already projects with two crew members in a modern tank, but their control systems and price leave much to be desired. New developments may be on the way. For more details about the evolution of tank crews, watch the video.

"First Swallow"

With these words, at the walls of the Kremlin, I.V. Stalin greeted the new, squat and tightly built cars, which made a good impression, during their presentation to the top leadership of the USSR on March 17, 1940. And already on the 31st the tank entered production lines; the country needed as many first-class vehicles as possible.

A-32

Source: pinterest.ru

Back in January 1940, the A-32 turned into the T-34, the armor was increased to 45 mm and had a rational angle of inclination, which increased its durability, and the 45 mm gun was replaced by a powerful 76 mm L-11 gun, which was replaced a little later on the F-34 (with better characteristics). The crew also had a pair of DT machine guns.

The new tanks had to be shown to the military in Moscow. The story of driving the first two “swallows” under their own power from Kharkov to Moscow off public roads even formed the basis of a feature film, which, however, is more like fiction.

T-34 of the first series with the L-11 cannon

Source: pinterest.ru

The main performance characteristics of the T-34 tank: “Combat weight 26.6 tons; diesel V-2 with a power of 500 hp. With.; maximum speed - 54 km/h; armor protection - 45 mm thick (35 - 15-10). Specific power 19.5 l. With. per ton of weight."

Test drivers Nosik and Dyukalov, who sat behind the controls of the two vehicles for the entire 750 km run, demonstrated the tank’s good maneuverability in front of the military leadership; the tank was also tested in Kubinka and even on the remains of anti-tank fortifications of the defeated “Mannerheim Line”. Only one event overshadowed the birth of the legend: M.I. died of pneumonia. Koshkin, already with a cold, got very wet, helping to pull out a stuck T-34 at the crossing. His work of developing a new combat vehicle was continued by A.A. Morozov - comrade-in-arms and student.

More detailed description of the T-34

Chassis and suspension.

The T-34 tank chassis, based on the Christie system, had five pairs of large rollers with a gap between the second and third pairs. The suspension of each roller was independent and suspended perpendicularly on a coil spring inside the housing. The drive sprocket was mounted at the rear, which reduced vulnerability. The same system was used on BT series machines. The drive sprockets rotated wide cast manganese steel tracks with central guide pins located on alternating tracks. Wide tracks gave a small specific pressure on the ground, not exceeding 0.7-0.75 kg/cm2. For British, German and American tanks, the value of this parameter was 0.95-1.0 kg/cm2. The fenders covered the upper part of the suspension system and protruded 25 cm in the front of the hull and 10 cm in the rear. The suspension allowed the T-34 tank to maintain high speed even when moving over very rough terrain, while the wide tracks of the tank weighing 28.3 tons made it possible to move through mud and deep snow.

Hull and armor.

The hull, designed by Nikolai Kucherenko, hung over the tracks and had sloping sides. It was welded from rolled sheets of homogeneous steel. The thickness of the hull armor at the front was 45 mm, 40 mm at the rear and 20 mm at the top. The quality of the welding was very poor, but not so bad as to allow the welds to fail. The front armor plate, 45 mm thick, mounted at an angle of 60 degrees, had no openings, with the exception of the driver's hatch and the embrasure of the ball machine gun mount. There was a periscope in the driver's hatch. The sloped armor provided excellent protection from projectiles and was equivalent in protective properties to a 75 mm thick vertical armor plate. In fact, the T-34 tank was the most invulnerable in 1941. The roof of the rear part of the hull behind the turret was slightly raised, and the engine compartment louvers and exhaust pipes were placed on it. The upper rear plate and engine cover were secured with screws. If it was necessary to replace the engine or transmission, they could be removed.

Engine.

The engine was located in the rear of the hull and was a V-shaped four-stroke 12-cylinder liquid-cooled diesel engine, originally developed for the BT-7M tank. This version of the 3.8 liter engine was upgraded for the T-34. At 1800 rpm it developed power of 493 hp. The power/weight ratio was 18.8 hp. per ton, which allowed the T-34 tank to reach a speed of 54 km/h on the highway and 25 km/h over rough terrain, depending on its nature, with an average fuel consumption of 1.84 l/km. When driving on the highway, this parameter improved significantly. The V-2 engine also made it possible to significantly increase the cruising range of the T-34 (up to 464 km) compared to tanks that had conventional gasoline internal combustion engines. The main fuel tank was located inside the hull, four cylindrical auxiliary tanks were located on the sides and two smaller tanks were located at the stern. The transmission was located in the rear of the hull and did not clutter up the fighting compartment and control compartment. At the beginning of the war, the transmission was unreliable, so some crews carried spare transmissions, tying them to the engine compartment with cables.

Tower.

All models of the T-34 tank had a low turret. Although the low silhouette of the turret was useful in combat, it limited the deflection of the main and secondary armament barrels, especially on a reverse slope or when firing at short range. In addition, it was cramped inside the tower. From the control room one could immediately get into the tower. On later models, handrails for landing began to be welded to the turret and hull.

| Types of turrets of the T-34 tank model 1943 |

Driver and controls.

The control area was separated from the engine compartment by a partition. The driver's workplace was located on the left side of the hull. It was equipped with a large hatch mounted on hinges. The hatch had a periscope for observation. The driver controlled the tank using a system with an onboard clutch and brake. The system was controlled by two control levers and a gear shift lever, as well as clutch pedals and a foot brake. The levers were connected to the transmission in the stern using metal rods running along the bottom of the gunk. To control the T-34 tank, it was necessary to exert more physical effort than to control Western-made vehicles, on which the transmission and gearbox were located next to each other. Driver mechanics of T-34 tanks often had to use a wooden hammer if the levers jammed. The four-speed gearbox on the last 100 T-34 tanks of the 1943 model was replaced by a five-speed one. As a result, it became easier to change gears and increase the speed of the tank. The floor contained the fuel injection, clutch and brake pedals. There was a pedal in the bottom (often called a “landing pedal”) that made it possible to stop the tank. There were also two compressed air cylinders for starting the engine at low temperatures.

Gunner-radio operator.

The radio operator's workplace was located on the right in front of the hull. The hatch for leaving the vehicle was located in the bottom directly in front of the radio operator. The gunner-radio operator's armament consisted of a 7.62-mm Degtyarev tank machine gun in a ball mount with a horizontal aiming angle of 24 degrees and vertical aiming from -6 to +12 degrees. Machine guns mounted on tanks of the 1942 model were equipped with an armored mask. Despite the fact that at the beginning of the war there were no radio stations on most T-34 tanks and, due to an acute shortage of personnel, the radio operator’s position was empty, the number of tanks equipped with radios was constantly growing. In 1941, the vehicles of tank company commanders were equipped with the 71-TK-Z radio station. Efforts were made to equip platoon commanders' tanks with radios. During the first two years of the war, 71-TK-1 radios were also used. The situation improved when, at the end of 1942, the mass use of 9-P radio stations began. Although the range of these radios was 24 km, when moving they were effective at a distance of 8 km.

The Germans, who paid increased attention to providing crews with stable radio communications, noted the low quality of tactical interaction between Soviet vehicles. Due to the lack of radio communications, the Russians had to rely on flag signals. There was even a special hole in the tower hatch for giving signals using flags. In practice, this was very inconvenient - the platoon commander was too busy controlling his own tank and shooting. Often he simply gave the command to other crews to follow him. The situation improved as radio production increased, and by the summer of 1943, 75-80 percent of all vehicles were equipped with them. Internal communication between crew members was carried out using the TUP system. Tank helmets were equipped with headphones and throat microphones.

Tank commander and loader.

The main drawback of all T-34 tanks was the poor ergonomics of the turret. There were three people in the turrets of the German vehicles: a gunner, a loader, and a tank commander, who was responsible for observing the terrain, managing the crew, and coordinating actions with the rest of the unit’s tanks. A completely different situation took place in the cramped, two-person turrets of the T-34. The commander had the same tasks as the German, in addition, he had to fire the cannon. This in itself is a serious matter, which distracted the commander from fulfilling his command duties. Loading also took a long time. Despite this, the Soviet command conducted a short and unsuccessful experiment, placing the responsibility for loading the gun instead of firing on the tank commander. The crew members who were on duty in the turret sat on seats hanging from the turret shoulder strap. The commander sat to the left of the gun, and the loader, who was also supposed to fire from the machine gun coaxial with the gun, to the right.

The quality of the optical equipment of the T-34 tank was inferior to the quality of the equipment of German tanks. The main 2.5x telescopic sight TOD-6, which was installed on the first T-34 models, was later replaced by the TMFD sight. Tanks that went into battle straight from the assembly line of the Stalingrad Tractor Plant in the fall of 1942 often did not have sights at all. They could only fire directly. Aiming was carried out by the loader directly through the barrel. To observe the surrounding area, the commander and loader used a PT-6 periscope. Later, periscopes PT-4-7 and PT-5 began to be used. Due to war-related shortages, periscopes were often not installed for loaders. The periscope's field of view was very narrow, and it could not be increased by holes in the armor made at the level of the commander's and loader's shoulders. Under the observation holes there were embrasures for firing a pistol, another embrasure. On later T-34 models these embrasures were absent.

Many German crew commanders preferred to fight with their heads out of the hatch. This provided them with a 360 degree view. If the T-34 commander tried to do this, the large forward-opening hatch would almost completely block his view. He would have to sit directly on the turret, not only risking coming under enemy fire, but also being hit by a very heavy hatch. The size of the hatch was such that, when opened, it also revealed the loader. T-34 tanks of the 1943 model had separate hatches for the commander and loader, but only the latest models were equipped with surveillance devices that provided a 360-degree view. The tower itself was originally made of rolled sheets with a cannon in a cast cradle. On the 1941 model, the cast cradle was replaced with a bolted corner cradle. In 1942, a cast turret with an armor thickness of 52 mm was adopted for service, although it was no different from a turret made of rolled sheets.

<< Back - Forward >>

During the terrible years of war

By June 22, 1941, the tank units and formations of the Red Army had a little more than a thousand new vehicles. In the very first border battles, the new vehicle distinguished itself: it not only showed its best side in battle, but also aroused respect from the enemy.

T-34 with F-34 cannon

Source: pinterest.ru

The production of tanks began at only two factories - No. 183 in Kharkov (the city soon fell into enemy hands) and at STZ (the factory was heavily damaged during the battles for Stalingrad). It is clear that the course of the war, the rapidly shifting front line and the evacuation of industry were the factors that prevented the rapid increase in production of the T-34.

T-34 mod. 1943

Source: pinterest.ru

The country's leadership, understanding the value of the new machine, is launching production of a new tank at (Gorky, now Nizhny Novgorod), Chelyabinsk Tractor Plant (Sverdlovsk, now Yekaterinburg), plant No. 174 in Omsk and Uralvagonzavod (Nizhny Tagil). Until 1943, development proceeded within the existing model. The production technology was simplified, production was increased under the conditions of the evacuation of enterprises (12,520 tanks in 1942, 15,696 vehicles in 1943). And this has already exceeded the German production of medium tanks. During the war years, over 53 thousand copies of the T-34 of all series and modifications were produced. And the production of over 6 thousand licensed post-war tanks in total made the “thirty-four” the most popular tank, and this primacy has been maintained to this day.

Already in the first months of the war, many of our tankers distinguished themselves in battles using the T-34. For example, Heroes of the Soviet Union Dmitry Fedorovich Lavrinenko (1st Guards Tank Brigade, 52 victories in 28 battles, title awarded posthumously); Vladimir Aleksandrovich Bochkovsky (1st Guards Tank Brigade, 36 victories); Nikolai Rodionovich Andreev (6th Guards Tank Brigade, 27 victories, one tank destroyed by a ram).

Production of T-34

Source: pinterest.ru

During the war, the T-34 design was constantly modernized and supplemented with new elements. The main goal was to reduce the cost and labor intensity of its production. At the same time, they tried to increase its combat effectiveness. A commander's cupola appears on the tank; the design of the towers itself has undergone changes - from cast and welded early types to the "nut"; There were attempts to install the most powerful 57-mm anti-tank gun at that time, the rollers were simplified, and much more. Self-propelled guns were also produced on the successful T-34 chassis (Su-122, Su-85, Su-100), there was a flamethrower version of the OT-34 and a repair and recovery vehicle.

Myths and truth about the T-34 tank through the eyes of a specialist

A man who has been restoring old military equipment for a private collection for many years helped to deal with the pitfalls that awaited the crews who fought on the T-34. My interlocutor asked to call him simply Mikhail.

Of course, those combat vehicles that we now have to restore have already been deprived of real weapons; in their place, emasculated models are being installed. However, the specifics of controlling the old tank and its systems practically do not change. And in previous years, Mikhail had a chance to ask a lot about the specifics of those who fought in the “thirty-four” during the Second World War.

In their memoirs, veteran tankers almost unanimously praised our T-34s. However, at the same time, they told Mikhail some of their observations and professional secrets, which were left behind the scenes by the creators of numerous films about the war.

Let's start with movement. Was he maneuverable? Yes. Fast? For its class, yes. But at the same time...

Here are a few characteristic points that make it possible to complete the picture of a tank march or maneuver performed on a T-34.

It turns out that the T-34 was very noisy. Moreover, to the decibels created by a 400-horsepower tank diesel engine, there was also added the roar and specific clanging of the tracks.

Experts unanimously praise the design of the T-34 chassis, which included, among other things, a fairly simple replacement of damaged road wheels (unlike the same German “Tigers,” for example). However, these skating rinks themselves were far from perfect at first.

Due to the difficult situation in Soviet tank building during the initial period of the war, when many factories were evacuated to new locations, early modifications of the T-34 with 45- and 75-mm guns were most often equipped with non-rubberized sloth rollers for tracks. Rolling over the bare iron of such rollers (commonly nicknamed “locomotive” by tankers), the caterpillar tracks made a loud metallic sound, by which soldiers at the front recognized from afar that the “thirty-fours” were coming. Only since 1943 has it been possible to provide rubber-coated rollers to all Soviet T-34s leaving the factory workshops, making them much quieter on the move.

However, this improvement did not affect another running problem of our miracle tank. There was a real danger that when making sharp turns at a decent speed, his fingers—the metal rods connecting the track tracks—would burst, unable to withstand the load. As a result of such an accident, the caterpillar ruptured, and the crew began strength exercises to connect it: with the efforts of several people it was necessary to tighten the sagging part of the string of massive tracks, connect the place of the rupture, driving in a spare one with a sledgehammer instead of the broken one...

There was another ambush for the driver mechanics. The four-speed gearbox found on early versions of the 34 was very tight. Pressing the lever required incredible effort to engage the desired gear. Often, one driver was simply unable to do this, and a radio operator located next to the driver’s seat came to his aid. With two manpower they coped with the unyielding gearbox, and this performance as a duet during maneuvering was repeated many times. The design of the stubborn gearbox was changed only on a later modification of the tank - the T-34-85 (these vehicles are shown in most of our films, installed on pedestals as monuments).

And again about the noise. So that the roar that reigned during movement inside the tank did not interfere with the crew communicating with each other and hearing commands, each “thirty-four” was equipped with a special intercom. However, it did not always work reliably, did not provide good audibility, and yet life depended on the speed and correct execution of commands in battle - especially by the driver! Therefore, smart crew commanders adapted to direct the actions of their driver with their feet - fortunately, it was easy to reach. He lightly tapped his boot on his right shoulder, which means he should turn to the right, and on his left shoulder, he should turn to the left. If the commander’s boot rests on your back, you need to increase your speed, and if he presses on top of your helmet, stop. This is how they “conducted”!

At the same time, the driver had to drive a heavy car in conditions of extremely limited visibility. According to the designers, during combat the hatch on the front slope of the hull in front of the driver's seat must be slammed shut and looked forward through a specially designed triplex. However, the quality of this optical device was very far from ideal, so the driver saw an unclear, distorted picture through the triplex. It was difficult, even dangerous, to navigate along it, so in real combat conditions the driver, violating official instructions, left the front hatch ajar approximately the width of the palm. Of course, there was a risk of catching fragments of a shell exploding outside or a stray bullet in this gap, but driving an armored vehicle blindly is even more dangerous.

And now – more about hatches. On early modifications of the T-34, its turret was equipped with one large hatch at the top. It was not easy to open it. Often it was necessary to do this together. Of course, the crew members could not like such specific design, but at the factory, at the repair base, when assembling and disassembling the turret through such a large opening, it was much easier to mount or, conversely, remove the breech mechanisms of a tank gun with a geared sector for vertical aiming. Still, in the end, we had to abandon such technological convenience for the safety of the crew members themselves, and provide two separate upper hatches in the design of the T-34-85 model.

Photo: en.wikipedia.org

Many of the veteran tankers recalled that during heavy rain, a real flood began inside their “thirty-fours”. The reason is that the rubber seals on the upper turret hatches and on the driver's hatch were either missing altogether or were so poorly made that they did not prevent water from leaking out. While on the move we had to put up with these water procedures, but during long stops the crew covered the tank with a large tarpaulin, saving it from rain jets.

In addition to such a tarpaulin, experienced tankers stocked up for a traveling kit (of course, standard spare parts and tools do not count) with an ordinary log, which was fastened along the hull of the “thirty-four” in the traveling position. This “special tool” was an indispensable assistant if the T-34 got stuck in the mud or in a hole: then a log was placed across the tracks, and the tank, clinging to it, pulled itself out of the trap.

Firing from a tank gun added a special flavor to the work of the T-34 crew. After each shot fired, powder gases flowed from the open breech of the gun. Another source of this choking mixture was a spent shell casing thrown out during reloading of the gun inside the tank (there were no special devices for removing such casings from the turret in the T-34 design).

To remove powder gases, the designers provided special fans. However, in real conditions, the effectiveness of such auxiliary devices on the early modifications of the “thirty-four” was low; in addition, due to a chronic shortage of components, this secondary equipment was not installed on every tank leaving the factory gates.

As a result, in order not to get burned in the improvised gas chamber, the crew prudently kept the lid of the upper turret hatch ajar (although this was fraught with fragments getting inside), and some even left it open and got used to immediately throwing shell casings out through such an opening (after firing they were hot, so I had to wear mittens). The most gas-vulnerable person in the tank was the loader. According to the recollections of old tank crews, it happened that this crew member, after inhaling gunpowder exhaust, even lost consciousness.

Another, even more serious danger awaited tankers when a shell or blank hit their vehicle. Of course, the hull, and especially the turret, were protected by armor, which not every German ammunition could penetrate. However, sometimes just a strong shell impact was enough for something irreparable to happen. On the outside, only a dent or even a scratch remained on the armor, but the crew members were incapacitated. They were injured or killed by small metal fragments that flew off upon impact from the joints of the armor parts that were not carefully welded at the factory. These pieces of scale turned into real shrapnel, which flew in all directions inside the hull.

In the middle of the war, with the advent of the T-34 modification, already equipped with an 85-mm cannon, a new problem arose when driving such armored vehicles. The new, larger-caliber gun had a much greater length than the 76-millimeter gun found on the previous thirty-four design. Of course, from the point of view of penetrating ability, it was much better, but at the same time it presented the tankers with an unusual surprise. A tank with such a long “trunk” in front, when overcoming a ditch, a hole, or a deep ditch with steep walls, could sweep its open muzzle along the slope and clog its front part with earth or sand.

If the crew does not notice this and starts shooting, at the first shot the gun will simply explode: its front part will turn into a “flower” of “petals” whimsically twisted outward. This is exactly the kind of misfortune that happened to the heroes of the feature film “White Tiger”, preventing them from destroying a mysterious fascist tank.

In general, those who fought in the “thirty-four” during the Great Patriotic War had more than enough specifics and difficulties. But all the more respect should be for these people who, even in such difficult conditions, managed to successfully fight the enemy and defeat him.

Putin, veterans, equipment at the 2019 Victory Parade

See photo gallery on the topic