Traditionally, anti-personnel mines used a high-explosive or fragmentation effect to hit a target. In the first case, the effectiveness is low, since the force of the explosion only injured the soldier who had the misfortune of stepping on the charge. The scattering range of the fragments is higher than the radius of propagation of the shock wave of a relatively small charge.

Fragmentation ammunition hit group targets, but for this the mine was installed openly, or the charge must be “jumping” and jump out of the ground after activation. And since the 50s, guided mines began to spread. One of them is the Soviet MON-100.

Predecessors

During the Great Patriotic War, the USSR was armed with the PMD-6 anti-personnel mine. It was a 200-gram TNT block in a wooden (other materials were also used, including slate) case. The PMD-6 was triggered by pressure, that is, you had to step on it.

In the post-war years, the mine was removed from service, and it was replaced by the PMN. The mass of the charge remained the same, but the body became plastic, and more advanced pressing and trigger mechanisms appeared. The PMN in various modifications was produced for a long time - the latest version was put into service in 1990.

Fragmentation mines were represented by such a sample as POMZ-2.

Its thick cast iron body contained 75 g of TNT. POMZ-2 was stuck into the ground using a wooden peg, and was triggered when the pin was pulled out by a torn tripwire. The radius of destruction of this mine was relatively small - only 4 m, but it was intended to be used as part of barriers. Thus, directional mines did not completely replace, but supplemented existing models.

Design Features

The elements of OZM-72 are:

- Guide glass. Steel is used for its manufacture. At the bottom of the glass there is a special chamber intended for attaching a tension cable connecting the glass to the impact mechanism. The glass contains a housing with an explosive charge and fragments.

- Charge. TNT is used as a charge for the OZM-72 mine, which fills the internal cavity of the clip. Located at the top of the central hub.

- Explosive charge. Designed to push an explosive device out of the ground to a height of 1 m. To make an expelling charge, black powder collected in a fabric bag is used. The charge is contained in a special tube.

- Impact mechanism. Located at the bottom of the central hub.

- Detonating capsule. It is placed in the socket of an additional detonator and is mounted only at the moment when the OZM-72 mine is directly installed.

- Carbines and cables. Designed for attaching explosive mechanism pins with guy wires.

- Wire stretchers. When installed, they are wound into coils and reach a length of up to 15 m. They are intended for arranging tripwire traps.

- Pegs made of wood and metal. Wooden stakes are used for arranging trip wires, and metal stakes are used for securing mines in frozen ground and installing a cable with carabiners. For the production of metal stakes, a duralumin corner is used.

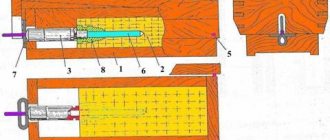

Device

The MON-100 mine in appearance resembles a thick disk with a concave surface, a quarter of a meter (23.6 cm) in diameter. Inside the steel case there is a charge - 2 kg of TNT. So, in terms of explosive mass, this ammunition is comparable to a 100 mm artillery shell.

During an explosion, of course, the body forms “natural” fragments, but the main threat is posed by ready-made lethal elements. These are steel rollers with a diameter of 10 mm (which is comparable to a normal caliber pistol bullet), placed between the TNT charge and the body. In total, the mine contains 400 such rollers.

The MON-100 must be turned towards the enemy with its concave side, in the center of which there is a fuse socket. The standard ammunition is not equipped with a fuse, but several detonators can be screwed into the socket. Firstly, the EDP-r electric detonator, in which the capsule is detonated using an electric igniter. This fuse is used if the mine is controlled by an operator.

If the mine is used as a trap, then the universal fuse MUV-2 (or the later MUV-3) is used.

This is a tension fuse, from which a pin is pulled to trigger it. Another option for using the MON-100 as an unguided explosive device is the MVE-72 electromechanical fuse. When the “trip wire” breaks, the fuse is triggered.

According to some reports, the VP-13 seismic fuse was also used with MON-100 mines. However, practice has shown that detonation of the charge by the operator is most effective. But more on that later.

An MD-5M fuse containing a detonator capsule with 0.2 g of lead azide is screwed into the fuse socket. The MON-100 mine itself can be armed for as long as desired. The ammunition does not have the ability to self-destruct, but nothing prevents it from being removed and neutralized. Some exceptions are mines that were installed using the MVE-72 fuse. Their neutralization is prohibited, but their validity period is limited. When the fuse battery runs out, the ammunition will stop working.

Since the ammunition is placed “on its side” to hit a target, it is equipped with a special bracket that is screwed into the ground or driven into suitable objects on the ground. Wing nuts connecting the MON-100 body to the bracket are used for more accurate targeting.

MON-100 gives the impression of a very powerful weapon (why it “produces” will also become clear later).

The detonation of 2 kg of TNT creates impressive “flash-noise” effects, and literally demolishes everything within a radius of 10 m. At the same time, heavy rollers at a distance of up to 160 m retain the ability, for example, to break through a steel truck door. That is, if the notorious truck ends up in the mine’s affected area, it will most likely be disabled.

The guaranteed destruction zone is about 80 m, 90% - 110 m. The range from 140 m to a maximum of 160 m is considered a 10% destruction zone. At the same time, the greatest width of the roller expansion sector is 10-15 m and is considered the zone with the lowest probability of damage.

Safety requirements when handling explosive objects

In order to prevent accidents when personnel are in a mined area and when explosive objects are detected, the following safety measures must be observed:

- If mines are detected or if mining is suspected, you should not try to remove the mine from the installation site or neutralize it yourself. A good professional will always make sure that the mine he installs has a non-neutralization or non-removal device. This work must be done by sappers. Before their arrival, it is necessary to fence off or at least mark the dangerous area with special signs with the words “mines”, and the personnel must be at a safe distance from the mines.

- As a rule, mixed (anti-tank and anti-personnel) mines are installed in minefields. When located dangerously close to mines, personnel may suffer from an explosion (after the self-destruction period has expired, when triggered by fallen branches, in strong winds, etc.). Depending on the type and design of fragmentation munitions, some of them can be dangerous at a distance of up to 300 meters.

- Mines are removed from their place and neutralized only if, due to the conditions of the situation, detonating them on the spot is impossible. In this case, the mine must be removed from the installation site using a sapper “cat” from a safe distance.

- Mine clearance work must be carried out in special equipment (sapper protective suit). But, unfortunately, such equipment, as a rule, is not available, so you usually have to make do with only a bulletproof vest.

- We must remember that planted mines are skillfully camouflaged. To make it difficult for mine detectors to find them, a large number of fragments and cartridges are scattered. To dull the sensitivity of mine detection dogs, mines can be doused with fuel and lubricants and crushed explosives can be scattered around.

- If you find an item of unknown purpose, it is forbidden to pick it up, you must stop work and call a specialist.

- It is strictly forbidden to bring or store explosive objects into troops' locations.

- It is strictly prohibited to discharge, throw or hit any explosive objects found.

- It is prohibited to pull down and disassemble wire fences with your hands, or pull out wires found on the ground, in grass or bushes, since surprise mines may be installed near them. The wire must be pulled down using a “cat” with a rope 50 m long, while in the shelter.

- Places for making fires should be dug to a depth of 40-60 cm and checked for the absence of explosive objects with a probe or metal detector.

- Movement of tracked and wheeled vehicles through the front line of enemy defenses is permitted only along passages previously surveyed by sappers. Deviation of equipment from designated routes is prohibited.

- The destruction of explosive objects by persons who do not have a special permit is strictly prohibited.

Exploitation

Although the MON-100 anti-personnel mine entered service in the early 60s, its use was limited. In fact, they tried to use it only in the 80s during the Afghan war. Ammunition supplies for export were also small. The reason is simple - the mine was unsuccessful and ineffective.

Yes, the destructive elements have significant destructive power and fly over a long range (for a mine). But in order to disable manpower or equipment, fragments must hit it. And given that the width of the beam of fragments in the maximum damage zone is only 5 m, the entire lethal flow could easily “fly in” for other purposes. This made it all the more difficult to incapacitate the group target.

This limited the scope of application of the MON-100, making controlled detonation from a remote control the only method of use. This method also turned out to be far from ideal. The safe range from the back of the mine was estimated in the regulations as 35 m, but practice has shown that individual fragments (especially the remains of the bracket) can fly further. So taking a position from which it was possible to accurately calculate the moment of detonation was not an easy task.

At the same time, the USSR adopted another directional mine.

It was a MON-50, basically copied from the American Claymore mine. It had half the weight and was more convenient to carry (having the shape of a compact rectangle). Its destructive elements had a shorter range of destruction, but the width of their spread reached 50 m, which made it easy to “cover” and disable an entire squad. At the same time, the MON-50 was also equipped with a sight-window in the body, through which the sapper operator observed the affected area.

The disadvantages of the MON-100, however, were not associated with the features of its design. This can be concluded from the fact that the MON-200 was adopted for service. The design was similar to the “hundredth”, but with one difference – the dimensions and weight were larger.

The weight of the ammunition reached 25 kg, and the charge - 12 kg (which is comparable to a large-caliber howitzer shell). As a result, the width of the affected area increased slightly (remaining within 10-15 m), but the ammunition itself became simply too heavy to lift. The danger zone for the operator has also increased.

Milking machine ADM-8

An example of a domestic milking device is the ADM-8 unit. Its production is carried out at the Kurganselmash enterprise, which provides equipment to livestock farms on the domestic and foreign markets. The inherent possibilities for modernization make it possible to change the operational parameters of the design by installing individually produced units.

Features of operation

The use of the ADM-8 milking unit is common in large farms with 100-200 cows. With a smaller herd size, the installation capabilities will be redundant, so it will be advisable to purchase smaller equipment.

There are two types of the unit, marked “100” and “200”, designed to work with the corresponding livestock. A productive system allows you to serve a larger number of cows and requires careful planning of the milking regime.

Each milker is assigned at least 50 units of livestock, and the total number of personnel is limited to four people. The maintenance process consists of periodic inspection of the tightness of vacuum connections, as well as routine repair of components and mechanisms.

Advantages and disadvantages

Advantages of the ADM-8 milking machine:

- automatic washing and disinfection of the milk line;

- comprehensive supply of milk after collection into the general milk compartment, and not into buckets;

- the ability to take a milk sample for research online;

- high mobility, allowing the feed passage not to be blocked for a long time.

Installation disadvantages:

- low reliability of the milk meter;

- vacuum surges cause stress in animals and can cause diseases (mastitis);

- the need to constantly monitor the oil level in vacuum pumps to avoid breakdowns.

Specifications

Let's compare the MON-100 mine with its more successful analogue MON-50. To complete the picture, we will also present their “improved” (more precisely, simply enlarged) models MON-200 and -90.

| MON-100 | MON-50 | MON-200 | MON-90 | |

| Weight, kg | 5 | 2 | 25 | 12 |

| Charge weight, kg | 2 | 0,7 | 12 | 6,2 |

| Number of damaging elements, pcs | 400 | 485 | 900 | 2000 |

| Damage range, m | 116 | 50 | 200 | 90 |

The MON-50 mine, created according to the American model, although it had a shorter range, turned out to be better adapted to real conditions and more effective. Unfortunately, the enlarged version of the MON-90 did not demonstrate a qualitative improvement in efficiency, but it “surpassed” the MON-100 in weight.

However, the “ninetieth” still remained an effective (albeit becoming inconvenient) weapon, unlike the “two hundredth”.

The MON-100 mine demonstrated that Soviet weapons, alas, are sometimes not the most convenient and effective.

And the attempt to develop a larger version means that the designers themselves are not always ready to agree with this. However, the bulky MON-100 continues to be in service today.

An excerpt characterizing MON-100

Meanwhile, Prince Vasily opened the door to the princess’s room. The room was dim; only two lamps were burning in front of the images, and there was a good smell of incense and flowers. The entire room was furnished with small furniture: wardrobes, cupboards, and tables. The white covers of a high down bed could be seen from behind the screens. The dog barked. - Oh, is it you, mon cousin? She stood up and straightened her hair, which had always, even now, been so unusually smooth, as if it had been made from one piece with her head and covered with varnish. - What, did something happen? – she asked. “I’m already so scared.” - Nothing, everything is the same; “I just came to talk to you, Katish, about business,” said the prince, wearily sitting down on the chair from which she had risen. “How did you warm it up, however,” he said, “well, sit here, causons.” [let's talk.] - I was wondering if something had happened? - said the princess and with her unchanged, stone-stern expression on her face, she sat down opposite the prince, preparing to listen. “I wanted to fall asleep, mon cousin, but I can’t.” - Well, what, my dear? - said Prince Vasily, taking the princess’s hand and bending it downwards according to his habit. It was clear that this “well, what” referred to many things that, without naming them, they both understood. The princess, with her incongruously long legs, lean and straight waist, looked directly and dispassionately at the prince with her bulging gray eyes. She shook her head and sighed as she looked at the images. Her gesture could be explained both as an expression of sadness and devotion, and as an expression of fatigue and hope for a quick rest. Prince Vasily explained this gesture as an expression of fatigue. “But for me,” he said, “do you think it’s easier?” Je suis ereinte, comme un cheval de poste; [I'm as tired as a post horse;] but still I need to talk to you, Katish, and very seriously.