12 gauge bullets are quite difficult to choose. It is important for a hunter to know in what conditions the hunt will take place and what kind of animal or game he wants to kill in order to choose the right modification of the bullet. They can be classified according to various criteria:

- manufacturing material. They use steel, brass, lead. Moreover, the latter can be used both in pure form and with the addition of arsenic and/or antimony;

- presence of sheath: lead without sheath; with an incomplete shell - semi-shell; lead with a sheath of steel or brass;

- level of destruction in the body of a killed animal: expansive; non-expansive;

- form factor designs that affect stabilization in flight: pointer; turbine; switch-turbine; round.

In our country today all types of the listed modifications are used. Homemade lead ones are:

- diabolo;

- cap-shaped

Homemade, but already targeted, include:

- Blondeau;

- Rubeykina.

Performed at factory facilities are:

- Brenneke;

- Jacana;

- Mayer;

- ideal;

- round, etc.

Models Strela, Kirovchanka and Poleva are also produced in a factory way, but in containers. Bullets for weapons of the “Paradox” model are placed in a separate category.

Polev's bullet

Hunting will never cease to attract people. Methods, weapons and ammunition are being improved. The 12-gauge Polev bullet is widely used among hunters in the post-Soviet space. Compared to other twelve-gauge products, it compares favorably in its performance. This applies to shooting accuracy and accuracy.

Structure

Polev's 12-gauge bullets are designed for smooth-bore weapons; they are of the arrow type - they are a lead destructive element attached to a plastic shank. To improve the sealing of the barrel bore during a shot (obturation) and for better passage of the bullet itself through the bore, a plastic container is placed on the lead lead part (after it leaves the barrel, it is separated from it).

The Polev 12 gauge bullet has three parts.

- 12 gauge bullets are made of lead alloy. There are production options in brass and steel. It has the shape of a cone, and there is a rod on the bottom. He fixes it in a plastic shank. The shank, also known as the wad-stabilizer, is made of high-density polyethylene. The front cylindrical part has a blind hole for the bullet rod. The inclined ribs (usually six) give the ammunition a rotational motion in flight.

- The shank acts as a seal (prevents gas breakthrough).

- When equipped, a container of two halves is put on the head part and inserted into the sleeve. The structure of the container has some special features: the inner upper part is made in the shape of a cone. The lower part is thickened and rests on the ribs of the shank. When the projectile leaves the muzzle, the container splits into two parts and flies away from the bullet.

Kinds

Polev's 12 gauge bullets quickly gained popularity among hunters. The author created several more modifications of his creation:

- Poleva-2 bullet – has a smaller diameter of the head part, the detachable wad-shutter and shank are somewhat modified;

- Polev-3 bullet – features a flat head with an expansive void, which greatly facilitates deformation upon impact with a target;

- Poleva-4 bullet – equipped with an expansive funnel (in the nose), has a mass of 40 grams (used for shooting large animals);

- The Palev-6 bullet is a relatively recent development; a removable wad helps compensate for the difference in barrel diameters for 12-gauge weapons.

Peculiarities

When loading ammunition with a Polev bullet, you need to pay attention to the following points:

- Do not increase the powder charge more than indicated in the recommendations. A powerful seal will significantly increase the pressure in the barrel.

- The head is inserted into the plastic sleeves to the end, thus moving the shares of the container apart. The projectile enters the sleeve with “tension,” which, in turn, will hold it even without rolling.

- This scheme allows the sleeve to be reused. You just need to make sure that its length does not exceed 70 mm.

- You can roll plastic sleeves. Paper ones are no worse and do not affect the accuracy of fire.

- There must be control over the correct installation of the container. This will help prevent one or both parts of it from flipping over.

- Bullets cannot be used if their container fits freely into the cartridge case. Lethal force indicators will decrease due to poor-quality obturation. The container must fit into both the paper and plastic sleeves with a tight fit.

12 gauge bullets are used for hunting big game. Primarily for bear, elk, wild boar. A good killing range (up to 150 meters) guarantees a successful hunt. At the moment it hits the target, under the influence of overload, the lead bullet is pressed very tightly into the shank. Her flattening is oriented in such a way that she is pressed even further into him.

These bullets are also used for sport shooting: at a “standing roe deer” or a “running boar.” Such ammunition is suitable not only for “breaking” guns, but also for semi-automatic devices (for example, TOZ-87).

Poleva-6 with a divided powder charge

The cartridges loaded with the Poleva-6 bullet were intended for testing in practical hunting.

At first everything went wrong. The hunting department was not prepared for our arrival - they did not bring a license for an elk. Everything came together only by the morning of the next day. Our two shooters were accompanied to their numbers by a very tipsy huntsman. The walk was quite far, several kilometers, overcoming small swamps, hills and dense bushes. From time to time the huntsman took a large bottle out of the bag and drank it. For some reason, he was wearing a black construction helmet with white ribbons on his head. When the hunters reached the place and settled down on the numbers, the huntsman finished everything to the bottom and sat down on a stump with a sense of accomplishment. The shooters positioned themselves along the bank of the ravine and froze, waiting for the beast.

Shooting a moose

They stood quietly for a long time. I really wanted to smoke. At this time, a stream of smoke rose above the place where the huntsman was sitting, which increased with every second. The huntsman lit a fire. That's it, the hunt is over. But at that very moment the characteristic barking of a dog and the crackling of bushes was heard. A handsome elk jumped out of the forest to the other side of the ravine. He was led by two dogs. The shooter, who stood closer, took aim at the shoulder blade and, slowly, fired. The elk was hit on its side by a bullet and overturned; there was no need to shoot a second time.

Soon the beaters arrived. Just for fun, we measured the distance - 84 (large) steps. As the autopsy later showed, the bullet passed just above the shoulder blade and hit the spine, according to the shooter, just above the aiming point. “Excellent shot, what did you use?” - “A separate charge with a Poleva-6 bullet.” The bullet split into several parts in the carcass, the largest of which, with a shank, crushed the spine.

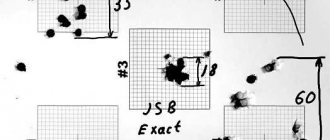

Shooting at a distance of 100 m - 120 m

The cartridges aroused widespread interest. On the same day, the entire population of the hunting base gathered on the field - more than 10 people measured 120 steps and hung targets. It's good that there was a lot of cartridges. They shot from different guns: MP-153, IZH and TOZ, there was Browning and Binelli. The shooters were amateur hunters and experienced rangers. The bullets were rated as excellent and flying very accurately at the target. It turned out that the best shooters' bullets fell in a heap, the spread diameter was about 10 cm. Sometimes they lay down so that the bullet holes touched each other. But the most important thing that the test showed: at a distance of 100 m and even 120 m, the Poleva-6 bullet in a cartridge with a split charge gives a conditionally straight shot. The shooter should not make any adjustments for the “drop” of the bullet, but aim exactly at the place he wants to hit. This greatly simplifies the task facing the hunter. The Poleva-6 bullet, even with a conventional charge in 12x70 or 12x76 cartridges, behaves excellently in open areas when the animal is not covered by bushes or tree branches. Of course, when shooting from distances of more than 50-60 meters, it is necessary to make an adjustment if you shoot with cartridges with a regular standard charge. Every hunter knows this. The practice of firing Poleva-6 bullets shows a high ability to hit large prey from distances of 100 meters or more.

Stopping effect of a bullet

According to the characteristics, it is 33 g, the flight weight on the trajectory is 28 g. V. Polev's latest development - the Poleva-6 modification bullet - differs from its predecessors (Poleva, Poleva-1, Poleva-2) in its greater stopping effect.

There is a hole in the head of the bullet. By the way, the Poleva-3 bullet also has such a hole and the same purpose; it is an expansive explosive bullet. When hitting the carcass or skeleton of an animal, bullets of the Poleva-3 and Poleva-6 modifications are greatly deformed and torn into pieces, and an increased amount of energy is released. The stopping effect increases.

Polev bullet designs

The Poleva-3 and Poleva-6 bullets differ in the design of the wad-shank. The Poleva-6 bullet is an improved modification of the Poleva-3 bullet. The novelty of the design lies in the fact that elements have been introduced that compensate for the different diameters of the cartridge cases, which reach 0.5 mm and worsen the ballistic performance of bullets of the Poleva, Poleva-2, and Poleva-3 modifications. If you do not take this into account when making cartridges, a breakthrough of powder gases is possible, many hunters know this. V. Polev provided for this in the design of the Poleva-6 bullet, providing the wad-shank with a special belt, which, when the bullet moves, is pressed tightly against the walls of the gun barrel, ensuring a full shot without loss of energy.

This case confirmed that the Poleva-6 bullet has excellent ballistic characteristics and performs well in smooth-bore weapons. We have used it before at long distances to shoot wild boar, ungulates in general, and wolves. Therefore, this result, to some extent, was expected. In some cases, when a bullet encounters thickets on its path, it changes direction depending on the thickness of the branch or branch, but its deviation from the line of flight is less than that of other types of bullets.

Mayer's bullet

The 12 gauge Mayer bullet is another representative of bullets for smoothbore weapons.

If we recall history and turn to the origins of the creation of this bullet, we can say that the Mayer bullet was invented by the Soviet engineer A.K. Mayer in 1963.

Among hunters, these 12-gauge bullets are called “turbinka” or simply “mayer”. This model was widespread and popular among Soviet hunters.

Characteristics

In appearance, the bullet has the shape of a cylinder. There is a channel inside where the rifling is made. On the outside there are inclined ribs, which, according to the author’s idea, center the bullet in the barrel and create rotational movements during flight.

The number of outer ribs usually reaches 6 pieces, but when passing through the barrel channels they are greatly crushed. The head of the bullet has more mass than the tail.

The Mayer bullet is made entirely of lead and weighs 34 g. It has a good destructive effect, so it is successfully used when hunting wild boar, elk and even bear.

If we talk about the accuracy of shooting from this bullet, then shooting at 100 meters is very effective for it, although worse than that of the Polev 12-gauge bullet.

Equipment

When equipping this bullet, you should pay special attention to which side to insert the bullet, where its head is, and where its back.

The head of the bullet is heavier and wider at the base, having a kind of “skirt”.

The first steps when loading a bullet are aimed at weighing and filling the gunpowder. If you use Sokol gunpowder, then you need to pour 2.0 g of it into the cartridge case. At an air temperature of -20 degrees, there is a need to slightly increase the powder weight by 0.1-0.2 g.

We place a cardboard pad with a diameter of 3.0 mm on the gunpowder. On top we send a greasy felt wad, which should be cut into four parts according to height.

Next, pour enough dry sawdust so that you can place all the other components and tighten the sleeve.

Place a cardboard pad with a diameter of 0.6-0.7 mm on top of the sawdust. Then we send a cardboard gasket 3 mm thick along the diameter of the base of the bullet body, that is, the diameter of the gasket should be equal to the diameter of the bullet at the base without inclined ribs.

After this, you need to twist the sleeve and you can successfully shoot a 12-gauge Mayer bullet.

Cutting the felt wad into four parts and using sawdust is required to prevent the wad from hitting the bullet while moving through the bores.

The presence of a thick cardboard spacer is used to prevent the bullet from cutting into the thin spacer and thereby closing the axial hole of the Mayer bullet.

Two bullets - two designers

In a previous article on shotgun bullets, slugs, they were classified by shape and outlined the most well-known brands (many of which are now practically unused) of the several hundred patented throughout the world. Today I would like to focus the reader’s attention on one more classification feature of bullets, and also tell more about the two most popular model series among hunters, their ballistic characteristics and the designers who created these bullets.

As for the classification feature, we are talking about caliber and sub-caliber bullets. For those who are just starting to shoot bullets from a smooth-bore gun, it may seem that the only difference between them is that some have the maximum diameter for a given barrel, while others have a smaller one. Moreover, from the questions not only from newcomers in gun and hunting forums, it is clear that the safety of shooting not only caliber, but also sub-caliber bullets from barrels with choke constrictions raises serious doubts among many.

In fact, most caliber bullets made of lead and lead alloys have special ribs or belts that crumple when passing through the choke, and for sub-caliber bullets their function is performed by an elastic polyethylene container. Perhaps in the only case there remains a risk of the barrel swelling or rupturing - this is when shooting a caliber bullet from a barrel with a narrowing of 1.25 mm, especially in the cold season.

Some people prefer one bullet or another based on their own short experience, others based on the advice of friends or recommendations from reference books. In this regard, I would like to note that the only true criterion can only be one’s own long-term experience in using one or another bullet from different manufacturers. Reference literature is usually promotional in nature, friends often evaluate the ammunition used biasedly, and short-term experience can be based on shooting with a defective model. Moreover, sometimes it is not just one or two series of shells that are defective, but the entire manufacturing technology, once “improved” so that the product differs from the original design sample like heaven from earth. Such a story, for example, happened with the Yakan bullet, good for short-range shooting at large and dangerous animals, which in domestic production lost its main advantage - expansion - and acquired deteriorated ballistics. In addition, a number of bullets are not at all universal in nature, such as the Shirinsky-Shikhmatov bullet, the use of which is only advisable for hunting in a den or large ungulates in open areas, since, being expansive, it unfolds when meeting the branches of a bush. What I mean is that an accidental experience of shooting such a bullet at small animals in dense forest or reeds can cause its completely undeserved exclusion from use.

No matter how much experienced authors write about the merits of specialized bullets, for most hunters, the determining parameters, along with accuracy, are the versatility (or rather, multifunctionality) of the bullet and the maximum distance at which it retains lethal effects. In this regard, judging by the demand, two model series stand out from the general range, to which this article is devoted: among caliber ones - the Brenneke bullet, among sub-caliber ones - the Polev bullet.

Brenneke bullets

Wilhelm Brenneke (1865-1951) received a patent for his first bullet intended for hunting large game in 1898, three years after its founding in Leipzig. The projectile turned out to be not only technologically advanced in production and revolutionary in design for its time, but also so effective in practice that, having undergone a number of modifications in 1915, 1930, 1935, 1993, 1994 and 1997, it is produced all over the world today.

Already in the very initial version, the designer used a greasy felt wad attached with a screw to the lead head of the bullet, sandwiched between two cardboard spacers. The wad restrained the breakthrough of powder gases into the pre-shell space, which contributed to an increase in muzzle pressure, contributed to stabilizing the flight of the bullet and helped reduce lead in the barrel. It should be noted here that a wad attached to the bullet with a screw or fixed on a lead shank has a better effect on ballistics than simply placed under the bullet, but it turns out to be far from perfect. First of all, the wad, with all its elasticity, while moving along the barrel under enormous pressure of powder gases, can deform the lead head, especially if the body of the bullet and the wad are misaligned. And this will not have the best effect on ballistics. In addition, it turns out to be by no means an ideal shutter, since at the moment of the shot it is subject to excessive axial compression by the fastening screw. However, as already mentioned, a salted felt wad attached to the bullet gave better results than the usual one.

As for the longitudinal guide ribs, they did not appear immediately. It was impossible to shoot full-bodied bullets from guns with choke constrictions, and the reduction in diameter led to an uncontrolled trajectory of the bullet inside the barrel and a general deterioration in ballistics.

Wilhelm Brenneke reduced the diameter of not the entire bullet, but most of it, leaving three transverse ribs that stabilized the position of the bullet in the barrel and at the same time thin enough to easily crumple when passing through the choke. Over time, the bullet has undergone major design changes. The transverse arrangement of the ribs did not have the best effect on external ballistics in itself. But, most importantly, passing through the muzzle

cut, each centering belt wrinkled unevenly along the entire perimeter and thus contributed to the displacement of the bullet axis relative to the axis of the barrel.

The idea of longitudinal ribs was gleaned from the inventor, apparently, in France. By the time Wilhelm Brenneke created his famous modification in 1930, at least one bullet design with four longitudinal ribs was already known.

In the 1850s, Nessler created a cylindrical bullet with a spherical head, and Boswell later reduced its diameter by making protruding longitudinal ribs on the lead body, which stabilized the movement of the bullet along the barrel and were easily crushed by the muzzle constriction. The muzzle velocity of the French bullet turned out to be small due to the breakthrough of powder gases into the gap between the ribs. For the Brenneke bullet, similar pressure losses became much smaller thanks to the screwed wad-shank, and nothing prevented him from facilitating the movement of the bullet by making the transverse ribs longitudinal. In the 1930 model there were six of them. But the designer decided to make the ribs not coaxial with the bullet, but at an angle to the axis, in order to give a twisting effect to the projectile moving along the barrel. They are designed so that the bullet always touches a flat surface only with its ribs. The model ceased to be a coil, it became arrow-shaped, and a helmet-shaped protrusion appeared on the flat upper cut. After experimenting with the number of ribs, in 1935 the designer settled on twelve, and since then this number has not changed. In addition, at the same time a modification with an almost flat head and a bullet for a 16-caliber gun saw the light of day.

In the 1990s, a number of bullet modifications appeared, most of them related to the wad. Now the bullet is produced with both felt and plastic wads of different configurations, which well seal the pressure of the powder gases behind the projectile. And in 1997, a bullet with a depression at the top of the head appeared.

Since 1971, the company, run by direct descendants of Wilhelm Brenneke, has settled in the town of Langenhagen, near Hanover, and this explains the origin of the term “Langenhagen Standard” (die Langenhagener Norm). The standard was established by the company several decades ago, and in accordance with it, the dispersion diameter in a series of five shots from a distance of 50 meters should not exceed 150 millimeters. Later the diameter was reduced to 100, and since 2004 to 50 millimeters.

It is clear that such accuracy can only be achieved with precision manufacturing of the bullet head and extremely precise alignment of the bullet body and wad. This does not trust anyone. Of course, the accuracy of loading and equipping cartridges also plays an important role in their quality, but Brenneke GmbH delegated precisely this procedure to several cartridge companies.

Of course, only those who have proven themselves well. And this is understandable, since on the box with cartridges the trademark and “Brenneke GmbH” are placed next to the manufacturer’s logo - “Original Brenneke” with three oak leaves and three acorns.

To those who say that they shot with a real Brenneke bullet and never received the accuracy determined by the Langenhagen Standard, I will note: shooting from a gun, even at a shooting range, from a good rest, is not at all the same as shooting from a ballistic barrel. The latter is a special thick-walled gun of the appropriate caliber with a hinged bolt and receiver fixed on a massive frame.

In general, it is recommended to take into account the following circumstances when shooting a Brenneke bullet:

• each type of bullet is designed for a certain maximum firing range;

• cartridges can be used for shooting from guns with any choke restriction;

• accuracy of shooting does not depend on the choke constriction, but the average aiming point shifts significantly, therefore, if there are interchangeable chokes, zeroing should be done with the choke that is intended to be used for hunting;

• shooting results with 12/70 caliber cartridges may deteriorate when shooting from guns with chamber lengths of 76 and 89 mm;

• one should not expect any improvement in shooting results from shotguns equipped with paradox attachments.

In conclusion, the following can be said about the Brenneke bullet: it is accurate if manufactured by the original manufacturer and, like all caliber bullets, is effective at a shooting distance of 40-50, maximum 80 meters.

Puli-Poleva

Polyethylene solved many of the problems of cartridge manufacturers, and the creation of sub-caliber bullets became possible largely thanks to this synthetic polymer. A polyethylene container surrounding a bullet, much smaller in diameter than a caliber bullet, not only crumples in the chokes more easily than lead, not only eliminates the lead lining of the barrel, but also has virtually no effect on the service life of the choke constrictions.

Viktor Polev's bullets are typical sub-caliber bullets, carefully packed in polyethylene and possessing only great energy, which is capable of hitting game at a distance of 150 and even 200 meters. At the same time, the accuracy of bullets from well-loaded cartridges also seems incredible.

Since the evolution of Viktor Vladimirovich’s developments continues, and they have not become part of history, it is somehow not customary to talk about dates in connection with Polev’s zeros. Nevertheless, some reference points will help us orient ourselves in time. Viktor Polev received basic knowledge of ballistics and aerodynamics at the Kirov Aviation College. Since 1982, he began working at the Kirov Plant of Hunting and Fishing Equipment (KZORS), where at that time the Vyatka caliber bullet and the Kirovchanka sub-caliber bullet were produced. While developing the latter, Polev created a structurally different bullet “Victoria”, today called “Poleva 1” or simply “Poleva”. Obtaining a patent for an invention took a lot of time and effort. The Poleva 2 modification was developed quite quickly. and then “Poleva 2E”, which later received the name “Poleva 3”. The Selena Corporation helped obtain a patent for the latter, and began producing it along with KZORS (currently non-existent). All this took less than four years, since, if I’m not mistaken, in 1986 I saw bullets already on sale.

The metal element of the bullet complex is a helmet-shaped head made of lead with a skirt and a relatively thin shank. "Poleva 2" was lighter than "Poleva 1", and due to this it had a higher speed. There are also differences in wads. In the first bullet, the wad and the stabilizer with eight blades were one piece; in the second and subsequent bullets, the sealing wad was separated from the stabilizer with several slightly deployed blades. The fact is that when firing the first bullet from strong chokes (up to DS 1.8 mm), the accuracy sharply decreased, since the wad-shutter-stabilizer came off at the muzzle from the lead head. The first, second and subsequent bullets are “dressed” in a plastic container consisting of two (and then three) petals, which are separated from the bullet immediately upon exiting the barrel. If in the first bullet the petals were uniform in thickness, then in subsequent modifications they became thicker in the upper part, which made it possible to better fix the bullet in the cartridge case.

Already "Poleva 1" showed good speed (with a 2.2 g "Falcon" weight, the average speed of a 30-gram bullet is 471 m/sec) and accuracy when firing from "cylinders" and barrels with choke constrictions (at 50 m the average dispersion diameter - 6 cm). “Poleva 2” has become even faster (under the same conditions, the average speed of a 28-gram bullet is -508 m/sec) and more accurate (the average dispersion diameter when shooting at 100 m is already 8.5 cm and at 200 m - 20 cm) . “Poleva 2” penetrates bushes well, unlike “Poleva 3”, which differs from the second one by the presence of an expansive funnel in the head part. This bullet at short distances (up to 70 meters, especially at 30-50 meters) shows good expansion, while at a distance of 100 meters or more it practically does not open up. The accuracy of the third bullet is almost the same as that of the second, but Polev himself recommends that hunters cut the head of the first or second bullet crosswise to a depth of 4-5 mm with a knife in order to obtain good expansion without loss of accuracy.

Viktor Polev solved the problem of the dispersion of the internal diameters of cartridges of the same caliber, which arises due to different wall thicknesses, by creating a compensator that makes it possible to equip any domestic or foreign cartridge case with a heavy (33 g) Poleva b bullet, especially effective for shooting in thickets.

Not only from the words of the author or from his own experience, but also from the words of independent experts (starting with the legendary former chief designer of IZHMEKH Nikolai Izmetinsky), as well as numerous hunters who publish reports on their hunts in forums, we can confidently say that any of Polev's bullets can kill any of the Russian game animals from a distance of up to 150 m, if you get into the slaughter area. And still

Complaints about accuracy and ballistic characteristics periodically appear in the press or in oral conversation.

Perhaps an exceptional case should be considered that at temperatures below minus 30 degrees the plastic bursts and the accuracy decreases. More realistic is the deterioration in accuracy due to non-compliance with the specifications during the industrial production of the bullet. In addition to KZORS, where Viktor Polev works as the chief designer, bullets named after him are produced by various enterprises and private entrepreneurs, but the quality of their products often does not correspond to the original in terms of accuracy and other parameters. Even mass-produced bullets at KZORS and sorted by weight give less accuracy than original bullets.

At one time, the Poleva 3 bullet was equipped with a container with half-cut petals - this was more technologically advanced when loading cartridges on automatic lines. However, at the same time, the dispersion diameter tripled, and the technology had to be complicated. Nevertheless, bullets with similar containers are still encountered, and the shooting results are disappointing.

However, even high-quality, original-made cartridges with bullets when fired from double-barreled shotguns often give a much greater spread than indicated in the series characteristics published by the factory. The fact is that double-barreled guns, as already mentioned in the previous article, have such a parameter as STP - the average point of impact, which coincides only at a certain distance for both barrels. Given the current quality of production of hunting double-barreled shotguns in Russia, it is far from certain that these points can coincide at all. And as experimental studies have shown, the trajectory of bullet trajectories when firing from different barrels also strongly depends on the weight of the bullet and the size of the charge. Viktor Polev was convinced from experience that for IZH27 the results were better with bullets weighing 28-30 g, for TOZ - about 34 g, for heavy IZH-54 35-37 g. Regarding gunpowders, it is well known that for firing a bullet the optimal are slow burning. The “Falcon” charge (for which 2.3 loads per 35 g of shot are recommended) for a light bullet (28 g) Polev recommends the one indicated on the instructions pasted on the can. True, with the caveats that the capsules must be KB “Zhevelo” or KB 21, otherwise - 0.1 g less. In winter, you can increase the weight of gunpowder to 2.5-2.6 g. From the Sunars, Polev recommends those for which weights of 2.1 g per 35 g of shot are recommended. The optimal weight of “Sunar-Magnum” is 2.3 g.

Experimenting with charges, Yu. Alekseev and V. Grolman showed that the maximum kinetic energy at the exit of Polev’s bullets from the barrel is achieved with a mass of 30-33 g and with slowly burning gunpowder. Moreover, the faster the gunpowder burns, the less the bullet should weigh. Optimal for the “Falcon” is 30 g, for the “Sunar 46” - 33 g. At the same time, a decrease in bullet weight has a slight effect on the decrease in kinetic energy, and an increase leads to a sharp decrease in it. The maximum kinetic energy was obtained by the testers with samples of Sunara 46 - 3.4 g; "Sunara 42" - 3.0 g; "Sokola" - 2.4 g; "Sunara 35" - 1.8 g.

And in conclusion of the article, it would be quite appropriate to say about the results obtained by the same researchers: “Falcon” imparts to the bullet kinetic energy comparable to the energy of a bullet from a 7.62×51 cartridge (.308 Win), and “Sunars 42 and 46” provide it with superiority over bullet energy of the 7.62×54 cartridge.

Less popular 12 gauge bullets

We will directly analyze several well-known models of bullets for 12 gauge, discuss them and talk about them in more detail.

Ball (spherical) bullet

The most ancient and easiest bullet to make (whoever has ever poured bullets knows). It is a regular ball of different diameters (depending on your wishes). It can be either sub-caliber or caliber. Despite all its simplicity, it is used for serious hunting even in modern times.

Brenneke

Another very common hunting bullet for smoothbore weapons in Russia and the world. Originally from Germany at the beginning of the 20th century. Today it is a classic representative of “turbine-arrow type” bullets. Essentially, a bullet for a smooth-bore weapon, which still rotates due to its inclined ribs. The bullet is caliber, which is why the containers do not interfere with the contact of the thin ribs of the bullet and the inner surface of the barrel. It has also established itself as a bullet for hunting large and very large animals (in our latitudes it kills absolutely everything). But due to its design, it has much less good accuracy than the same Poleva.

Diablo Lyman

A very interesting bullet, reminiscent in shape of match pneumatic bullets. It has earned a lot of praise from shooters who shoot for accuracy, but do not want to spend a lot of money on the technologically complex Poleva. The sub-caliber, due to its shape, does not produce ricochets. Today it has become widespread among those who make their own bullets. Many companies make overclocking-quality “watering cans” for it, which makes it easier for those struggling to find a tool. It is worth noting that the fairly simple shape of the bullet allows you to quickly make a large number of pieces, which is important for people who prefer to shoot a lot and often.

Bullet Lee

A sub-caliber bullet, which became widely known thanks to the distribution of cheap tools from the Lee company, among which was a “watering can” for this bullet. There are two modifications of the Lee bullet, they differ from each other only in weight. The Lee itself is a simple cap-shaped bullet (that’s what it’s popularly called) with an internal stiffener rib. Simple, cheap, easy. There aren’t enough stars in the sky, but, frankly, that’s not what it was made for. The bullet performs its task—low-cost training and “bubbling”—and nothing more is required or expected from it.

Bullet Tandem

I thought for a long time about which steel bullet to talk about in this article and after much thought I decided to settle on the Tandem bullet, as it is more famous (thanks to the release of cartridges of the same name by SCM). So, as mentioned above, Tandem is a steel bullet. When we say “steel”, we immediately mean the complete impossibility of creating it in a “greenhouse” home environment. I won’t talk about the advantages of steel over lead now; I will only mention that the steel is practically not deformed when passing through the barrel, and gives much less deformation when it enters the body of an animal. The downside to this is the increased possibility of ricochet, which is important for people shooting indoor ranges and ranges with hard catches. Tandem is a sub-caliber bullet (few people would want to damage barrels with steel), has extremely mediocre accuracy, and is designed for shooting at not very long distances.