RS-20 "Voevoda" SS-18 "Satan"

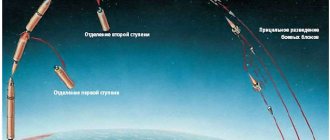

R-36M is a two-stage intercontinental ballistic missile.

It was equipped with a monoblock warhead and a MIRV IN with ten warheads. Developed at Yuzhnoye Design Bureau under the leadership of Mikhail Yangel and Vladimir Utkin. Design began on September 2, 1969. LCTs were carried out from 1972 to October 1975. Tests of the warhead as part of the complex were carried out until November 29, 1979. The complex was put on combat duty on December 25, 1974. Entered service on December 30, 1975. The first stage is equipped with an RD-264 sustainer engine, consisting of four single-chamber RD-263 engines. The engine was created at the Energomash Design Bureau under the leadership of Valentin Glushko. The second stage is equipped with a propulsion engine RD-0228, developed at the Chemical Automation Design Bureau under the leadership of Alexander Konopatov. The fuel components are UDMH and nitrogen tetraoxide. The OS silo was finalized at KBSM under the leadership of Vladimir Stepanov. The launch method is mortar. The control system is autonomous, inertial. Designed at NII-692 under the leadership of Vladimir Sergeev. A set of means for overcoming missile defense was developed at TsNIRTI. The combat stage is equipped with a solid propellant propulsion system. The unified control gear was developed at TsKB TM under the leadership of Nikolai Krivoshein and Boris Aksyutin. Serial production of missiles began at the Yuzhny Machine-Building Plant in 1974. On September 2, 1969, a government decree was issued on the development of missile systems R-36M, MR-UR-100 and UR-100N, equipped with MIRVs, the advantages of which are explained mainly by the fact that it allows the best distribution of existing warheads among targets. increasing the capabilities and providing flexibility in planning nuclear missile strikes.

The development of the R-36M and MR-UR-100 began at the Yuzhnoye Design Bureau under the leadership of Mikhail Yangel, who proposed using a mortar launch, “tested” on the RT-20P missile. The concept of a heavy cold-launch (mortar) rocket was developed by Mikhail Yangel in 1969. Mortar launch made it possible to improve the energy capabilities of missiles without increasing the launch mass. The chief designer of TsKB-34, Evgeny Rudyak, did not agree with this concept, considering it impossible to develop a mortar launch system for a missile weighing more than two hundred tons. After Rudyak left in December 1970, the Special Engineering Design Bureau (formerly KB-1 of the Leningrad TsKB-34) was headed by Vladimir Stepanov, who reacted positively to the idea of “cold” launching of heavy missiles using a powder pressure accumulator.

The main problem was the depreciation of the rocket in the silo. Previously, huge metal springs served as shock absorbers, but the weight of the R-36M did not allow them to be used. It was decided to use compressed gas as shock absorbers. The gas could support more weight, but a problem arose: how to maintain the high-pressure gas itself throughout the entire service life of the rocket? The Spetsmash design bureau team managed to solve this problem and modify the R-36 silos for new, heavier missiles. Volgogradsky began producing unique shock absorbers.

In parallel with Stepanov's KBSM, the Moscow KBTM under the leadership of Vsevolod Solovyov was working on the modification of the silo launcher for the rocket. To cushion the missile located in the transport and launch container, KBTM proposed a fundamentally new compact pendulum missile suspension system in the shaft. The preliminary design was developed in 1970; in May of the same year, the project was successfully defended at the Ministry of General Mechanical Engineering. The final version adopted the modified silo launcher of Vladimir Stepanov. In December 1969, a project was developed for the R-36M missile with four types of combat equipment - a monoblock light warhead, a monoblock heavy warhead, a multiple warhead and a maneuvering warhead.

In March 1970, a missile project was developed with a simultaneous increase in the security of the silo.

In August 1970, the USSR Defense Council approved the proposal of the Yuzhnoye Design Bureau to modernize the R-36 and create the R-36M missile system with an enhanced security silo launcher.

At the manufacturing plant, the missiles were placed in a transport and launch container, on which all the equipment necessary for launch was placed, after which all the necessary checks were carried out at the factory control and test stand. When replacing old R-36s with new R-36Ms, a metal power cup with a shock-absorbing system and launcher equipment was inserted into the shaft, and the entire enlarged assembly at the test site, simplified, was reduced to only three (since the launcher consisted of three parts) additional welds at the zero mark of the launch pad. At the same time, gas exhaust channels and gratings that turned out to be unnecessary during a mortar launch were thrown out of the launcher structure. As a result, the mine's security has increased noticeably. The effectiveness of the selected technical solutions was confirmed by tests at the nuclear test site in Semipalatinsk.

The R-36M rocket is equipped with a first-stage propulsion engine developed at the Energomash Design Bureau under the leadership of Valentin Glushko.

“The designers assembled the first stage of the R-36M rocket consisting of six single-chamber engines, and the second stage - from one single-chamber engine, maximally unified with the engine of the first stage - the only differences were in the high-altitude chamber nozzle. Everything is the same as before, but... But Yangel decided to involve KBHA Konopatov in the development of the engine for the R-36M... New design solutions, modern technologies, improved methods for fine-tuning liquid propellant engines, modernized stands and updated technological equipment - all this could be put into the balance by Design Bureau Energomash, offering his participation in the development of the R-36M and MR-UR-100 complexes... Glushko proposed for the first stage of the R-36M rocket four single-chamber engines operating according to the afterburning scheme of oxidizing generator gas, each with a thrust of 100 tf, pressure in the combustion chamber of 200 atm , specific thrust impulse at the ground 293 kgf.s/kg, thrust vector control by deflecting the engine. According to the classification of KB Energomash, the engine received the designation RD-264 (four RD-263 engines on a common frame... Glushko’s proposals were accepted, KBHA was entrusted with the development of the second stage engine for the R-36M." The preliminary design of the RD-264 engine was completed in 1969. The design features of the RD-264 engine include the development of pressurization units for oxidizer and fuel tanks, consisting of oxidation or reduction low-temperature gas generators, flow correctors and shut-off valves.In addition, this engine had the ability to deviate from the rocket axis by 7 degrees to control the thrust vector.

A difficult problem was ensuring the reliable start of the first stage engines during a mortar launch of a rocket. Fire tests of engines at the stand began in April 1970. In 1971, the design documentation was transferred to the Yuzhny Machine-Building Plant for preparation of serial production. Engine tests were carried out from December 1972 to January 1973.

During flight tests of the R-36M missile, the need to boost the first stage engine by 5 percent was revealed. Bench testing of the boosted engine was completed in September 1973, and flight tests of the rocket continued.

From April to November 1977, the engine was modified at the Yuzhmash stand in order to eliminate the causes of high-frequency vibrations detected during startup. In December 1977, the Ministry of Defense issued a decision to modify the engines.

The R-36M second-stage propulsion engine was developed at the Chemical Automation Design Bureau under the leadership of Alexander Konopatov. Konopatov began developing the RD-0228 liquid rocket engine in 1967. Development was completed in 1974.

After Yangel’s death in 1971, Vladimir Utkin was appointed chief designer of the Yuzhnoye Design Bureau.

The control system of the R-36M ICBM was developed under the leadership of the chief designer of the Kharkov NII-692 (NPO Khartron) Vladimir Sergeev. A set of means for overcoming missile defense was developed at TsNIRTI. Solid propellant charges of powder pressure accumulators were developed at LNPO Soyuz under the leadership of Boris Zhukov. A unified command post with increased security of the mine type was developed at TsKB TM under the leadership of Nikolai Krivoshein and Boris Aksyutin. Initially, the guaranteed shelf life of the rocket was 10 years, then 15 years.

A great achievement of the new complexes was the ability to remotely retarget before launching a missile. For such a strategic weapon, this innovation was of great importance.

In 1970-1971, KBTM developed designs for two ground-based launch complexes to support throw tests at site No. 67 of the Baikonur test site. For these purposes, the main equipment of the 8P867 launch complex was used. The installation and testing building was built on site No. 42. In January 1971, throwing tests of the rocket began to test the mortar launch.

The essence of the second stage of throwing tests was to test the technology of mortar launch of a rocket from a container using a powder pressure accumulator, which ejected a rocket filled with an alkaline solution (instead of real components) to a height of more than 20 m from the top edge of the container. At the same time, three powder rocket engines located on the pallet retracted it to the side, since the pallet protected the first stage propulsion system from the pressure of the PAD gases. Then the rocket, having lost speed, fell not far from the container into a concrete tray, turning into a pile of metal. In total, 9 missile launches were carried out to study the mortar launch.

The first launch of the R-36M flight test program in 1972 at the Baikonur test site was unsuccessful. After exiting the shaft, it rose into the air and suddenly fell straight onto the launch pad, destroying the launcher. The second and third launches were emergency. The first successful test launch of the R-36M, equipped with a monoblock warhead, was carried out on February 21, 1973.

In September 1973, the R-36M version, equipped with a MIRV with ten warheads, entered testing (the press provides data on a version of the missile equipped with a MIRV with eight warheads).

The Americans closely followed the tests of our first ICBMs equipped with MIRVs.

“The US Navy ship Arnold was off the coast of the Kamchatka test site during the missile launches. A four-engine B-52 laboratory aircraft, equipped with telemetry and other equipment, was constantly patrolling over the same area. As soon as the plane flew off to refuel, the rocket was launched at the test site. If the launch could not be carried out during such a “window,” then they waited until the next “window” or used technical measures to close the channels of information leakage.” It was impossible to completely close these channels. For example, before launching missiles, Kamchatka warned its civilian pilots by radio about the inadmissibility of flights during a certain period of time. Carrying out radio interception, American intelligence agencies analyzed the meteorological situation in the area and came to the conclusion that the only obstacle to flights could be upcoming missile launches.

In October 1973, by government decree, the design bureau was entrusted with the development of a homing warhead "Mayak-1" (15F678) with a gas-cylinder propulsion system for the R-36M missile. In April 1975, a preliminary design of a homing warhead was developed. Flight tests began in July 1978. In August 1980, tests of the homing warhead 15F678 with two variants of terrain-sighting equipment on the R-36M missile were completed. These missiles were not deployed.

In October 1974, a government decree was issued to reduce the types of combat equipment of the R-36M and MR-UR-100 complexes. In October 1975, flight design tests of the R-36M in three types of combat configuration and MIRV 15F143 were completed.

Development of warheads continued. On November 20, 1978, by government decree, the monoblock warhead 15B86 was adopted as part of the R-36M complex. On November 29, 1979, the MIRV 15F143U of the R-36M complex was adopted.

In 1974, the Southern Machine-Building Plant in Dnepropetrovsk began serial production of the R-36M, warheads and first stage engines. Serial production of warheads 15F144 and 15F147 was mastered at the Perm Chemical Equipment Plant (PZHO).

On December 25, 1974, a missile regiment near the city of Dombarovsky, Orenburg Region, went on combat duty.

The R-36M missile system was adopted by government decree of December 30, 1975. The same decree adopted the MR-UR-100 and UR-100N ICBMs. For all ICBMs, a unified automated combat control system (ASBU) of the Leningrad NPO Impulse was created and used for the first time. This is how the missile was placed on combat duty.

“The project included a scheme.” . Let us note that the combat crew (duty shift) does not “control the missile”, but executes orders from higher control levels and monitors the condition of all missile systems. Combat missile systems with R-36M ICBMs were placed in missile divisions that were previously armed with R-36 missiles, and were in service until 1983. From 1980 to 1983, R-36M missiles were replaced by R-36M UTTH missiles.

YANBERYAYU lap pya-20yu (SS-18), YANGDYUMMYU OND PSYNBNDYARBNL TSKYUBMNTSN YNMYARPSYRNPYU b. t. sRYKHMYU, ON YABNHL UYUPYUREPHYARKHYUL OPEBNYAUNDHKYU “lHMHRLEM-3”. schryu PUYERU ЪBKЪKERYA NDMNI HG YAYUSHU YPSOMSHU X BSHYANNSCHTTTEYRKHBMSHU YARPURETSKHVEYAYHU YAKHYAREL X MEDUPNL ONKSVKHKYU MU GYUOYUDE MUHLEMNBYUMHE "yaYURYUMYU".EE OEPBSHI HYAOSHRYUREKEMSHI OSYAY YANYARNKYA B TEBPYUKE 1973 TSNDYU. oPHMRYU MU BNNPSFEMKHE 30 DAYUAP 1975 TsNDYU. pyuyeryu DBSUYARSOEMVURYU I fpd, YANAPYUMYU ON YAUELE “RYUMDEL”. rNOKKHBN: NYHYAKHREKE - YUGNRMSHI RERPNYYAHD, TsNPCHVEE - mdlc. YAHYARELYU SOYUBKEMKH - KHMEPZHHYUKEMYU.

gYULEMEMYU B YAEPEDHME 80-U TsNDNB MU LNDHTHYUZHHCH pya-20a (SS-18 Mod.2) OEPBSHI HYAOSHRYUREKEMSHI OSYAY YNRNPNI YANYARNKYA B NYRYAPE 1977 TsNDYU. oPHMRYU MU BNNPSPHEMHE B DEYUAPE 1980 TSNDYU.

PYUYERYU five-20yu (SS-18) YARYUKYU OPHVKHMNI TSKSANYNTSN AEYAONYNIYARBU gyuoyudyu, RYU YUY UBKKYUYAE YAYULNI LNYMNI AYUKKHYARKHVEYAYNI YAKHYARELNI, YNRNPYU YNCDYU-KHAN ASHKYU PUGPYU ANRYUM.

YARYUPR HG jos "UNKNDMSHI". oEPBSHE KERMSHE HYAOSHRYUMKH ASHKH OPNBEDEMSH B YUOPEKE - LYUE 1972 C., LND. 2 - B YAEMRYAPE 1973 C., LND. 3 - B 1975 C., LND. 4 - B 1977 Ts. y 1981 Ts. ASHKN PUGBEPMSRN 308 paws PC-20, RNVMNYARE KHU ONOYUDYUMH YANYARYUBKKYU 200 L.

KHYARNPKHYANGDYUMKH. mYUVYUKN PYUGPUANRYH 1964 C; mkhnyp 1964-1969 CC. xMFEMEPMSHE HYAOSHRYUMHЪ 1969-1974 CC;

oEPBNE K╦RMNE HYAOSHRYUMHE pya-20 — YOOPEKE/LYUI 1974 Ts, pya-20yu (SS-18Mod2) — 1976 Ts, pya-20yu (SS-18Mod3) — 1976 Ts, pya-20а (SS-18Mod4) — 1979 Ts .

mYUZHEKHBYUMKHE: RHO ZHEKEY - SYPEOK╦MMSHE ZHEKH, RUYKHE YUY LYUURSH AYUKKHYARKHVEYAYHU PUYER, YUBKHYUAYUGSH, YNLYUMDMSHE ZHEMRPSH;

pHVMNYARE/ybn - 0.14 L. LHKH (260 L), 0.1 L. LHKH (190 L).

dNONKHMHRECEMN. yNMYARPSYZHKH AKNYU PUGBEDEMKH pya-20yu (SS-18Mod2) HLEKYU YAEPE╦GMSHE MEDNYARURYKH. YANNAYUKNYAE, VRN B 1985 Ts ASDER BBEDEMYU B SHYYAOXYURYUZHCH pya-20a (SS-18Mod5) ( DEYARE ac LNYNYARECH 550- 750 YR, ybn - 250 L), MN NMJU ON-BHDHLNLS ME ASHKYU PUGB ╦PMSRYU. nFKhDYUKNYAE PUGB╦PRSHBYUMKHE LNDKHTHZHHPNBUMMNI PUYERSH pya-20, YNRNPYU LNTSKYU ONKSVKHRE NANGMYUVEMKHE pya-20b bNEBNDU. th 1974TS ASHKN OPNHGBEDEMN 35 HYAOSHRYUREKEMSHU OSYAINB, B RNL VHYAKE 18 - B 1974 Ts.

noHYUMHE pya-20a.

rЪF╦KYU FKhDYNRNOKKHBMYU lap VERB╦PRNTsN ONYNKEMKH, NYAMYUY╦MMYUЪ ac KHMDHBKHDSYUKEMNTSN MYUBEDEMKH.

yNMYARPSYRNPYAYNE AChPN: ya UMTSEC; OPNHGBNDYARBN PYUGLEYEMN B dMEOPNOERPNBYAYE.

yNKHVEYARBN ANETsNKNBNY 10;

lnymnyare ANETsNKNBNY 500-550 YR.

pYUGBEPRSHBYUMKHE: OSYAINBYU SYARYUMNBYU/MNYAHREKE OEPENANPSDNBYUMMSHE KH DNONKMHREKEMN SYPEOK╦MMSHE YUURSH SS-9; PUYERU PYUGLEYEMYU B YNMREEMEPE;

pYUGLEYEMHE - LEYARE AYUG - UKEIYAY; dYULAYUPNBYAIKHI; HL. qYuYAREKKN; yUPOYURSH; sFSP (64 ІУУРШ); fYUMTSHG-rNAE;

oPNVMNYARE OSYAYNBNI SYARYUMNBYKH ON MEINRNPSHL YANNAYEMKHL "PYUYERYU PUGLEYYUERYA B YAYULSHU OPNVMSHU B LHP yuURYUU"; OH OEPBNMYUVYUKEMSHL YANNAYEMHYL - 2500-4500 psi, MEINRNPSHE YUURSH - 6000-7000 psi;

ynNKHVEYARBN PUGB╦PMSRSHU - 308 (YAEPEDKHMYU 1988 C), B NYAMNBMNL - pya-20a;

GYOOSYAY - UNKNDMSHI.