Review of the M4 quad anti-aircraft machine gun

Review of the Maxim machine gunReview of the Maxim-Tokarev machine gun Detailed photos of the M4 ZPU Photo of the M4 ZPU on trucks Photos of the ZPU M4 anti-aircraft guns captured by the Finns and Germans

In the mid-1920s, as military aviation grew in the world, the question of combating it also became a question.

So in the Red Army, at first they began to use the Maxim machine gun and its modifications on tripods of various types as an anti-aircraft weapon, but one Maxim machine gun had a low fire density to be effective enough to shoot down planes. In 1928, the Main Artillery Directorate gave the task to the design bureau of the Tula Arms Plant to create a ZPU from 2-3-4 Maxim machine guns of the 1910/30 model. So in 1928, the development of an anti-aircraft machine gun began for the needs of air defense. Work on the creation of a new anti-aircraft machine gun was completed in 1931. A quick way to create a new anti-aircraft machine gun was to increase the number of machine guns on an anti-aircraft installation. the M4 Anti-Aircraft Machine Gun Mount or simply ZPU M4 appeared It was adopted for service as a “ 7.62-mm quad anti-aircraft gun mod. 1931. ”. The development of the M4 quad anti-aircraft gun was carried out by a team led by the famous Soviet gunsmith N.F. Tokarev. A.I. took part in the team that created the M4. Panov, S.A. Prilutsky and G.G. Kurenkov. Tokarev created an anti-aircraft installation by combining four Maxim machine guns of the 1910/30 model. The installation had forced circulation of water using a hand pump, which circulated water through the machine guns into a water container located below. Instead of boxes for 250 rounds, the M4 anti-aircraft machine gun was equipped with boxes for 500 rounds for each machine gun, later increased to 1000 rounds. Counterweights and shoulder rests (sometimes missing). Ring sights were used for aiming. The machine gun could fire at aircraft at altitudes of up to 1,400 meters and flight speeds of up to 500 km/h. The machine gun was often used to support infantry. The 1929 sight was later replaced by the 1936 and 1938 model sights. For fastening to the floor of a car or ship, the ZPU M4 had three legs for brackets. In winter, a special compressor fluid was used consisting of 50% glycerin and water and 0.1% sodium hydroxide. This liquid did not freeze even at minus 50 degrees below zero. The compression fluid kept the machine gun's water cooling from rupturing and clogging the machine gun's water cooling.

Also adopted by the Red Army were a ZPU of three Maxim-Tokarev machine guns, as well as a ZPU of coaxial PA-1 machine guns. The combat crew of the M4 ZPU consisted of three people: a shooter, a gunner, and a servant.

One of the famous moments of using the M4 anti-aircraft machine gun against enemy personnel was in the Brest Fortress, when the 393rd separate air defense division held back German attacks until the anti-aircraft installations were destroyed by 1800 kg air bombs dropped from the JU-88.

The anti-aircraft machine gun was successfully used for protection from enemy aircraft on all armored trains, ships, on the roofs of high-rise buildings, etc. In the first years of the war, the anti-aircraft machine gun successfully coped with the defense of the sky from “uninvited guests,” but after about a year and a half it became clear that the M4 ZPU had become ineffective. The aircraft became faster and more secure, and their survivability also increased; therefore, in February 1943, the anti-aircraft machine gun was removed from the air defense system as obsolete and ineffective, but in practice the M4 ZPU continued to be used until the very end of the Second World War. Captured M4 ZPUs were successfully used by the German and Finnish armies. So the Finns, instead of water cooling, used air cooling, making holes in the barrel casings. Most likely this is due to the fact that the machine guns were used in winter, and simply the water in the cooling system from the cold led to the machine guns jamming, significantly reducing the weight of the installation and simplifying operation.

In the 1930s, on the basis of the Maxim machine gun, in addition to the M4 ZPU, ZPU from three air-cooled Maxim-Tokarev machine guns and ZPU from two PA-1 aviation machine guns were adopted.

The quad Maxim machine gun was replaced by more powerful machine guns and anti-aircraft guns, such as the DShK and KPVT. During the war, according to some sources, 12,000-14,000 M 4 ZPUs were produced. Subsequently, the machine guns managed to fight in Vietnam against US Army helicopters and in China.

Performance characteristics of the M4 quad anti-aircraft machine gun

| Number of shots | 250/500/1000 in tape |

| Barrel diameter | 7.62x54 mm, 4 grooves |

| Combat rate of fire | 1200-2000 rounds per minute |

| Maximum rate of fire | 2400 rounds per minute |

| Sighting range | 1600 meters horizontally 1400 meters altitude |

| Effective sighting range | 600 meters |

| Maximum firing range | 3900 meters |

| Initial departure speed | 800-860 m/s |

| Target speed | 500 km/h |

| Automation | barrel recoil |

| Weight | 460 kg+14.6 kg (belts of 500 rounds) / 29 kg (belts of 1000 rounds) |

| Dimensions | 1140 |

Weapons for the dictatorship of the proletariat. A little about Maxim. Part 4.

Home » Small arms of the past, present and future » Weapons for the dictatorship of the proletariat. A little about Maxim. Part 4.

Small arms of the past, present and future

Oleg N. 12/13/2021 975

18

in Favoritesin Favoritesfrom Favorites 9

Looking to the sky.

Since the advent of combat airplanes, machine guns have become one of the most effective means of combating them. At first these were standard infantry models, used from standard machine tools or homemade devices for anti-aircraft shooting. And at first, indeed, there were enough machine guns, and the planes did not fly very well. But as the altitude and flight speed of combat aircraft increased, it was necessary to come up with specially designed machine gun mounts, and later multi-barrel anti-aircraft machine gun mounts that could hit the plane many, many times, with the right aim. And they also had to be invented.

In the Russian army, the first anti-aircraft machine gun was a tripod designed by I.N. Kolesnikov, created by him in 1915. The tripod had an original guidance unit (a little later used by Kolesnikov for his infantry machine) and telescopic legs. But they released very few of them. Either there were few planes on the German front, or, as always, the industry “couldn’t do it,” or the snobby generals from the GAU didn’t like it.

Anti-aircraft tripod machine designed by I.N. Kolesnikova.

The first Soviet anti-aircraft gun was designed by M.N. Kondakov under a machine gun of the Maxim system mod. 1910. It was made in the form of a tripod and connected to the machine gun using a swivel. Possessing simplicity and reliability, installation of arr. 1928 provided all-round fire and large elevation angles. Anti-aircraft tripod machine model 1928 with swivel M.N. Kondakova had a mass of 16 kg. The tripod was a folding mechanism consisting of three support tubes and one telescopic tube. Due to the telescopic pipe with a bracket (swivel) for the machine gun, height adjustment is possible. It was equipped with a ring sight, intended for firing at aircraft moving at speeds of up to 320 km/h at a distance of up to 1500 m. Subsequently, with an increase in flight speed, the sight was repeatedly upgraded. The anti-aircraft machine was an addition to the Sokolov machine gun. The tripod turned out to be easy to use due to its good stability, the ability to adjust the height of the machine gun, and the ability to conduct all-round fire at large elevation angles. A tripod with a machine gun was often installed on trucks, military trains, torpedo and patrol boats.

Anti-aircraft tripod machine model 1928.

The production of anti-aircraft tripods was established at the Kiev Arsenal and the plant named after. Stalin NKTM in Voronezh (Voronezh Diesel Plant). In 1941, due to the sharply increased need for anti-aircraft machine gun mounts, Degtyarev DA and DA-2 machine guns began to be massively installed on tripods.

In 1931, under the then fashionable motto of “versatility”, the universal wheeled tripod machine S.V. was adopted. Vladimirov model 1931 weighing 39 kg. To fire at aircraft, the machine-gun machine with a swivel was removed from the wheeled travel, telescopic pipes extended from the openers, thus turning the wheeled machine into an anti-aircraft tripod.

Maxim machine gun on the Vladimirov universal machine model 1931

In the early 30s, a special anti-aircraft machine was produced for cavalry units, mounted on a machine-gun cart. The disadvantage of such a machine was the limited possible sector of anti-aircraft fire. Therefore, it was quickly withdrawn from the troops, although it was shown at parades, thereby confirming the power of the Red Army.

But since one Maxim machine gun had a low fire density to shoot down planes effectively enough, in 1928, by a decision of the GAU Art Committee adopted in July 1928, the design bureau of the Tula Arms Plant was entrusted with the design and construction of coaxial, triple and quad Maxim machine gun installations for shooting at air targets.

By 1930, designers N.F. Tokarev, G.G. Kurenkov, S.A. Prilutsky and A.I. Panov completed the task.

These installations at that time were usually designated by a common name - “complex”. Their design made it possible to install them permanently: on the ground or special platforms, and movably: in the back of a car, on a cart, on a railway platform or wagon, and on ships of the sea and river fleet.

Based on the test results, all installations developed under the leadership of Nikolai Fedorovich Tokarev (son of the famous gunsmith) were accepted into service with the Red Army. Twin and triple installations were put into service in 1930, quadruple - in 1931.

Paired and stacked complete installations. Drawings from the Instructions.

The twin installation was used mainly on armored cars and was produced in small quantities.

Data on the actual production of the built installation in 1931-1941. not available.

Complex anti-aircraft installations of Maxim machine guns were produced until 1941.

The producers were: plant No. 393 NKV, Kiev (Arsenal) and the Agricultural Machinery Plant named after K. E. Voroshilov, Kolomna.

Paired and stacked complete installations. Real photos.

The most powerful of the complex installations created, a quadruple one, was named the M4 quadruple anti-aircraft machine gun mount of the 1931 model . It was also the most common in the Red Army.

The power of the quad Maxims was first confirmed by their actions against Japanese aircraft during the armed conflict near Lake Khasan in 1938. The ZPU mod. 1931. Operated on Khalkhin Gol in 1939, in the battles of the Soviet-Finnish War of 1939-1940, in the Great Patriotic War.

Quadruple anti-aircraft machine gun M4 model 1931.

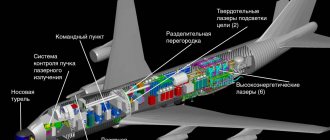

The installation consisted of a base, a swivel, a swinging frame with counterweights, shoulder pads and a trigger rod, a sight and a forced cooling system. The base was a metal cabinet with a telescopic vertical pipe, balancing springs and a rack and pinion lifting mechanism. The base was secured to the platform with three arms (arrows). The tubular swivel rotated on the pipe on bearings. A frame was placed on the swivel sector, on which four Maxims were mounted in a row, united by one cooling system, common sights and trigger. Boxes with high-capacity cartridge belts (500 rounds) were placed on the swivel. To prevent the tapes from twisting, gutters were introduced into the design of the ZPU for them.

A block of machine guns (weighing up to 80 kg) was aimed at the target by the gunner using shoulder arcs. In the vertical plane, machine guns can be aimed in an angle range from - 10° to + 82°; in the horizontal plane, a 360-degree circular fire is provided. The cooling system was designed to increase the cooling intensity of the barrels and prevent steam formation, which would interfere with the gunner’s work.

Initially, the ZPU was used with an anti-aircraft ring sight model 1929, to change its range settings, there was a shaft with a handwheel on the frame. Then they installed sights o6r.1936 and model 1938. For shooting at ground targets, they used the usual sight of the second from the left (main) machine gun. A complex anti-aircraft machine gun installation with four Maxims, possessing a high combat rate of fire, convenient and fast aiming at the target and flexible fire maneuver, in many ways surpassed similar foreign weapons that appeared later. To determine the settings of the ZPU sight, a stereo rangefinder ZD with a meter base was used.

Four quadruple installations were introduced into the staff of the rifle regiment - the Maxim installation laid the foundation for the regimental anti-aircraft weapons. At the beginning of the war, the rifle regiment had an anti-aircraft company of three 12.7 mm machine guns and six 7.62 mm mounts, another six mounts were part of the division's artillery, and a cavalry regiment was supposed to have three mounts. In reality, by the beginning of the war, these states were not provided with, which had an extremely negative impact on the anti-aircraft cover of troops and facilities.

Due to the shortage of air defense systems at the beginning of the war based on PV-1 aircraft machine guns, N.F. In August 1941, Tokarev created a built-in anti-aircraft gun, consisting of a base and a swivel with a head for PV-1 machine guns that were in arsenal storage. The base was a pipe with three struts and three legs for mounting on the platform. Three PV-1s were installed on the swinging head.

This weapon, despite its unsightly appearance, significantly strengthened the military air defense of the Red Army. The aircraft machine gun differed from the Maxim machine gun in the absence of water cooling, which made it possible to reduce the weight of the weapon. The weight of all three PV-1s without cartridge belt was 43.5 kg. The total rate of fire of the built anti-aircraft installation was over 2200 rounds/min. At the same time, for the much more complex and heavy quad M4, this figure was 2400 rounds/min.

The Tokarev surrogate anti-aircraft installation, created in a short time, with less weight and cost, was practically not inferior in efficiency to a specially designed quad installation. Mass production of built anti-aircraft machine gun installations using PV-1 began at the end of 1941 in Tambov. In 1941, the military accepted 626 such installations, and they were produced in 1942. ZPU were used in the defense of Leningrad and Stalingrad.

Built anti-aircraft machine gun installations in battle.

But by the middle of the war, it became completely clear that the increase in speed, as well as the increase in security and survivability of aviation, did not allow the ZPU, created on the basis of Maxim rifle-caliber machine guns, to effectively fight enemy combat aircraft. Actually, the inadequacy of the 7.62 mm caliber for anti-aircraft guns was clear even on the eve of the war due to the increased survivability of combat aircraft. And since February 1943, 7.62-mm quadruple anti-aircraft launchers designed by Tokarev were removed as obsolete from the anti-aircraft regiments of the RGK anti-aircraft divisions. However, the installations located in the active army in secondary sectors fought until the very end of the war.

MODERNIZATION OF THE MAXIM MACHINE GUN

MODERNIZATION OF THE MAXIM MACHINE GUN

“Combat practice, the combat experience of maneuver warfare proves to us with complete clarity,” wrote M.N. in 1925 in the monthly infantry magazine “Vystrel”. Tukhachevsky, “that a heavy machine gun, even as heavy as the Maxim machine gun with bronze parts, was still always the most reliable friend of the advanced infantry chains and never lagged behind them.” There was some slyness here - it was necessary to justify the temporary introduction of heavy machine guns instead of light machine guns into small units and to convince them of the possibility of using the reliable but cumbersome Maxims in maneuverable combat operations. The domestically produced “Maxim” machine gun, which received the affectionate nickname “Maximka” among the troops, really earned recognition and trust for its ability to conduct intense fire and accuracy, but this was achieved mainly by the large mass of the machine gun and machine, and the water-cooled barrel. Already at the beginning of the 1920s, natural demands were put forward to create a less cumbersome heavy machine gun, but this required time not only for development, but also for the reconstruction of production. But the existing production made it possible to carry out a second modernization of the proven Maxim system to increase its combat and operational capabilities and simplify the technology.

The modernization was preceded by considerable experimental work. Back in 1926, designers Sverchkov, Shanin and others proposed a set of changes to simplify the production of a machine gun - changes were made to the bolt (lock), receiver, trigger mechanism, box cover and other parts. Modernization of the heavy machine gun became one of the main tasks of the Design Bureau of the First Tula Arms Factories. Besides P.P. Tretyakov and I.A. Pastukhova participated in the modernization K.N. Rudnev, A.A. Tronenkov and others. Modernization work was carried out in collaboration with the Scientific Testing Weapon and Machine Gun Test Site, and in 1929 an experimental batch of machine guns was produced. They used a number of design solutions proposed when Tula developed a “light” machine gun in 1912–1913. It is curious that a wide water-filling hole in the barrel casing appeared on these machine guns, but then this change was not accepted for mass production.

The crew of the Maxim machine gun during an exercise. Early 1930s Let's pay attention to the camouflage coloring of the shield

The modernization was accelerated by the adoption of a new cartridge with a heavy long-range bullet D (Dobzhansky and Smirnsky systems) with a maximum flight range of 5 km. This forced a significant change in the sight of the Maxim machine gun. The new sight made it possible to hit targets at greater distances than before. Moreover, the Maxim was equipped with an optical sight and a quadrant protractor for firing at long ranges with semi-direct and even indirect (based on the reference mark) aiming. The same problems were solved by the optical sight mod. 1932, made according to the German model. The armor shield was also changed accordingly - an oval window for a sight appeared in it.

Much attention was paid to the use of standard heavy machine guns in the air defense system. I.P. Uborevich, studying the military development of Germany in 1928, especially Fr.

To study the design of the Maxim machine gun, “split” machine guns were widely used by the troops and in the OSOAVIAKHIM system

Therefore, a completely logical conclusion to the modernization of the Maxim was the introduction into service in 1931 of the universal machine of the S.V. system. Vladimirov, designer of the Tula Design Bureau. The machine, folding out into an anti-aircraft tripod, allowed fire on ground and air targets. In addition to the universal machine S.V. Vladimirov’s troops used a folding tripod designed by M.N. for anti-aircraft shooting. Kondakova arr. 1928. The small (16 kg) weight of the tripod allowed it to be serviced by one person, as well as transported in a special pack together with Sokolov’s machine. Before the Great Patriotic War, a machine gun company of a rifle battalion was required to have one such tripod. The same tripod arr. 1928 was used for anti-aircraft firing from DP and DT machine guns. Creation and use of a universal machine arr. 1931 and anti-aircraft tripod mod. 1928 significantly expanded the combat capabilities of the Maxims, but did not solve the issue of “universalization”; moreover, due to the heavy weight (39 kg), the S.V. Vladimirov could not displace the machine of the A.A. system. Sokolova. It was produced in parallel with it, but in smaller quantities.

7.62-mm heavy machine gun "Maxim" mod. 1941 (with a receiver for canvas and metal tape) on a universal machine mod. 1931 Vladimirov system

In the summer of 1928, the Tula Design Bureau was asked to design twin, triple and quad anti-aircraft machine gun mounts for Maxima system machine guns. Several PKB designers were involved in this activity: N.F. Tokarev (son of F.V. Tokarev), G.G. Kurenkov, S.A. Prilutsky and A.I. Panov. By 1930 they completed the task.

The basic requirements for a quad installation and a horse-drawn carriage for it were approved by the USSR Revolutionary Military Council by Protocol No. 25 in 1929. Initially, it was assumed that the installation would be able to mount any 7.62 mm machine guns with a rate of fire of at least 500 rounds/min. (apparently, there was an expectation of the imminent appearance of a light machine gun). But in February 1930, the Chief of Armaments of the Red Army demanded that Maxim machine guns be used on the installation, and clarified the requirements for the installation. In 1930, the Tula Design Bureau reviewed several projects for twin, triple and quadruple installations. At the same time, quad installations were developed in two versions - on a horse-drawn carriage P-21 and for stationary mounting or placement on cars, railway platforms, ships, etc. Based on the results of an internal competition, the quad installation N.F. was recognized as the best. Tokarev. In 1931, the Tokarev ZPU was adopted by the Red Army. Twin installations on carts were also used. Pivot installations were also developed for anti-aircraft firing from the Maxim from a car and a folding installation for firing at ground and air targets from a cart - the Maxim was attached to such an installation with a Sokolov machine gun. Carts were used in the Soviet cavalry until the 1950s, but mainly for transporting machine guns - for this, two Maxims (machine gun platoon) were often placed on a cart.

Crew of the 7.62-mm quad Maximum anti-aircraft machine gun mount. 1939

When modernizing the machine gun, attention was also paid to reducing the cost of production. It was decided to finally replace non-ferrous metals with steel. This primarily affected the tape receiver, which began to be made using steel milling instead of brass. Later it was made in even simpler ways, but more on that later. Since 1934, the Tula Arms Plant began to pay special attention to improving the production technology of heavy machine guns. A special bureau was created for these purposes. The surface grinding machines developed here for processing the walls of the Maxim machine gun box completely replaced the heavy manual labor of mechanics, while sharply reducing the volume and time of work. The fact that the metal link belt, the need for which was recognized long ago, was not accepted for use in machine guns, is explained by the lack of appropriate stamping and pressing equipment for its mass production.

Installation of a Maxim machine gun on a cavalry cart with anti-aircraft firing capability

Production of the modernized machine gun continued at TO3 until 1940. The production dynamics are as follows: 1931 - 16,305 machine guns, 1933 - 8637, 1934 - 4899, 1935 - 4409, 1937 - 8052, 1938. - 16,094. In 1940, the Red Army received only 4049 Maxim machine guns - the decrease in production was associated with the production of DS heavy machine guns (which will be discussed later). Operational assembly was introduced, which made it possible to put it on the conveyor with a given rhythm of work. That is, the good old “Maxim” was transferred to in-line technology.

The navy retained pedestal installations for the Maxim machine gun. Before the widespread production of the DT tank machine gun, they tried to use the Maxim machine gun to arm tanks and armored vehicles; in the 1930s and 1940s it remained the armament of armored trains and motorized armored cars.

"Maxim" has earned a reputation as a reliable, easy-to-use and accurate machine gun. However, high accuracy and accuracy were achieved by the heavy weight of the machine gun on the machine. In terms of its size and weight, the Maxim no longer met modern requirements by the end of the 30s, especially taking into account the officially adopted concept of “deep combat,” which required infantry units to have high maneuverability and good application to the terrain. The mass of “Maxim” on Sokolov’s machine (without water in the casing) was 66 kg, on a tripod arr. 1928 - 35 kg, weight of a box with cartridge strip - 9.88–10.3 kg, box with a portable set of spare parts - 7.2 kg. On the move, the machine gun had to be serviced by a team of 5–7 people who made up the machine gun squad, and in battle - 2–3 people. Correctly equipping a canvas tape with cartridges required constant alignment and was not very convenient even when using a mechanical machine. The distortions and folds of the canvas belt, especially taking into account the separately installed machine gun box, caused a standard firing technique - one of the crew numbers (usually the gunner’s assistant) supported and fed the tape while the machine gunner fired. In addition, the reliable operation of the machine gun required high precision during assembly and debugging, i.e., the presence of a large number of highly qualified assemblers. However, in order not to disrupt the chronology too much, we will return to the topic of the lightweight heavy machine gun a little later.

Domestic anti-aircraft machine gun installations. Part 2

In the post-war years, the Soviet Union continued to improve its means of combating enemy air. Before the mass adoption of anti-aircraft missile systems, this task was assigned to fighter aircraft, anti-aircraft machine guns and artillery installations.

During the war, the large-caliber 12.7-mm DShK machine gun, created by V.A. Degtyarev and modified by G.S. Shpagin, was the main anti-aircraft means of protecting troops on the march. DShK, mounted on a tripod in the back of a truck, moving as part of a column, made it possible to quite effectively fight enemy low-flying aircraft.

Large-caliber machine guns were widely used in site air defense and for the defense of railway trains. They were installed on heavy tanks and self-propelled guns as additional anti-aircraft weapons. The DShK has become a powerful weapon in the fight against enemy aircraft. Possessing high armor penetration, it significantly surpassed the 7.62 mm ZPU in terms of range and height of effective fire. Thanks to the positive qualities of DShK machine guns, their number in the army constantly grew during the war years. During the war, about 2,500 enemy aircraft were shot down by anti-aircraft machine guns of the ground forces.

At the end of the Great Patriotic War, K.I. Sokolov and A.K. Korov carried out a significant modernization of the DShK. The power supply mechanism was improved, the manufacturability was improved, the barrel mount was changed, and a number of measures were taken to increase survivability and operational reliability. In 1946, under the DShKM brand, the machine gun was put into service.

DShKM

Externally, the modernized machine gun was distinguished not only by a different form of muzzle brake, the design of which was changed back in the DShK, but also by the silhouette of the receiver cover, in which the drum mechanism was abolished - it was replaced by a receiver with two-way power supply. The new power mechanism made it possible to use the machine gun in twin and quad mounts.

Quadruple DShKM installation of Czechoslovak production, used by the Cubans in the battles on Playa Giron

Large-caliber machine guns in the DShKMT version intended for installation on armored vehicles were used as anti-aircraft guns on almost all types of post-war Soviet medium and heavy tanks.

DShKM machine guns have been in service for a long time; at present, they are practically ousted from the Russian army by more modern models.

The last case of combat use of these machine guns by Russian units was in the North Caucasus, where they were used to fire at ground targets.

In 1972, the NSV-12.7 “Utes” heavy machine gun, designed by G. I. Nikitin, Yu. M. Sokolov and V. I. Volkov, was adopted for service, on a non-universal 6T7 tripod machine designed by L.V. Stepanova and K.A. Barysheva. The rate of fire of the machine gun is 700-800 rounds/min, and the practical rate of fire is 80-100 rounds/min.

The mass of the machine gun with the machine was only 41 kg, but, unlike the DShK, on the universal Kolesnikov machine gun, which had more than twice the mass with the machine, it was impossible to fire at air targets from it.

For this reason, the Main Rocket and Artillery Directorate gave the KBP enterprise the task of developing a light anti-aircraft gun for a 12.7 mm machine gun.

The installation should have been developed in two versions: 6U5 for the DShK/DShKM machine gun (machine guns of this type were available in huge quantities in mobilization reserves) and 6U6 for the new NSV-12.7 machine gun.

R. Ya. Purtsen was appointed chief designer of the installations. Field and military tests began in 1971. Test sites and subsequent military tests of anti-aircraft machine gun mounts confirmed their high combat and operational characteristics.

In accordance with the decision of the commission, only the 6U6 installation entered service with the Soviet Army in 1973 under the name: “Universal machine designed by R. Ya. Purtsen for the NSV machine gun.”

NSV-12.7 machine gun on the U6U universal machine

The installation carriage is the lightest of all modern similar structures. Its weight is 55 kg, and the weight of the installation with a machine gun and an ammunition box for 70 rounds does not exceed 92.5 kg. To ensure minimal weight, the stamped and welded parts that make up the main part of the installation are made of steel sheet with a thickness of only 0.8 mm. At the same time, the required strength of the parts was achieved using heat treatment.

The peculiarity of the carriage is such that the gunner can fire at ground targets from a prone position, while the back of the seat is used as a shoulder rest. To increase the accuracy of shooting at ground targets, a fine aiming gearbox was introduced into the vertical guidance mechanism. For shooting at ground targets, the 6U6 installation is equipped with a PU optical sight. Air targets are hit using the VK-4 collimator sight.

The universal anti-aircraft installation with the NSV-12.7 machine gun today has no analogues in terms of weight and size characteristics, and has good service and operational data. This makes it possible to use it in small mobile units and carry it disassembled.

The NSVT-12.7 machine gun has firmly taken its place as an anti-aircraft gun on the turrets of Soviet and Russian main tanks T-64, T-72, T-80, T-90 and self-propelled artillery mounts.

[/center]

NSVT

The NSVT is mounted on a installation that provides shelling of ground and air targets at vertical guidance angles from -5 to +75°. For shooting at air targets, the K10-T collimator sight is used, and for ground targets, a mechanical sight is used. The tank version of the machine gun is equipped with an electric trigger.

During various local conflicts, the NSVT anti-aircraft gun was usually used to fire at ground targets. The large vertical guidance angle allows firing at the upper floors of buildings during combat operations in the city.

In 1949, a 14.5-mm Vladimirov heavy machine gun on a Kharykin wheeled machine gun (under the designation PKP - Vladimirov heavy-caliber infantry machine gun system) was adopted for service.

It used a cartridge previously used in anti-tank rifles. Bullet weight is 60-64 g, initial speed is from 976 to 1005 m/s. The muzzle energy of the KPV reaches 31 kJ (for comparison: the 12.7 mm DShK machine gun has only 18 kJ, and the 20 mm ShVAK aircraft gun has about 28 kJ). The target firing range is 2000 meters. The KPV successfully combines the rate of fire of a heavy machine gun with the armor penetration of an anti-tank rifle.

Effective ammunition for hitting air targets with armor protection at distances up to 1000-2000 m are 14.5 mm cartridges with an armor-piercing incendiary bullet B-32 weighing 64 g. This bullet penetrates armor 20 mm thick at an angle of 20 ° from the normal at a distance of 300 m and ignites aviation fuel located behind the armor.

To engage protected air targets, as well as for zeroing in and adjusting fire at a distance of up to 1000-2000 m, 14.5 mm cartridges with an armor-piercing incendiary tracer BZT bullet weighing 59.4 g are used (GRAU index 57-BZ T-561 and 57 -BZ T-561 s). The bullet has a cap with a pressed-in tracer compound, which leaves a luminous trace visible at a great distance.

The armor-piercing effect is slightly reduced compared to the B-32 bullet. At a distance of 100 m, a BZT bullet penetrates 20 mm thick armor placed at an angle of 20° to the normal.

To combat protected targets, 14.5 mm cartridges with an armor-piercing incendiary bullet BS-41 weighing 66 g can also be used. At a distance of 350 m, this bullet penetrates armor 30 mm thick, located at an angle of 20 ° to the normal.

The result of a 14.5 mm sighting-incendiary bullet hitting a duralumin sheet

The installation's ammunition can also include 14.5 mm cartridges with an armor-piercing incendiary-tracer bullet BST weighing 68.5 g, an instant-action incendiary bullet MDZ weighing 60 g, and a sighting-incendiary bullet ZP.

In 1949, in parallel with the infantry, anti-aircraft installations were adopted: single-barrel installation ZPU-1, twin-barrel ZPU-2, quadruple ZPU-4.

ZPU-1 was developed by designers E. D. Vodopyanov and E. K. Rachinsky. The ZPU-1 anti-aircraft machine gun mount consists of a 14.5 mm KPV machine gun, a light carriage, wheel travel and sighting devices.

ZPU-1

The carriage provides all-round fire with elevation angles from –8 to +88°. On the top of the carriage there is a seat on which the gunner sits during firing. The lower machine of the carriage is equipped with a wheel travel, allowing the installation to be towed by light army vehicles. When the installation is transferred from the traveling to the combat position, the wheels of the wheel drive are rotated to a horizontal position. A combat crew of 5 people transfers the installation from a traveling position to a combat position in 12-13 seconds.

The lifting and rotating mechanisms of the carriage ensure that the weapon is aimed in the horizontal plane at a speed of 56 degrees/s; in the vertical plane, guidance is carried out at a speed of 35 degrees/s. This allows you to fire at air targets flying at speeds of up to 200 m/s.

To transport the ZPU-1 over rough terrain and in mountainous conditions, it can be disassembled into separate parts and transported (or carried) in packs weighing up to 80 kg.

The cartridges are fed from a metal link belt placed in a cartridge box with a capacity of 150 cartridges. The ZPU-1 uses a collimator anti-aircraft sight as sighting devices.

Along with the single ZPU-1 anti-aircraft machine gun mount, a twin anti-aircraft gun mount was designed. Designers S.V. Vladimirov and G.P. Markov took part in its creation. The installation was adopted by the Soviet Army in 1949.

ZPU-2

ZPU-2 entered service with anti-aircraft units of motorized rifle and tank regiments of the Soviet Army. Through foreign economic channels, a significant number of installations of this type were exported to many countries around the world.

ZPU-2 consists of two 14.5 mm KPV machine guns, a lower carriage with three lifts, a rotating platform, an upper carriage (with guidance mechanisms, cradle and cartridge box brackets, as well as gunner seats), a cradle, sighting devices and wheel travel .

For firing, the installation is removed from the wheels and placed on the ground. Its transfer from the traveling position to the combat position is completed in 18-20 seconds. Although the mass of the installation with wheels and cartridges reaches 1000 kg, it can be moved over short distances by calculation forces.

Guidance mechanisms allow for all-round firing with elevation angles from –7 to +90°. The speed of pointing the weapon in the horizontal plane is 48 degrees/s, pointing in the vertical plane is carried out at a speed of 31 degrees/s. The maximum speed of the target being fired is 200 m/s.

In order to increase the tactical mobility of anti-aircraft machine gun units and provide air defense to motorized rifle units on the march, the ZPU-2 version was designed in the late 1940s, intended for placement on armored personnel carriers. It was designated ZPTU-2.

In 1947, the design bureau of the Gorky Automobile Plant developed the BTR-40 A anti-aircraft installation, which consisted of a light two-axle armored personnel carrier BTR-40 and an anti-aircraft machine gun installation ZPTU-2, located in the troop compartment of the armored personnel carrier.

ZSU BTR-40A

The BTR-40 unit was put into service in 1951 and was mass-produced at the Gorky Automobile Plant.

In 1952, an anti-aircraft installation was put into production, created on the basis of the three-axle armored personnel carrier BTR-152 with the placement of a twin 14.5 mm ZPTU-2 installation in it.

The quad ZPU-4 became the most powerful anti-aircraft machine gun mount developed in the USSR. It was created on a competitive basis by several design teams. Tests have shown that the best installation is the design of I. S. Leshchinsky. The ZPU-4 installation was adopted by the Soviet Army in 1949.

ZPU-4

To ensure the necessary stability of the installation when firing, there are screw jacks on which the installation is lowered when transferring it from the traveling position to the combat position. A team of 6 people performs this operation in 70-80 seconds. If necessary, the installation can also be fired from wheels.

The maximum rate of fire is 2200 rounds/min. A destruction zone is provided at a range of 2000 m, and at an altitude of 1500 m. On the move, the installation is towed by light army vehicles. The presence of wheel suspension allows movement at high speeds. The ability to move the installation by crew forces is difficult due to the relatively large weight of the installation - 2.1 tons.

To control fire on the ZPU-4, an automatic anti-aircraft sight of the APO-14.5 construction type is used, which has a counting mechanism that takes into account the target speed, target course and dive angle. This made it possible to use the ZPU-4 quite effectively to destroy air targets flying at speeds of up to 300 m/s.

It was exported through foreign economic channels to many countries around the world, and in China and the DPRK it was produced under license. This installation is still used today not only in the military air defense system of a number of countries, but also as a powerful means of destroying ground targets.

In 1950, an order was issued to develop a twin installation for airborne troops. When put into service in 1954, it received the name “14.5-mm ZU-2 anti-aircraft machine gun mount.” The installation could be disassembled into lightweight packs. It provided a higher speed of aiming in azimuth.

ZU-2 in the Vladivostok Fortress museum, photo by the author

E.K. was involved in the installation of ZU-2. Rachinsky, B. Vodopyanov and V.M. Gredmisiavsky, who previously created ZPU-1. The design of the ZU-2 is in many ways similar to that of the ZPU-1 and consists of two 14.5 mm KPV machine guns, a carriage and sighting devices.

Unlike the ZPU-1, an additional seat on the right for sighting and right and left frames for cartridge boxes are mounted on the upper machine of the carriage. The lower machine of the carriage has a non-separable wheel drive. By simplifying the design of the wheel drive, it was possible to reduce the weight of the unit to 650 kg compared to 1000 kg for the ZPU-2. At the same time, the stability of the installation when firing also increased. On the battlefield, the installation is moved by crew forces, and for transportation in mountainous conditions it can be disassembled into parts weighing no more than 80 kg each.

However, transporting the ZPU-1 and ZU-2, not to mention the ZPU-4 on a four-wheeled cart in mountainous and wooded areas, presented great difficulties. Therefore, in 1953, it was decided to create a special small-sized mountain installation for the 14.5 mm KPV machine gun, disassembled into parts carried by one soldier.

In 1954, designers R.K. Raginsky and R.Ya. Purtsen developed a project for a 14.5-mm single anti-aircraft mountain installation ZGU-1. The weight of the ZGU-1 did not exceed 200 kg. The installation successfully passed field tests in 1956, but did not enter mass production.

ZGU-1

They remembered it in the late 60s, when there was an urgent need for such weapons in Vietnam. The Vietnamese comrades turned to the leadership of the USSR with a request to provide them, among other types of weapons, with a light anti-aircraft gun capable of effectively fighting American aircraft in conditions of guerrilla warfare in the jungle.

ZGU-1 was ideal for these purposes. It was urgently modified to accommodate the tank version of the Vladimirov KPVT machine gun (the KPV variant for which the ZGU-1 was designed had been discontinued by that time) and was put into mass production in 1967. The first batches of installations were intended exclusively for export to Vietnam.

The design of the ZGU-1 is distinguished by its low weight, which in combat position, together with the cartridge box and 70 cartridges, weighs 220 kg, while ensuring rapid disassembly (within 4 minutes) into parts with a maximum weight of each no more than 40 kg.

Although the role of rifle-caliber anti-aircraft machine guns in the post-war period was minimized during the development and adoption of new models mounted on machines and turrets, the technical conditions specified the possibility of conducting anti-aircraft fire.

Soon after the end of the war, the SG-43 heavy machine gun underwent modernization. His improved version of the SGM on a new tripod adjustable machine with the ability to conduct anti-aircraft fire was significantly lighter.

On armored personnel carriers and BRDMs, the SGMB version was installed on a pivot mounting

In 1961, the USSR Armed Forces adopted a single PK machine gun, developed by M.T. Kalashnikov. Its mounted versions of the PKS had the ability to conduct anti-aircraft fire. For firing at air targets, the machine has a special rod.

PKS machine gun, with night sight, in anti-aircraft firing position

The armored personnel carrier version with a pivot mounting received the designation PKB.

The PKB was used on armored vehicles that had an open-top design without a rotating turret (BTR-40, BTR-152, BRDM-1, BTR-50) as well as on early versions of the BTR-60 - BTR-60P and BTR-60PA.

Not long ago, reports appeared about the creation of a T-90SM tank for modification; instead of the usual NSVT anti-aircraft machine gun, a remote-controlled machine gun mount of 7.62 mm caliber appeared.

T-90SM

Obviously, the effectiveness of such an “anti-aircraft” rifle-caliber machine gun as an air defense weapon will be extremely low, and this weapon is most likely intended to destroy tank-dangerous manpower.

Despite the improvement of such high-tech means of combating low-flying air targets as MANPADS, they could not completely displace anti-aircraft machine gun installations from the air defense arsenal of the ground forces. ZPUs have proven to be especially in demand in local conflicts, where they are successfully used to destroy a wide variety of targets - both air and ground. Their main advantages are versatility, unpretentiousness, ease of use and maintenance.

Based on materials: https://warsite.ru/ https://arsenal-info.ru/b/cat/russia/ https://www.telenir.net/transport_i_aviacija/tehnika_i_vooruzhenie_1998_02/p7.php