Hundreds of thousands of people in our country own hunting weapons - both smooth-bore and rifled. Some people use it several times a week, while others take it out of the safe only once every few years. Some prefer to use magazine ammunition, while others prefer homemade ammunition. And if you're aiming to be among the latter, it might be helpful to learn how to load 16-gauge ammunition. There are a lot of subtleties and nuances here. Their knowledge determines how successful and safe the use of ammunition will be.

Pros of self-loading cartridges

In hunting stores today you can see a huge assortment of cartridges costing from 20 rubles to several hundred. So, everyone can find a suitable option among them. Why does 16 gauge loadout remain so popular? It's actually simple. Not everyone can afford to buy expensive foreign cartridges. But the quality of cheap ones very often varies: the same manufacturer can produce two batches - of acceptable quality and of extremely low quality.

Therefore, by loading the cartridges yourself, the hunter can be 100% sure that they will not fail at the critical moment.

Another important reason is the age of components. Manufacturers often use primers and gunpowder that are approaching their expiration dates. After all, the packs of cartridges indicate the expiration date, starting from the moment of charging. Of course, in this case, a misfire may also occur. If this happens when hunting a hare or duck, it’s okay - at most the hunter will be left without a trophy. What if you need to shoot a wounded wild boar or an angry bear?

Therefore, it is not surprising that experienced hunters prefer to trust themselves rather than the ammunition manufacturer.

"Glavpatron"

Domestic-made ammunition produced by the Tula plant, known in our country as one of the most reliable manufacturers. Most hunters prefer to purchase products from this company only due to the fact that they have a low cost, although one cannot fail to note their quite good technical characteristics. "Glavpatron" pleases its consumers with an excellent rate of fire and high combat stability.

This brand produces both sporting and hunting ammunition of the following varieties:

- magnum and semi-magnum;

- classic;

- special;

- standard;

- bullets.

Among the assortment you can find varieties with or without a wad container, so you can easily select ammunition for professional or amateur hunting. The prices are reasonable, the quality is at the highest level - what else does a Russian hunter need?

Possible disadvantages

Of course, such a solution also has disadvantages. Firstly, you need to purchase a large number of specialized tools: from scales to a rolling device. And they cost much more than we would like. Secondly, loading cartridges takes quite a lot of time - after spending the whole evening, even an experienced hunter will not be able to load more than a hundred. Thirdly, this is an extremely responsible matter that requires great concentration. By mistakenly pouring a quarter gram more gunpowder into a cartridge case than required, the hunter risks being left not only without a gun, but also without fingers.

Characteristics of Sokol gunpowder

Gunpowder is produced in plates having a rectangular shape. Their base is nitrocellulose. This powder is stable, has a stable chemical composition, and does not stick together.

The surface of the plates is graphitized and gelled (just to protect it from sticking and electrification). Length varies from 1.28 to 1.7 mm, thickness 0.13 mm.

Gunpowder is produced in two grades - highest and first. How much gunpowder is in a pack? Release form: tin cans of 200-250 grams. If you purchase the option in a galvanized box, then its weight is 45-50 kg. How long will the gunpowder be stored? When properly stored in cans, gunpowder does not lose its properties for about 6 years, in a galvanized box - 25.

Today, Sokol is used by many domestic manufacturers of cartridges, for example, Azot, Fetter, Poliex and others.

How long can supplies be stored?

When buying cartridges, wads, containers and bullets or buckshot, you don’t have to worry about the expiration date - these products have practically unlimited expiration dates.

But gunpowder and wads cannot boast of this.

The average shelf life of gunpowder is 5 years. But if certain conditions are met (no temperature changes, low humidity), it can be doubled. But this only applies to a sealed jar. Once it has been opened, it is advisable to use up all the gunpowder as soon as possible, within a maximum of two years. Moreover, this applies to all types of gunpowder: “Sunar”, “Falcon”, “Bars”.

The situation with capsules is a little different. For them, high humidity is not so critical. But there are still certain limitations here too. “It is advisable to store no more than three years. “Zhevelo-N” wins in this regard - its shelf life is six years.

Types of bullets

Sub-caliber are bullets with a diameter less than the diameter of the bore. They can be used with choke constrictions, do not injure the barrel when passing through and, as a rule, are equipped with a seal container. Due to their reduced size, they have a greater initial speed and flight distance. But the destructive power is noticeably less than that of a caliber one.

Caliber bullets are bullets with a diameter almost equal to the diameter of the bore. As they pass, they deform themselves and can cause damage to the trunk. They have great lethality, but cannot be used with PSCs.

Do you need a rolling device?

Some people are frankly confused about how to load 16-gauge ammunition without a rolling device at hand. Others never used it at all. How useful is it?

In fact, the answer here is clear and obvious. It all depends on which sleeves you prefer (we’ll talk about the pros and cons a little later).

If you like plastic cartridges and shoot from semi-automatic weapons, then you cannot do without the device - it not only eliminates the possibility of buckshot or shot spilling out, but also adjusts the cartridge strictly to a certain length.

Do you like the 16 gauge brass case? In this case, the device will not be needed: it will not be able to bend the metal edges; it will most likely fail on its own. How to ensure reliability? This is achieved in different ways. For example, many experienced hunters, having loaded a cartridge and inserted the last wad, fill it with a small amount of molten wax, paraffin or plasticine. Immediately after this, the excess is poured out before it has time to harden, but the resulting crust prevents the charge from spilling out, and at the same time reliably seals the cartridge, eliminating the possibility of getting wet in high humidity conditions.

Bullets for 16- and 20-gauge shotguns

For shotguns of 16 and 20 calibers, bullets should be used - with the described methods of equipment - the "Falcon" loads indicated in the table. 40. When using this table, it should be remembered that the largest recommended powder charges can only be used in the heaviest guns of a given caliber.

Shooting large ungulates and bears from small caliber rifles (28 and 32) with commercially available bullets is not recommended. We have already talked about how to equip small-caliber bullet cartridges with bullets for shooting medium-sized animals.

Selecting suitable scales

If you want to know how to properly load 16 gauge ammunition, the first thing you need to do is purchase a scale. Moreover, pharmaceutical ones are as accurate as possible. Shot and buckshot are measured in grams, and gunpowder is measured in tenths and hundredths of a gram. Any error can ruin the cartridge and even pose a danger to the shooter.

Relatively recently, only ordinary scales with two cups and a set of weights were used for this. Of course, weighing gunpowder on such scales took quite a lot of time.

Fortunately, with the development of electronics, fairly accurate and at the same time very inexpensive electronic analogs have appeared on sale. Working with them is much easier. The main thing when purchasing is to take into account that the minimum step should be no less than 0.1 grams, and better - 0.01. And the maximum limit is 50 grams or more.

Experienced hunters, loading different types of 16-gauge cartridges, use different amounts of gunpowder - this depends on the striking element (shot, buckshot or bullet). In addition, experts recommend increasing the amount of gunpowder by about 0.1 grams when hunting in the cold season.

Some shooters, to save time, make a special measure for gunpowder - they simply cut the plastic sleeve at a suitable level and attach a kind of wire handle to it. This greatly simplifies the loading process - you don’t need to weigh the gunpowder, just scoop it up. But this approach does not allow changing the weight accurately enough, and is generally not recommended as it is not safe enough.

Loading different types of bullets

General rules

The ammunition is loaded as follows. Using the existing device, insert the igniter primer into the primer socket of the cartridge case to a depth of 0.2 mm (it is acceptable for the primer to fit flush with the bottom of the cartridge case). Weigh smokeless powder on a scale with an accuracy of +0.01 g and pour it into the cartridge case. After this, wads made of hard cardboard with a total thickness of 2.5-3 mm or a polyethylene seal are placed into the sleeve. The latter is more desirable, but at the same time the charge of Sokol powder should be reduced by 0.2 g compared to that recommended for cardboard wads for 12, 16 and 20 calibers. Then send the greasy felt wad (their height should be the same for all cartridges) with a force of 6-8 kg, which is achieved when sending it with a hand, the elbow of which does not leave the table. With the same effort, additional non-greased felt wads are sent, if necessary, and then the bullet. You cannot place any wad on the bullet. Under the twist, the same size edges of the sleeve tube should be left, and the twist should have a recess in the matrix (on how to make it; see OiOKH, No. 1, 1980) to accommodate (when rolling) the head of the bullet. To facilitate rolling of the polyethylene sleeve, we can recommend slightly heating the edge of the tube. The edge of the polyethylene cartridge case tube with the inserted bullet is leaned against a 100-watt light bulb for 30 seconds and immediately after that it is twisted.

Round bullet (Sputnik)

Long-term experience of shooting Siberian commercial hunters with smooth-bore guns shows that when hunting animals in the forest and bushes, they are quite satisfied with a smooth round (ball) bullet or “Sputnik”. To load the cartridge, a caliber bullet is used for the cylindrical barrel, and a matched sub-caliber bullet is used for the check ones. For a charge of gunpowder under a bullet, as usual, a cardboard powder wad 2.5-3.0 mm thick is placed in the cartridge case and the gunpowder is wadded with a force of 6-8 kg. A semi-caliber main greasy felt powder wad and the required number of dry additional felt wads on top are sent to it with constant compression. Powder felt wads are covered with a cushioning cardboard wad 0.8-1.0 mm thick, on which a round bullet is placed. The charge of “Falcon” gunpowder for shooting in the summer from a 12-gauge gun is 1.9-2.4 g. As noted by E. Keller (OiOKH, No. 9, 1985), a 12-gauge round bullet (diameter 17.0-17.1 mm, weight 29-30 d) with a “Falcon” charge of 1.9g, it pierces an elk right through at 38m. Therefore, using a forced charge for this bullet, as many do, is not only pointless, but also harmful. At the same time, the speeds increase slightly, the pressure in the barrel rises strongly, and the spread of bullets increases. Among all lead bullets, round bullets are the least susceptible to deformation during the firing process, so their shooting accuracy is high. To center and secure a sub-caliber bullet in the cartridge case, take four identical matches, place them tightly against the wall of the cartridge case at the ends of the mutually perpendicular diameters of the bullet, and the latter is filled with wax or paraffin to 3/4 of the height. After they have cooled, the matches are removed from the sleeve. Sometimes a paper tube 3/4 high of the bullet diameter is used to center and secure a sub-caliber bullet, the inner diameter of which is equal to the diameter of the bullet, and the outer diameter is equal to the inner diameter of the cartridge case. You can also center and fix a round sub-caliber bullet with a tray cap. To do this, the tray-cap is stamped from cardboard to the size of the bullet and cartridge case with a wall height of 3/4 of the bullet diameter. They also use plastic cups and wad containers for shot, in which the tube or petals are cut to the height of the bullet. The use of plastic tray caps when loading cartridges with a sub-caliber smooth bullet is the best and most perfect way. Here the bullet is precisely centered along the axis of the barrel, its friction and the possibility of shocks when passing through the muzzle are eliminated, which allows for higher initial speed, flatness and lethality. After placing round sabot bullets into cartridges, no matter how they are centered, the cartridge cases must be rolled. Good rolling of the muzzle increases the boost pressure, reduces the muzzle pressure of the powder gases, which improves the stability of the bullets leaving the barrel, i.e. their accuracy, accuracy and damaging effect. At the same time, no wads are placed on top of the bullet, since when fired, this wad can be tightened and jammed between the bullet and the wall of the barrel bore in the check narrowing, which will cause swelling or rupture of the bore. When loading bullet cartridges for small-caliber shotguns (32 and 28) with a cylindrical bore, smooth round caliber bullets are also widely used. But with conventional cartridge loading, significant bullet dispersion is observed. The reason for the large scatter is the impact of heavy powder wads on them. To eliminate this drawback, G. Yunakovsky proposed this method of equipment. Three cardboard wads of about 1 mm each are placed on the charge and the gunpowder is wadded. Then, a mixture of dry small sawdust and talc in a volume of 9:1 is filled to the top of the cartridge case and the filling is compacted with a special filler with a hemispherical end, the diameter being equal to the diameter of the bullet. A bullet is placed into the resulting recess, which is poured on top 3-4 mm above half its diameter with a molten mixture of paraffin and technical petroleum jelly in a 1:1 ratio. When fired, a compacted wad made of sawdust and talc is not compressed into a monolith; outside the barrel it crumbles into small pieces and does not have a knocking effect on the flight of the bullet.

Bullet "Vyatka"

Designed for hunting large animals - elk, deer, bear, wild boar. Consists of a lead body and a polyethylene stabilizer. The bullet body has a teardrop shape, 6 centering ribs, an internal hole and a central rod. The polyethylene stabilizer consists of a cylinder with a narrow sealing belt. The end of the rod is flared and this ensures the integrity of the bullet elements during its flight. The Vyatka bullet is convenient and easy to load; The polyethylene belt provides reliable sealing when firing. The advantages of the Vyatka bullet are increased flight speed, better flight stability, better combat accuracy, increased penetration and expansiveness, and reduced ability to ricochet. It can be loaded into either a paper or a plastic case, the capsule is “Zhevelo”, and the gunpowder is “Falcon”. The weight of gunpowder at sub-zero temperatures and a plastic seal for the 12-gauge is 2.3 g, with two cardboard spacers with a total thickness of 3 mm - 2.5 g; at positive temperatures, the weight in both options must be reduced by 0.1 g. Two felt wads (the lower one is greasy), cut almost completely into 4 parts, are sent to the seal or gaskets. Then the bullet is sent in and the cartridge case is rolled. The head of the Vyatka bullet should not extend beyond the upper cut of the cartridge case before it is rolled. Of course, before loading Vyatka cartridges, the body of each bullet must be measured at its widest part in order to make sure that the body of the bullet passes freely through the muzzle. The centering ribs are easily crushed when passing through the choke. Unfortunately, the weight of Vyatka bullets varies in different batches - from 30 to 35 g for 12 gauge and 24-26 g for 16 gauge. This is a significant drawback, since for a new batch of bullets you have to re-shoot the gun. When loading cartridges with the Vyatka bullet, you must remember that sending this bullet directly to the gunpowder is dangerous: the accuracy increases, however, but the pressure rises to dangerous levels, and the deformation of the bullets increases. The figure shows the Vyatka bullet after being fired with a cartridge in which there was no felt wad or spacer under the bullet. This is how some hunters load cartridges, believing that the plastic wad attached to the bullet is sufficient. With such equipment, the skirt of the seal, pressed by the high pressure of the powder gases to the walls of the cartridge case, is almost completely torn off from the shank, and the hot powder gases that broke into the head of the bullet burned a decent hole in it, at the same time melting the rod on which the seal is placed.

Loading cartridges with bullets having felt stabilizer shanks

(Jakana, Brenneke, second version of “BS”, etc.)

They do this: a powder cardboard wad is placed on the same charge of gunpowder as when equipped with Vyatka bullets. Due to the limited length of the cartridge case, only one felt, greasy main powder wad is sent to it, which is covered with a cardboard spacer cut into 4 parts. After this, a bullet selected for the gun is placed in the cartridge case and the barrel is rolled. There is an opinion that a plastic sleeve is preferable to a paper one. Capsule "Zhevelo". A significant drawback of these bullet cartridges is the lack of reliable sealing of the powder gases located in the space behind the projectile. This is due to the fact that the stabilizing wad for these bullets, due to strong axial compression and impaired elasticity of the felt, provides insufficient obturation of the powder gases, and the use of only one powder felt wad with a thickness of 7-10 mm is ineffective. However, in such cartridges, an increase in boost pressure, an improvement in the obturation of powder gases with a decrease in their muzzle pressure, an increase in the initial speed of the bullet by about 10% and an increase in the accuracy of the fire by 5-6 times can be achieved by using a polyethylene wad-obturator, which is placed on the gunpowder instead of a cardboard one. powder wad. When loading a batch of bullets, it should be taken into account that the height of the stabilizer wad should be the same for all bullets. All these arrow-type bullets have one common drawback - they are subject to deviations due to deformation of the shank and the asymmetry of the bullets, which was introduced during assembly, even with the most well-established technology. Therefore, stamped bullets will always be better than cast ones, and a shank mounted on a lead rod is less susceptible to distortion than one screwed on.

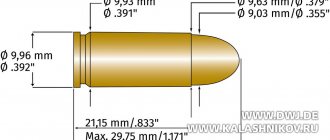

Features of equipment for Brenneke caliber and sub-caliber bullets

The Brenneke bullet has a diameter equal to the cylindrical part of the bore. The 12-gauge bullets we produce along the leading belt have a diameter of 18.5 mm. However, due to the internal cavity, this bullet is considered safe for shooting from shotguns with chokes. Over the years, the Brenneke bullet has not undergone significant design changes, but they are necessary. The fact is that it was created during the period of predominant use of black powder and was designed for initial speeds of 350-380 m/s. Currently, when the initial speed of a bullet reaches 450 m/s or more, the bullet undergoes significant deformation at the moment of firing, which leads to a decrease in the accuracy of the battle. The wad under the Brenneke bullet does not have the qualities that protect it from excessive deformation. The cardboard spacer between the bullet and the felt wad is too thin and does not always withstand the pressure that occurs when using smokeless powder. There have been cases of a felt wad being pressed together with a cardboard spacer into the internal cavity of the bullet. The height of the felt wad is insufficient. Such a wad does not protect the bullet from deformation and does not have the necessary obturating qualities. All this affects the accuracy of this bullet. Taking into account the fact that the domestic version of this bullet is made of soft lead, when equipping it, all techniques that reduce the deformation of the bullet should be used. To do this, first of all, you should reduce the charge of gunpowder (for 12 gauge by 0.1 g), shoot the bullet with Bars gunpowder, starting with a load of 1.9-2.0 g for 12 gauge. This gunpowder takes up a small volume and, when equipped, will allow the bullet to be sent with the shank not onto the shutter, but onto a greasy felt wad. When using Sokol gunpowder, do not weigh it in 12-gauge cartridges more than 2.25-2.35 g. It is advisable to use a polyethylene seal with a corresponding decrease in the powder charge by 0.2 g, and place a 2 mm thick cardboard spacer between the bullet and the felt wad. Some hunters believe that it is best to take 16-gauge Brenneke bullets as sub-caliber bullets for 12-gauge barrels, since their weight (32 g) is approximately the same as a light 12-gauge projectile. Lighter sub-caliber bullets sometimes worsen the burning conditions of Sokol powder, which results in defective shots. Such cartridges (for example, 12 gauge) are loaded as follows. They fill up the powder charge as usual, send in a cardboard and felt wad, and take, for example, a 16-caliber Brenneke bullet. Before placing it in the sleeve, a part of the tube is cut off from a 16-gauge paper sleeve with a height equal to the height of the metal part of the bullet and cut along the axis into four parts, three of which are placed around the bullet head. Since the wad of a domestically produced 16-gauge Brenneke bullet matches the internal diameter of a 12-gauge case very well, such a bullet with facings is sent into the case and twisted.

| Loading cartridges with the Stöndebach “Ideal” bullet and the first version of the Sokolov brothers’ bullet The powder cardboard and felt main salted powder, additional dry wads and a cardboard spacer are sent to the gunpowder in such a way that the total height of the wads and spacers allows, after inserting the bullet, to leave a free edge of the barrel for twisting or crimping with an “asterisk”. |

Mayer double caliber turbine bullet

Its equipment is the most complex compared to others, however, the success of shooting with this bullet requires strict adherence to the author’s recommendations when equipping. For 12-gauge cartridges, 2.0 g (!) of “Falcon” gunpowder is poured into a paper sleeve with a “Zhevelo” capsule (with a bullet weight of 33 g and at a temperature not lower than -4 ° C); gunpowder is compressed with a force of 4-5 kg. It makes sense to increase the amount of gunpowder at temperatures of -20°C and below. A cardboard powder wad 2.5-3.0 mm thick in a monolith or a set of thinner wads of the same thickness is placed on the gunpowder. Then the main greasy felt wad, half the caliber of the bore, cut through the center along the height into four parts. A layer of dry, not very fine sawdust is poured onto the felt wad so that, after compressing it, all other components can be placed in the sleeve and closed by rolling. A cardboard spacer 0.6-0.7 mm thick is placed on the sawdust, and on it is a monolithic cardboard spacer wad about 3 mm thick, the diameter of which is equal to the diameter of the bullet base body without guide inclined ribs-blades. This wad is placed in the center of the cartridge channel and a bullet is placed on it, after which the barrel is well rolled at the cartridge case so that its end rests against the annular leading belt on the head of the bullet. A.K. Mayer uses a split felt wad and sawdust in order to prevent the wad from hitting the bullet when it leaves the barrel, and places a dense and thick cardboard wad pad to prevent the bullet from cutting into a thin cardboard pad, which can shot to clog the axial channel of the bullet and thereby disrupt its turbine action.

When loading bullet cartridges, you need to remember: having selected the most suitable bullet for your gun, you should use it all the time, taking into account the possibility of making it at home or purchasing a large number of identical high-quality bullets from one batch at once.

When equipping a Mayer bullet, you must not confuse the top and base of the bullet, since such errors exist even in some manuals. Firstly, like all arrow bullets (except Blondeau), the weight of the Mayer bullet is shifted towards its head. Secondly, the through conical channel with inclined ribs has a larger base at the head of the bullet. The center of gravity of the Mayer bullet is approximately a third of the distance from the head. With proper equipment, the cartridges provide a dispersion diameter of 10 cm at 35 m, and 25 cm at 100 m. It should be noted that this dispersion diameter can only be obtained by manufacturing bullets exactly according to the recommendations set out in the article by A. Mayer “New bullet for smoothbore guns” "(ОиОХ, ?9, 1965). In the factory cartridges with the Mayer bullet, equipped with TOZ, judging by the article by V. Klyuchnikov (OiOKH, No. 11, 1989), a strong deviation was made from the recommendations of the author of the bullet, and the results of shots with these cartridges are clearly unsatisfactory. Conclusion: it is better for the hunter to equip cartridges with this bullet himself.

Mayer double-turbine sabot bullet

It is most advisable to use a sabot bullet in light guns, say 2.9-3.0 kg with a 12 gauge, since with this bullet and the loading method described above, the pressure in the barrel is not great. The weight of 16-gauge bullets is 27-28 g. For equipment, a polyethylene wad-concentrator with cut petals is used, into which the bullet is placed. The best equipment option would be Mayer's recommendation. Some hunters use a plastic shock absorber wad from a polyethylene wad container, placing it on the powder, and on top of it is a felt wad filler 7 mm high. In this case, it is better to take the weight of Sokol gunpowder 1.9 g.

Bullet "Kirovchanka"

Popular hunting guides do not recommend using this bullet due to its low aerodynamic qualities. However, V. Borodin (OiOKh, No. 12, 1989) considers this bullet more preferable than the Mayer sub-caliber bullet due to its greater destructive power. The bullet is produced in 12 gauge in a factory container, the weight of the bullet is 29 g, the weight of the container is 4 g. The main disadvantage of the bullet is the deformation in the barrel of both the container and the bullet itself. In our opinion, it is possible to protect the bullet from this deformation, given its considerable length, only by reducing the powder charge to 1.8-1.9 g (Falcon gunpowder) with this method of equipment. A plastic wad-shock absorber from a polyethylene wad-container is placed on the gunpowder, a thin felt pad is placed on it, and a container with a bullet is placed on top. The paper sleeve is rolled.

Polev's bullet

The easiest way to load cartridges with a Polev bullet: the bullet in a container and with a wad-stabilizer is sent directly to the gunpowder (Fig. 63). The weight of a 12-gauge bullet is 31.5 g, of which 2 g is for the container, and 3 g is for the stabilizer wad. The weight of “Falcon” gunpowder for a 12-gauge cartridge is 2.2 g (for guns weighing 2.9-3.0 kg - 2.1 g). In no case should you increase the charge of gunpowder for a Polev bullet: thanks to the powerful seal, the Polev bullet significantly increases the pressure in the barrel. Thus, already with the Sokol weighed at 2.4 g, the average maximum pressure jumps to 750 kgf/cm2 instead of the permissible 663 kgf/cm2. For 16-gauge cartridges, the charge of Sokol gunpowder is 1.8-1.9 g. When determining the charge size, we recommend focusing on charges with polyethylene wad seals. Capsule "Zhevelo". V. Polev gives the following recommendations on equipment. “When using plastic cartridges, the head should be inserted all the way, and it will push the lobes of the container apart, the projectile will enter the sleeve with tension and can be held without rolling the barrel neck. This will allow the sleeve to be used multiple times. When using the sleeve repeatedly, however, it is necessary to ensure that its length does not increase beyond 70 mm. Rolling a plastic sleeve longer than 70 mm impairs the accuracy of shooting a bullet from a gun with chambers 70 mm long.” Many manuals recommend using rolled plastic sleeves. Rolling a paper cartridge does not affect the accuracy of fire. It is necessary to pay attention to the correct installation of the container: so that one or both of its parts are not turned over to the other side (see carefully the figure in the equipment manual). If the Polev bullet container fits freely into the cartridge case, such bullets cannot be used: combat performance will be significantly reduced due to poor sealing. The Polev bullet container must fit into the plastic (paper) sleeve with an interference fit. The third model of the Polev bullet (with an expansive void) is significantly superior to other models of bullets available to hunters in terms of accuracy, range, and damaging effect, but, like any expansive bullet, it is afraid of dense thickets.

Hunter V. Karpov upgraded the 16-gauge Polev bullet to a 20-gauge bullet for firing from the MTs20-01. At the same time, the diameter of the bullet (14.4 mm) remained the same, and the diameter of the wad seal was reduced on a lathe to 15.6 mm with the removal of the seal skirt. The 16-gauge Polev bullet, after upgrading to 20-gauge, weighs 24.55 g, including 2.15 g for the plastic stabilizer. For insurance, each bullet is driven through calibers 14.5 mm - lead part, 15.6 mm - plastic. The lead purity of the bullet itself is fixed in the stabilizer to the base, and not as when equipping standard bullets with some clearance. The method of loading such a cartridge is: paper sleeve, “Zhevelo-Powerful” capsule, “Falcon” gunpowder weighed 1.7g in summer, 1.8g in winter, polyethylene powder wad. The side surface of the wad is oiled for any season. The wad is sent to the gunpowder with a force of up to 10 kg. Then a 5-mm felt wad is sent, cut out with a die cutter with a diameter of 15.8 mm, which is also greased around the circumference to a depth of 3 mm and sent into the sleeve with the same force. By inserting a felt wad, improvement of obturation, shock absorption, raising the bullet to the height necessary for rolling the cartridge case is achieved, reducing the impact after the powder wad leaves the barrel to the bottom of the bullet. Instead of plastic petals, liter kefir packaging is used as a carrier (concentrator) of the bullet in the barrel. The dimensions of one petal (two in total) are 19x22 mm so that the carrier fits tightly to the leading edge of the stabilizer and extends to the cutting level of the bullet head. Having inserted the stabilizer into the cartridge case, cover the bullet with petals and lower it until it stops on a felt wad. The bullet is sent to its place with a pestle with felt glued to the end so as not to deform the top of the bullet and not to disturb its streamlining. For better rolling, the cut of the sleeve is wiped with paraffin. The twist is made with a funnel in the center for the bullet head to fit into. The loaded cartridge is driven through a 17.0 mm caliber. At a distance of 100 m from the MTs20-01 with an optical sight, the dispersion diameter of the bullets was 12 cm.

Bullet "Arrow"

The equipment is similar to that for the Polev bullet - the bullet in the container is sent directly to the gunpowder. The “Falcon” powder weights and bullet weights for the 12th and 16th calibers are 2.2 g and 1.75 g of gunpowder, respectively, and 32+1 g and 28+1 g. The equipment is given in more detail when describing the bullet.

Bullet "Diabolo" (Gorbantes)

Loaded into a paper or plastic sleeve, Zhevelo capsule; the mass of Sokol gunpowder, which is indicated in the instructions or on the can and is the maximum for a given batch, should be reduced by 0.2 g when using cartridges in summer and by 0.1 g when using cartridges in winter. A cardboard (thick) gasket 2.5-3 mm thick is sent to the gunpowder; the diameter of the gasket must be 0.1 mm larger than the inner diameter of the sleeve; a felt wad with a thickness of 13-15 mm and an additional felt wad of the required thickness (can be cut along the diameter into four equal parts, folded along the cut lines and inserted into the sleeve); cardboard spacer 0.3-0.5 mm thick. With a polyethylene wad, the weight of Sokol gunpowder is 2.2 g. Turn the bullet with the shank up and fill the cavity with dry, small sawdust, compacting it with your finger. The sawdust serves as a shock absorber during a shot and prevents the wad from “sticking” into the shank of the bullet. Sawdust can be replaced with cork chips. You should not fill the shank cavity with wax or paraffin. To prevent sawdust from spilling out, the cartridge case should be put on the shank from above until the bullet stops in the wad. Then the cartridge case is rolled.

Cap bullets

In recent years, these bullets have become popular among hunters both due to their ease of manufacture (from lead battery plates) and due to their good stopping effect. When it hits the body of an animal, the wounds are large due to the deformation of the bullet - the expansion of the body of the skirt. Equipping cartridges with cap bullets is almost no different from equipping the Diabolo bullet (see above), which is also essentially a cap bullet. 12-gauge bullets should be loaded into new paper cartridges as follows: smokeless powder “Falcon” - 2.3 g, a polyethylene wad-obturator (cut off bottom from the wad-container), two cardboard pads with a total thickness of 3 m, two soft felt wads (the lower greased ), the thickness of all wads should ensure that the height of the cartridge case neck for the twist is approximately 5 mm, the cardboard spacer is 0.5 mm thick, the bullet itself, the cartridge case is rolled. Before loading, the bullet cavity is filled with cork chips, wood (dry) sawdust, or filled with sealing wax and paraffin to prevent the wad from being pressed into the bullet. Based on the experience of many hunters, it has been established that a decrease in the gunpowder charge reduces the accuracy of the shot, and with an increase in the gunpowder charge, the deformation of the bullet increases. The best results for shooting with a cap bullet are shown from guns with vertically positioned cylindrical drill barrels. When firing from an IZH-27 gun at a distance of 50 m from a rest, the dispersion of 10 bullets does not exceed 13 cm. All holes are round in shape.

Bullet "Blondeau"

First of all, you need to match the diameter of the bullet with the diameter of the narrowing of the bore. Then, 2.2-2.4 g of Sokol gunpowder is poured into a 12-gauge cartridge case, preferably plastic, but paper can also be used, then a greasy polyethylene seal, then a greasy felt wad 7 mm high, and an additional wad on it. The wads are cut into 4 parts, but not completely. Some hunters place 1-2 thin cardboard spacers between the plastic shutter and the felt wad to ensure a sure shot in case the shutter is destroyed. The column of wads and spacers should be 10-12 mm so that there is sufficient space for rolling the sleeve.

The Blondeau bullet creates higher pressures at the moment of firing than lead bullets. For this reason, you need to very carefully and gradually move from 2.2 g of Sokol gunpowder to 2.3 and 2.4 g, but not more than 2.5 g. The criterion for assessing sufficient initial speed can be the nature of the holes at 80-90 m. If the holes are from bullets have a round or slightly oval shape, the initial speed is sufficient and further increase in the amount of gunpowder does not make sense. You can achieve a reduction in the maximum pressure when firing Blondeau bullets by selecting shock-absorbing wads. For example, gluing thin cardboard and felt wads together until the desired height is achieved. For gluing, use rubber glue in small quantities. The Blondeau bullet gives the best results in terms of combat accuracy when the cartridges are loaded with French T-1 and T-2 gunpowders. Equipment is carried out as follows: a plastic sealing wad with a fairly high sealing side (about 3 mm) is placed on the gunpowder, followed by a shock-absorbing wad (it also plays the role of a filler wad) made of dense felt, slightly impregnated with a special composition, then a Blondeau bullet. The sleeve is twisted. When weighing T-2 gunpowder 2.6 g for 12 gauge, the initial bullet speed is approximately 460 m/s. At this initial speed, the bullet remains stabilized up to the 90-100 m mark. The original 12 gauge Blondeau bullet weighs 32.6 g; 16 gauge - 29.1 g. Deviations from the average weight are no more than 0.05 g. The weight of a 20 gauge bullet is in the range of 25.5-25.7 g.

Currently, hunters, making their own Blondeau bullet, are trying to simplify its production while maintaining ballistic qualities. Of the many proposals, the most promising are the removal of the lead sealing bands and placing the bullet in a plastic container. Thus, hunter V. Blokhin (ОиОХ, no. 11, 1991) places the head part of a Blondeau bullet in a polyethylene container cut along the longitudinal axis into two parts, having 12 longitudinal ribs, and a polyethylene wad seal with an obturating skirt is rigidly screwed to the tail part. (The bullet is machined from brass, bronze or steel). To increase and adjust the weight, lead is poured into the axial channel with an MB thread in the bullet version. The weight of a 12-gauge brass bullet assembled with a wad-stabilizer is 32-32.2 g, container weight is 1 g. When loading a cartridge, such a bullet drops directly onto the gunpowder. When flying out of the barrel, the halves of the container fly apart, and the wad-stabilizer, moving with the bullet, helps to better stabilize it in flight. The weight of Sokol gunpowder when equipped is reduced by 0.2 g (12 gauge) compared to that specified in the instructions for this batch. The seals are made of polyethylene.

Rubeykin's bullet

To equip cartridges with a Rubeykin bullet, like any other non-deformable bullet made of steel, bronze or brass, an indispensable condition is that the diameter of the bullet matches the diameter of the bore. It is advisable to recall that the tolerance on the bore diameter is +0.2 mm, which, with nominal differences in the production of barrels at our enterprises of +0.3 mm, determines a possible difference of +0.5 mm. Therefore, with the correct equipment of the Rubeykin bullet, it is necessary:

- coordinate the diameter of the container with the bullet with the diameter of the bore; in this case, burrs must be removed, partially stiffening ribs that prevent the free placement of the bullet;

- separate the seal from the container and remove the jumpers connecting them; a wad made integral with the container should not be used, since when fired, due to the relative lateral displacement of the shutter and container during the aftereffect of the gases, conditions are created that violate the stability of the bullet;

- cut the container with the connecting jumpers removed lengthwise into two parts. This ends the preparatory and most labor-intensive operations. Next comes the actual equipment.

2.2-2.4 g of Sokol gunpowder (depending on the batch of gunpowder) is poured into a cartridge case, preferably a plastic one. A plastic seal is applied to it with a force of 5-6 kg. A set of thin cardboard spacers with a total thickness of 2 mm is installed on it. This helps to avoid “wild” shots associated with the destruction of the shutter when fired. — Plastic seals with a central hole should not be used, because most of them are destroyed by increased charges of gunpowder, and one cannot expect a good fight. One, preferably a wood-fiber wad, is placed on the spacers; if you use felt, it should be soft, and it should be cut lengthwise into 4 parts to soften the impact of the bullet during the aftereffect period. A set of thin cardboard spacers with a total thickness of 1 mm is placed on top of the wad. The thickness of all wads should ensure that the height of the sleeve neck for the twist is approximately 5 mm. Then the halves of the container are folded together, a bullet is inserted and all this, without distortions or mutual displacements, is sent into the sleeve and rolled without undue effort with a regular twist. The petals of the container should not protrude above the bullet; the protruding part must be cut off. Following these basic rules will ensure an accurate shot.

Bubliya and Pasechny bullets

These bullets of a similar design are improved versions of the Rubeykin bullet by inserting lead inserts into the head of the bullet. The main condition for equipment, as for all non-deformable bullets, is matching the diameter of the bullet container with the internal diameter of the barrel. Equipment details are given in the bullet description.

Steel bullet with Alexandrov aerodynamic tip

It is an improved version of the Witzleben pointer bullet with a plastic shank and an aerodynamic tip that extends during the firing process. The weight of a 12-gauge bullet is 35 g, and the weight of the steel striking element is 32 g. When loaded, the bullet should be placed in the case directly on the gunpowder. Centering the steel striking element, a ring cut into two parts should be inserted between the cartridge case and the bullet and secured with the rolled edges of the cartridge case. The recommended amount of Sokol gunpowder for a hunter’s existing batch should be reduced by 0.15 g for guns weighing 3.3 kg or less. A plastic case is preferable; the bullet is placed directly on the gunpowder. The maximum pressure of the powder gases in the chamber will be 412-548 kgf/cm2, and the bullet speed 50 m from the muzzle of the gun will be 294-304 m/s. The dispersion diameter is no more than 12 cm. For guns weighing more than 3.3 kg, including the MTs21-12 self-loading gun, the Sokol powder weight should be left unchanged. The speed at a distance of 50 m will be equal to 323-33 m/s, and the pressure will be in the range of 505-659 kgf/cm2. The bullet dispersion diameter will be no more than 15 cm. Bullet manufacturers recommend using the bullet in guns with choke constrictions of no more than 1 mm. But since the diameter of the striking steel element of the bullet and the diameter of the centering split ring assembled with the bullet (OiOKh, No. 10, 1994) are not given, before loading it is necessary to check that the diameter of the ring assembly is consistent with the diameter of the bore. The bullet is recommended for hunting in thickets, especially for wild boar and bear.

Should I use a container or not?

Another question that faces beginners who want to know how to properly load 16-gauge ammunition is the container. Or rather, the justification for its use.

It is a small plastic container that is inserted into the cartridge case after the gunpowder is poured. Shot or buckshot is already poured into it. Of course, its use increases the cost of a homemade cartridge - by 2-3 rubles. It would seem like a small thing. But if you need to load a hundred rounds of ammunition in a row, then the increase in cost is already noticeable. And the question arises: is it necessary to use containers at all?

It really depends on the goal. After all, the container increases the range of a shot or buckshot by 10-30 meters, and at the same time provides greater accuracy over a long distance. Sometimes this is very useful. And in other cases, increased accuracy, on the contrary, is undesirable. For example, if you are shooting at ducks flying at an altitude of 20-30 meters. At such a distance, when shooting with a container, the shot, even small ones, does not have time to scatter and goes in a heap, almost like a bullet. Of course, hitting a small, fast-moving target becomes much more difficult.

So, it is impossible to give a clear answer to the question of how to load 16-gauge cartridges - with or without a container. Experiment and draw appropriate conclusions.

About choosing a work space

Before you begin the procedure, you need to prepare your workplace. The quality of homemade cartridges will also depend on a well-prepared room. It is best to work in a garage, shed or workshop. When choosing a room, consider the following requirements:

- It is important that this room has as limited access as possible. In other words, so that strangers and children cannot get here.

- The room must have dry air. Otherwise, the gunpowder will become damp.

- It will be much more convenient for you to work on a special workbench with key-locked drawers.

Device for capsules

Many people refuse to use devices for removing and installing primers, considering it a waste of money. Instead, they knock out the spent primer with a homemade device. Often made of wood with a needle inserted, after which a new one is installed, driving it in with a hammer with precision. Of course, this allows you to reduce costs when purchasing equipment.

But still, a special device greatly simplifies the work. It becomes easier to remove the primer, and the risk of damaging the bottom of the cartridge case (if a centrifugal primer is used) is reduced. Moreover, it makes it easier to install the capsule - it only takes a second or two. There is no risk of the capsule exploding due to a careless blow with a hammer. So, if possible, it is still worth purchasing this useful device. Many hunters who independently load 16-gauge cartridges leave mostly positive reviews about it.

Brass sleeves or plastic?

But this is a very important question. The answer depends on both the hunter's habits and the weapon used.

For example, if you prefer a classic single-barreled or double-barreled weapon, then the use of brass cartridges is completely justified. Yes, they cost tens of times more than plastic ones, but they can be charged several hundred times, while plastic ones rarely survive two or three charges. But if you are using a semi-automatic weapon that ejects shell casings, then it would be better to use plastic ones. After all, it will be very difficult to find brass ones, standing in thick grass or knee-deep water. Accordingly, such an important advantage as repeated use is no longer so significant. Of course, you can use a special pocket into which spent cartridges fall. But it gets in the way a lot - it clings to branches and equipment, which can cause a moment’s delay, and this is extremely undesirable when hunting.

So, when buying cartridges, decide for yourself which option is more acceptable for you.

Selecting the damaging element

In stores you can see one and a half dozen types of shot, varying in size, a dozen types of buckshot and about 2-3 dozen bullets. We will leave the latter for discussion among specialists, because disputes on this issue have not faded away for many decades. Some discuss the advantages and disadvantages of different options (“Poleva”, “Brenneke”, “Sputnik”, “Foster” and many others). Others believe that any bullet in a 16-caliber cartridge behaves approximately the same - it all depends on the skill of the shooter.

But with shot and buckshot everything is simpler. They need to be selected depending on what specific prey you are going for. Is your target snipe or woodcock? Take the smallest shot - from 7 to 9. Do you hunt black grouse and duck? It is better to choose a larger fraction - 4-6. To confidently hit a hare - from 2 to 00. Do you want to tickle your nerves and go hunting for a wild boar or deer? In this case, buckshot shows itself well, and preferably larger ones.

What shot to shoot a duck with a gun

Ducks can be hunted in spring, summer, and autumn. However, due to the seasonal characteristics of the structure of birds, methods and methods of hunting, cartridges should be equipped differently.

It is very important during any hunt not to leave wounded animals behind.

In duck shooting, this happens not only from poor shooting skills, but also from an incorrectly loaded cartridge, from not knowing which shot is suitable for different types of ducks and different seasons. Ducks are usually hunted with 16 and 12 gauge shotguns. The shot used, depending on the size of the duck and the season, is from No. 7 to No. 4.

But how to correctly determine the fraction number? The hunting season can be divided into three periods:

- the first - immediately after the opening of the hunting season until the end of August;

- second – September;

- third – October – season closing.

Accordingly, with each period the size of the pellets should be increased by one unit.

After all, waterfowl are gaining more and more fat, acquiring down and strong feathers. The question arises, which shot is better for hunting. Usually for small ducks - teal - take No. 7, for mallards and some diving ducks - No. 5.

To hit sessile birds, a cartridge with a compact firing pattern is required with sufficient concentration of pellets towards the center.

With a smaller number of pellets, it is much easier to achieve such indicators. But in order to kill a bird in flight, another condition must be met - a uniform scattering of pellets with sufficient accuracy. The choice of which shot to shoot ducks is determined not only by the type of waterfowl, but also by the distance from which you have to shoot.

So, if immediately after the opening of the hunting season, when the duck is still not frightened and allows the hunter to come to a close distance (up to 20 meters), you can shoot with shot No. 7. A distance of 50 meters requires an A+.

Also, for shooting over long distances, it is necessary to take not only a more powerful shot, but also a larger portion of the shot in the cartridge. 12 gauge cartridges are divided into the following categories based on the shot load:

- light - ≤ 28 grams;

The order of loading cartridges

Now we’ll briefly tell you how to load 16-gauge cartridges.

Are you using an old sleeve? Knock out the primer and clean the anvil (if there is one, the Zhevelo primer cartridges do not have one). If new, then feel free to skip this step.

Insert a new capsule - preferably using special equipment. Now pour in the gunpowder - using a measuring stick or carefully measuring each grain on the scale - it's your choice. Next is the wad – thick, made of felt or pressed sawdust. But if you use a container, you can do without it - plastic solves this problem.

Then the shot is filled in or the bullet is installed. Now it all depends on the type of sleeve: either a finishing paper wad (when using brass ones), or twisting on a machine (when working with plastic ones). When working with brass, all that remains is to fill the sleeve with wax or paraffin and everything is ready - you can go hunting!

Some hunters go even further

Some hunters go even further and suggest shooting bullets fired directly onto gunpowder - without any wads at all. Moscow hunter V. Staroe made bullets of approximately the same type that were used in ramrod rifled weapons of the mid-19th century, and presented them to the authors of this book. According to his proposal, the cartridges were equipped as follows: the cartridge case was paper, the capsule was “Zhevelo-M”; gunpowder "Falcon" - 2.5 g; a bullet weighing 33-33.5 g was sent directly to the gunpowder; the sleeves were not rolled. The authors of the book loaded another series of cartridges with the Falcon weight reduced to 2.3 g.

First, the cartridges were fired on a ballistic barrel; 6 shots were fired with cartridges from each series. The cartridges of the first series, that is, with 2.5 g of “Falcon”, gave maximum pressures (Pm) of 607-1137 kgf/cm²; speeds 10m from the muzzle (V10) were 354-406 m/s. The cartridges of the second series (with 2.3g "Falcon") gave Pm 571-1045 kgf/cm2, V10 - 341-393 m/s.

Then the cartridges were shot from the lower barrel of the IZH-27 with a drill bit; distance - 50 m, temperature - 17°C; shooting was carried out while sitting, from a rest position. The cartridges of the first series of 5 shots gave a spread of 29.5 cm; 4 bullets fit into a circle with a diameter of 10 cm; two bullets hit the target flat. With three shots, pieces of torn cartridge tubes flew out of the barrel along with the bullets; 4 cartridges were torn lengthwise; two have their heads torn off; Only one cartridge was intact. The cartridges of the second series gave a spread of 45 cm; 4 bullets fit into a circle with a diameter of 14 cm; 4 bullets hit the target flat; The head of one cartridge was torn off. This shooting did not yield anything new, confirming what has long been known: the absence of the shock-absorbing effect of the wads sharply increases the pressure in the barrel.

Everything that has been said irrefutably indicates that each bullet works well only in the form in which it was created by the designer, and in the conditions for which it was designed. Therefore, we strongly discourage hunters from “improving” known bullet types or shooting unknown bullet designs. This does not do anything good, and can even become (and sometimes does become) the cause of swelling or rupture of the barrel.