Among the variety of small arms that were used by Soviet troops in World War II, not a single type of weapon received such controversial assessments as the SVT-40 automatic rifle. Most experts have a not very flattering opinion about this weapon. It is believed that this rifle was unsuccessful, which is why it was discontinued.

The release of SVT-40 occurred during wartime, when product quality receded into the background, and quantity and manufacturability of production became the main thing. Perhaps, if not for the war, this weapon could have been improved and its shortcomings eliminated. In addition, not everyone who has had the opportunity to use this weapon speaks negatively about it.

The cause of the problems of this type of weapon is the overly powerful rifle cartridge, which is what led to the excessive weight of the weapon.

It should also be noted that the Tokarev self-loading rifle was a desired trophy for our opponents, the Germans and Finns, and they were well versed in small arms. Only two countries in the world entered the war armed with a serial self-loading rifle - the USA and the USSR. For the Americans it was the M1 Garand, and for the Soviet Union it was the Tokarev rifle. Moreover, in the USSR they made a serial automatic rifle earlier than in America.

What preceded the creation

The idea of creating an automatic weapon from an ordinary gun appeared a long time ago. Humanity turned more closely to this idea towards the end of the 19th century. But all developments ended with the creation of experimental samples that did not meet the requirements.

The Russian Empire was no exception; similar work was carried out on its territory. Fedor Vasilyevich Tokarev (1871 - 1968), was one of the founders of these projects.

At the time of providing his first developments, he was a centurion of the 12th Don Cossack Regiment, a self-taught former gunsmith. This happened in 1908, while studying at the Officer School near St. Petersburg. The model was created on the basis of a three-line magazine rifle; the automated system functioned based on the principles of barrel recoil.

The barrel bore was locked by closing the bolt. The rifle had a non-removable magazine, which means that it is not considered the predecessor of the SVT-40.

The subsequent years of the history of the Russian Empire and the Soviet Union were disastrous for its economy and were not conducive to technical development.

The culprits were the following historical events:

- World War I.

- Revolution of 1917.

- Civil War.

- Years of devastation and hunger.

Only after the relative restoration of the young republic, development was continued in the mid-30s of the last century. During this period, the Red Army was armed with the ABC-36, a Simonov automatic rifle that had a number of shortcomings.

Based on this, a decision is made to replace it with a new, more advanced model. A competition is announced, in which Simonov, Tokarev, and Rukavishnikov take part. Fedor Vasilievich presented his new development, which later received the marking SVT-38. The rifle, in comparison with its analogues, was smaller in size and had a simple design, this was the reason for its victory over its competitors.

One should not miss the fact that Tokarev was personally acquainted with the Supreme Commander-in-Chief; the names of other designers were not known to Stalin.

Serial production was launched at the arms factory in Tula, the first copy appeared on July 16, 1939. Just 1 year later, Tokarev received instructions to improve his rifle.

The outbreak of the Finnish War and exploitation in combat conditions identified the following shortcomings:

- Heavy weight.

- Frequent and obligatory need to lubricate mechanisms.

- Vagaries when particles of dirt get in.

- Refusal to work in cold weather.

The Design Bureau, headed by Tokarev, modernizes the SVT-38 rifle, eliminating the discovered deficiencies and presents the Defense Committee with a new model, the SVT-40.

Subsequently, for his technical developments, Tokarev was awarded the title of Hero of the Soviet Union, became a Doctor of Technical Sciences and received the Stalin Prize.

He dreamed about this all his life

Among the enthusiasts working in this direction was the young gunsmith Fedor Tokarev . The novice designer presented his first version, which involved remaking the Mosin rifle, in 1908.

Having received approval, Tokarev continued his work, but did not have time to complete it before the outbreak of the First World War. The master returned to designing weapons in 1921, at the Tula Arms Factory.

In subsequent years, Fedor Tokarev created a huge number of different types of weapons, including the famous TT pistol. But the project of a self-loading rifle could not be brought to mass production.

Video: Provided by Kalashnikov.Media

History of SVT-40

On April 13, 1940, the SVT-40 rifle, by order of the Defense Committee, was adopted for service; however, while all this was happening on documents. At enterprises that were previously involved in the production of models of the 1938 model, production was suspended and it was quite difficult to organize mass production of the new model.

Due to the aggravation of the situation in Europe and the growing momentum of the Second World War, a lot of money and effort was spent on rearmament of the Red Army. Another plant is opening, located in Izhevsk. The number of weapons produced on it is amazing; in just 3.5 months of one year, the manufacturer produced more than 30,000 rifles of this type.

After the Great Patriotic War began, production increased significantly. In the first year of hostilities alone, more than 1 million rifles were collected. However. The quality of production and service life during this time decreased significantly. Adult professionals from factories went to the front, and inexperienced women and children took their place. As for the soldier composition, dramatic changes have also taken place here.

Instead of dying soldiers who had combat experience in the Civil, Finnish and even the First World Wars, rural residents or workers who had never held a weapon in their hands came. Many of them did not even suspect that the rifle needed to be periodically cleaned and lubricated, especially since the resulting rifle needed competent maintenance and careful care. Thus, due to the decline in qualified specialists in production and in the army, weapons often failed.

This is not the fault of ordinary soldiers.

The fact is that, provided the recruit was technically competent, he ended up in tank or other mechanized forces.

Citizens who had no training were predominantly selected for the infantry. At the same time, the training period for future soldiers did not allow them to fully master the skills of using SVP.

general description

The Tokarev automatic rifle of the 1940 model worked on the principle of using powder gas, discharged from the barrel bore through a hole near the front sight and pushing out the piston.

The piston was not integral with the bolt, but was simply a pusher. A regulator installed in the gas chamber determined the amount of gas removed from the barrel to move the piston. Thus, the weapon was adapted to environmental conditions, types of ammunition and the technical condition of the mechanisms. Now this seems unnecessary, but in those years it seemed simply necessary.

The bolt receives an impulse thanks to the gas piston moving backwards; it is driven back into the reverse position by a return spring. The channel in the barrel was locked by a skewed bolt, consisting of a firing pin and a mechanism designed to eject empty cartridges.

The SVT magazine is box-shaped, double-row, with a capacity of 10 rounds. It can be reloaded without removing it, using 2 classic clips from a Mosin rifle.

The sighting device consists of a front sight mounted on the SVT 40 muzzle and a rear sight, adjustable depending on the shot range.

Trigger mechanism

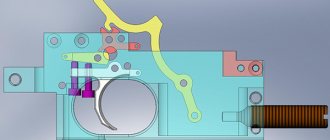

30. Trigger mechanism

(Fig. 29) consists of a trigger guard, hammer, automatic trigger, automatic trigger axis, automatic trigger spring, mainspring guide rod, guide rod support pin, mainspring, rocker arm, trigger, trigger axis, trigger rod, trigger spring pull rod, trigger rod spring pin, safety catch, safety stop spring, safety spring slide, magazine latch, magazine latch spring, and magazine latch pin.

Rice. 29. Trigger mechanism:

1 — trigger guard; 2 - trigger; 3 — automatic descent; 4 — automatic descent axis; 5 — automatic release spring; 6 — guide rod; 7 - support pin; 8 — mainspring; 9 — rocker arm; 10 — trigger; 11 — trigger axis; 12 — trigger rod; 13 — trigger rod spring; 14 — spring pin; 15 - fuse; 16 — fuse stopper spring; 17 - valve; 18 — magazine latch; 19 — magazine latch spring; 20 - latch axis

31. Trigger guard

(Fig. 30) serves to connect parts of the trigger mechanism. It has: trunnions for connecting to the receiver; cross cut for latch tooth; front cutout for magazine latch; hole for the latch axis; hole for the automatic release axis; cutouts for rocker arm journals; hole for the trigger rod spring pin; longitudinal cutout for the trigger rod spring; hole for the trigger axis; channel for the fuse rod; groove for the fuse spring bolt; vertical hole for fuse stopper; trigger window; cutouts for trigger pins; socket for the magazine release spring and socket for the automatic release spring.

Rice. 30. Trigger guard:

1 - axles; 2 - transverse cutout; 3 - front cutout; 4 — hole for the latch axis; 5 — hole for the automatic release axis; 6 — cutouts for rocker arm journals; 7 - pin; 8 — longitudinal cutout; 9 — hole for the hook axis; 10 - channel for fuse; 11 — groove for the valve; 12 - vertical hole; 13 - window; 14 — cutouts for the trigger

32. Trigger

(Fig. 31) serves to strike the striker. It has: trunnions for connection with the trigger guard; automatic cocking for connection with automatic release; combat platoon for connection with the rocker sear; longitudinal cutout and pin for connection with the guide rod of the mainspring; a head for striking the striker; the comb of the head for striking the bolt stem when the bolt is not closed, thereby eliminating the possibility of a premature shot.

Rice. 31. Trigger:

1 - axles; 2 - automatic platoon; 3 - combat platoon; 4 - longitudinal cutout; 5 - pin; 6 - head with comb

33. Guide rod

(Fig. 32) serves to direct the mainspring and open the trigger rod with the rocker arm. It has: a head with a cutout for connection to the trigger; an annular protrusion for resting the end of the mainspring; a cut for lowering the trigger rod when cocking the hammer; a lower cutout that allows the front end of the trigger rod to rise upward and separates the trigger rod from the rocker arm with its rear cut when the trigger is released; side cuts for passage into the oval hole of the rocker.

Rice. 32. Guide rod:

1 - head; 2 - cutout; 3 - annular protrusion; 4 - cut; 5 - lower cutout; 6 - side cuts

34. Automatic release

(Fig. 33) serves to protect the trigger from being cocked when the bolt is not closed. It has: a hole for the axle; protrusion for connecting to the trigger; tide for automatic descent disconnector; socket for the self-timer spring stop.

Rice. 33. Automatic release:

1 — hole for the axle; 2 - protrusion; 3 - tide; 4 - socket; 5 - spring

35. Rocker

(Fig. 34) serves to keep the trigger cocked. It has: trunnions for connection with the trigger guard; sear for cocking the hammer; lower cutout for passage of the end of the trigger rod; an oval hole for the passage of the mainspring guide rod; a socket for resting the end of the mainspring and a transverse ledge for the protrusion of the trigger rod.

Rice. 34. Rocker:

1 - axles; 2 - sear; 3 - lower cutout; 4 - oval hole; 5 - socket; 6 - transverse ledge

36. Trigger rod

(Fig. 35) serves to release the hammer cocking from the rocker sear. It has: a front flat end for passage into the rocker cutout; a stand on which the mainspring guide rod acts and lowers the trigger rod down; a protrusion for acting on the ledge of the rocker and a curved end for connection with the trigger.

Rice. 35. Trigger rod:

1 - front flat end; 2 - stand; 3 - protrusion; 4 - bent end

37. Trigger

(Fig. 36) serves to activate parts of the trigger mechanism. It has: a head for connecting to the trigger rod; axle hole; a cutout for the passage of the long feather of the trigger rod spring and a tail for acting on it with a finger.

Rice. 36. Trigger:

1 - head; 2 — hole for the axle; 3 — cutout for the spring; 4 - tail

38. Trigger rod spring

(Fig. 37) moves the front end of the trigger upward and the tail of the trigger forward. It has: a curved short feather for acting on the trigger rod; a long feather to move the tail of the trigger forward; curved end for a pin that holds the spring from longitudinal displacement in the trigger guard.

Rice. 37. Trigger rod spring:

1 - curved short feather; 2 - long feather; 3 - curved end

39. Trigger safety

(Fig. 38) serves to protect against accidental shooting. It has: a rod for connecting to the trigger guard; a flag that limits the movement of the trigger back when the safety catch is released; protrusion of the head to limit rotation of the fuse; a cutout for the stop head, which, under the action of a spring, fixes the position of the fuse box.

Rice. 38. Fuse:

1 - rod; 2 — checkbox; 3 - head protrusion; 4 - cutout for the stop head

40. Magazine latch

(Fig. 39) is used to mount the magazine in the receiver window. It has: an upper cut that extends over the ledge on the rear wall of the magazine; hole for the axis connecting the latch to the trigger guard; semicircular cutout for the passage of the magazine ledge; socket for magazine latch spring; tail connected to the latch using an axis. When the magazine is installed, the tail of the latch folds back, making it impossible for the magazine to randomly jump out of the receiver window when the magazine latch is accidentally pressed.

Rice. 39. Magazine latch:

1 - upper cut; 2 — hole for the axle; 3 - semicircular cutout; 4 - socket; 5 - tail; 6 - tail axis

Specifications

If we compare the technical characteristics of the SVT-40 with the American Grand M-1 automatic rifle, another participant in World War II, the domestic version is confidently in the lead in many respects.

For example, with a length of 1.2 m, it is much lighter and more balanced, which affects shooting.

| Characteristic | Magnitude |

| Caliber, mm | 7,62 |

| Length without bayonet, mm | 1 226 |

| Length with bayonet, mm | 1 470 |

| Barrel length, mm | 625 |

| Weight with bayonet, g | 4 130 |

| Store capacity, pcs. | 10 |

| Sighting range, m | 1 500 |

In addition to the data presented, we can say that the accuracy of SVT shots was not good.

In this characteristic, it was even inferior to its predecessor: the three-line, which was in service in pre-revolutionary times.

Bayonet

52. Bayonet

(Fig. 52) serves to defeat the enemy in bayonet combat. It consists of: blade; blade handles; handle heads with a groove for connection with the projection of the muzzle; latches with a spring securing the bayonet to the rifle; bayonet stop with which the bayonet is connected to the muzzle bushing; the side of the bayonet latch protects the bayonet from accidentally jumping off the rifle in bayonet combat when accidentally hitting the latch.

Rice. 52. Bayonet:

1 - blade; 2 — blade handle; 3 — handle head; 4 - head groove; 5 — bayonet latch; 6 — bayonet stop; 7 — side of the latch

53. scabbard

(Fig. 53) is used to carry the bayonet on the waist belt. It has: a ring for attaching a loop with which the bayonet is worn on the waist belt, and a ring with a spring that keeps the bayonet from falling out of the sheath.

Rice. 53. Sheath:

1 — ring for belt; 2 — leather loop; 3 - ring with spring

Design Features

If the first acquaintance of Soviet soldiers with the SVT took place in a positive atmosphere: a convenient design, the ability to fire without reloading, a large caliber - all this played to the benefit of the new type of weapon, then subsequent operation turned out to be completely different.

Due to its official marking, the rifle received the nickname “Sveta” or “Svetka”.

Most of the soldiers and officers died in the first months of the war, and the recruits who replaced them were able to appreciate only its capricious nature. First of all, this concerns design features and the presence of small parts. This led to the fact that the failure rate of the SVT-40 due to the loss of one or another spare parts element was a record 31%, while for the “three-line” the value did not reach 1.

Certain actions associated with the use of a rifle are indeed quite complex for the use of weapons in combat. For example, in order to rearrange the regulator, a key is needed. The subsequent procedure involved painstaking manipulations, the implementation of which required time and at least minimal technical knowledge.

It should be noted that some units used the SVT Tokarev rifle until the end of the war. These included marines, specially trained NKVD groups and secret reconnaissance battalions. They were predominantly composed of technically competent people who were able to understand the complex design of weapons.

Modifications

Over the short period of their production, Tokarev SVT rifles acquired several different modifications with significant design differences.

Automatic rifle

The difference in appearance lies only in the design of the trigger mechanism and the safety box, which has 3 positions:

- Included.

- Fire.

- Queue.

Adopted into service in 1940, withdrawn 2 years later, but these data are disputed due to the fact that several years ago, AVT-40, produced in 1943-44, appeared on sale under the label of SVT-O hunting carbines. The automatic firing mode is blocked in accordance with the legislation of the Russian Federation, but the position of the fuse is preserved, as well as the model index “AVT”, cut out on the butt.

This rifle was intended primarily for single-fire or bursts lasting 3...5 shots. If caught in an intense firefight, the fighter was allowed to fire automatically until the magazine was empty. Moreover, such shooting should not be more than 30 shots, otherwise the situation may result in excessive heating of the barrel.

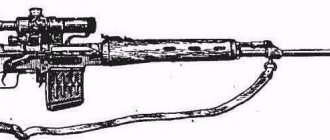

Sniper rifle

It entered service with the Red Army in the year of development, in 1940. The difference was better processing of the barrel bore and the ability to install a bracket for optics.

48,992 units were produced, production ceased in 1941. The SVT-40 sniper rifle, in comparison with a similar development by Mosin, had worse shot accuracy, which was explained by 2 factors:

- Automatic reload, reducing the possibility of being hit.

- Shorter barrel length of the SVT.

These reasons were the result of many snipers using the Mosin sniper rifle.

Automatic Tokarev carbine

The first self-loading carbine, developed by Fedor Vasilyevich, was provided by the developer at a field test in 1940, its design was based on the Model 38 and the Simonov carbine. During test shots, the model is recognized as unfinished.

9 months later, in September, the designer designs a new modification based on the SVT-40, but at the October field tests it again receives a negative assessment.

The commission was dissatisfied due to the fact that hitting the target was not normal. The accuracy of a shot from a distance of 100 m when firing from a rest was at least 9 cm, and in automatic mode, around 70 cm in short bursts and about 1 m in long bursts.

Tokarev carbines were not in service, but the Tula Arms Plant produced several hundred copies based on the 1940 rifle.

Among them were not only standard models, but also the following modifications:

- Self-loading.

- Automatic.

- Sniper.

- Sniper self-loading.

- Sniper automatic.

In 1941, several gift modifications of carbines were produced on special order. Their further history is not known; the only information from the archives reveals that one was presented to Marshal of the Soviet Union K.E. Voroshilov, the other to the first secretary of the Tula Regional Committee V. G. Zhavoronkov.

After another offensive by the fascist army, at the end of 1941 the plant was evacuated east to Mednogorsk, where production continued in small batches.

Very rarely they were encountered at the front, in the hands of the Red Army. At the same time, the Wehrmacht did not disdain self-loading carbines; it was adopted for service under the marking SiGewehr 259/2.

Grade

The Tokarev SVT-40 self-loading rifle was used during the Soviet-Finnish War of 1940 and the Soviet-German War; in a number of units it was the main individual infantry weapon, but in most cases it was issued only to some of the most trained soldiers. In the first year of the Soviet-German war, the Tokarev rifle was the only mass-produced model of individual automatic weapons until the production of submachine guns was launched.

A self-loading rifle requires obviously more careful attention than a simple magazine rifle. In the first months of the war, most of the rank and file of the Red Army, who knew how to competently operate SVT, died or were captured. Most of the older reservists who were called up did not understand either the design of the rifle or the need to carefully monitor it and follow the rules of lubrication. Therefore, in the Red Army, the Tokarev self-loading rifle earned the reputation of not being a very reliable weapon, sensitive to pollution and frost. Nevertheless, many units and individual soldiers of the Red Army who had sufficient training, in particular the Marine Corps, very successfully used SVT until the end of the war. And the enemy troops used the SVT-40 much more competently, which made it possible to smooth out its inherent shortcomings. The Finns and Germans greatly valued captured SVT; the Germans even adopted this rifle as a weapon of a limited standard and issued captured SVT as trophies to their troops. After the war, Americans also spoke quite highly of the SVT-40.

After studying the SVT-38 that fell into the hands of the Finns, the experimental rifle “TaRaKo” appeared, named after the names of the developers - N. Talvenheimo, O. Paronen and N. Koivula. Practically copying the Soviet prototype, the Finnish system was distinguished by a number of innovations. The improvements consisted of improved fastening of the receiver to the stock, the use of a solid thickened stock, the installation of a thick-walled barrel, the introduction of protective sides for the sight, as well as simplification of the muzzle with the muzzle brake being located in a separate part. The location of the swivels has been improved, the front sight has been replaced with one that is adjustable vertically and horizontally. Since with the beginning of the Soviet-German war SVT-40 began to fall into the hands of the Finns (17 thousand in 1941 alone), and the capabilities of the Finnish industry had always been modest, it was decided to abandon the mass production of TaRaCo.

The unreliability of the Tokarev self-loading rifle in front-line conditions can be explained by several factors. Firstly, the low general training of the bulk of the Red Army infantry soldiers and the low level of weapon maintenance in front conditions (including low-quality and/or unsuitable lubricants, lack of frost-resistant lubricants, improper lubrication of weapons, incorrect setting of the gas regulator position). Secondly, the gunpowder supplied from the USA had additives that ensured long-term preservation of the cartridges and preserved the barrel from corrosion, but caused increased carbon formation in the gas ducts. The rifle's automatic operation was based on a short piston stroke, and therefore required frequent cleaning. The open gas chamber of the DP-27 and DPM machine guns was less susceptible to clogging with combustion products of Lend-Lease gunpowder. American gunpowder also had a different pressure curve in the barrel from domestic ones, which also could not but affect the stability of the weapon with cartridges loaded with different types of gunpowder without proper adjustment of the gas outlet unit. In addition, during the war, a decrease in workmanship was inevitable. The design of the rifle did not have a strength reserve to compensate for wartime production costs.

Soviet self-loading rifles were distinguished by good shooting accuracy; the gross output SVT at ranges up to 600 m was not inferior in accuracy to the carbine mod. 1938. The sniper version of the SVT-40, due to its flatter rifling pitch, was inferior in accuracy and effective firing range with a heavy bullet to the Mosin sniper rifle of the 1891/30 model. However, a sniper armed with the SVT-40 was able to quickly fire a second aimed shot to finish off the target, which somewhat compensated for the low firing range. The famous Soviet sniper Lyudmila Mikhailovna Pavlichenko, whose personal account was 309 killed Nazis, preferred to use the sniper version of the SVT-40. By the middle of the war, the SVT-40 sniper rifle was replaced in production by the outdated and slower-firing, but more accurate at long ranges, “three-line” (even the more modern SVD rifle is inferior to the sniper rifle model 1891/30 in terms of accuracy of combat).

The decision to produce the SVT in an automatic version (AVT-40) completely undermined the authority of the rifle. The receiver, not adapted to such a load, simply became deformed when firing in bursts. It is obvious that the troops abused the automatic fire mode, which had to be used only in tense moments of battle.

As a result, the experience of operating Tokarev rifles helped in the development of post-war individual automatic weapons, which should have been very simple and extremely unpretentious.

Production of SVT-40 during the war

Any military operations require periodic updating of the armament of armies. The Great Patriotic War was no exception. At the time of entry into the war, more than 7.7 million rifles and carbines were officially listed in the armed forces; by the end of the year, another 1.5 million were produced. At the same time, the value of those lost is announced as 5.5 million.

Thus, as of January 1, 1942, there were only 3.7 million rifles. It turns out that at the time of the attack by Nazi Germany, the USSR was fully supplied with rifles, but the catastrophic retreat and losses of soldiers created such conditions that there was a need not for additional supplies of small arms, but for the creation of a new army.

The available reserve stocks did not compensate for the huge losses on the fronts, so the idea of starting production of the old “three-line” was accepted and implemented.

This was primarily due to the cost of production: SVT was almost 3 times more expensive. The suspension of the production of Tokarev rifles made it possible to provide the Soviet military with small arms.

It should be noted here that the decision was not made to abandon the use of SVT, but only its main role in arming the army. The production of rifles did not stop completely, the pace simply slowed down, and more attention was paid to the “three-line”.

Stock and receiver

46. Stock and receiver

(Fig. 45) when assembled, consist of the following parts: stock, lower casing, dowel bolt with bushing, receiver lining, upper casing, stock ring, spring latch for the stock ring, lower swivel, butt and trigger guard spring.

Rice. 45. Stock and receiver trim:

1 - stock (a - fore-end, b - neck, c - butt); 2 - lower casing; 3 — dowel bolt; 4 — receiver pad; 5 - upper casing; 6 — stock ring

Lodge

(Fig. 46) serves to connect parts of the rifle and make it easier to use. The fore-end of the stock has: a window for placing the receiver and trigger guard; a transverse hole into which a threaded tube for a dowel bolt is inserted; socket for placing the trigger guard spring; cutout for easy use of the fuse; longitudinal groove for the trunk; ramrod path; spring latch to hold the stock ring; side recesses for easy holding of the rifle; on the butt there is a back piece to protect the butt from splitting and a lower swivel for attaching a rifle sling.

Rice. 46. Stock:

1 - window; 2 - transverse hole; 3 - spring socket; 4 - cutout for fuse; 5 - back of the head; 6 — lower swivel; 7 - longitudinal groove; 8 - track; 9 - spring latch; 10 - side recesses

47. Bottom casing

(Fig. 47) is a continuation of the forend stock. It has a rear widened end for connection with the stock fore-end; front end for connection with the muzzle socket; longitudinal cutout for the spring latch of the stock ring; bends for connection with the upper casing; round holes for lighter and better barrel cooling.

Rice. 47. Bottom casing:

1 - rear end; 2 — front end; 3 - longitudinal cutout; 4 - bends; 5 - round holes

48. Dowel bolt

(Fig. 48) serves to attach the receiver to the stock. It has: a threaded end for connecting to a dowel tube; a head for screwing and unscrewing the bolt using a wrench and a longitudinal cut for better fastening of the bolt with the dowel tube.

Rice. 48. Dowel bolt:

1 - threaded end; 2 - head; 3 - longitudinal section

49. Receiver pad

(Fig. 49) serves to protect the shooter’s hands from burns and to protect the rod and piston from accidental impacts. It has: a rear cutout for the passage of the sight block; groove for the rod; transverse cuts for better barrel cooling; studs to protect against longitudinal cracks and a ledge at the front end for connection to the casing.

Rice. 49. Receiver pad:

1 - back cutout; 2 - gutter; 3 — transverse cuts; 4 — studs; 5 - ledge

50. Upper casing

(Fig. 50) is a continuation of the receiver lining. It has: a widened rear end for connection with the receiver lining; front end for connection to the muzzle; rear side to limit the displacement of the stock ring; side bends for connection with the lower casing; holes for lighter and better cooling of the barrel and internal projections with which the casing rests on the barrel.

Rice. 50. Upper casing:

1 - rear end; 2 — front end; 3 — rear side; 4 - side bends; 5 - holes; 6 - internal protrusions

51. Stock ring

(Fig. 51) serves to connect the stock, receiver lining, lower and upper casings with the barrel. It has a boss with a hole in which a ring for a rifle sling is placed.

Rice. 51. Stock ring:

1 - tide; 2 — ring for rifle belt

Foreign analogues

The main disadvantage of the domestic model is that it was used to a greater extent by workers and peasants who were en masse called up to the front.

If lubrication and cleaning of weapons were carried out in a timely manner, it would not create any special problems in operation. As an example, you can use foreign analogues of the Russian legend, built according to the scheme of the SVT rifle:

- SiGewehr 259/2.

- Selbstladegewehr 259.

- G.41 (M) "Mauser".

- SAFN M4.

- G.41 (W) "Walter".

Throughout the war, the Germans and Finns successfully used these modifications, created according to the Russian prototype. Moreover, according to Tokarev’s project, not only automatic types were developed, but also semi-automatic and sniper ones.

This confirms that the SVT-40 simply ended up in the wrong hands, which affected its future fate.

Judging by the plans of the leadership of the Red Army, the SVT-40 rifle was supposed to replace the morally and technically outdated model of the three-line model, produced in 1891-1930. It should be an “unkillable” and reliable specimen ready to fire with cartridges of any quality.

In addition, it was planned to equip all models with a sight. The outbreak of war disrupted rearmament plans and suspended subsequent development related to improving the tactical, technical and operational characteristics of weapons.

Moreover, initially work on the rifle took place at an accelerated pace.

The production of new weapons is always accompanied by difficulties associated with changing the equipment of factories, retraining workers, and eliminating defects. All this takes time and money; if the Soviet Union had no problems with the latter, there was a catastrophic lack of time.

Although at that time, there were only 2 countries in the world that had this type of weapons in their armed forces: the USSR and the USA.

Moreover, the SVT was superior to the American M-1 in some characteristics. And yet Tokarev’s work was not in vain. Based on the SVT, other types of weapons were developed that served in the troops just like their progenitor.