Gear classification

The final drive is a transmission unit.

It is installed on the sides of vehicles in front of the drive wheels or directly in them. Final drives are used to increase torque, which is supplied to each drive wheel. The classification of gears is based on the number of rows of gearing that provide the desired gear ratio. In this regard, two-row and single-row gears are distinguished.

Double row transmissions are:

- planetary,

- simple,

- combined (one row is planetary and the other is simple).

Single-row gears are divided into simple, equipped with fixed axles, and planetary.

All transmissions, without exception, taking into account the location of the axes of the driven and drive shafts, belong to one of two varieties:

- Coaxial (the axes of the driven and drive shafts are in a straight line).

- Misaligned.

A number of high-speed vehicles with tracks are equipped with a coaxial (single-row planetary) gear. Moreover, the driven element becomes the carrier, and the driving element becomes the sun gear. The carrier is connected to the driving wheels of the mover, the epicyclic gear remains motionless.

T-72B3 tanks will receive automatic gear shifting

The existing fleet of armored vehicles continues to be updated. The other day it became known that during the ongoing modernization of combat tanks of the T-72 family, it was proposed to use new components that would further enhance the characteristics of the equipment. In addition to the already ongoing project to update radio-electronic equipment, weapons, etc. Now it is planned to introduce new power plant and transmission units that will affect the mobility of tanks and their operational characteristics. According to Izvestia, the T-72 main battle tanks will receive additional equipment in the form of an updated gearbox control system during the modernization of new batches of equipment. The new version of the T-72B3 modernization project involves the use of an APP-172 automatic gearshift. The automatic system will replace the manual control lever connected to hydraulic drives. It is expected that such modernization will significantly simplify the operation of armored vehicles, as well as make it easier to control and reduce the negative consequences of driver errors.

According to available data, a new version of the T-72B3 modernization was developed by the Uralvagonzavod corporation at the request of the Ministry of Defense. The next contract of the Ministry of Defense for the repair and modernization of armored vehicles available to the troops, among other things, implies the use of a new automated gearbox. The contract signed in March involves the restoration and renewal of one and a half hundred T-72B tanks. This equipment, along with other new systems, will receive APP-172 assault rifles.

Tank T-72B3. Photo: Wikimedia Commons

It is reported that the APP-172 automatic transmission, proposed for use on T-72B3 tanks, was borrowed from the T-90SM project. Thus, through the use of new units, it is planned to improve the characteristics of existing tanks to the level of the latest developments. Updating the transmission will simplify the operation of the equipment and bring such parameters to a new high level.

The automatic gearshift APP-172, proposed for installation on modernized tanks, was developed at NPO Elektromashina, part of the Uralvagonzavod corporation. The device is made in the form of a single unit with a set of necessary controls, which can be installed in the control department of the equipment being modernized. Installation of the machine and its connection to the necessary on-board systems can be carried out both at factories and in the field.

The APP-172 system is capable of monitoring transmission operating parameters and independently performing gear shifts. There are manual and automatic operating modes. In addition, in automatic mode, it is possible to change gears manually. When operating automatically, the machine spends about 0.2 seconds to change gear. The automatic transmission is connected to the on-board systems via a two-wire circuit and is installed to the right of the driver’s seat, in the same place as the standard gearbox control systems.

Automatic gearshift APP-172 (light blue block) in the control compartment of an armored vehicle. Photo Npoelm.ru

The body of the APP-172 assault rifle has a set of necessary controls. There is a toggle switch to turn on the device with LED indication, as well as a movable lever with a scale that imitates a standard gearbox control. Thus, the use of the machine does not require complex retraining of personnel to master new principles of equipment control.

The use of an automatic gearshift, according to the developer, allows you to optimize the operation of the transmission through proper control of it. Correct transmission control allows you to reduce the acceleration time from zero to 50 km/h by 2-3 seconds. The average highway speed can be increased by 15-20%. Fuel consumption is reduced by 10-15%. Thus, the installation of a relatively simple and small device can significantly increase the mobility of an armored vehicle and improve its performance characteristics.

The first domestic tank to receive the APP-172 automatic gearshift was the T-90SM. In addition, such equipment was used in one of the special projects. Now this system is offered for installation on updated T-72B3 for combat units. Thus, the original innovation will be able to get into the troops and have a positive impact on the operation of modernized armored vehicles.

Tank T-72B3M. Photo: Wikimedia Commons

According to Izvestia, the first batch of 32 T-72B3 tanks with the APP-172 assault rifle will be modernized by the end of this year and will go to the disposal of the 1st Guards Tank Army of the Western Military District. In the future, the troops will receive the remaining vehicles, which will be updated in accordance with the recent order.

It should be noted that the project to equip T-72B3 tanks with automatic gear shifting is not the first option for updating the power plant and transmission of armored vehicles of this type. Thus, back in 2014, the main tank T-72B3M (also designated T-72B4) was presented, intended for participation in the “Tank Biathlon”. This vehicle was a modified version of the original T-72B3 using components and assemblies from the T-90SM. The “racing” tank was equipped with an uprated V-92S2F engine with a power of 1130 hp, a new power plant control system, an automatic gearshift and other equipment for various purposes, including new sighting equipment.

The T-72B3M was tested on the competition track and performed well. However, this modification of the tank is not yet planned for mass production, and the modernization of the armored vehicles available to the troops is being carried out according to the T-72B3 project. However, according to recent reports, updated cars of new batches will receive automatic transmission control borrowed from previous projects. This will further improve the performance of armored vehicles without significant costs for replacing certain components.

Based on materials from the sites: https://izvestia.ru/ https://npoelm.ru/ https://bastion-opk.ru/

High reliability

Some cars are also equipped with a similar type of final drive. The sun gear causes the three planet gears to rotate. Rolling along the epicyclic (fixed) gear, they rotate the carrier, which is connected to the hub.

Similar final drives differ:

- small in size,

- large gear ratio.

At the same time, they are characterized by high reliability. But the design, when compared with a non-coaxial (simple single-row) transmission, is distinguished by its complexity.

Wheel drive shafts and gears are made of chromium-nickel and chromium steel. The crankcases are made of special steel and ductile iron. Transmission oil serves as a lubricant for the final drive.

For wheeled and tracked vehicles

Wheeled vehicles are characterized by the transfer of work from the motor to each drive wheel using units:

- gearbox (variable),

- main gear (continuous).

When a similar scheme is extended to tracked vehicles, the appearance of significant gear ratios before the onboard clutch leads to an increase in the torque received from the engine. To avoid slipping of the clutch, it is necessary to increase its size and install stronger springs. The disadvantages of this device are obvious. For this reason, the tracked vehicle system needs to provide a gear ratio within acceptable limits to the onboard clutch.

The maximum level of gear ratios behind the final clutch can be obtained using the final drive. Their formation between the caterpillar and the motor occurs three times. This is the main difference from the wheeled vehicle system.

Auto service specialists "NizhegorodAVTO" repair a manual transmission or automatic transmission.

Mechanical cargo gearbox design

There are two types of gearboxes installed on trucks - manual and automatic. The first ones appeared much earlier; they are more reliable, durable and better maintainable.

The truck shifts gears thanks to the presence of stages with toothed gears. The change in speed occurs due to the movement of these gears. The teeth meshing with the gears provide the ability to synchronize the wheels and torque.

Speaking about the structure of a truck's manual transmission, it is necessary to mention the following:

- Its design includes a large number of transmission components - overrunning clutches, gear blocks, and a reverse gear unit.

- The crankcase is filled with oil, which is necessary to lubricate gears that are in constant motion.

- The clutch is located next to the flywheel, mounted directly on the power plant.

- Thanks to synchronizers, speeds are switched smoothly, without shocks, vibrations or vibrations.

Features of the transmission design eliminate the risk of engaging several gears at once - for this purpose, a rocker is used that blocks spontaneous gear changes.

Demultiplier and divider

It is logical that such a large number of gears entails certain difficulties with switching them. To simplify the driver’s task, to relieve him of the need to search for the desired speed and “get into” it, the designers invented a fundamentally new solution, units that significantly simplify the work with trucks, but at the same time do not complicate the design of the transmission. We are talking about a divider and a demultiplier. Let's take a closer look at them.

So, a divider is a part that is, to some extent, a gearbox for a gearbox. It is made in the form of a gearbox, consisting of two stages, the first of which is direct, and the second is step-up. When installed, for example, on a 4-speed transmission, the divider doubles the number of gears, making it 8.

As for the range multiplier, it is also a 2-stage gearbox, but its lower stage is a reduction one. In other words, to get a 16-speed gearbox, take a standard gearbox and connect it to both a divider and a multiplier. The resulting formula is 4 by 2 and by 2 equals 16. The units described above are controlled using levers and buttons additionally installed on the gearbox.

A particularly large number of speeds is important when the car is climbing a significant slope, and the engine resources are not enough to create the required traction. Among other things, transmissions with dividers and range factors are characterized by increased wear and greater efficiency.

Symptoms of a problem

There are several signs that your truck transmission may need repair:

- Movement speeds change spontaneously.

- The gear does not engage (as a rule, this happens due to wear and tear on the gear switch drive mechanisms).

- It becomes more and more difficult to change gears; you have to make an effort to do this. In such cases, it is necessary to urgently contact a service station, because A similar sign may indicate a broken input shaft spline.

- While driving, extraneous sounds and vibrations appear, which are evidence of bearing failure.

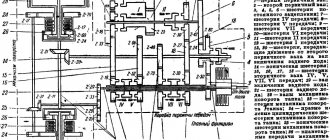

Adjusting the tank steering drive control drive

- Place the control levers in the lowest position.

- Adjust the pull rods of the shoe brakes so that the shoes are pressed tightly against the drums under the action of the springs, and the control levers have a free play of 25-30 mm along the handle. The springs are tensioned by a handwheel, which turns the shaft using eccentric spring supports.

- Adjust the gap at the adjusting screws of the hydraulic presses that rotate the control shaft so that, as soon as the free play of the control levers is selected, the adjusting screws of the presses rest against the valve stems.

- Continue raising the control levers. As soon as the rollers find the protrusions of the profiling cams, the clutch activation levers should press the valve rods for engaging the hydraulic clutch presses. The moment of activation of hydraulic clutch presses is adjusted using adjusting screws. When the levers are raised further, the onboard brakes should be activated.

- Using turnbuckles located on the rods, adjust the onboard brakes. If the turnbuckle is fully tightened, and the onboard brake slows down weakly or does not brake at all, it is necessary to unscrew the turnbuckle so much that the ends of the rod are held in the coupling by the thread of at least five threads of the screw, and move the rod to the next hole in the shackle and adjust the onboard brakes again.

- Having completed the adjustment, start the engine and, turning the tank to the right and left at low speeds, check the operation of the turning mechanism and, making sure that it is in good working order, lock the adjusting screws. It must be remembered that when raising the right or left turn lever, the shoe brake must first turn off; at the same time, the hydraulic press lever must press the valve stem, after which the clutch is activated (the lever presses the valve stem); only when the clutch is engaged; The onboard brake should engage.