General Omar Bradley became famous during World War II as a military leader trying to avoid unnecessary casualties among his soldiers. After the end of the war, active participation in helping veterans settle into peaceful life added to this image. So it is not surprising that it was decided to name the first American infantry fighting vehicle, the M2 Bradley, after him.

The development and production of infantry fighting vehicles in America began quite late - in the 70s, when, for example, the BMP-1 had already been tested in combat. But this made it possible to use in the creation not only the American experience of using armored personnel carriers, but also the analyzed results of the combat debut of Soviet infantry fighting vehicles.

History of creation

In 1959, the US Army adopted the M113 armored personnel carrier, a simple and cheap vehicle. He had a full-scale baptism of fire in Vietnam, and it showed that even if nuclear weapons were not used, the idea of a fighting vehicle that allowed infantry to fight without leaving it made sense. The soldiers who tried to dismount from the armored personnel carrier were immediately covered with fire.

The machine gun turret of the armored personnel carrier was open - the shooter was also easily hit. In field conditions, the problem was solved by installing additional machine guns on the roof of the vehicle behind armored shields, but this was a temporary solution.

As part of the work on an improved combat vehicle, FMC proposed the XM734 - M113 with side embrasures and a protected turret with coaxial machine guns. They managed to test it in the field, but by this time it became clear that such modifications were also half measures.

The M113 could not fight on its own, and it was difficult for the landing party to stay in this vehicle for a long time.

The next step taken by FMC was the XM765 - a converted M113, armed with a 20mm cannon and protected by spaced composite armor. It was not accepted into service in the United States, but a number of vehicles were sold for export.

Meanwhile, in the late 60s, the first infantry fighting vehicles were implemented. In addition, the USSR adopted the new BTR-60PB with 14.5mm machine guns, capable of easily destroying the M113. Fearing that they would fall hopelessly behind, the Americans began a new stage of research work. FMC was asked to create a vehicle similar to the XM765, but with better maneuverability and mobility (so that the infantry fighting vehicle could effectively interact with future tanks), as well as better protection.

As a result, an experimental XM723 infantry fighting vehicle was built on the chassis of the LVT-7 heavy marine armored personnel carrier. She will become the future Bradley. However, the development of the vehicle was delayed due to the desire to replace the 20mm M139 cannon with a gun with an external automatic drive, as well as due to the cancellation of the program to develop a promising BRM.

Now a modification of the infantry fighting vehicle was supposed to be used as a reconnaissance vehicle, and a new two-seat turret began to be designed for the XM723.

The last obstacle was an attempt to evaluate the feasibility of producing infantry fighting vehicles, based on the experience of using Soviet vehicles, and to find cheaper alternatives.

The German Marders and the French AMX-10P were considered unsuitable, and converting the hulls of obsolete M48 tanks into heavy infantry fighting vehicles turned out to be no cheaper, but twice as expensive, than the production of new equipment. Finally, the issue of armor was decided as follows - it can either reliably protect against small arms fire, up to large-caliber weapons, or against anti-tank missiles, and all the options “in the middle” are impractical.

In 1977, the BMP project received the index XM2, and the BRM - XM3. They were officially approved in early 1980 and went into production in 1981. It was then that the BMP was named in honor of the recently deceased general.

Development history

In 1961, the American army received the M113 tracked armored personnel carrier, which for many decades became the main armored vehicle of the US Armed Forces. The M113 is still the main armored personnel carrier of the American army today; it is also used in 44 other armies around the world.

The Vietnam War showed that infantry units needed not only “battle taxis” that could transport soldiers to the battlefield, but also vehicles that could support the infantrymen in battle and go on the attack with them. In other words, an infantry fighting vehicle with more reliable protection and powerful weapons was needed. The designers tried to increase the firepower of the M113 armored personnel carrier by installing additional machine guns on it, but this did not change the situation too much.

In 1965, the XM701 appeared, which was, in essence, an attempt to increase the level of protection and firepower of the M113. The new vehicle turned out to be simply a much heavier version of the M113 and was not accepted for service. The next attempt to create an infantry fighting vehicle was the XM765 project. The M113A1 was taken as the basis; its armor protection was significantly strengthened, an automatic 20-mm cannon was installed, and the shape of the hull was changed. In 1973, the Vietnam War ended, and funding for the work was sharply reduced. But the efforts spent on development were not in vain: vehicles based on the XM765 were adopted by several countries.

Work on the creation of a new infantry fighting vehicle began in the mid-60s, but only in 1971 did the army command prepare technical specifications for the creation of a new vehicle. She received the index XM723.

The development of the new American infantry fighting vehicle took more than fifteen years; the M2 Bradley was put into service only in 1981. During this period, several new vehicles were created, some of which were deep modernization of the M113, others were completely new models of equipment.

In 1971, the XM723 project was launched. His goal was to create a simple infantry fighting vehicle with a high level of armor protection. They planned to arm the new vehicle with a 20-mm cannon, its side armor was supposed to withstand fire from a 14.5-mm machine gun, and its frontal armor was supposed to withstand fire from a 30-mm cannon. The development of the new machine was carried out by FMC Corp.

To achieve such high performance, the company's designers had to develop a fundamentally new armor protection system for infantry fighting vehicles. It consisted of several screens made of layers of steel with different hardnesses.

The outer screen was installed at a distance of 100-150 mm from the machine body and the inner screen. This design provided a level of protection superior to all materials and technical solutions existing at that time.

In 1976, testing of the new vehicle began, after which the American military department expressed its comments and prepared a list of improvements that the manufacturer needed to complete. The military insisted on installing a two-man turret with an automatic 25-mm cannon and a TOW ATGM, creating a reconnaissance modification (BRM) based on the vehicle, and ensuring the buoyancy of the new infantry fighting vehicle.

In 1977, prototypes of new infantry fighting vehicles and infantry fighting vehicles were ready: XM2 and XM3. The US leadership was asked to create and purchase new infantry fighting vehicles with an increased level of armor protection. The military justified their demands by the experience of the recent Arab-Israeli conflict and the high level of losses of the Soviet BMP-1. In their opinion, the new American infantry fighting vehicle should have a higher level of protection.

In 1979, a pilot batch of XM2 and XM3 was manufactured, and testing began. In 1981, the vehicle was put into service and was named the M2 Bradley BMP. The Americans spent $5.6 billion on the project to create a new infantry fighting vehicle. The cost of one machine, taking into account the funds spent on development, is $3.16 million.

If you compare the M2 Bradley infantry fighting vehicle with the XM723, you can immediately detect several differences: the mass of the infantry fighting vehicle adopted for service increased to 22.3 tons, the number of paratroopers decreased (to seven people), the automatic cannon of the new vehicle could hit the frontal projection of the Soviet infantry fighting vehicle -1 (with a sub-caliber projectile at a distance of 1.5 km), and TOW ATGMs can effectively work against tanks at a distance of up to 3 km.

Design

The body of the Bradley infantry fighting vehicle is welded from aluminum alloys. This decision pursued two goals - firstly, weight reduction. Secondly, the aluminum armor plate that provides the required protection will be thicker than steel - but still lighter, and the thickness will ensure the overall strength of the structure.

The aluminum armor on top is covered with steel screens, the gap between the body and the screen is filled with polyurethane. The exact thickness of the Bradley's armor was not announced, but according to the technical specifications it was supposed to provide protection from 14.5mm bullets, which means the equivalent thickness is approximately 50-60mm.

The Bradley's layout is classic for infantry fighting vehicles: the engine is in the nose, shifted to the right; behind it is the fighting compartment with a turret, and the landing compartment in the stern.

In this case, the landing compartment will be separated by a bulkhead. The engine of the car is an eight-cylinder Cummins VTA 903 turbodiesel with a volume of 14.8 liters, developing a power of 500 hp. The HMTP-500 gearbox is hydromechanical, three-stage.

Since the Bradley turret is shifted to the starboard side, behind the driver's seat there is a “tunnel” between the left side and the fighting compartment bulkhead. Two paratroopers are sitting in it, facing the side. The main part of the Bradley troop compartment is behind the turret, housing four more soldiers - two facing the starboard side, and two facing the aft door. The fighters sit on shock-absorbing, adjustable seats and have viewing periscopes and embrasures.

To exit the vehicle, either a hydraulically driven stern ramp or a door provided in the ramp is used. There is also a hatch in the roof of the BMP. The vehicle (squad) commander and gunner sit in the turret. The Bradley has limited buoyancy and requires the installation of a special casing to overcome water obstacles.

M3 Bradley combat reconnaissance vehicle (USA)

The M3 Bradley

reconnaissance combat vehicle is based on the M2 Bradley infantry fighting vehicle. The M3 Bradley reconnaissance vehicle differs little in appearance from the M2 Bradley infantry fighting vehicle. Its main differences are the embrasures covered with caps on the rivets, the absence of viewing blocks on the starboard side and additional antennas. The main armament has not changed, but the cannon's ammunition capacity has been increased to 1,500 rounds (900 rounds are stored in the turret in belts and on the rack), the coaxial machine gun's ammo capacity has been increased to 4,300 rounds, and the ATGM's ammo capacity has been increased to 10 missiles. To make the vehicle lighter, the mine-resistant reinforcement of the bottom has been removed. The layout of the troop compartment has been changed - it houses two observers, an M60 machine gun, five M16A1 rifles, ten TOW ATGMs in ammunition storage on folding shelves on the starboard side, as well as a motorcycle on the left side. Radio stations AN/VRC-12 and AN/PRC-77 are installed for communication. The M3 Bradley BRM is equipped with a portable AN/PRS-15 ground-moving target reconnaissance radar (human detection range - 1500 m, vehicle detection range - 3000 m with an accuracy of 10 m in range and ± 1.2 ° in azimuth), as well as night vision devices, including portable ones. Reconnaissance can be carried out both by car and in combination - with the allocation of a dismounted group of two or three people.

In late 1983, M2 Bradleys began to be delivered to the US 7th Army in Europe. By the end of 1985, 10 motorized infantry battalions had already been equipped with new equipment.

Work on modernizing the Bradley infantry fighting vehicle began shortly after it was put into service. The launchers and loading devices were adapted for the modernized BGM-71D ATGM of 152 mm caliber with improved characteristics of the main engine and IR tracer (TOW-2 complex, designed to defeat Soviet T-64 and T-72 tanks with dynamic protection).

Along with the introduction of a shot with an elongated armor-piercing projectile and an increased charge of gunpowder into the cannon's ammunition, its barrel was somewhat lengthened and the breech was strengthened. Care has been taken to prevent damage to the barrel by external housing equipment. Boxes with smoke grenades were removed from the front part of the turret, leaving in their place canvas loops for attaching spare parts. The M76 smoke grenade was added to the ammunition load, providing protection in both the visible and infrared regions of the spectrum.

The outer walls of the baskets for spare parts were made vertical, increasing their capacity and ease of packing, the laying of camouflage nets was changed, and the mounting brackets for the watercraft casing were improved. The vehicles received an improved M13A1 filter-ventilation unit with a gas separation filter.

Small changes were made to the equipment of the driver's seat - his seat received soft upholstery, and the surveillance devices received a protective visor-bracket. Two prismatic viewing blocks were installed in the cover of the upper hatch of the troop compartment. The 38 liter water tank was replaced with two 19 liter tanks.

These changes were tested on the prototype M2E1, which passed standard operational tests at the Aberdeen Proving Ground.

to the design of the M3 Bradley BRM: one of the reconnaissance observers was moved to the center of the compartment, and he received four observation blocks in the top hatch cover, the embrasures were removed - the side armor plates became solid, the FVU on the M3A1 served both crew members and and reconnaissance observers.

Since 1986, serial production of modifications M2A1 and M3A1 began. In the same year, the “Bradley High Survival” program was developed, embodied in the A2 modification. Two years later, production of the “first phase” M2A2 and M3A2 combat vehicles began.

Modification A2 has armor according to the “steel-steel-aluminum-Kevlar” scheme. The frontal part, as well as the sides of the hull and turret, are reinforced with steel screen sheets 30-32 mm thick, which are bolted. Such armor was supposed to provide protection from 30-mm cannon shells. The width of the machine has increased to 3.6 m.

According to the modernization plan, it was supposed to reduce the number of side embrasures, but the side screens completely blocked them, and the U231 machine guns were removed. In connection with this, the layout of the troop compartment has changed: three infantrymen are placed in a row in its front part, facing in the direction of travel, behind them three more - two on the right, facing the stern, and one with his back to the port side. The stern embrasures have been preserved. There is a cutout in the front left screen so as not to block the driver's view. The introduction of the frontal screen forced the removal of the wave-reflective shield (especially since the buoyancy of the weighted vehicle decreased) and the installation of lighting devices was changed: headlights and signal lights were mounted higher in special casings. The commander's periscope device is also covered with an armored casing. The gunner received a combined sight with a thermal imaging channel. On the lower part of the gun mantlet there are new boxes for smoke grenades, smaller compared to the M2 and M3.

The overhead screens have sockets for installing elements of dynamic or passive protection against cumulative ammunition. Dynamic protection elements (43 per vehicle) measuring 305x457x50.8 mm are mounted on the sides and frontal part of the hull, forming solid panels. On the march, these panels can be covered with covers, which also play the role of a kind of overlay. The M2A2 Bradley remains the only infantry fighting vehicle standardly equipped with dynamic protection. To reduce the impact of the explosion of its elements on the machine itself, they are mounted on a gasket made of cellular material, developed jointly with Israeli specialists. The inner sheets are reinforced with a Kevlar lining, which reduces the likelihood of damage to the crew, troops and equipment from armor fragments. The ammunition stowage in the hull has been changed in order to isolate the ammunition from the habitable compartment.

The M2A2 Bradley and M3A2 Bradley are equipped with a SIN-CGARS radio. It provides single-channel simplex communication in telephone mode and secure data transmission in fixed tuning or frequency hopping mode (about 2000 operating frequencies in the range 30-88 MHz) with a high level of interference. The communication range in the parking lot is up to 30 km. in motion - up to 25 km.

The NPO and the watercraft casing were modernized, and the laying of cable, hydraulic and fuel systems was changed. When installing an additional cooling or heating system, radiator blocks are placed in the middle of the side screens.

In May 1989, production of vehicles of the “second phase” A2 modification began. Due to the increased weight of the infantry fighting vehicle to 33 tons, the diesel engine was boosted to 441 kW, the transmission was modified accordingly, the capacity of the cooling system was increased, and reinforced torsion shafts were introduced into the suspension.

In total, FMC produced 2,300 M3 Bradley base modifications, 1,400 A1 modifications, and about 1,400 A2 modifications for the US Army (of which 600 were “phase one” with a 368-kilowatt engine). In addition, 600 vehicles were transferred to the US National Guard.

Since 1983, at the request of the US Army, FMC has been conducting research on replacing the metal armor of M3 Bradley with ceramic and composite materials - the so-called “ceramic” and “plate-metal” hull armor. This body included two upper elements made of composite layers, an aluminum lower part (chassis frame) and a composite sheet of underbody protection. The composite was reinforced by ceramic elements made of titanium diboride. With ballistic protection levels similar to the M3A1, the body weighed 27% less. The use of composite materials allows, in addition, to increase protection against cumulative ammunition, reduce the formation of internal armor spalls, reduce the radar, acoustic and infrared signature of the vehicle, extend its service life due to high corrosion resistance and 60% greater fatigue strength, and reduce production costs .

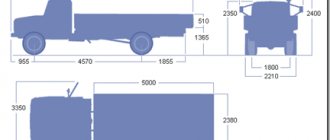

Tactical and technical characteristics of the M3 Bradley BRM Combat weight, t 21.3 Crew, people 3+2 Overall dimensions, mm; length 64S0 width 3200 turret roof height 2580 ground clearance 450 Armament: 25 mm M242 automatic cannon, 7.62 mm M240S machine gun, TOW PU ATGM Ammunition 1500 rounds, 10 TOW ATGMs, 4300 rounds Cummins VTA-903T engine. 8-cylinder diesel engine with turbocharging, power 368 kW at 2600 rpm Specific engine power. kW/t 19.0 Specific ground pressure. MPa 0.045 Maximum speed on the highway, km/h 66 Cruising range on the highway, km 483 Fuel capacity, l 662 Obstacles to be overcome: ascent, degrees. 30 wall height, m 0.91 ditch width, m 2.54 ford depth, m floating

Modifications

The M3 BRM (according to American terminology - “cavalry fighting vehicle”) differs from the M2 only slightly - in the amount of ammunition and the placement of the crew. A crew of three is retained (commander, gunner, driver), and two observers are located in the aft compartment. The freed up space was used to accommodate additional ammunition.

It was planned to include a motorcycle in the BRM configuration, but this decision was later abandoned. The embrasures were muffled, but all periscopes were retained for use by observers.

М2А1/М3А1 - received a fire extinguishing system, a new filter-ventilation unit and enhanced weapons (TOW ATGM was replaced by TOW-2).

On the M2A1 BMP, in addition, they added space for the seventh paratrooper immediately behind the turret.

M2A2/M3A2 – modification with improved protection. The armor provides protection from 30mm shells “all around”; it is possible to install dynamic protection. The rear of the BMP received spaced armor, and the inside of the Bradley received a Kevlar lining. The number of paratroopers was again reduced to six - the position immediately behind the driver was abolished. The embrasures were completely abandoned, and in addition, both versions of the Bradley lost their buoyancy. The BMP engine was boosted to 600 hp.

М2А3/М3А3 – “Bradleys” received a new fire control system, satellite navigation, and the roof protection of the infantry fighting vehicle was increased with the help of titanium armor plate.

М2А4/М3А4 – since previous modifications of the infantry fighting vehicles have become “heavier” and have somewhat lost mobility, the Bradley is planned to be modernized with a more powerful engine and reinforced suspension.

Description

The Bradley infantry fighting vehicle is designed according to a design traditional for infantry fighting vehicles: the power compartment is located in its front part, and the troop compartment is located in the rear. You can get into the landing compartment through the top hatch and rear ramp. The crew consists of three people: a gunner, a commander and a driver. Landing group - six people.

The body is welded from aluminum armor, which significantly reduces the weight of the vehicle without compromising its security. The front and side armor is reinforced with steel sheets, and the bottom is similarly reinforced. On the A2 modification, the crew is protected from fragments by an internal Kevlar lining.

The engine and gearbox are located in the front of the body on the right, with the driver's seat to the left of them.

The fighting compartment is located in the center of the BMP; there is a two-man turret with a rotating turret. The turret houses the positions of the gunner and vehicle commander.

The cannon and machine gun are stabilized in both planes, and a TOW ATGM launcher is installed on the left side of the turret.

The landing compartment is separated from the combat compartment by a partition with a passage.

The Bradley infantry fighting vehicle is armed with an automatic 25 mm M242 Bushmaster cannon, a 7.62 mm M240C machine gun, a TOW ATGM and six M231 FPW assault rifles installed in the troop compartment.

The gun has a two-belt feed.

The TOW ATGM can hit armored targets at distances of up to 3,750 meters.

The Bradley infantry fighting vehicle is equipped with a VTA-903 V-shaped turbodiesel engine with a power of 500 hp. With. (later versions have a more powerful motor). The transmission is hydromechanical, with three forward gears and one reverse gear.

Armament

The Bradley infantry fighting vehicles and infantry fighting vehicles are armed with a 25mm Bushmaster stabilized automatic cannon with an automatic chain drive and a dual feed system. Initially, two types of projectiles were developed for it. The high-explosive fragmentation M792 has a mass of 185 grams and is equipped with 34 grams of “Composition B”, its initial speed is 1100 m/s.

The M791 sub-caliber projectile, which is a tungsten core weighing 102 grams with a detachable tray, was intended to defeat light armored vehicles.

It penetrated armor about 60mm thick. Already at the end of the 80s, the M919 feathered armor-piercing projectile with a uranium core entered trial operation - its armor penetration exceeded 100 mm. The M240S machine gun of 7.62mm caliber is paired with the cannon.

To combat armored vehicles, TOW guided missiles are used, starting with the A1 - TOW-2 series. The mass of their cumulative warhead is about 6 kg, they can penetrate armor 900 mm thick. A launch container for two missiles is located on the left side of the BMP turret, additional ATGMs are located in the Bradley's fighting compartment.

Originally, the Bradley solved the issue of firing by paratroopers from inside the vehicle. Having reasoned that it would be impossible to conduct targeted fire from the embrasures, they installed weapons adapted for suppressing fire - M231 assault rifles.

They differed from standard M16s in the absence of a stock, a very high rate of fire, and the fire was fired from an open bolt. Only tracer bullets were used for shooting. After the appearance of the Bradley with reinforced armor, the M231, as well as embrasures in general, had to be abandoned. They are sometimes retained as crew self-defense weapons.

Combat use

Bradley infantry fighting vehicles and infantry fighting vehicles were actively used during Operation Desert Storm. The infantry fighting vehicles performed well - they destroyed even more Iraqi equipment than the Abrams tanks. Losses from enemy fire were minimal - only three vehicles. But 17 Bradleys were destroyed by “friendly fire.” After that, the M2 and M3 were in combat only during the next invasion of Iraq.

However, already in 2007, the vehicles began to be withdrawn from the country - the main threat to armored vehicles was explosions from improvised mines, and the Bradleys were poorly protected from them. By the time the infantry fighting vehicles were replaced with “mine-resistant” armored personnel carriers, about 150 vehicles were lost.

In addition to the United States, the M2 Bradley is in service in Saudi Arabia, and a number of vehicles have been delivered to Lebanon. Saudi Arabian infantry fighting vehicles participated in the invasion of Yemen, but details about their participation are scarce.

Specifications

Since the Bradley is a representative of the second generation of infantry fighting vehicles, it can be compared with the Soviet BMP-2, which appeared at the same time.

| M2 Bradley | BMP-2 | |

| Weight, tons | 22,8 | 15,7 |

| Length, meters | 6,5 | 6,7 |

| Height, meters | 3,02 | 2,4 |

| Speed, km/h | 66 | 65 |

| Cruising range, km | 483 | 600 |

The small dimensions of the Soviet infantry fighting vehicle, on the one hand, ensured less weight and stealth. However, the density of the arrangement often led not only to fatal damage to the vehicle, but also to the incapacitation of the landing party. Experience with the Bradley, on the contrary, has shown that when an infantry fighting vehicle is disabled, the crew usually survives.

The frankly weak armor of the BMP-2 protected only from rifle-caliber bullets, which was corrected on the BMP-2D with additional armor. At the same time, the Bradleys with enhanced protection were designed to withstand automatic guns. It is worth noting that the BMP-2D also lost its buoyancy. It can be noted that the automatic cannon of Soviet vehicles has a higher rate of fire, and the Bradleys are armed with a more powerful ATGM.

"Bradleys" were used in battle rather limitedly, but managed to establish themselves as vehicles with high combat qualities.

However, they were developed within the framework of the concepts of the 70s, when no one imagined what wars the machines would have to participate in.

The Bradleys turned out to be not very suitable for counterguerrilla operations. However, modernization programs indicate that the United States will not abandon its infantry fighting vehicles in the near future, which means that they satisfy most of the requirements.