The GAZ-4301 medium-duty truck appeared in the plant's production program in 1984. The car differed from previous models in the use of a diesel engine developed by specialists from the Gorky Automobile Plant based on the Steyr unit. Due to difficulties with development, serial production of the truck began only in 1993, and a few years later the assembly was discontinued.

About the history of the model

The development of the GAZ-4301 truck model started at the Gorky Automobile Plant back in the early 80s. In 1982-1983, a pilot batch of these machines underwent serious testing. Since such trucks were intended mainly for agriculture, the first tests were carried out on collective farms near Moscow. Then a test motor rally of nine thousand kilometers was organized - from Gorky to Kuibyshev, then to Aralsk, Tashkent, with the finish line in the Pamir Mountains.

The tests were successful, but the diesel GAZ-4301 reached mass production only in 1992. In a country with a planned economy and absolute dominance of the state in all spheres of the economy, there was no urgent need to switch to diesel cars, although it was recognized that it needed to be ensured. Gasoline was still cheap, and car factories were consistently supplied with orders for gasoline trucks.

In parallel with the production of the GAZ-4301 on the assembly line, the production of a dump truck “agricultural truck” on its chassis was organized - under the GAZ-SAZ-4509 brand. This agricultural grain dump truck was intended to work as part of the 8.6-ton GAZ-6008 dump truck train (together with the GKB-8536 trailer). In general, the prospects for the GAZ-4301 truck in Soviet-style agriculture would be good. However, after the collapse of the USSR, there was no agriculture in the country, at least in its previous form. It was completely destroyed.

A note from 1984 about the prototype of the GAZ-4301 diesel dump truck “agricultural truck”, exhibited at VDNKh.

Since the very concept of a truck created on the basis of the GAZ-3307 was archaic, and the economic conditions in the country had radically changed (no government subsidies, no demand for such vehicles), the new diesel truck was discontinued by 1995.

Release history

Trucks began to be produced at the capital's plant, it was ZIL, and the GAZ plant began developing a model code-named 4301. A leading group of design engineers worked on it. In the construction of this car, names such as Prosvirin and Butusov appear. It was thanks to them that this brand of GAZ truck type car was released at the end of 1982. The truck was tested for sowing and harvesting work for a whole year.

Then, the truck waited for a route 9 thousand km long.

Engine GAZ-4301

GAZ-4301 trucks were equipped with six-cylinder 125-horsepower air-cooled diesel engines GAZ-542.10. This was the first diesel engine developed by specialists at the Gorky Automobile Plant. To introduce it into production, they used licensed German technologies.

An air-cooled diesel engine for a truck is a rather rare solution, which, besides Deutz, is probably only used in real practice by Tatra. However, for our country, with its long cold season and fairly moderate heat in the summer, it is completely justified. Which, by the way, was convincingly proven by tens of thousands of Magirus-Deutz trucks purchased by the Soviet Union during the construction of the BAM.

The cylinders of this motor are easily removable, with external fins. The oil cavity at the cylinder-crankcase interface is sealed with a copper gasket. Cylinder heads are separate for each cylinder, with external and internal fins to ensure cooling by passing air, with insertable cast iron seats and valve guides, with V-shaped valves.

The pistons have three compression rings and one oil scraper ring. Connecting rods - with an oblique connector of the lower head. The connecting rod is finished together with the cap, so the connecting rod caps are not interchangeable. The crankshaft is seven-bearing, with removable counterweights.

The engine is equipped with an overhead valve timing mechanism with a lower camshaft. The camshaft here is seven-bearing, at the rear end of which there is a timing gear. With its help, through the crankshaft gears, the camshaft is driven.

The high-pressure fuel pump (HFP) is in-line, with a mechanical two-mode centrifugal regulator. The low pressure fuel pump is a piston type. The fuel pump is a plunger pump with manual fuel pumping.

The GAZ-542.10 engine uses closed-type injectors, the pressure at which the needle begins to rise is 22 MPa (220 kgf/cm2).

The cooling system is air, with a gear-driven fan through an adjustable fluid coupling.

There are two filters for the fuel system: coarse filter (sump filter with a mesh element) and fine filter (with replaceable paper filter elements). The engine air filter is installed with a replaceable element and a maximum fill indicator.

To facilitate engine starting in frosty weather, an electric torch device (EFD) and an air diesel starting heater are provided.

Technical characteristics of the GAZ-542.10 diesel engine:

- Power at 2800 rpm - 82 kW or 125 horsepower.

- Maximum torque, at 1600-1800 rpm. – 37 N.m.

- The maximum engine speed at idle is 3040 rpm.

- The minimum engine speed at idle is 575-625 rpm.

- Cylinder diameter – 105 mm, piston stroke – 120 mm.

- Compression ratio – 18.

- The operating order of the cylinders is: 1-5-3-6-2-4.

The control fuel consumption when measured in the summer on a run-in car with a full load, moving on a flat paved road at a speed of 60 km/h, is 15 liters of diesel fuel per 100 kilometers.

Motor: device and features

The GAZ 4301 was radically different from previously released models in that it was the first to use a new powerful engine - a diesel engine. A GAZ 542 engine with six cylinders was installed. Its power was 125 liters per second. Its appearance was associated with a license purchased from Deutz. The GAZ 542 engine itself was developed by the Austrian company Steyr. He became a pioneer in the production of diesel engines at the Soviet plant. The car's diesel fuel consumption is only 16 liters per hundred kilometers.

The engine is equipped with two pumps. They serve diesel fuel:

- the first, a low-compression piston fuel injector, maintains low pressure;

- the second - a high-compression mechanical centrifugal adjustable dual-mode in-line injector - provides high-level compression.

If necessary, the driver can manually pump up the diesel himself. This is possible thanks to a special fuel priming pump.

If a situation arises when the engine operates for a sufficiently long time, several types of fuel purification systems are provided:

- The third system is associated with dry air filtration. This is possible thanks to filtration components that can be changed and a contamination sensor. Cooling of the motor is provided by a fluid coupling and a six-wheel fan transmission.

- Secondary – fine, or deep, type of cleaning. It is provided with paper filter components.

- Primary – a rough type of cleaning. A filter separator is used here. It is equipped with mesh components.

Be sure to read: GAZ-330811 Vepr

Transmission

The transmission of the GAZ-4301 truck includes a single-plate dry friction clutch with a diaphragm spring and a hydraulic drive. As well as a manual five-speed gearbox, three-way, with synchronizers in all gears except first and reverse. There are two synchronizers at this gearbox, of the inertial type.

Gear ratios: I - 6.286; II - 3.391; III - 2.133; IV - 1.351; V - 1.0; reverse gear - 5.429.

Cardan transmission - two open shafts with an intermediate support; three universal joints on needle bearings. The main gear is conical, hypoid type. Gear ratio – 5.857. Differential - bevel, gear, with forced locking. The locking mechanism is controlled remotely by a pneumatic valve.

Vehicle control system and suspension

The steering system of this production model of the car includes a hydraulic booster, which improves driving performance. It significantly eases the effort when turning and reduces the steering gear ratio. As a result of its use, there was no need to turn the steering wheel intensively when necessary. This was a great advantage of the car when driving in a narrow, confined space. Turning has become less energy-consuming, and the driver has become less tired. The wheel turning mechanism includes a globoidal-type worm gear and a 3-ridge wheel on a bearing. This allows you to smooth out shocks to the steering wheel when driving on an uneven, bumpy road, making it easier to control a truck in a difficult situation (a broken tire, stones and cobblestones on the road).

Be sure to read: MAZ-5334 truck crane and other modifications

The car suspension combines the body, the supporting frame and the wheel part. Its purpose is to evenly distribute the load during movement and reduce the negative impact of impacts. If the suspension is done correctly, the movement will be smooth and the truck will be stable while driving.

The GAZ 4301 diesel uses two types of suspension:

- Front suspension. It consists of two front springs (semi-ellipse type) and rubber plates (compression kit). Its goal is to reduce the load and optimally distribute it to the supporting parts while driving.

- Rear suspension. This includes two springs and leaf springs. Its purpose is to smooth out and reduce impacts on the body. This is due to hydraulic shock absorbers attached to the frame and axle supports.

Thanks to the improvement of various components, the car has become more stable. What has been improved? Firstly, they improved the design of the gearbox, lowered the center of gravity, increased the wheel track width, and added a remote pneumatic system.

Steering and brake control

The steering design is a globoidal worm with a three-ridge roller on a ball bearing. Gear ratio – 21.3 (average). The steering system of the GAZ-4301 is complemented by a hydraulic booster, which is absolutely not superfluous for a car of this class.

The truck is equipped with a modern dual-circuit brake system (working, spare and parking). Drum brake mechanisms mounted on each wheel have two autonomous drives for operating them. The dual-circuit brakes of this truck are equipped with pneumatic boosters and hydraulic drive.

Gasoline tanker truck GAZ-4301, manufactured in 1994.

The brake drums of each wheel are solid, cast iron, cast. The front drums are centered and mounted on the edges of the hubs, and the rear drums are mounted on the edges of the axle shafts. To facilitate control, they are made removable. In addition, the brake system of the GAZ-4301 truck is equipped with a device for automatically adjusting the size of the gap in the shoe-drum working pair. The role of parking brakes is assigned to the brake mechanisms of the rear wheels, which are equipped with a mechanical drive.

Brake system and chassis

The car's braking system is made with a high percentage of reliability of all components. There are two separate actuators capable of operating dual-circuit brake units at each wheel.

The length of a car's braking distance greatly depends on the load distribution on each wheel. It is very important that one of the pairs of wheels does not lock prematurely.

Important! If the front wheels are blocked, the car loses control, and when the rear wheels go into skid braking mode, there is a high probability of skidding. To avoid these consequences, it is necessary to correctly distribute the braking torque - equally on all four wheels.

Under this condition, maximum safety of the process itself and minimum braking distance are ensured.

When braking, the vehicle's dynamic center of gravity redistributes the load on the axles: approximately 60% on the front and 40% on the rear.

As a result, the front wheels are adjusted to more intense locking.

It was to increase reliability and safety that the designers provided two brake systems with one hydraulic drive and two pneumatic boosters.

The GAZ-4301 is also equipped with a brake system with a pneumatic installation for a trailer.

The truck is equipped with brake drums on 4 wheels, which are made of cast iron.

This mechanism provides a device for automatically controlling the air gap between the block and the drum.

All four drums are easily removable, allowing access to system maintenance.

The parking brake is provided by a manual drive with a gear mechanism, and the pads are released only on the rear wheels.

The wheel rims are a unique element of this truck and are designed specifically for it. They have ventilation hatches, which increases airflow to the brake drums.

Wheel rims are centered by a hole that fits onto the edge of the hub, as opposed to the common flare nut system.

The diameter and class of tires are determined by the series of intended use; for a given vehicle it is 8.25P20. Tires in this series have a ply level of HC12. The pressure in the front tires is normalized to 370 kPa, and in the rear – 540 kPa.

Chassis, suspension

The GAZ-4301 uses a front suspension on two longitudinal semi-elliptic springs, with an additional rubber compression buffer. The rear suspension is based on two longitudinal semi-elliptical springs with additional metal springs and shock absorbers. The shock absorbers on the front axle are hydraulic, telescopic, double-acting.

To increase the energy capacity of the springs and limit their deflection, rubber compression springs are installed on the frame side member in the area of the front axle. Rubber buffers are also installed on the lower flange of the rear frame side members, above the rear axle, to limit the degree of spring deflection.

The wheels on the GAZ-4301 are disc-mounted, with a two-component rim and a split bead ring. Tires - pneumatic, radial, size 8.25 R20, ply rating - NS-12. The recommended tire pressure is: front wheels – 370 kPa, or 3.8 kgf/cm2; rear wheels - 540 kPa, or 5.5 kgf/cm2.

______________________________________________________________________________

Truck GAZ-4301 with a diesel engine

Description of the onboard vehicle GAZ-4301 The GAZ-4301 truck is a domestically produced medium-duty rear-wheel drive truck with a GAZ-542/544 diesel engine. The car has a spacious, modern two-seater cabin equipped with an effective ventilation and heating system. It differs from its predecessors in the use of a diesel engine with the possibility of constant operation as part of a road train. Serial production of the GAZ-4301 car was launched in 1992. The truck was produced with a 6-cylinder air-cooled diesel engine GAZ-542 with a power of 125 hp, which was a licensed copy of the Deutz engine (the license was purchased for a whole family of diesel engines of different power). GAZ-542 is the first diesel engine produced by the Gorky Automobile Plant. In addition to the diesel engine, other components and mechanisms of the GAZ-4301 car also have special features: front axle, gearbox, rear axle with optional differential lock, suspension, frame, cardan drive.

Another difference from GAZ-53 cars is the dual-circuit braking system with hydraulic drive and two pneumatic boosters. Good stability of the car was ensured by a low center of gravity and a wide track of the front and rear wheels. An effective heating and ventilation system, an electric torch device to facilitate engine starting, a device for blowing and washing a semi-panoramic windshield, an adjustable sprung driver's seat, and power steering are aimed at improving the consumer qualities of the GAZ-4301 truck. There are differences between the GAZ-4301 and GAZ-3307 trucks, but they do not play a big role.

For example, these are original wheel rims with four small holes between the ventilation windows (such wheels cannot be installed on cars of other models, since in the GAZ-4301 the disk is centered on the hub not by the conical part of the wheel nuts and footings, but by the central hole) and two main brake cylinders with pneumatic boosters, which are located on the left on the frame behind the cabin in front of the fuel tank. Technical characteristics of the GAZ-4301 truck Engine GAZ-542 Model - GAZ-542 Type - Diesel, four-stroke (air-cooled) Number of cylinders - 6 Cylinder operating order - 1-5-3-6-2-4 Direction of crankshaft rotation - Right Cylinder diameter and piston stroke, mm - 105x120 Displacement, l - 6.23 Compression ratio - 18 Rated engine power at 2800 rpm, kW (hp) - 92 (125) Maximum torque at 1600-1800 rpm min, N m (kgf m) — 37 (37) Maximum idle speed, no more, rpm — 3040 Minimum idle speed, rpm — 575–625 Ventilation system — Closed High-speed fuel pump pressure (fuel pump) GAZ-542 - In-line, with a mechanical two-mode centrifugal regulator Low pressure fuel pump - Piston type Fuel priming pump - Piston type for manual pumping of fuel Injectors - closed type, needle lifting pressure 17.16 MPa (175 kgf/cm2) Fuel filters GAZ-542: coarse - Sump filter with fine mesh filter element - With replaceable paper filter elements Air filter - Dry type, with replaceable filter element and maximum clogging indicator GAZ-542 diesel cooling system - Air with gear fan drive through an adjustable fluid coupling Means for facilitating starting - Electric torch device (EFD) Starting heater for diesel GAZ-542 - Air diesel Transmission GAZ-4301 Clutch GAZ-4301 - Single-disc, dry friction, permanently closed, with a diaphragm spring. Clutch drive - hydraulic GAZ-4301 gearbox - Mechanical, five-speed, three-way, with synchronizers in 2nd, 3rd, 4th and 5th gears Gear ratios: I - 6.286; II - 3.391; III - 2.133; IV - 1.351; V - 1.0; z.x. — 5.429 Cardan transmission — Two open-type shafts with an intermediate support, three universal joints on needle bearings Main transmission — Conical, hypoid type. Gear ratio 5.857 Differential - Bevel, gear with forced locking Control of the locking mechanism - Remote, pneumatic crane Chassis GAZ-4301 Wheels - Disc, with a two-component rim, with a split bead ring Tires - Pneumatic, radial, size 8.25P20, ply rate - NS12 Tire pressure, kPa (kgf/cm2): - front wheels - 370 (3.8) - rear wheels - 540 (5.5) Wheel toe-in, mm - 0–3 Front suspension - On two longitudinal semi-elliptic springs with additional solid rubber compression spring Rear suspension - On two longitudinal semi-elliptic springs with additional springs Shock absorbers - Hydraulic, telescopic, double-acting, installed on the front axle Steering GAZ-4301 Steering mechanism - Globe worm with a three-ridge roller on a ball bearing. Gear ratio - 21.3 (average) Power steering - Hydraulic Brakes GAZ-4301 Service brake system - Dual-circuit, with separate axle braking, with a pneumohydraulic drive and two pneumatic boosters, with drum brakes on all wheels, has a two-wire pneumatic outlet for controlling the brakes trailer Spare brake system - Each circuit of the service brake system Parking brake system - The function of the parking brake system is performed by the brake mechanisms of the rear wheels, which have a mechanical drive Electrical equipment GAZ-4301 Type - Single-wire, negative terminals of current sources are connected to the car body Rated voltage, V - 24 Generator - 5101.3701 AC with built-in rectifier and voltage regulator Batteries - Two 6ST-110A with a capacity of 110 Ah each Starter - 3002.3708 Lights - Two FG122-VV1 Front lights - PF130AB Rear lights - 35.3716 Instrument and starter switch - 2101.370400 0-10 with anti-theft device Sinic cleaner-201.5205010 Glass carrier-1112.5208000-03 The cabin-4301 cabin-double, two-door, metallic, equipped with places of fastening of the seat belts-oil heater, with two radiators included in the engine lubricant Independent heater-air, double-mode, operates on diesel fuel, operates on diesel engine Seats - Separate - driver and passenger Tail - Metal with an alligator-type hood and a folding grill grille Special equipment GAZ-4301 Power take-off - Mechanical, single-speed

______________________________________________________________________________

______________________________________________________________________________

- Clutch GAZ-3308, 3309

- Dismantling the GAZ-3308, 3309 gearbox

- Drive axles GAZ-3308

- Transfer case and cardans GAZ-3308

- Cardans GAZ-3307, 3309

- Rear axle GAZ-3309, 3307

- Suspension GAZ-3309

- Steering GAZ-3309

______________________________________________________________________________

______________________________________________________________________________

- Clutch GAZ-53, 3307

- Gearbox GAZ-53, 66

- Rear axle GAZ-53

- Steering GAZ-53, 66

- Ignition installation GAZ-53

- Clutch GAZ-66

- Drive axles GAZ-66

- Brake system GAZ-66

- Winch and power take-off GAZ-66

- Operating systems of the GAZ-66, GAZ-3307 engine

- Engine ZMZ-402 Gazelle GAZ-2705

- Clutch Gazelle GAZ-2705

- Gazelle GAZ-2705 gearbox

- Front axle Gazelle GAZ-2705

- Cylinder head and camshaft Cummins ISF 2.8

- Fuel system of the Gazelle Cummins ISF 2.8 engine

- Cylinder block and piston group of the Cummins ISF 2.8 engine

- Crankshaft engine Cummins ISF 2.8 Gazelle

- Engine Cummins Valdai GAZ-33106

- Clutch and gearbox Valdai

- Bridges Valdai

- Steering Valdai

Catalogs of spare parts and assembly parts

Technical specifications in numbers

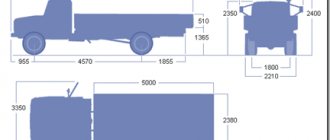

- Overall dimensions: length – 6.42 m; width – 2.38 m; height – 2.42 m (over the cabin), 2.87 m (over the awning).

- Wheelbase - 3.7 m.

- Front wheel track – 1.7 m; rear wheel track (between the middles of the double slopes) - 1.71 m.

- Minimum ground clearance (with maximum load) – 245 mm.

- Overhang angles with full load: front - 36 degrees; rear (along the tow hook) - 31 degrees.

- The minimum turning radius along the track axis of the front outer wheel is 8 m.

- The maximum incline a vehicle can climb when fully loaded is 25 degrees.

- Load capacity: onboard – 5 tons; with awning - 4.85 tons.

- Overall dimensions of the cargo platform – length 3490 mm, width 2170 mm; side height 510 mm.

- Curb weight of the vehicle - onboard - 3.9 tons; with awning - 4,050 tons.

- The total weight of the vehicle is 9.05 tons.

- Load distribution: front axle – 2.35 tons; on the rear axle - 6.7 tons.

- The permissible weight of the towed trailer is 7 tons.

Technical characteristics of the injection engine (2016 model)

- Engine

- model ZMZ-524400 (for GAZ-3307)

- description:

V-shaped, 8-cylinder, 4-stroke gasoline engine with liquid cooling, with a distributed injection power system, OHV valve mechanism with hydraulic compensators, aluminum block and cylinder head, fourth environmental class (Euro-4).

- working volume, l 4.67

- compression ratio 8.3

- maximum power l. With. (kW) / rpm 137 (100.8) / 3200—3400

Max. gross torque, kgf m (N m) / rpm 32 (314) / 2400—2800

- control fuel consumption at a constant speed of 60 km/h l/100 km 19.6, at 80 km/h 26.4

- weight, kg 3275

- fuel: unleaded motor gasoline AI-92 “Regular”. The use of unleaded gasoline AI-95 “Premium” is allowed.

Cabin GAZ-4301

The car has a two-door and two-seater all-metal cabin, equipped with places for fastening seat belts. The cabin heater is equipped with two radiators included in the engine lubrication system. Independent heater - air, dual-mode, running on diesel fuel.

The driver and passenger have separate seats, in contrast to the common “sofa” that the GAZ-52 and GAZ-53 were equipped with. The driver's seat is equipped with a suspension that consists of a coil spring and a hydraulic shock absorber.

To ensure a comfortable fit for drivers of any size. Changing the longitudinal position of the seat is ensured by a slide that has eight fixed positions. The total travel of the slide is 136 mm.

The seat cushion has three fixed positions, which provide a level of inclination of 4, 7 and 10 degrees to the horizontal. Changing the angle of inclination of the seat back is provided by a hinge mechanism, which infinitely changes the degree of inclination of this backrest. The passenger seat in the GAZ-4301 cabin is folding to facilitate easy access to the independent heater.

Reviews from GAZ-4301 owners

In general, reviews from GAZ-4301 owners about these cars are positive. The truck is durable, unpretentious, and has a large load capacity. A “workhorse” that “carries anything, anywhere.” The suspension is soft and works efficiently. The actual diesel fuel consumption, according to the owners, is 19-22 liters per 100 km in the urban cycle and 16-17 liters per 100 km when driving on the highway.

The GAZ-542.10 engine is characterized by many owners as quite reliable, durable and high-torque: “For a mileage of more than 1.5 million km, there was only one engine repair and two fuel system repairs”; “Once I was driving loaded, and calmly pulled a loaded ZIL behind me. The operating temperature of the engine is up to 170 degrees, but it never heats up above 120 degrees. It takes care of its working life up to the “capital” without problems, only the rings and liners are changed. And - no problems with the cooling system, since it is air.

But not everyone is lucky. There are also reviews that these engines “do not run for a long time” and also have an extremely unpleasant “disease”: their crankshaft bursts, and so “successfully” that it makes a hole in the block. Any repair of this engine, just because it belongs to the “autoexotic” category, becomes a serious problem. Spare parts for it cannot be found during the day, and they are very expensive.

Therefore, those who “burned themselves” by buying a GAZ-4301, “buying themselves problems,” are advised to choose another, some more mass-produced truck model and avoid such a less common model. Because behind the external gloss and decent condition, there may be a twisted mileage and an already exhausted engine. Few technicians undertake repairs because they do not know the motor.

The synchronizers that are installed on the gearbox of this vehicle require very careful treatment. The gearbox itself works clearly and reliably, the speeds are switched on smoothly. The performance of the braking system also deserves positive feedback (the brakes on the GAZ-4301 are pneumohydraulic, like on the PAZik). The power steering is the same as on the GAZ-66, it is good, but in severe frosts (about -30 degrees) it may not always work. The metal from which the truck cabin is made is not of high quality - after 5-7 years it begins to rust and rot non-stop.

In general, many owners call the GAZ-4301 an “eternal car” - because “you will never sell it to anyone.” “In 1995, I bought a new GAZ-4301 for $5,000... If only prices for new equipment were like this now!”

How does the model differ from others?

The reviews for this car are simply impressive. The owners are especially pleased with the presence of original disks, which in addition to 4 oblong ventilation windows have 4 more small holes located between them.

GAZ wheels cannot be installed on another car, since their structure was developed specifically for the GAZ-4301. Another advantage is the presence of two main brake cylinders with a pneumatic booster, which is located to the left of the frame between the cab and the fuel tank. The car comes with special wear-resistant tires that have a ply class of HC12. Maintenance and repair of the Gazelle is not very expensive, which cannot but please the owners.

The steering has a hydraulic booster, which significantly improves driving. This device pleases all drivers, as the large truck takes corners wonderfully. Moreover, the presence of such a device reduced the number of turns of the steering wheel, which made life much easier for the owner of the device. Most of all, the presence of a hydraulic booster manifests itself during maneuvers in confined spaces.

This is what the steering column looks like for Gas 4301.

Due to this mechanism, shocks to the steering mechanism from road imperfections are absorbed, and the controllability of the device also improves when in contact with large bumps, or in the event of a punctured wheel.

The stability of the car is quite high. The plant engineers managed to achieve this by installing remote control of the differential lock using a pneumatic valve. Moreover, the updated transmission and axles had a positive effect. The GAZ is based on a frame made of high-strength material, which is considered wear-resistant and will last for quite a long time. The front suspension significantly reduces loads, distributing them evenly across all pairs of wheels. Improves vehicle traction performance.

This is what the frame looks like for Gas 4301.

There is an installed pair of semi-elliptical front springs with an additional compression kit made of rubber plates. The rear suspension consists of a pair of springs and additional leaf springs. All these characteristics are significantly higher than those of other car models of the same type. The advantages of the GAZ-4301 are obvious. However, due to the fact that all parts for the GAZ truck are only suitable for original ones, you will have to look for spare parts. Most often, car dismantling comes to the rescue. It is there that you can find all the necessary details.

Cost of a used GAZ-4301 truck

Indeed, despite the low prevalence of this model, there are many advertisements for the sale of such a truck on the secondary car market. For some reason, especially many GAZ-4301 are sold in Ukraine. In Russia, the price of a diesel GAZ-4301 produced in 1992-1995 varies from 75 to 250 thousand rubles; in Ukraine – from 2 to 12 (!) thousand dollars.

Go to other RUBRICS of the site

Vehicle modifications and improvements

Subsequently, some modifications to the car were made. For better stability, the nodes have been changed and updated. The gearbox has become completely different; a differential lock using pneumatics has appeared. The front axle has also been improved. But a more powerful power unit was installed on it, which increased the load. After this, the car began to get stuck in unstable ground. Subsequently, during times of crisis, the truck lost its relevance. So, in 1995 it was discontinued.

Nowadays such a truck is quite difficult to find. But in many villages it still serves its purpose. If someone is going to repair a car, then it will not be easy to find spare parts for it. To do this, it is best to contact a disassembler or those who sell the remaining parts. If you want to convert such a car, you will need to obtain permission from the traffic police inspection.