GAZ-AA is a truck of the Nizhny Novgorod (1932) and later automobile plant in the city of Gorky, with a load capacity of 1,500 kg. The model is also called “lorry”. The debut 5-year plan for improving the economy of the Union of Soviet Socialist Republics (1928-1932) made it possible to begin a majestic development program.

The plan provided for the construction of more than 1,500 massive objects, including hydroelectric power plants, metallurgical plants, automobile and tractor factories. To implement all these projects, transport was needed, therefore there was a difficult strategic task - to organize a full-scale production of trucks. The entire GAZ model range.

GAZ-MM 1942

When driving in winter, they tried to insulate the hood, not the cabin - the driver remained exposed to all the winds.

The upper “ramp” was used as a window. During winter driving, they tried to insulate the hood, not the cabin - the driver remained exposed to all the winds. The upper “ramp” was used as a window

When driving in winter, they tried to insulate the hood, not the cabin - the driver remained exposed to all the winds. The upper “ramp” was used as a window

Power point

Has the following characteristics:

- engine brand - "GAZ-A";

- type - gasoline;

- configuration - four-cylinder, in-line;

- working volume - 3285 cubic cm;

- maximum power - 40 hp. With.;

- torque - 1200 rpm at 165 Nm;

- cylinder, diameter - 98.43 mm;

- compression ratio - 4.22;

- piston stroke - 87 mm;

- cooling system - water;

- block head - cast iron;

- cylinder block - cast iron;

- number of cycles - 4;

- maximum speed - 70 km/h;

Transmission - manual, four-speed gearbox.

GAZ-AA

GAZ-AA

GAZ-AA

GAZ-AA

Thanks to mass conveyor production, the GAZ-AA turned out to be the most “high-volume” truck of those years. In general, priority production of trucks is the main feature of the Soviet automobile industry of the 30s. The rapid development of industry, agriculture and the army required, first of all, a large number of trucks. And Soviet factories devoted all their efforts to their production, making the USSR the world leader in the production of trucks.

Flaws

The weakest point of the lorry was the starter and battery. Their service life barely reached six months, then the unit broke down and the battery had to be repaired. Usually the car was started with a crank.

Another significant problem in the operation of GAZ-AA was the acute shortage of tires. It got to the point that the rear axle of the car was not equipped with four wheels, as it was supposed to be according to the passport, but only two, because of which the load-carrying capacity of the car decreased.

And yet, the “lorry” was the most popular Soviet car in the pre-war and war years. The GAZ-AA chassis was also used for modified developments - these were ambulances, various tanks, light and acoustic installations, repair mobile "flights", anti-chemical, hygienic and sanitary auto laboratories, radio stations and early warning radio systems, charging and lighting stations and aviation starting units.

GAZ-AA

The lever on the steering wheel is the light switch.

The lever on the steering wheel is the light switch.

The lever on the steering wheel is the light switch.

As easy as pie

Henry Ford's cars have always been well thought out. Each part was designed based on precise consideration of loads, was high-tech, lightweight and simple in configuration. The design of components and assemblies was also not something very complicated, which greatly contributed to simplifying the process of operation and repair.

The GAZ-AA engine, a not very intricate design, had a low compression ratio, so it could run on any type of gasoline, including kerosene in hot weather. The gearbox was 4-speed and did not have synchronizers. The suspension had three springs: one transverse at the front, two longitudinal cantilever springs at the rear. This mechanism is very original: the spring is, as it were, inverted and is fixedly attached to the frame with its center, with its front end through the earring also to the frame, and with its rear end to the bridge. Brakes are mechanical with cable drive on all wheels. There were no boosters - drivers simply pressed the pedal harder. The simplest electrical equipment system, gravity supply of fuel from the gas tank in the engine panel and many other successful technical solutions did not require deep knowledge of mechanics from drivers and simplified maintenance.

Only in 1938 the Ford design was slightly improved. Engine power increased from 40 to 50 hp, the weak universal joint was replaced with a more reliable Spicer type, and a new steering mechanism appeared. Such “one and a half trucks” received the GAZ-MM index.

With one headlight

If the serial pre-war “one and a half” GAZ-AA was considered simple in design, then ours with the GAZ-MM-V index was even simpler than shelling pears due to the difficulties of wartime. In fact, the truck was simplified into a cart with a motor.

Advantages and disadvantages

Pros of the car

- High-quality and reliable body metal;

- Good ground clearance;

- Excellent vehicle cross-country ability;

- Small dimensions of the truck;

- There is a windshield wiper (on the driver's side);

- Unpretentiousness in fuel;

- Clear service;

- American roots of Ford;

- The windshield extends;

- Trailers can be transported.

Cons of the car

- There are no hydraulic power steering and brake systems of the car;

- There are no steering wheel and sofa adjustments;

- Ascetic look of the interior;

- Weak power unit;

- Simple and cool cabin;

- Dependent suspension;

- High fuel consumption;

- Low transportable weight;

- Lack of any comfort.

GAZ-AA

Only the tailgate was folding, but in front-line workshops they sometimes remade the body or changed it.

Only the tailgate was folding, but in front-line workshops sometimes they remade the body or changed it.

Only the tailgate was folding, but in front-line workshops they sometimes remade the body or changed it

By 1941, GAZ-AA and GAZ-MM vehicles accounted for 58.5% of the Red Army's vehicle fleet. This turned out to be one of our advantages during the war. “Lorry” vehicles were the most unified with other equipment: the engine, in addition to trucks, was also installed on GAZ-M1 passenger cars, on BA-64 armored cars and GAZ-67 jeeps, and was used as pumps and aircraft starters, on snowmobiles and small ships. Finding spare parts for it was not difficult. And the designs of all Soviet vehicles were so simple that it became common practice in autobats to assemble one chassis from several broken down trucks. And the whole process took no more than a day! Some Mercedes-Benz, MAN or Büssing may have been much more advanced and better than the ZIS-5 or GAZ-MM, but German spare parts were only suitable for cars of their own brand, and if they were not at hand, then you had to wait until rear services will ensure their supply. In addition, the Wehrmacht was equipped not only with vehicles produced directly in Germany itself, but also with equipment representing the industry of all conquered European countries: French Renault, Peugeot, Laffly, Licorne and Hotchkiss, Czechoslovakian Tatra, Praga and Skoda, Austrian Austro Daimler, Saurer, Buessing and Steyr, Danish DAF.

But first, German soldiers posed smiling against the backdrop of broken lorries, which in the summer of 1941 were scattered by the hundreds along the roadsides - most of the army’s fleet was lost in the first months of the war. The factories were required not only to compensate for these losses, but also to provide the front and rear with the necessary number of trucks. Therefore, with the beginning of the war, the design of the GAZ-MM was revised based on raw material and technological requirements - the already simple car was simplified even more.

Chassis

The design of the “one and a half” rear suspension was original and unusual. Semi-elliptic springs were located in a special way, in front of the rear axle beam, so that their shock-absorbing action took on a lever-like nature. Thanks to this design, the rear suspension became compact and much more technologically advanced compared to full elliptical springs. But this design had one drawback - when braking, the spring blocks took on multiple loads and often failed. The stepladders became loose, and the spring leaves began to move relative to the longitudinal axis.

GAZ-AA

The vacuum-type windshield wiper was driven by a vacuum in the intake manifold.

The vacuum-type windshield wiper was driven by a vacuum in the intake manifold.

The vacuum-type windshield wiper was driven by a vacuum in the intake manifold.

The front wings became flat, they were bent on a bending machine, and then welded - this saved on scarce stamping steel and speeded up the manufacturing process. They also saved steel on the cabin: at first it became wooden, and then completely lost its hard roof - it was replaced by a fabric awning. Instead of the usual doors, tent “rollers” appeared. Everything unnecessary was removed - this applied not only to the unnecessary bumpers at the front, but also to the front brakes, side tailgates (loading was carried out only through the rear), as well as the muffler. All vehicles were equipped with only one, left, headlight - the same ones were installed on tanks, self-propelled guns, and armored vehicles. Naturally, the enterprises that supplied headlights were working at the limit of their capabilities and could no longer provide the trucks with two headlights.

Almost a million

In 1944, the pre-war equipment was partially returned: doors appeared, and the wooden cabin became wood-metal and remained so until the end of production, front brakes, folding side walls and a second headlight returned to their place. The last GAZ-MM left the Gorky assembly line on October 10, 1949. But even later it was assembled in Ulyanovsk - the question of technology for restoring the destroyed country was acute. In total, almost a million trucks were produced.

History of car development

The appearance of the legendary “lorry” was the result of a contract signed in May 1929 by the Supreme Council of the National Economy (VSNKh) of the USSR and the famous American company Ford Motor. This agreement provided for the construction of a new automobile plant, as well as the establishment of mass production of a small truck and a passenger car with the provision of all the necessary technical documentation.

It is interesting that in those years the United States did not have diplomatic relations with the Soviet Union, which did not prevent Henry Ford from taking personal part in the negotiations and subsequent signing of the treaty. Apparently, American capitalists then treated the USSR much more “pragmatically” than in subsequent decades.

The site for the construction of the automobile plant was chosen back in April 1929 - the choice fell on Nizhny Novgorod. This city, as you know, stands on the banks of the Volga and is approached by many transport arteries, which is quite convenient for the development of a large industrial complex.

The company was supposed to start with the production of two basic models, which were copies of the Ford-A and Ford-AA cars. Both of these cars appeared in 1926 and were considered quite modern at that time.

Ford-AA truck, manufactured in 1929

In addition, representatives of the USSR really liked the comparative simplicity of the design, clearly visible even in the drawings, as well as the practicality of the samples proposed by Ford.

Construction of the Nizhny Novgorod plant was completed at the beginning of 1932. Meanwhile, back in 1930, Ford Motors began supplying vehicle kits - essentially, ready-made but disassembled Ford-AA trucks. They were assembled at a hastily created “temporary” plant, on the basis of which a bus production enterprise subsequently emerged. This “screwdriver production” helped the engineers of the future GAZ to become thoroughly familiar with the design of the American truck and put forward a number of proposals for its improvement.

The following components of the car have been changed:

- steering mechanism;

- clutch housing;

- body;

- air filter.

The first truck with these improvements rolled off the assembly line on January 29, 1932. At first it was called NAZ-AA. But at the end of the same year, Nizhny Novgorod became Gorky, and the abbreviation had to be updated - now it looked like GAZ-AA.

The next step was the final “localization”. It was necessary to ensure the enterprise's independence from foreign suppliers. This was achieved in 1933 - from now on only Soviet components were present in the design of the truck.

Another year later, the production of a metal cabin that was quite modern for those years was mastered. Only the roof was made from another material (leatherette). Previously, it was necessary to use pressed cardboard and wood, as in the “original”.

GAZ-MM

At the front, the “lorry” carried everything and sometimes could even replace special vehicles, as in this photo - instead of fuel tankers, fuel from tanks is poured into barrels in the back.

At the front, the “lorry” carried everything and sometimes could even replace special vehicles, as in this photo - Instead of fuel tankers, fuel from tanks is poured into barrels in the back

At the front, the “lorry” carried everything and sometimes could even replace special vehicles, as in this photo - instead of fuel tankers, fuel from tanks is poured into barrels in the back

A comment

Ivan Barantsev, columnist:

Ivan Barantsev

− The car turned out to be so durable that individual copies of the GAZ-AA and GAZ-MM were in use until the 70s. Then the “one and a half” trucks were written off and sent for scrap, but some examples were given the honor of being placed on pedestals in front of the gates of auto plants. Only recently has a fashion for these cars emerged among collectors. One of them, Evgeny Shamansky, restored the military version of the GAZ-MM-V in his workshop. This is both a worthy specimen in the collection and a memory of the Great Patriotic War.

GAZ-AA: car of war

Specifications

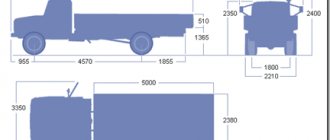

As already mentioned, the drawings of the “one and a half” had to be made virtually from scratch, taking Ford’s designs only as a starting point. This was especially true for GAZ AAA, which had a three-axle model. The car could climb a steep slope (up to 18° slope), move through 40-centimeter ditches and ditches, drive along river crossings with hard soil at the bottom with a total depth of 60 cm. On the ground, the GAZ-AAA could travel at a speed of 25 km at hour, and on a paved highway - 65 km per hour.

The wheelbase was 3.2 meters, and the total weight of the loaded truck was 2.475 tons. Of the 10 gears, 8 were forward, and 2 were rear. The main use of this truck during combat operations was the transportation of towed artillery. Of course, such vehicles were diligently and persistently destroyed by enemy units, artillery and aviation.

Therefore, relatively few examples have survived to this day, the vast majority of which served as the basis for mobile auto repair shops. Since 1943, GAZ-AAA was discontinued. From time to time, the number of vehicles of this type, as well as GAZ-AA, increases due to the efforts of search teams that discover another truck in a swamp, at the bottom of a lake or far in the forest at battle sites.