We will talk about a knife that opens using the gravity of its blade. So he received the name “German gravity knife” for his specific folding, which translated from German means “German gravity knife”. This Luftwaffe knife, designed for cutting parachute lines, still “lives” and has its own distribution, but its purposes, of course, are different.

Gravity knife.

History of origin

The beginning of the 20th century was marked by the First World War. Based on the conclusions made by the countries at the end of it, the world community understood perfectly well that it was necessary to increase its combat power against a sudden attack by any invaders.

The art of war did not stand still; new weapons systems were developed. As well as new types of troops, ground and air. Thus, using the example of the USSR, Germany also adopted the experience of parachute troops.

Such units were strategically important and without them it would have been difficult to fight.

The parachutes developed at that time were quite dangerous. There is no close comparison with modern analogues. We had to land at extremely low altitudes in order to get to a given point. There were no provisions for adjusting the parachute's movement control.

This complicated the work of the parachute units. There were obvious problems with the lines and they had to be dealt with quickly. The question arose almost immediately when the problem was discovered.

Many fighters were injured and even died. The German command made a decision: to supply each paratrooper with a special knife and a sling cutter.

And in this case, German engineers managed to construct a truly amazing blade. It was put into service in May 1937, and its name was “M-1937”.

For airborne troops, the gravity knife turned out to be very useful. The only drawback was his fear of pollution, but more on that later.

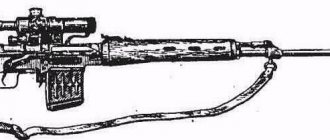

Gravity knife M-1937.

Legality[edit]

See also: Knife legislation

In some countries, such as the UK, Canada and some US states, the gravity knife is defined by law as a prohibited weapon with associated criminal sanctions. Other laws may criminalize the possession, sale, importation, or carrying of a gravity knife, whether concealed or uncovered. In the United States, some state criminal codes prohibit the possession or carrying of gravity knives, either by name or by including a functional description of their opening mechanisms. Other state criminal codes prohibit gravity knives, redefining them variously as switchblades or balisongs (butterfly knives). [3][8][10] Local jurisdictions, including cities and counties, may also restrict the possession or carrying of gravity knives. [eleven]

In some jurisdictions, such as Colorado[12] and New York[13], courts have periodically attempted to classify conventional lock-blade folding knives with a blade that can be opened by centrifugal force (usually by a flick of the wrist) as a gravity knife , which subjects the owner of the knife to the same criminal penalties as illegal possession of a gravity knife. [9] [14] New York's law banning gravity knives was declared "unconstitutionally undefined" by a federal district court in March 2022. [15] New York State legalized the ownership of gravity knives on May 30, 2022, [16] but New York City maintains a ban on public transportation.[17]

Parachute knife: its features and purpose

But now we can talk about the minus - the knife was not dismountable. This caused a lot of problems while using it. It is impossible to disassemble and clean a parachutist’s knife, and if the blade broke, it was impossible to replace it.

The problem was quite serious considering the way it opened.

And it was like this: to bring the blade into working condition, you had to lower the knife down, remove the fastener and make a sharp swing up. Under the influence of inertia, the blade was thrown out and snapped into place.

If it was filled with dirt or other viscous impurities, such a trick would not work. The blade remained in place. The technical characteristics of the M-1937 knife were:

- when unfolded, the total length of the knife is 25.5 cm;

- folded 15.5 cm;

- the blade is made of stainless steel, its length was 10.5 cm;

- the butt is quite decent 4-4.2 mm;

- all metal parts were coated with chrome to prevent rust;

- the handle was made of oak or walnut, fastened with copper rivets.

There was also a switch awl; it helped to untangle knots on slings or was used for various other purposes. Despite the short length of the blade, the knife performed its main task perfectly - it cut slings wonderfully.

There were no complaints about it, a little later its collapsible brother was released, and there were practically no downsides. These blades also had another name - inertial. The name comes from the opening technique.

German gravity knife.

There was a special bow on the handle, to which a rope was attached and tied to the jacket. The knife itself was hidden in a pocket on the trouser leg and closed with a button. The rope prevented its loss and helped with emergency removal of the blade. By sharply pulling it, the knife ended up in the hands.

LiveInternetLiveInternet

Military attachés from many countries were present at these exercises, but only the Germans realized the prospects this new branch of troops offered, which fit perfectly into the strategy of lightning war. The high combat effectiveness of the Third Reich's air infantry was not the result of the "unique qualities of the German soldier," as Goebbels claimed, but of the German military's receptiveness to new technological advances.

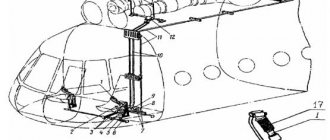

They were greatly impressed by the Kyiv maneuvers of the Red Army in 1935 with the parachute and glider landing of thousands of soldiers. The head of the delegation, Colonel Kurt Student, saw in this an unprecedented opportunity for effective action at strategically important points and immediately reported this to the Luftwaffe chief Goering. He watched with concern the strengthening of his rival Himmler with his elite guard - the SS troops. The Reichsmarshal needed such an elite unit. But the most important thing: the mobility of the Airborne Forces ideally corresponded to the nature of the planned new type of war - blitzkrieg. Of course, at first there were doubts about the effectiveness of “vertical envelopment of the enemy”: would lightly armed soldiers be able to hold out against enemy machine guns, artillery and tanks? In a real battle, will they have enough ammunition until reinforcements arrive? But in Germany in those years, ideas were quickly put into action, and the Germans began creating airborne troops. The driving force behind the matter was Goering, who received the Fuhrer’s consent to this. Parachute schools arose in Stendhal, Wittstock, Gardelegen, Braunschweig, and later 2 schools were added to them in France.

The germ of the Luftwaffe Airborne Forces was the Hermann Goering regiment, which had the same rules as the SS. The selection was extremely tough; Only smart, physically well-prepared volunteers who had proven themselves to be outstanding infantrymen were allowed to take part in the verification tests; preference was given to former soldiers of the Condor Legion with experience of the war in Spain.

Aggression, initiative, and self-confidence were considered the most important things in candidates. Two out of three could not withstand the load and returned to their previous units, but still there was no end to those interested. In the Third Reich, everything related to military affairs was valued (as in the USSR: “First of all, first of all, airplanes”), and this was a real business for brave guys, a magnet that attracted extraordinary people into the troops, predisposed precisely to such activities. The military-technical organization National Socialist Flying Corps, an analogue of the Soviet Osoaviakhim, also took care of replenishing the ranks of the Airborne Forces. In terms of the number of holders of the Knight's Cross, Hermann Goering is one of the top five among the military ground formations of the Third Reich.

On January 29, 1936, the Commander-in-Chief of the German Air Force (Luftwaffe), Hermann Goering, issued an order to create a parachute battalion, which marked the beginning of the airborne formations of Nazi Germany. The battalion was stationed in the city of Stendhal-Borster, located near Berlin. A training center for training paratroopers was also located here. These units experienced their baptism of fire during operations in Scandinavia in the spring of 1940. Airborne units were successfully used in the first stage of World War II during operations in Belgium, Holland, Greece, Denmark, Norway and Poland and received the nickname “Goering's green devils” from the Allies. The airborne units of the Luftwaffe belonged to the elite of the German armed forces; the most advanced types of weapons, equipment and equipment were developed for them.

Paratroopers' small arms

The personnel were armed with some of the best pistols, the Luger P-08 (private personnel) and the Walter P-38 (officers). It was for the airborne units that the famous Erma MP-39/40 submachine guns were developed (among our soldiers they were known as Schmeisser); the Fallschirmlandunsgewehr-42 (FG-42) assault rifle, ahead of its time; assault rifle "MP-44"; signal pistol “Kampfpistole” with a rifled barrel, which allowed firing signal flares, high-explosive fragmentation, explosive and smoke grenades; anti-tank rifles PzB 39 and sPzB 41.

To transport light artillery weapons, an original small tractor, the Kettenkrad, was used, and to transport personnel and equipment, the world's largest glider, the Me-321, was created, which later served as the basis for the giant transport aircraft Me-323.

Large landing glider Me-321

Against this background, it is surprising that as one of the main types of weapons - the parachute system, parachutes RZ1 (until 1940), RZ16 (until 1941) and RZ20 (RZ - Ruckenpackung Zwangauslosung backpack parachute) with an extremely unsuccessful fastening system were used sling for harness based on the outdated Italian Salvatore system. The only advantage of this system was that it allowed landing from fairly low altitudes of 100–120 m (during the operation in Cyprus, some paratroopers were dropped from a height of 75 m).

At the same time, this system had significant disadvantages:

- a strong jerk when the parachute canopy opens;

- the parachute mount did not allow the parachutist to control the direction of descent;

- high rate of descent.

These shortcomings required the paratroopers to master a rather complex parachute jump technique in order to avoid injury due to the strong dynamic impact when opening the parachute canopy (the famous “dive” of the German paratroopers). In addition, due to the fact that the parachutist could not control the parachute during the descent, he could hang on trees, buildings, or land on water. The lack of ability to control the direction of descent did not allow the descent speed (3.5–5.5 m/sec) to be suppressed by turning downwind. Therefore, the landing was accompanied by a rather strong blow. And since during the descent, due to the peculiarities of the fastening system, the parachutist’s body was tilted forward at an angle of 45°, when landing he simultaneously touched the ground with the toes of his boots, knees and hands. To absorb the force of the impact, the parachutist performed a forward somersault. Acrobatic somersaults in the air and on the ground, accompanied by dynamic loads, led to the fact that the landing was carried out “light”. The paratrooper had only a pistol with him as a weapon. All equipment and other weapons were thrown out separately in special containers. In addition, we had to develop a special helmet, protective knee pads and elbow pads. In addition, the features of the system did not allow one to quickly “extinguish” the parachute canopy by adjusting the length of the lines. In strong winds, the parachutist was often thrown over onto his back and dragged along the ground. It is not surprising that even with the use of special protective elbow and knee pads, injuries were common. In order to quickly free himself from the parachute lines if necessary, the paratrooper needs some kind of compact cutter.

All these problems were unknown to the Allies, since their parachute systems were free from these shortcomings, and to cut the lines in emergency circumstances, the paratrooper always had the opportunity to do this with a standard combat knife, which was with him during the drop. For quick release from parachute lines, a special knife-sling cutter was developed by order of the Luftwaffe, which entered service with the airborne formations of Nazi Germany on May 24, 1937. The knife was called “Fliegerkappmesser - FKM” (flight cutter knife) or “Kappmmesser” (sling cutter knife). In Western literature, this knife is also known as the “Luftwaffe Fallschirmjäger-Messer” (Luftwaffe parachute knife), “German gravity knife” (German gravity knife), “Luftwaffe gravity knife” (German Air Force gravity knife), “Paratrooper gravity knife” - ( gravity knife of a paratrooper), “Bundeswehr gravity knife” (gravity knife of the Bundeswehr), as well as “Bundeswehr-fallmesser” (emergency knife of the Bundeswehr) and so on.

Various modifications of the sling knife

German gunsmiths managed to create a simple, compact and reliable knife, which was destined not only to survive the Third Reich, but also to become one of the most famous army knives in the world, which is still in service with the Bundeswehr and some NATO countries. In total, five different modifications of this knife are known, of which the first two were produced during the period of Nazi Germany, the remaining three - in the post-war period.

The first model of the sling cutter “M-1937”, or Type I FKm, was produced between 1937 and 1941 in Solingen, at German and “SMF” (Solinger Metallwaffenfabrik Stoecker & Co) enterprises. The total length of the knife was 25.5 cm, folded - 15.5 cm. The blade had the classic shape of a penknife with a drop point, was made of stainless steel and had a length of 10.5–10.7 cm with a thickness butt - 4.0–4.2 mm. To prevent corrosion, all metal parts were nickel plated. The handle plates were made of oak, walnut or beech and attached to it with copper rivets. The knife had a non-separable design; in addition to the blade, it contained a folding pile - an awl 9.3 cm long for untangling knots. This pile could also be used as a probe for searching for mines. On the handle of the knife there was a bow for attaching a lanyard. The line cutter was worn in a special pocket of the parachute pants above the right knee, which was fastened with buttons. To make it easier to remove a knife from a pocket, as well as to prevent its loss, there was a cord, which was attached at one end to the handle and the other to the parachutist’s jacket. When folded, the blade was fixed inside the handle. Opening the knife could be done with one hand. To do this, it was necessary to press the latch, tilt its mouth down, or perform an energetic wave of the hand, after which, due to gravity, the blade was pulled into the working position (hence the name “gravity” or “inertial” knife). When using the first model of the knife, its significant drawback was revealed - the non-dismountable design practically did not allow cleaning the knife after contamination in the field. This drawback was eliminated in the next model, the M-1937/II (Type II FKm), which was produced from 1941 until the end of the war. In addition to the above-mentioned companies, knives were also manufactured at the enterprises of other companies, including.

Model 1941 (M 1937/II)

The main difference of the second model is the ability to quickly disassemble the knife into its component parts for cleaning or replacing a damaged blade with a new one. Moreover, no special tools were required to perform these operations. In addition, oxidation was used instead of nickel plating on the guard and locking lever, and they were dark in color. Beginning in 1942, the manufacturers' marks on the blades of knives were replaced by their factory codes (Reichsbetriebnummer). So, for example, knives with the stamp “M7/43” were manufactured, and “M7/13” - “SMF”. During the war, due to a shortage of raw materials, oxidation was first used on the blade instead of nickel plating, and then they began to be made entirely from carbon steel with bluing. Knives were not only in service with airborne units, but also with Luftwaffe flight personnel and tank units. After samples of Luftwaffe sling cutters fell into the hands of the British, a decision was made to establish the production of such knives in England for the special forces of the Special Operations Executive (SOE) and other special-purpose units. The English version of the knife was developed by the Sheffield company, at whose enterprises the first batch of 500 sling cutters was manufactured.

English copy

The knives completely repeated the design and dimensions of the German M-1937/II. The exception was black corrugated handles made of bexoid fiberglass, although a small part of the knives were also made with smooth wooden handles. Subsequently, the production of such knives was organized at the factories of other companies in Sheffield and Yorkshire. In total, about 3,200 knives were produced in England during the war years. According to some reports, all the knives remaining after the war were collected together and sunk in the North Sea.

The first post-war model of the sling cutter, the “BW Kappmesser für LL-Truppe” (Type III FKm), was released in 1955, a year after the re-establishment of the Airborne Forces units in the German armed forces. The production of these knives was mastered at the enterprises of companies that specialized in the manufacture of cutlery - “WKC” (Weyersberg, Kirshbaum & Co) and “Anton Wingen Jr.” The knife had a non-separable design, and since there was no pile, the handle of the knife was thinner compared to knives from the war period. The blade, its mouth and the locking lever were nickel-plated to protect against corrosion. The black grips were made of plastic and were grooved in the form of three groups of parallel stripes for a more secure hold in the hand. To prevent contamination, the mouth of the handle was closed with an oval folding metal plug (trap door).

First post-war model (1955)

Returning to a non-separable design, the Germans stepped on the same rake as when adopting the first pre-war model of a sling cutter. In addition, many Airborne Forces veterans wanted to have a familiar military model knife in their hands. Therefore, already in 1961, a new version of the sling cutter was released. It was adopted into service (Bundeswehr designation - 7340-12-140-10-31, Messer, Kapp - LL - Truppe) as the "M-1963" (Type IV FKm) knife. The knife was again made collapsible and in appearance resembled the 1941 model. The difference was the olive-colored plastic handle with corrugation. The inscription “BUND” or “BW” (Bundeswehr) was stamped on the handle. This knife was manufactured by Anton Wingen Jr., WMF (Württembergische Metallwarenfabrik), OWF (Otto Förster, Witzhelden) and Carl Eickhorn Waffenfabrik AG.

1963 Bundkswehr parachute knife

The knife is still in service with parachute, tank and aviation units of the Bundeswehr. Due to its reliability and practicality, the knife was very popular. After completing military service, military personnel often took it with them into civilian life. The enterprises also produced civilian models of inertial knives.

Inertia knives

In 1975, one of the companies whose factories produced knives of the fourth model, Carl Eickhorn Waffenfabrik AG, went bankrupt and ceased to exist. A new one created on its basis (Annette Eickhorn Solingen) began to produce modified sling knives. They were visually distinguished from the previous 1963 model by their smaller size and the presence of a bottle opener on the knife guard. The developers have reduced the number of parts of the knife, making the knife more technologically advanced.

Knives

The knife blade (length - 8.6 cm, butt thickness 3.6 mm) was made of 440 A stainless steel. The olive-colored handle was made of reinforced polyamide. The name and year of manufacture were printed in the central part of the handle (AES 1978, AES 1979, etc.). The total length of the knife was 28 cm. A few years later, the company suffered the same fate as its predecessor - it went bankrupt. The company's shares were bought up by a Scottish company, which acquired all rights to use the Eickhorn brand, patents and all intellectual property. The production of “AES” knives continued under the “Original Eickhorn-Solingen Limited” brand, but with a new name “LL 80” (LL - presumably from Luft-Lande - air-to-ground). In addition to the blade with a regular blade, versions of the knife with serrated sharpening were also produced. The knives were intended for civilian and military use (respectively, they had a black or olive-colored handle).

Sling cutter – tool LL80

All of these knives were marketed as paratrooper knives. However, all of them were never in service with the Bundeswehr, although they were used in army units. In foreign literature they are sometimes called the fifth generation of German sling cutters (Type V FKm). In 2003, after tightening legislation, the production of commercial versions of the strop knife in Germany was discontinued. In the early 1980s. Based on the “LL-80” sling cutter, a version of the knife was developed for units and services working in emergency situations - firefighters, police, etc. The knife was called “RT” (RT - rescue tool - “emergency tool”). The knife was produced in two versions - “RT-1” (with a red handle) and “RT-1 TAC” (black). Unlike the paratroopers' sling cutter, the tip of its blade was shaped like a hook, and part of the blade was sharpened in the form of a fine-toothed saw (serator). In addition, the knife guard had a conical glass breaker. The total length of the knife was 22.2 cm, the length of the blade was 8.5 cm with a spine thickness of 3.3 mm. The blade was made from stainless steel X55 CrMo14 (1.4110), the hardness of the cutting edge was 56 units. Rockwell. The weight of the knife is 210 grams.

The practicality and reliability of the design of this knife, as well as the halo of Luftwaffe paratroopers surrounding it, led to the production of its copies in more than 50 countries around the world. In the USA, this knife is produced under the name “CSAR Tool LL80” (Colt Search and Rescue - a knife for rescue work and emergency situations). The total length of the knife is about 22 cm, with a blade length of 8.5 cm. The 3.3 mm thick blade is made of 440 A stainless steel. The weight of the knife is 210 grams.

American knife Colt Search and Rescue

In knife literature, the kopmesser sling cutter is often classified as a combat knife. However, there is no real evidence of its use in hand-to-hand combat. In addition, like all knives with OTF (out-the-front) blade ejection, it had a strong blade play. To enhance its combat properties, foreign copies of these knives were supplemented with brass knuckles, and knives with a fixed dagger-shaped blade were produced on its basis.

Foreign variations on the theme of the Kopmesser knife

In general, the knife-strop cutter was used by military personnel primarily as a convenient multifunctional tool. Moreover, the parachute units were also armed with the Luftwaffe kampfmesser M42 combat knife.

Luftwaffe paratrooper combat knife

In his book “Combat Knives of Special Forces,” the famous expert in the field of edged weapons, Dietmar Pohl, writes that when asked about the use of this knife in hand-to-hand combat, veterans of the German airborne forces could not remember a single such case. Most likely, such use of the kopmesser took place only during the famous Operation Mercury in Crete. However, this was dictated by extraordinary circumstances. Due to bad weather and strong anti-aircraft resistance, some of the paratroopers were dropped directly above enemy positions, and they had to engage in battle immediately after landing, carrying only a pistol and a sling cutter (losses during the operation amounted to 3,637 paratroopers out of 8,500 who took part in her participation). After Operation Mercury, many paratroopers began to sharpen their sling cutter, giving the blade a dagger shape, so that after landing, in addition to a pistol, they would also have a knife with them, which could be used as a bladed weapon. To be fair, it should be noted that the hand-to-hand combat training program for the English special forces during the war included training in combat with the English equivalent of a knife, including the use of an awl for silently removing sentries. As already noted, the Allied Airborne Forces did not need a special parachute knife-strop cutter. In the USSR, such knives appeared only in the 50s. last century. Their production was organized at (now the Saro enterprise) in the city of Vorsma. The blade of the knife had a length of 13 cm, with a handle length of 10 cm. The blade of the knife was a double-sided saw of a concave shape. The tip of the blade was rounded for safety. The knife was produced in several versions, differing in the shape and size of the blade and handle. The knife was equipped with a leather sheath, which was later replaced by a plastic one.

Soviet parachute knives

This sling cutter was in service with Air Force and Airborne Forces units. In the airborne forces, it was used mainly in training centers, although some were also supplied to combat units. Typically, a standard bayonet-knife was used as a line cutter, which during a parachute jump is located in a special pocket of the reserve parachute. At the end of the 50s. A more compact and safer to use version of the strap cutter was released. In everyday life, the knife was called “NP-58” after the name of one of the parachute models. Its blade, like a German knife, moved out of the handle under its own weight. The carbon steel blade with double-sided sharpening did not have a serrated blade. The handle linings of the sling cutter were made of bakelite. However, the practice of its use showed that due to the reduction in the size and shape of the blade, as well as its strong play, it was less convenient and practical. The knife was produced until the early 1980s.

After the war, a modernized version of this knife was in service with the Bundeswehr and the Warsaw Pact countries.

In total, five different modifications of this knife are known, of which the first two (M-1937 and M-1937/II) were produced during the period of Nazi Germany, the remaining three (M-1955; M-1963 and sling cutters) - in the post-war period.

German paratrooper knives from World War II

Since 1942, another blade was used quite widely by the German paratroopers. It was called the Luftwaffe combat knife. It had a clear guard, and it had a double-sided dagger sharpening. The handle was made of wood and fastened with three rivets.

The blade had an acceptance number and a stamp with an image of an eagle. The sheath is metal, painted black, with a clip for attaching to a piece of clothing.

The first modification of the gravity knife

Taking into account all the previous shortcomings, and specifically the lack of ability to clean the knife, German designers made the first modification in 1941. At the height of World War II they released M-1937/II. In fact, there were no differences, but the opportunity arose to disassemble it.

The first modification of the gravity knife.

And even in the field, without any special tools. This blade served German paratroopers, tank crews and Luftwaffe pilots for the rest of the war, until the Wehrmacht fell.

Second modification of the gravity knife

Quite a funny story with the revival of the M-1937 blade, only in the third variation. At the end of World War II, gravity knives were forgotten for almost a decade. Until the Bundeswehr revived its airborne forces in 1954.

And a year later, production of the third generation of gravity knife “M-1937/III” was launched. Like the initial model, it had a non-separable body, but the awl was removed. The body became noticeably thinner, and the handle was made of plastic. But to prevent the ingress of foreign debris, a long “plug” was invented, which performed its functions very poorly.

The second modification of the gravity knife.

Dirt just wanted to fill the handle of the blade. A rather strange move by German designers - “step into the mud a second time.” Did they really use old drawings, given that the problem was known from the beginning?

Equipment of AKM and AK-74 (1978 and 1989)

The 1978 model bayonet became a kind of calling card of the USSR in the military market. The Kalashnikov assault rifle is known all over the world; in some countries it is even depicted on elements of the coat of arms (Zimbabwe, East Timor). The product is made in a classic configuration for its segment, multifunctional, practical and reliable.

The 1989 version is a completely different bayonet configuration from its predecessor. The shape of the blade has changed, as has the material used to make the handle and sheath. The type of fastening has also undergone modernization, being located on the right in the horizontal plane. The developers believe that the modified configuration of the blade and mount will make it possible to avoid the blade stopping between the enemy’s ribs during close combat.

German post-war model paratrooper knife

Without thinking twice, in 1961 German developers released the fourth version of the blade called “M-1937/IV”. This modification of the sling cutter was the most successful, and was very reminiscent of the 1941 version. And already in 63 it was put into service.

The only difference was the plastic handle with the inscriptions “BUND” or “BW”. This knife has survived to this day and is now in service with the Airborne Forces and aviators of German units. Civilians also liked this successful option.

German post-war model paratrooper knife.

A little later, a well-known German company launched mass production of gravity blades for the population. And in 1978, the AES group also began commercial production of AES-1978 blades for the public.

It was slightly smaller in size and had a beer opener.

The commercial decline of the civilian sling cutter occurred in 2003. The legislation was tightened, and they stopped mass production. And the version “M-1937/IV” still finds its use among various military units.

Bayonets

Separately, it is worth highlighting the airborne bayonet knives. Several variations have been developed in this direction in the Soviet and Russian armies:

- Bayonet for a Mosin rifle. This truly terrible melee weapon inflicted deep, penetrating and long-lasting wounds. This feature is due to the tetrahedral shape of the needle blade and the small entrance hole, which does not make it possible to really assess the depth and severity of the lesion.

- Bayonet for AK (model 1949). It is worth noting that the first Kalashnikov assault rifles were not equipped with bayonets at all. The “6 x 2” product appeared only in 1953; it had a blade identical to the analogue for the SVT-40 rifle, although with a different locking mechanism. In general, the design of the product turned out to be quite successful.

- Bayonet model 1959. This modification for the AK-74 has been replaced by a lightweight and universal version, the basis for which was an experimental model developed by Lieutenant Colonel Todorov.

Famous world analogues of the German paratrooper knife of later modifications

In the post-war period, many countries tried to create knives with similar characteristics and reliability. But not everyone succeeded. The most famous analogues of later models were:

- a representative of the USSR of the 50s - a knife cutter for the Airborne Forces was undoubtedly of no worse quality;

- knife "RT-I-TAC" from, has a total length of 22.2 cm, blade length of 8.5 cm, a spine of 3.3 mm and a total weight of 210 grams. The handle is made of plastic linings of various colors, and the blade has a partial serrated sharpening. Thanks to this, it cuts slings perfectly;

- another attempt by the USSR - a blade called NP-50. It was created as a sling cutter, but did not have a serrator, it turned out to be not very convenient, its production was stopped in the 80s.

In principle, any blade can be used as a bladed weapon. And the examples were no exception. You just need to have certain fighting skills.

American variations

US Army units were also actively developing airborne knives. A description of the M-2 modification is given below:

- configuration – knife with one blade;

- folding type – automatic using a button;

- equipment - spring-lever serving as a lock, bracket.

When folded, a cantilever spring was placed along the back of the handle. It was placed on a stopper that was unlocked by pressing a button. The design of the product also included a stopper against self-opening, which was a slider configuration fuse. The weapon was worn on the chest of a special jumpsuit.

The M-2 modification was highly appreciated by US airborne units and was recommended for use by flight teams with some structural modifications. The updated version was named MS-1 and was made in the form of a folding version, on the reverse side of which a hook-shaped sling cutter with a concave tip was provided. Since 1957, this model has been part of the equipment of pilot crews during emergency and rescue operations.

Additional uses

The main use of such knives, of course, is its direct purpose - to cut slings. But any blade, with certain skills in the hands of a trained person, can become both a bladed weapon and an excellent assistant in any situation.

For example, the very first blade “M-1937” had a switching awl, its purpose was to untangle the knots created on the slings. But if you use a little imagination, the military of those years came up with the idea of using it to test the soil for the presence of mines.

And also, if you attack an enemy from behind, you can stab him in the neck with this awl. So there is no single use for any blade; in the right hands it can become anything.

Previous

Sharpening knivesHolder for sharpening knives with your own hands

Next

Making knives DIY Yakut knife at home

Impact characteristics

It is difficult to judge the impact characteristics of this instrument, since it was not originally intended for combat. Even the paratroopers of World War II, after the end of the war, could not remember a single case of using the Luftwaffe and the 3rd Reich landing force to fight the enemy.

The only exception is the well-known Cypriot operation of the Germans, when sling cutters not only saved lives, but also took them away. However, this case is atypical and is associated solely with the prevailing circumstances. The fact is that when deploying the airborne forces, mistakes were made, due to which most of the landing force landed directly on the enemy’s positions. As a result, after being released from the parachute, the fighters found themselves with sling cutters in their hands and there was simply no time to change weapons.

Combat use was difficult due to the design:

- the teardrop-shaped blade did not allow effective penetration of ammunition;

- one-sided sharpening and small sizes aggravated this situation;

- there was no reliable guard to prevent the hand from slipping onto the blade upon impact.

Blades were made from stainless steel, which could become deformed when hitting a hard surface.

Types and varieties of turning equipment

There is a division of machines according to the following criteria:

- The largest permissible size of the workpiece being processed above the bed.

- RMC – distance between centers (small – up to 150 mm, medium – 150–300 mm, large – more than 300 mm).

There are also many types of lathes, each with its own specific characteristics:

Screw-cutting lathes

Very common due to its versatility. The principle of operation is simple: an object clamped on a spindle in a horizontal position is given rotation, and cutting occurs with the help of a movable cutter. The cutter can be either fixed or separate.

CNC lathes

Automated machines controlled by CNC. The numerical control system ensures high accuracy and serial processing. Operator participation is minimal: creating a control program and monitoring its execution.

Turret machines

As the name suggests, a support with a turret is located on the bed guides. A cutter can be installed in each groove of the turret head.

During processing, the cutters replace each other, scrolling, which eliminates the need to waste time replacing tools.

Carousel machines

Designed mainly for processing large objects weighing several tons. The main structural element is the faceplate - a horizontal disk on which the workpiece is mounted and which gives it rotation.

Hence the name of this type of machine. As a rule, a rotary-type machine has two supports for installing cutters - vertical and lateral. This allows you to process the workpiece on the outer and inner surfaces.

Backing machines

Backing is a special method of sharpening the end surfaces of tools for drilling, milling and threading.

This operation is necessary to restore the shape of the working surfaces of the tool after long-term use. The design of the backing machine is similar to a screw-cutting machine, but has a number of features.

The object being processed is also rotated by the spindle, and the support, together with the cutter, performs reciprocating movements, cutting off (backing) the surface of the object by one tooth.

Lathes

They are similar to rotary lathes and also have a faceplate, but on lobe lathes the faceplate is installed vertically. Rotary and lobe lathes can mutually replace each other.

As a rule, they are used for cutting from the end, that is, from the “forehead”. Hence the name. Designed for processing objects whose diameter significantly exceeds their length (wheels, gears, pulleys).

Machines with continuously variable drive

A continuously variable drive is a mechanism that allows you to smoothly change the spindle rotation speed, without sudden changes and stopping the machine.

This function allows you to gradually select the desired rotation speed during operation, rather than estimating it “by eye”.

Pipe cutting units

As the name suggests, they are designed for processing pipes. They are very similar to screw cutting machines, but there is one significant difference in the design of the spindle: in order for long pipes to be securely held, a tunnel passes through the body of the machine, in which the pipe is clamped by the spindle at two points.

This ensures that the object rotates without play. There are also additional supports for pipes if they significantly exceed the distance between the cartridges.

Turning and milling machining center

A multi-purpose complex that combines turning and milling functions. It has a milling head on which a cutting tool can be mounted.

This head is movable and can process an object both from the side, on the outer surface, and from the end, on the inside.

Automatic longitudinal turning

Designed for serial production and processing of small-sized parts with a diameter of 1–60 mm and a length of 5–300 mm.

The machine is designed as follows: a workpiece is secured in a movable spindle using a collet, while the cutters remain stationary or move horizontally; the spindle together with the workpiece is brought one by one to the required cutters and processed.

Multi-spindle lathes

Machine tools with three or more spindles on which workpieces are mounted for simultaneous or alternate processing. Used exclusively in mass production.

How to make your own arapnik

Making a whip with your own hands, including in the form of a traditional Cossack whip, is not something difficult. This ancient military weapon can be made using fairly modern materials, based on diagrams and practical recommendations.

Making your own arapnik begins with making a handle. For this, hard types of wood are traditionally used - beech, oak, ash, acacia. In general, the material of the handle should be strong, but light, so it is also permissible to use textolite or ebonite, but light metal alloys, on the contrary, are not recommended. To prevent the handle from becoming too thick, before braiding it is necessary to reduce its diameter by an amount that is equal to the thickness of the strips of leather used for braiding.

The classic requirement when making whips is to use natural rawhide, preferably cowhide, as raw material. Belts prepared for weaving must first be soaked in ordinary water: the weaving process will become much easier as a result, and after the leather has dried, the weave will become stronger.

The weaving of the whip-arapnik is made in two main types: regular or with a laid core (vitem). The presence of a core makes the whip less flexible, but enhances the blow, which is why such whips were most often used for hunting or fighting.

Weaving with vitna

In patterns of this type of weaving (for any classic type of arapnik, including a whip), horsehair is traditionally used as the core. In modern conditions, it is not easy for many to obtain it, so a nylon cord attached to the future handle is quite suitable for the base. The strips are screwed to the base so that those that go from left to right are wound first, and then the opposite ones. The end is secured with threads.

Approximate weaving pattern for making a whip