- May 9, 2019

- Weapons and ammunition

- Natali Michaelis

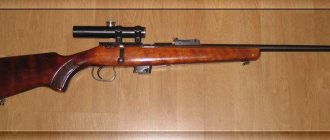

The MC-21-12 hunting rifle today is something truly iconic and unique. Of course, you can find many analogues that have improved technical characteristics, but this self-loading “single-barreled gun” continues to be popular among certain circles of owners. In our article we will talk about which cartridges are best to use for the MTs-21-12. Also here you will find a rating of the most famous manufacturers of 12 gauge ammunition.

History of creation

The MTs-21-12 hunting rifle has more than fifty years of development history, which began back in 1965. The engineers of that time faced a rather difficult task: it was necessary to take into account all the shortcomings of previous models and create something fundamentally new with improved technical characteristics. The work was completed almost completely. Soon, hunters were presented with a 12-gauge self-loading single-barreled shotgun, which to this day is produced only in this version.

It is also impossible not to note that the model almost immediately fell in love with Russian hunters and commercial hunters, which was especially noticeable at the Leipzig Fair, where the weapon was awarded a gold medal. Over time, the model began to become outdated against the backdrop of the TOZ that appeared, but lovers of rarities can to this day purchase weapons secondhand from the same connoisseur of single-barreled guns.

What to do: buy a foreign car or support a domestic manufacturer?

For those who do not want to think and do mechanics, it is easier to purchase an imported “self-loading”. Such single-barreled hunting rifles are beautiful, lightweight and almost trouble-free. There is one small drawback: the price of such weapons can be several times, or even an order of magnitude, higher than the cost of our MTs 21. There are also so-called budget models, but their quality cannot be compared even with our “handicraft” production; this is money thrown away .

Today, the whole world is again gripped by an economic crisis; the cost of imports is steadily rising, as a result of which their supplies are declining. Domestic gunsmiths have an excellent chance to occupy the emerging niche of this market not only in Russia and the CIS countries, but also in Europe. Agree that it is better to purchase inexpensive equipment from Russian gunsmiths and, if necessary, modify it slightly, than to be left without your hobby at all. Turkish consumer goods do not solve the problems - their self-loading single-barreled shotguns are more expensive than domestic ones, and they have similar problems with quality, although commercials say the opposite.

MC 21 was valued by experienced hunters in the past, and now it is bought by those who cannot afford expensive weapons, or by experienced connoisseurs. Of course, this gun has modern competitors, such as the legendary Murka MP-153, TOZ-87 and Bekas-auto. “Bekas” and “Murka” are also very controversial representatives of semi-automatic hunting rifles, but the TOZ-87, if it were manufactured at a higher quality level, could become the best domestic self-loading rifle. The MP-153 rightfully occupies the title of “national”, but its cost is one and a half times higher than the MTs 21-12, and in comparison with it this model is often inferior in the quality of the barrel, has a narrow, inconvenient sighting bar, and is also characterized by misalignment of the muzzle nozzles The guns of Tula gunsmiths are traditionally distinguished by excellent barrels and remarkable action. Many hunters purchasing MC 21 today make their choice precisely because of these qualities.

Design features

To make it easier to understand which cartridges are best used for the MTs-21-12, you must first read a brief description of the weapon in order to know its design features. It's worth starting with the fact that the gun can only use 12-gauge cartridges loaded with shot or slug. The magazine is filled with one piece of ammunition at a time. The shooter can also block the supply of ammunition into the barrel using a special cartridge cutter. The MTs-21-12 uses a non-automatic flag-type safety, which protects the owner from an accidental shot by locking the trigger. Also quite an interesting feature is the ability to move this very flag to the left side, which greatly simplifies the operation process for left-handed people. The butt of the weapon is made in the form of a pistol. The stock is removable and is fixed with a special nut located on the magazine body.

The gun has a good appearance, has an increased practical rate of fire, high ballistic performance, trouble-free operation and is in demand among hunters. Self-loading shotgun MTs21-12

Ishkhneli Yu.G., Candidate of Technical Sciences, Karaganda © ? 5'97

Our conversation will focus on the only domestic shotgun, the automation of which operates on the principle of a long barrel stroke. It has been produced unchanged for more than thirty years and enjoys well-deserved popularity. The historical prototype of the MTs 21-12 is the Browning AUTO-5 - a semi-automatic hunting weapon that operates, like some artillery pieces, on the recoil-recoil principle and was created at the beginning of the century by John Browning.

This model was developed at TsKIB SOO V.A. Nikolaev and put into mass production by the TOZ plant in 1965. This model was originally manufactured by TsKIB SOO. In the late 1950s and early 1960s, this model was produced in small quantities, with a 675 mm long barrel, having an accuracy regulator and a chamber for a 65 mm long sleeve. Currently, the gun is produced in regular and piece versions with a barrel length of 750 mm and a chamber length of 70 mm.

Let's try to briefly but clearly talk about the main thing - the operation of the mechanism, hidden from the shooter's eyes both by the casing and forearm, and by the lightning speed of the processes taking place. The entire operating cycle of the gun’s mechanisms is divided into two phases: “rollback” and “rollback”. The beginning of the first phase, “rollback,” is the extreme forward position of the shutter. At this moment, a loaded cartridge is in the chamber, the next one, partially extended from the magazine, rests against the cartridge stop located on the bolt. The combat stop, located in the bolt frame, is located in the hole in the barrel shank, due to which the barrel and the bolt are in an interlocked state. The hammer is cocked and its combat hook is on the trigger hook.

When fired, the pressure force of the powder gases is transmitted through the bottom of the cartridge case to the bolt and the barrel connected to it, imparting movement to them in the box. This coincides with the beginning of the movement of the projectile along the barrel and is accompanied by compression of the springs: the hammer (the hammer is cocked), the return barrel and the bolt. The barrel, with its protrusion, releases the left stop of the cartridges, and it, coming out of the groove of the receiver, delays the cartridge, allowing it to exit the magazine by a small amount. Next, the protrusions of the barrel and bolt release the right stop of the cartridges. The barrel and bolt continue to move backwards. Having reached the rearmost position, the bolt is delayed by the feeder lever, and the barrel, under the action of its return spring, disengages from the bolt (the lug is retracted into the bolt frame). In this case, the release hook of the trigger will align with the corresponding disconnector hook. The feed tray is in its lowest position.

After completion of the “rollback” phase, the next phase begins - “rollback” - the movement of the barrel, and then the bolt, forward, under the action of its springs. The barrel, disengaged from the bolt, releases the spent cartridge case, held on the bolt by the extractor and retainer, and with the help of a fork-shaped protrusion on the shank, reflects the cartridge case from the box through the side window of the lid. When the barrel approaches the extreme forward position, with its protrusion on the shank it presses on the left stop of the cartridges and recesses it into the groove of the box. The released cartridge, under the action of the magazine spring, moves to the feeder tray and presses the feeder latch with the sleeve flange, which leads to the release of the bolt, which begins to move forward. As the bolt moves, it presses on the feeder, which, rotating, lifts the cartridge, and the bolt moving forward sends it into the chamber. The extractor and bolt lock snap onto the flange of the bottom of the cartridge case, entering the corresponding grooves located in the front of the chamber. The next cartridge is held in the magazine by the right stop until the bolt reaches its extreme forward position. When the bolt approaches the extreme forward position, the bolt with its protrusion presses the right stop of the cartridges, and the released cartridge, under the action of the magazine spring, moves slightly backward until its flange stops against the cartridge limiter on the bolt. Since at this moment the release hook of the trigger is on the corresponding release hook, then to fire the next shot it is necessary to release the trigger. As a result, under the action of the spring, it will rotate on its axis, and the trigger, under the action of the mainspring, will jump from the disconnector hook to the trigger hook. At this point, the rolling phase ends, and the gun mechanisms are in the appropriate position necessary to complete the next working cycle - the gun is ready for the next shot.

When loading a gun, there are three options for feeding cartridges into the chamber. The first option is described in the gun's operating instructions. This is when, with the bolt manually retracted to the rearmost position, the hammer is cocked and the bolt stops on the feeder lever. The cartridge is inserted by hand through the lid window into the chamber and by pressing the latch button the bolt is released and moved to the extreme forward position.

The second option for feeding a cartridge into the chamber is to jerk the bolt and feed it into the chamber from the magazine. In this case, the bolt moves back along with the cartridge moving out of the magazine. Continuing to move backward, the bolt presses the left stop into the groove of the box and the cartridge moves to the feeder tray, pressing the feeder latch with its flange. The bolt, not held by the feeder latch, begins to move forward under the action of the spring, pressing on the feeder lever, which, rotating, lifts the cartridge to the line of movement of the bolt. The bolt, resting against the bottom of the cartridge case, sends it into the chamber. The trigger is cocked.

The third option for feeding a cartridge into the chamber from the magazine is the following position of the gun mechanisms. The cartridge cutter is installed by turning counterclockwise with the knurled head forward. The bolt is pulled back with a sharp movement of the hand and remains in the rear position, held by the feed lever. In this case, the cartridge rests with its flange on the protrusion of the cartridge cutter. The trigger will be cocked. By turning the cutter counterclockwise with the knurled head back, the cartridge is released, which moves onto the feeder tray and presses the latch. The released bolt, moving forward, acts on the feeder, which, rotating, moves the cartridge in front of the moving bolt. The next moment, the bolt sends it into the chamber, and the lug will enter the hole in the barrel shank, thereby ensuring its reliable closure. In all cases of loading a cartridge into the chamber, it is necessary that the gun be set to safety.

One of the advantages noted by fans of self-loading shotguns is the presence of only one barrel. This can be seen from a comparative analysis of the internal ballistics of single-barreled and double-barreled shotguns, which ultimately affects their external ballistics. The operation of single-barrel shotguns is in more favorable conditions, since the barrel during shooting is not influenced by the neighboring one, which is observed in shotguns with twin barrels. During shots, the pressure of gases on the bottom of the cartridge case causes the barrel with the bolt to move backward, and the walls of the cartridge case are pressed tightly against the chamber by gas pressure, preventing the breakthrough of powder gases towards the bolt. This causes an oscillatory movement of the barrel and its heating. In the case of twin barrels, the oscillatory movement of the barrel, and therefore the projectile, will be influenced by the neighboring barrel, which at this time is not involved in the work. In addition, uneven temperature heating in twin barrels will also have an adverse effect on the internal and then external ballistics of the projectile ejected from the barrel. This is especially important when shooting a bullet.

A self-loading gun has less noticeable recoil, all other shooting conditions being equal; it is extended during the movement of the bolt and barrel back, and is therefore more easily perceived.

We won’t discuss the main advantage - 5 shots is not 2.

However, in addition to the above advantages, it has one drawback: the operation of the mechanisms is poorly protected from atmospheric influences. The entry of dust, reed particles, and straw into the bolt box through the cartridge ejection hole and the feeder hole can significantly impair the smooth operation of the mechanisms, and sometimes leads to their complete failure.

It is necessary to constantly monitor the cleanliness of all mechanisms and lubricate them with oil appropriate for the season.

Particular attention must be paid to the recoil system, which includes the brake, brake buffer, buffer-return spring, barrel return spring and support ring. All these parts are located on the magazine body. When fired, the support ring with the barrel, moving backwards, compresses the brake with its internal cone, which is a cut ring, which is compressed from the outside by a ring spring. On the other hand, the brake is compressed by the inner cone of the buffer, which is acted upon by the barrel return spring. In this position, you can fire more powerful charges (with proper lubrication). When turning the buffer backside, i.e. with the inner cone to the spring, increasing the amount of lubricant appropriate to the season, you can shoot with reduced charges. The lubricants used are RZh, Industrial I-5A, CIATIM-201, MS-70, etc. In winter, spindle oil, transformer oil, and technical petroleum jelly can be used to lubricate the mechanisms of the gun.

Thus, the correct selection of charges, temperature conditions, type of lubricant and, accordingly, a correctly assembled recoil device make it possible to shoot cartridges of different power from the same gun, widely varying the weight of the shot shell and gunpowder.

In addition to the problems encountered when shooting from a self-loading gun, indicated in the passport, it is necessary to note several other possible failures of the mechanisms. These are such as a cartridge falling out of the chamber, jamming of the bolt when it is withdrawn manually (the lug does not disengage). Sometimes, when using cartridges that have not been checked by the control sleeve or for other reasons, the barrel and bolt get stuck in the rearmost position. The reason for this is that the lug did not come out of the hole in the barrel shank. Sometimes it happens that after a shot the cartridge case remains in the chamber, and the next cartridge from the magazine is lifted by the tray onto the chambering line. When the bolt moves forward, the latter sticks into the cartridge, and the cartridge into the sleeve that has not been removed from the chamber.

In addition, a likely cause of failure during reloading may be poor lubrication of the bolt return spring, which is located in the butt body tube. Some hunters, after many years of hunting with a gun, not only do not lubricate this spring at all, but also do not clean it of old grease and dirt.

There are spontaneous or double shots. They may be caused by clogging or poor lubrication of the parts of the trigger, disconnector and trigger, which with their hooks move from the release hook to the firing hook when the trigger is released to fire the next shot.

With the above types of failures, reloading the gun most often leads to normal operation of the automation, but then the failure recurs. To eliminate these malfunctions, a complete disassembly is necessary, during which the degree of wear, clogging and lubrication of all components and parts is determined by inspection. To determine the operation of the automation, they use mock-ups - cartridge cases with broken primers, filled to the full height with wads and sealed with a twist.

When determining the reason for the failure of the mechanisms of a self-loading shotgun using mock-ups, repeat the “recoil-roll” cycles several times by sharply pressing the barrel, moving it along with the bolt to the rearmost position.

If, after determining the cause of the failure, it is impossible to eliminate the malfunction, you must contact a repair shop.

Q:

Please respond to the owners of this thing. I am interested in all aspects of this device and glitches during use.

Alex Melnichenko 2:4521/2.3:

Look in the “Hunting and Game Management” libraries. Good articles (8 photos) on MTs 21-12 in “OiOKh” 7/80, on p. 30-32 “O&OKh” 4/90, p. 20-21 "OiOKH" 3/77 - equipping cartridges for MTs 21-12. "OiOKH" 4/84, there on p. 19 tell how to prevent the appearance of cracks in the forend. "OiOKH" 7/70, on p. 28-29 technology and manufacturing drawings of a firing accuracy regulator for a semi-automatic machine (you can look at it, but make it... - 65G steel, heat treatment with an accuracy of 50 degrees, removing part of the ventilation strip and cutting threads at the end of the barrel). Also articles in issues 2/72 - 12/73 - 1/80 - 4/81 - 2/87.

BY DESIGN:

If you believe the periodical press, the quality greatly depends on the year of issue. SOF 2/96 said that until the mid-80s, the manufacturing quality of the IZH-27 and MTs 21-12 was quite decent, but now, whatever happens... It also said that in the CIS conditions, guns with automatic weapons based on the recoil of the barrel have a certain advantage. Gas-operated guns require imported powders that produce minimal soot. The MC 21-12 has a good receiver, which is, IMHO, a big +. Having one barrel:

| Pros: | less cleaning  |

| more accurate combat | |

| easier to shoot with bullets | |

| Minuses: | one type of choke |

| if it misfires, you are unarmed |

The trigger mechanism is mounted on one easily removable base, which is very convenient and this is a plus. The gun is complex and if the workmanship is also low, then this is a huge minus. It is made in such a way that it is easy to disassemble. (comparison with double-barreled guns in this matter is not appropriate - during their entire service life, if there are no breakdowns, they can never be completely

and not to make it out - there is no need.) My experience is not rich, subjective :(((, but it may be useful to you.

BY SERVICE:

When you plan disassembly-cleaning-assembly, keep in mind that it will take at least 3 hours (at first). Don't be afraid of the number of details. You can't assemble the mechanism incorrectly - this is its +. Don't hit the gun, handle it gently. If a part doesn’t fit, move it (fuse) or try inserting it on the other side (shutter assembly), push on adjacent parts... in short, sooner or later everything will come together easily

Don't be afraid of the number of details. You can't assemble the mechanism incorrectly - this is its +. Don't hit the gun, handle it gently. If a part doesn’t fit, move it (fuse) or try inserting it on the other side (shutter assembly), push on adjacent parts... in short, sooner or later everything will come together easily

, but I repeat once again, do not use excessive force. Don’t just click the trigger on the bolt - you’ll break the trigger. If you need to pull the trigger, then move the shutter to the rear position, with one hand constantly press the trigger with the other, holding the shutter, let it slowly move forward. If it has already been in use, be sure to remove the buttstock (carefully the spring flies out!) and inspect the tube, bolt return spring and rod for corrosion. If you don’t take care of this place, it will be the first place to corrode. I use spindle and transformer oil. (we don’t have hunting stores in our city . If the gun sits idle for a long time, then I preserve CIATIM-201 (I checked it on a polished brass sleeve - everything is OK) And where thick CIATIM doesn’t fit, I use a syringe to mix up a mixture of CIATIM 201 + transformer oil. The literature does not advise dripping oil into the hole for the striker in the valve body, misfires are possible due to the hydraulic resistance of the oil.

Don’t just click the trigger on the bolt - you’ll break the trigger. If you need to pull the trigger, then move the shutter to the rear position, with one hand constantly press the trigger with the other, holding the shutter, let it slowly move forward. If it has already been in use, be sure to remove the buttstock (carefully the spring flies out!) and inspect the tube, bolt return spring and rod for corrosion. If you don’t take care of this place, it will be the first place to corrode. I use spindle and transformer oil. (we don’t have hunting stores in our city . If the gun sits idle for a long time, then I preserve CIATIM-201 (I checked it on a polished brass sleeve - everything is OK) And where thick CIATIM doesn’t fit, I use a syringe to mix up a mixture of CIATIM 201 + transformer oil. The literature does not advise dripping oil into the hole for the striker in the valve body, misfires are possible due to the hydraulic resistance of the oil.

ON AUTOMATION OPERATION:

It is regulated: 1) by varying the quantity and quality of lubricant of the tubular magazine body (the surface on which the buffer-return spring, brake, and 2 brake buffers (there are systems with 1), and the barrel support ring are placed. 2) by the position of the rings in the recoil rolling system, i.e. ring(s) - brake buffer is placed with the conical part or flat end to the barrel brake (it is made of brass) and the position of the ring is put on the brass barrel brake. 3) weighing a powder charge (I do not regulate this). 4) the rigidity of the buffer-return spring. (I don’t regulate this).

ON AMMUNITION:

Use new paper and plastic sleeves, domestically produced. All

Check the cartridges with a test sleeve - they should ENTER FREELY AND NOT PROTECT THE ENDS.

This is important, that’s why I highlighted it. Remember the choke - drive all

the bullets through the barrel.

PS: But to be honest, the second time I would take something simpler.

Serge Ageev 2:5030/527.44:

A terrible glitch was noticed: with a large load of gunpowder, sometimes the bolt remained in the rear position. It was treated whenever. Sometimes he took the gun by the barrel and energetically hit the ground with the butt in the direction of the axis of the barrel. Sometimes, if this did not help, I carefully hammered the handle of the knife hard on the reloading handle in the direction of the chamber. If this did not help, then there was a partial and, in case of failure, a complete dismantling. I mean the case when the barrel and bolt, when engaged, rolled back and did not disengage. And in this form they remained in the rear position. It was necessary to use the method of physical pressure

Here, using scientific research, I found a way to prepare glitch-free cartridges for the MTs21-12. Everything is as usual, but you need to roll it up with a 16-gauge screw instead of a 12-gauge one! The cartridges are not cylinders, but rather “cylinders with pressure”. The end of the cartridge turns out to be about 2 mm narrower than necessary and, as a result, fits perfectly into the chamber. Moreover, the sleeve is only suitable for a thick plastic one. If the sleeve does not fit into a 16-gauge screw, then the screw needs to be improved. Or first put the sleeve in a 12 gauge screw and twist it a little. So far everything is fine, the chamber is not torn, the fingers are in place ;).

research, I found a way to prepare glitch-free cartridges for the MTs21-12. Everything is as usual, but you need to roll it up with a 16-gauge screw instead of a 12-gauge one! The cartridges are not cylinders, but rather “cylinders with pressure”. The end of the cartridge turns out to be about 2 mm narrower than necessary and, as a result, fits perfectly into the chamber. Moreover, the sleeve is only suitable for a thick plastic one. If the sleeve does not fit into a 16-gauge screw, then the screw needs to be improved. Or first put the sleeve in a 12 gauge screw and twist it a little. So far everything is fine, the chamber is not torn, the fingers are in place ;).

Sergey Lebedev 2:5020/213.35:

Heavy as crowbar 3700 MTs21-12 against 3100 TOZ-87. Low rate of fire (due to the long barrel stroke). Capricious over time due to the muzzle brake (although people seem to sharpen a wider brake from berylium bronze). Long due to the reloading system (long barrel stroke). Does not like dust and dirt (due to the design of the long stroke of the barrel). In the case of a wedge, it requires lengthy manipulations with the butt resting on the ground and hanging on the trunk.

Andrey Semenov 2:5030/741:

Q

: What to look for when buying?

A

: Barrel. Take a cartridge case without a primer and insert it into the chamber when checking. Look from the side of the muzzle - the rings should be perfectly round and even. Then remove the sleeve and look at the “mirror”: along all channels the barrel should shine like a cat’s egg. Feel the barrel with your hands for any swelling, look at the ventilated sighting bar to see if it’s crooked. Handguard. Remove and by external inspection make sure there are no cracks.

If you identify something wrong with these points, feel free to put it aside.

Take an empty folder sleeve, carefully cut it or roll it up with a tool. Move the bolt to the rearmost position and throw the cartridge case into the receiver window. Press the button. If the bolt sends the cartridge case into the chamber, everything is fine, if not, find out the reason (the cartridge or the cartridge case). Turn on the supply from the store. Place the cartridge case in the magazine. Pull the shutter sharply - the cartridge case should be in the chamber. Finally, the third method of manual loading: put the cartridge case in the magazine, turn off the feed from the magazine, pull the bolt back. Turn on the feed from the magazine - the cartridge case should jump out onto the feeder, and the bolt that breaks from the stop should send it into the chamber.

We hit the receiver cover with the edge of our palm, in the direction “from the butt”, move it and separate it. We inspect the “offal” and the internal surface of the receiver for corrosion.

Alex

Since time immemorial I have had a MC of 21-12, well, it’s sooooo old. He is excellent at his work, although not right away, he did it himself. It’s not difficult for me; as a child I dabbled in homemade shooting guns. Now I come to Russia only for hunting. My MC has become a public center in our team. Where they will take a beginner on a hunt, where they will give it to a guest. Overall reliable. And on my last hunting trip, one of our newcomers asked me to help him choose a MC in the store. Having recently read opinions on hunting sites about the poor quality of Russian weapons, I almost dissuaded him. It's good that you decided to go have a look. We ask the seller to let us look at this with a walnut stock, interchangeable chokes and a paradox attachment (at least look at a curiosity) I know the usual. And the seller is so proud to us, come on guys. It was only returned due to a complaint, jammed

.

Of course I don’t know who the advertiser is. But I think we know one reason. If you understand the reason, consider it no longer there. I suffered for about ten to fifteen minutes while I removed the barrel, bolt cover, bolt, and trigger mechanism. He beat off all hands. And what do I see? The reason is known to me - the entire mechanism was made without gaps and tolerances, plus poor-quality milling of these longitudinally sliding surfaces. There is no problem, a few evenings with a needle file and a drill, and the mechanism shoots like a machine gun. This is only a service, the main thing is the trunk. Let's look at the barrel, it's perfect!

. Paradox - that’s my dream, with my choke I can’t afford a bullet, the barrel is a pity, I think even with sub-caliber ones it can gradually roll out. Made theoretically correctly. The approach to the rifling is almost straight, smoothly turning into a steep screw. So what's the metal of the barrel like? And considering that an imported one of a similar class (though not jammed) costs 10 times more. Everyone is not very good with banknotes right now.

Old Henk

I already wrote here about the pain of choosing a weapon, but I still bought it. So: We looked at the TOZ-87-03, MP-153 store. I wrote about TOZ; in addition, we looked again at the magazine tube, it is green and made of duralumin. In general, I didn’t take the TOZ. I looked at the MP-153 with choke tubes, and for some reason the mechanism also did not inspire confidence. In short, we settled on MTs-21-12. In principle, what they write on hunting sites about the MC and the build quality of recent years corresponds to the truth. We spent 3.5 hours digging around the store. We went through 4 copies. One of the barrel drills looked as if the drill was dangling. The second is a curved sighting bar along the entire barrel, and the barrel, in my opinion, is also curved (the mechanisms of these two were not examined at all). The third barrel has a pronounced metal grab at the muzzle from below. They also put it aside.

We stopped at the fourth one. The barrel is magnificent, all the attachments, including the paradox, are perfectly fitted and aligned. Mechanism: my opinion remains the same: blind craftsmen work at TOZ, plus they don’t know in principle what a file, needle file, or sandpaper is, and all the work is done with large rasps and hammers with a sharp end. In short, everything is beaten, with grooves from rough milling, etc. etc. The longitudinally sliding surfaces of the barrel, bolt and box are, oddly enough, in excellent condition - there are no scuffs, burrs, or anything else. Blackening - g:.e, on the lid of the box there are 3 areas that are not blackened, on the aiming bar at the top in the middle 40 cm. There is no blackening at all. The sighting bar itself at the very beginning has a barely noticeable curvature in an area of about 10 cm, then it is flat. Artistic engraving: I don’t understand at all why it was made in this form, moreover, by the same blind craftsmen - at random.

We checked the machine in the store in every possible way (the seller smiled at first, and by the end of the 3rd hour he turned from “smooth” to “coniferous” - his hair was already moving). Apparently such a show with a choice of weapons has not been seen here. When checking, it turned out that all the mechanisms worked quite smoothly, but when the barrel was manually pushed back, a “fuck” occurred with the idle rolled-up cartridge not being ejected. We considered that this is because a hand is a hand, and powder gases are a completely different case. In general, we decided to take the MC for the length of the barrel, the quality of drilling, the massiveness and visual reliability of the mechanism. On the way home we turned into the forest and shot now my MC. Yes, I completely wiped it clean of grease, and since there was no gun oil in the store, I lubricated the entire mechanism with ordinary Lukoil standard motor oil. We shot a total of 110 rounds (without grinding). The result of the shooting, after everything I read on the Internet about the MTs-21-12, stunned me. During the entire shooting there were 4 delays with reloading. Namely:

- Cartridge "Iskra" shot? 4 in a polyethylene sleeve, after firing the bolt and barrel did not reach the extreme position, the cartridge case was not ejected, the bolt and barrel did not disengage and returned to the forward position. Treatment: I pulled the bolt handle, everything came loose, the cartridge case was thrown out, the next cartridge was chambered - fire! Suspicion: a crappy cartridge, since the Iskra is not distinguished by its workmanship at all.

- A self-loading cartridge with a Poleva bullet - at the moment of the shot, it blew strongly into the face from the receiver window and poured out like sand (apparently unburned gunpowder), the cartridge case was skewed in the ejector window at an angle of 90 degrees. Treatment: pulled back the bolt, threw out the cartridge case, reloaded - fire! Thoughts: Most likely something is the same with the cartridge, since I loaded them under IZH-43.

- “Spark” in a cardboard sleeve, shot? 2. After the shot (it was the last one in the queue), the bolt remained in the rearmost position, the cartridge case was not thrown out, but the metal “butt” was torn off. Treatment: we removed it from the chamber using a special crap that comes with the device for tightening the cartridge cases. The sleeve turned out to have burst, and when examining the torn part, it is clear that the cardboard simply burned through the edge of the metal. By the way, this is a constant problem with the Iskra folder; the same crap happens in a double-barreled shotgun!

Shot: Taiga shot? 5, Taiga fraction? 3, Safari fraction ? 2, Safari fraction ? 5 - 10 pieces of all cartridges. Five self-loading bullet cartridges and everything else - 65 pieces - self-loading cartridges, loaded for IZH-43, Iskra and Azot. What caused bewilderment: what with a strong choke, what from the cylinder with the same cartridges: Safari? 2 (container), Spark ? 2 (without container) accuracy results from 50 steps are the same! That is, 5-7 pellets fell into a rectangle measuring 20x35 cm! But with small shot the picture is different - the shot gives better scree at the same range. I liked the fight, the sharpness is normal: a pine board at 50 steps on average for all cartridges of 3-4 diameters. Moreover, the factory ones have higher sharpness! You will need to slightly increase the amount of gunpowder in your self-loading guns. Cool result from a cylinder with a Poleva bullet! Places bullets in a 15x15 square at 72 steps. Although, it seems to me, the spread of bullets in a square is due to unfamiliarity (my friend and I have no experience of shooting from the MC, but it will take a little getting used to). We haven’t tried the “Paradox”; it requires bullets with centering belts. In short, all the fun costs 9,000 rubles.

And to everyone who recklessly criticizes our arms industry, I want to say: “Boys!

When you buy a gun, you need to examine and feel it, like a woman before getting married (in today’s times, you might end up dressed as a man), don’t be embarrassed by anyone and don’t listen to anyone when choosing (you need to listen and read about weapons before the store), if you’ve already decided to buy something then check the automation with specially rolled blank cartridges (don’t be lazy!). After all, even before buying a lighter at a kiosk, they try to light it. In general, that's it! Test: MC21-12

© ? 2'2000

During the tests, the task was to determine the practical reliability of the gun's automation when firing a given number of shots in a limited period of time. Since the main complaints are made regarding the discrepancy between the reliability characteristics of the gun and the specified parameters, ammunition was selected for shooting that corresponded in its characteristics to those with which the gun undergoes mandatory factory reliability tests.

We will try to explain our position. Any weapon is a mechanism designed to perform a certain job under certain conditions. The more complex a mechanism is, the more complex work it can carry out and the narrower the scope of conditions is optimal for its operation. Many gun manufacturers adhere to this logic, directly warning against the use of self-loaded cartridges or cartridges that do not meet certain requirements in their models.

Apparently, it is illogical to expect even the highest quality self-loading gun to work reliably with some abstract cartridges, equipped with some abstract shooter, if the characteristics of these cartridges and the method of equipment are unknown in advance. When developing weapons, designers focus on certain, more or less variable values of the basic parameters of cartridges, and these cartridges must be fairly widespread and suitable for solving the tasks for which the weapon is being created. Ensuring high reliability of weapons with such cartridges is the responsibility of the designer, and if this requirement is not met, one can conclude that the weapon is not sufficiently suitable for use.

When planning to test the MTs 21-12, we intended to evaluate its performance as a mechanism as a whole, without going into such areas as determining the survivability of a weapon or determining the ammunition most (or least) suitable for a given gun.

Shotgun MTs 21-12 for ? 000573, release date - February 22, 2000, was taken at random (which was our main condition) from the pyramid of finished guns right in the workshop. After that, the test master conducted his own factory tests for reliability, during which 50 shots were fired from it at the highest speed with cartridges loaded with 32 and 24 g shot. We did not notice any delays in the operation of the automation. Without allowing the barrel to cool completely, we began our own test. During the tests, we used Azot cartridges with a plastic sleeve from four different batches of 1998-1999, loaded with 32 g of shot. 4. A total of 200 shots were fired in approximately 30 minutes. The shooting was so intense that the barrel of the weapon became hot beyond any reasonable measure. The receiver also warmed up very noticeably. And this was our second condition: no cleaning or additional lubrication, much less fitting parts - the gun was straight from the workshop and the most severe shooting conditions.

The massive design and especially the automatic system with a long barrel stroke sufficiently softened the feeling of recoil, allowing you to quickly restore the weapon's aim and fire repeated shots. We have not experienced a single delay due to improper cartridge feeding or ejection. Starting from our 162nd shot (don't forget about the first 50) we had 6 delays

, due to the fact that after the shot the bolt of the weapon remained in the rear position. To eliminate this delay, it was enough to effortlessly press the bolt stop button, after which the bolt moved forward, chambering the next cartridge. The panel of experts agreed with our opinion that the reason for such delays could be contamination of the weapon mechanism. Having disassembled the gun after testing, we saw a large number of unburnt particles of gunpowder covering the bore, the inner surface of the receiver and the trigger mechanism, which confirmed our assumptions.

It is necessary to say about the quality of specific batches of Azot cartridges used during testing: some cartridges gave a strong flash when fired, including through the receiver window when removing the spent cartridge case. According to TOZ representatives, when using cartridges with high-quality gunpowder, contamination of the weapon mechanism with powder particles is minimal and the possibility of such delays is practically excluded. And which of us will argue that gunpowder should burn normally, without leaving a residue, but this is a question for patrons, not gunsmiths. In our opinion, the reliability shown during the tests is quite sufficient for a hunting weapon not intended for intense and prolonged fire combat. The delays that occurred can be attributed to the cartridge; in addition, they were not critical and could be eliminated with virtually no disruption to the rate of fire with a minimum of effort. When assessing MC21-12, it is extremely important not to lose sight of the economic side of the issue. At the time of testing, the retail price of this gun in an ordinary version with a beech stock in the factory store was 3,618 rubles. Is it right to compare such weapons with foreign semi-automatic weapons that cost 10 or more times more? Which of the foreign-made guns, structurally and tactically similar to the MTs 21-12, can today be said to be available to the average Russian? To what extent does their superiority over the MC 21-12 in design, ergonomics, prestige, and, perhaps, partly in reliability, justify their price in the eyes of a citizen of a country where the official minimum wage is 83 rubles? We deliberately do not touch here on the primacy of one or another model of domestically produced self-loading weapon. In order to answer this question, it is necessary to conduct comprehensive comparative tests of various models, but is this necessary at all? One of the advantages of the market is the possibility of choice, and some qualities perceived by one user as a disadvantage of a weapon, for another, may serve as the main motive for purchasing this particular model. However, if there can be such a thing as a “classic Russian self-loading shotgun,” then, in our opinion, the MTs 21-12 fits ideally into this category.

Conclusion:

The minimum price and fairly high consumer qualities allow us to conclude that MTs 21-12 meets the requirements for working hunting weapons. The gun provides high reliability when using the appropriate cartridges.

Specifications

Now you know more about the MTs-21-12 device. It's time to talk about the tactical and technical characteristics that can be found in the weapons passport (included with purchase). They look something like this:

- type – smoothbore gun;

- number of trunks – one;

- reload type – semi-automatic;

- caliber – 12;

- weight – 3.2 kilograms.

The manufacturer guarantees that the owner will be able to fire 6,500 shots from this gun without any breakdowns. If you think that this is not enough, then just look at the Saiga warranty card, which indicates the figures for 2000 shots.

General debugging

Hunting rifle toz-106. toz-106: technical specifications, photos

There are specimens in which the case flange is severely deformed after firing. This occurs as a result of poor fit of the locking mechanism. This defect can only be detected after shooting.

Before operating the gun, it is necessary to determine the smaller diameter coil of the brake spring. Use this ring to put it on the magazine tube. You should also use a velvet file to smooth out the sharp parts on the last turn of the spring. In this case, the ferrule tube will not be scratched.

When jerking the shutter, you need to make sure that the rod and spring do not jam in the shank of the box. If something bothers them, the cause should be eliminated. In addition, you need to check the operation of the ammunition cutter. If you turn the flag counterclockwise, the cartridge should stop at the cutoff when the bolt is pulled back. And in the future do not reach the left stop.

Advantages

Based on the above technical characteristics, we can talk about the features and disadvantages of the MTs-21-12 shotgun, a photo of which is given below.

Of course, the main advantage of the weapon, which immediately catches the eye, is its caliber, which is considered universal for most types of hunting. Judging by the reviews, cartridges for the MTs-21-12 are excellent for hunting both ducks and large game. You just need to take into account the weight of gunpowder and the number of shot used in the ammunition.

It is also impossible not to note the rather low recoil for a gun that uses 12-gauge cartridges. It was almost completely eliminated thanks to the already mentioned pistol stock, which, if desired, can be replaced with any other.

But perhaps the main advantage over other guns is that the MTs-21-12 is a real paradise for lovers of tuning and all kinds of modifications. You can install almost any modern body kit on your weapon or completely change its appearance thanks to parts made of expensive wood and plastic.

Description and features of the gun MTs 20-01

The proven hunting classics have remained relevant for almost 50 years, and this despite the fact that the market of modern weapons is constantly replenished with new and interesting models (Figure 1).

The MC 20 01 hunting rifle has three main qualities: a simple and convenient design, versatility in use, and a low price compared to other models.

The MTs 20 01 is perhaps the most accurate smoothbore gun in the history of domestic weapons - a short flash suppressor, a shortened barrel and a folding butt allow it to be used not only for fishing, but also as an effective and reliable means of self-defense. For this reason, even outdated versions that have been discontinued do not leave their leading positions in sales.

In the basic configuration, the technical description of the MC 20 01 is quite simple:

- This is a smoothbore hunting carbine equipped with a box magazine and bolt action typical of sniper rifles.

- One of the features is the constant narrowing of the barrel “poluchok”, as for sighting devices - these are standard rifle rear sights and front sights.

- The main model is presented in 20 gauge; modifications in 28 and 32 sizes are quite rare.

Figure 1. This model is one of the most popular types of firearms

Where it is produced - MTs 20 01 is produced at the Tula Arms Plant. The first version was produced from the 60s until 1971 - after a long break, it was replaced by an improved version intended for hunting. The modernized weapon went on sale in 1979 - it is still produced and sold today, and is widely used for hunting and self-defense.

Advantages and disadvantages

If we talk about the pros and cons of the gun, then the weight and design of the MTs 20 01 can rather be attributed to its weaknesses than to its strengths (Figure 2).

Among them also:

- Not a particularly reliable fuse - there is a risk of failure when the butt hits the ground.

- The magazine is fastened with two latches - there is a high probability of misalignment during installation and locking on one side, which is why it often falls out when fired.

- The blunt-ended cartridges used may rest against the breech, preventing loading.

- Poor processing of the bolt surfaces, the need for a sharp reload to remove the cartridge case, which sharpens in the receiver as a result of the smooth retraction of the bolt.

- The impossibility of firing with a doublet, which is often practiced by hunters.

- Mounted rifle sights make it difficult to track fast and chaotically moving game.

- Very harsh recoil, which leads to cracks in the lightweight stock, which ineffectively absorbs the energy of the shot.

Despite these dubious features of MTs 20 01, the characteristics of the product are not so bad; it has its strengths:

- The sample is designed for firing bullet cartridges, equipped with a rifle rear sight and front sight.

- Again, the rifle design of the bolt with two side protrusions guarantees reliable locking of the barrel, which provokes some owners to equip cartridges with a reinforced charge, with which you should be extremely careful.

- Due to the box magazine, the specimen has an increased rate of fire compared to double-barreled horizontal and vertical guns.

Figure 2. The design of the gun cannot be called absolutely perfect

In addition to good shooting qualities, the product is visually attractive - elegant and laconic, due to the bolt action, it looks like a sniper rifle.

Purpose and varieties

The most widespread in the hunting environment was a replica of the MTs 20 01 shotgun, the length of which varied on different models. It was produced from 1979 to 2006 and produced about 80% of the game during the Soviet period.

The weapon was intended for hunting small ungulates and predators; it was also allowed to be used for self-defense.

Some versions differed in caliber; for MTs 20-02 and MTs 20-03 there were 28 and 32 sizes of ammunition, respectively.

Varieties of 20 gauge MTs 01 include:

- Basic example with a semi-pistol beech stock.

- MTs 24-04 with a 295mm shortened barrel and a folding metal stock.

- Another sawn-off shotgun MTs 20-08 - 550 mm barrel, pistol grip instead of a butt.

- Another short-barreled MTs 20-08 with a full stock, like the original.

Flaws

Now it’s time to talk about the shortcomings, which, unfortunately, in most cases are irreparable:

- Firstly, this model is considered outdated, which is why young hunters who are accustomed to comfort and convenience will not want to purchase it. Although this disadvantage can be compensated for by various devices.

- Secondly, the lack of different caliber variations does not allow you to choose the optimal ammunition “for yourself,” which is why the hunt often ends in large wounded animals and a decrease in the trophy value of the prey.

- And thirdly, a single-barreled shotgun does not allow the use of two different types of ammunition at once during hunting, like the same double-barreled shotguns, which are the standard of hunting weapons in Russia.

Also, if you read information from various thematic forums, you will be convinced that these are not the only shortcomings of the MTs-21-12. Yes, most grievances are based on the individual preferences of hunters, but they cannot be ignored at all.

Instructions for safe use

Like any hunting weapon, the MTs 21-12 self-loading carbine requires compliance with basic safety rules when using it. Gun owners should:

- Maintain the cleanliness of all weapon components;

- Before starting shooting, check that there are no grease residues in the barrel bore, as well as any foreign objects;

- If a misfire occurs, it is recommended to open the shutter only 10-15 seconds after the shot, since there is a possibility of a so-called “lingering shot”;

- In the event of a malfunction of a hunting weapon or its complete failure, you must immediately stop shooting until the problem is accurately identified. As a rule, this requires contacting a specialist;

- Upon final completion of shooting, be sure to completely unload the weapon and make sure that there is no cartridge in the chamber.

No later than 24 hours after shooting is completed, it is necessary to lubricate and clean the weapon in a room warm enough for these purposes. The MTs 21 shotgun, compared to gas-operated semi-automatic weapons, is much easier to clean, since after firing only the barrel is clogged with combustion products. To maintain, clean and lubricate the MTs 21-12 shotgun, it requires partial disassembly. Like all domestic weapons from the times of the USSR, this carbine can be disassembled without the use of additional tools.

When lubricating a gun with MTs 21-12, the oil should not accumulate in drops, but should only shine on the metal parts with a thin film. Otherwise, these droplets will collect dust and dirt. For winter and summer, especially in the conditions of the Far North, different types of oils are used, otherwise in severe frost the lubricant thickens and the gun cannot be reloaded.

MC 21-12 disassembled

Disassembling the gun

Disassembly of the MTs 21-12 hunting rifle must be carried out strictly according to the instructions supplied with the weapon. Many hunters limit themselves to the following operations:

- Unscrew the tubular magazine nut;

- Remove the forend moving forward;

- Holding the barrel, the bolt is pulled back, while it disengages and releases the barrel, being removed from the magazine tube.

Next, it is better to first remove the trigger block. To do this, the opposite (protruding) part of the safety flag is recessed, which is removed in an intermediate position between “fuse” and “fire”. The trigger block can be easily removed when you press the shutter stop button.

To remove the bolt, the stopper (a small part located at the bottom of the bolt body) is pushed forward until the mechanism comes out of the box. The bolt itself should be disassembled when thick lubricant gets into the firing pin cavity: in the cold, this is what can lead to dangerous failure and the risk of a “lingering shot.” To disassemble the shutter, you need to press the stopper and slide the part at the bottom of the shutter; after removing it, the shutter is disassembled into two halves, which is more than enough for its maintenance. For cleaning and lubrication, it is better to use liquid oils, but not in abundance, as this leads to severe contamination.

If the gun is very dirty or wet, you can pull out the bolt return spring located in the butt and clean it. To do this, you need to remove the shock absorber by unscrewing two screws and unscrew the plug of the return spring tube.

Reassembling the weapon is done in the reverse order. It is recommended to install the bolt first, and then the trigger, which is connected with the bolt rods: it is easier to get them into the spring tube when the trigger is not installed. When installing the trigger, it is recommended to ensure that the feed tray is in the lower position, and do not forget to press the shutter stop button, otherwise it will not be easy to insert this unit.

The MTs 21-12 shotgun is recognized as a fairly powerful and accurate hunting weapon, well suited for commercial and amateur hunting of birds and ungulates.

"Glavpatron"

The rating of the best cartridges for MTs-21-12 opens with products from Cartridge Manufactory LLC, which appeared on the market relatively recently. The cooperation of the Tula plant with Italian arms factories makes it possible to create really good ammunition for smoothbore shotguns, which are in great demand among hunters due to the ideal price-quality ratio.

Judging by the reviews, for the MTs-21-12 these cartridges are more suitable for sports than for hunting. In this regard, they are not inferior even to such imported manufacturers as Clever and Fiocchi. However, for hunting it is better to take something more serious.

"Fetter"

The fourth place in our top is taken by the cartridges produced by , founded in 2001. All ammunition is produced exclusively on Italian equipment by experienced employees. In the production process, domestic and imported gunpowders of the highest category are used, which undoubtedly speaks about the quality of this product.

The plant produces ammunition for hunting and sporting purposes, which can be used at various distances. It is also worth noting the rather convenient marking theme, which allows you to quickly determine what type of prey this or that ammunition is used for: “Duck”, “Pheasant” and the like.

"Fiocci"

The top 3 best cartridges for MTs-21-12 are opened by commercial products, which have been extremely popular for almost a century and a half. The company was founded by Giulio Fiocci back in 1876. Since then, it has been supplying only high-quality ammunition to markets around the world.

The company presents 12-gauge cartridges in almost the entire spectrum: classic, magnum, semi-magnum, special, and so on. This product often takes leading positions at various exhibitions, but due to its high cost it is only in third place.

"Rottweil"

This company began producing cartridges four years earlier than its competitor described above, but by 1921 it had become a real trading empire, when it first produced the first cardboard cartridge, “Black Weidsmaheil.” After this, the company began to be loved and respected in wide circles.

Today, Rottweil ammunition is considered the standard of quality, reliability and excellent technical characteristics. However, the concern does not pay close attention to all the components that are used in the production of ammunition, which is why we put it in second place.

Operating principle

The weapon works on the principle of recoil of the barrel and longitudinally sliding bolt mechanism during recoil. To reload, you need to apply a certain force to move the barrel back and forth.

The explosion of powder gases causes the bolt and barrel to move, causing them to roll back to the rear position.

The spring is compressed and the hammer is cocked. When fired, the barrel moves forward due to the straightening of the spring part. Initially, the bolt is held by the suppressor lever. The return spring pushes the bolt to its original position, the cartridge moves into the magazine and the barrel channel is locked. The firing cycle ends.

When there are no shells left in the magazine, the bolt part remains behind. To reload, you need to make a long stroke of the barrel (moving it back and forth).

When firing, the gun should be held like this:

"Clover"

Well, the clear favorite of our top is the products of the Clever brand, the production of which began in 1952 thanks to the union of four enthusiastic friends who understood the design of firearms.

Clover products are very popular among hunters for a number of reasons. Firstly, at one time the company launched a rather convenient marking of cartridges, which greatly simplified the process of choosing them for novice hunters. Secondly, for the production of wads, special felt plastic with special impregnation is used, which can be reused if the primer is replaced. And thirdly, instead of the usual lead shot, steel shot with an admixture of antimony is used here. In addition, the company tries to keep prices for its ammunition reasonable, which is why most hunters choose this particular product for the MTs-21-12.

Loading ammunition at home

Unfortunately, today the cost of even domestic ammunition leaves much to be desired. The cheapest 12-gauge cartridge in 2022 costs no less than 25 rubles apiece, which is why most hunters prefer so-called rolling papers, purchasing them second-hand or making them themselves. Such a process does not require any serious knowledge and skills from you. The only thing you need is to purchase a special machine for pressing gunpowder and rolling cartridges, and also acquire a pharmacy scale.

During the process of creating your own cartridges, you will need to maintain the optimal ratio of gunpowder and shot, which is shown in the table below. As an example, we took Sokol brand gunpowder and number five shot.

| Powder to shot ratio | Gunpowder in grams | Fraction in grams |

| 15,8 | 1,9 | 30 |

| 14,7 | 1,9 | 29 |

| 15,5 | 1,8 | 28 |

| 15,0 | 1,8 | 27 |

| 15,3 | 1,7 | 26 |

Remember that even the slightest error in measurements can lead to dire consequences, so use high-quality electronic scales, checking their functionality in advance with some weight or object whose exact weight you probably know.

Instructions for equipping rolling papers

The indisputable advantage of rolling cigarettes is not only the low cost of the original ingredients, but also the possibility of using already fired cartridges, provided that the primer is replaced with a new one. However, for this you will have to use cartridges made of high-quality plastic, otherwise the material may simply ignite inside the barrel.

To create rolled-up cigarettes, it is recommended to adhere to the following algorithm of actions:

- We check the cartridge for integrity, paying special attention to its primer.

- We measure the required amount of gunpowder on the scales and pour it inside.

- We press in the gunpowder using a machine and install a gasket on top.

- We measure the required amount of fraction on the scales and repeat the procedure.

- We roll the cartridge using a machine using the star method.

After this, all that remains is to mark the cartridge with a felt-tip pen so as not to forget what fraction you used in the process of creating it. The shelf life of such ammunition is no more than 5 years, provided it is stored in a dry place without sudden temperature changes.

Some tips for loading ammo

I would also like to share with novice hunters some tips that will allow you to create better cartridges for the MTs-21-12 at home:

- to increase accuracy at long distances, use tape before rolling the cartridge - this way the shot will retain its original shape longer;

- to increase the initial speed of the shot, increase the amount of gunpowder by 10%, but no more, since too much energy can lead to rupture of the barrel;

- Try experimenting with different loads and powders, then practice shooting at wooden targets to find out which cartridge suits you best.

We also invite you to watch a short video that will allow you to understand in more detail how to load 12-gauge cartridges at home. Watch it to the end if you want to create really high-quality ammunition.

We hope you now understand which ammo is best to use for the MTs-21-12. The MP-153 is the main analogue of this weapon, so you can purchase a gun from the Izhevsk Mechanical Plant if you do not like the above-described version of the self-loading single-barreled gun.

Proper gun care

Cleaning, inspection and lubrication must be done immediately after shooting. It is necessary to assemble and disassemble the tool in a certain sequence, which is indicated in the passport. However, avoid applying too much force or hitting the equipment.

Wipe, lubricate or clean the barrel from the chamber side. Repeat lubrication and cleaning of the barrel on the second, and also on the third day, just in case, after the last shot. After cleaning, inspect the fabric that was tightly passed through the bore. Ideally, there should be no soot or lead on it.

When a shot occurs, some part of the powder gas will enter the box, and therefore it is necessary to carefully clean this part. To clean the grooves, you need to use wooden sticks, having first made an appropriate profile out of them.

Lubrication and cleaning of a gun that is stored without use should be done approximately once every few months. If the weapon is not used for a long time, it should be preserved. Always apply a thin layer of lubricant to parts. The surface should shine from the applied lubricant. To do this, moisten a piece of soft and clean cloth with lubricant, squeeze it tightly and wipe the surface. If you apply too much lubricant, it can lead to failures when firing. Lubricant can get clogged in the bolt hole under the firing pin exit, and this often causes a misfire.

If you hunt in a humid environment, in rainy weather or near the sea coast, then lubrication and cleaning must be done daily, regardless of whether you fired a shot or not.

The lead lining of the barrel bore must be removed using a metal brush, which is generously moistened with oil. If there is carbon deposits in the bore, it can be softened with soapy water or a solution of caustic soda. If there is no RJ oil, then we clean and rinse with ordinary alkaline oil.

Under no circumstances should the muzzle of the barrel be pressed against the floor when cleaning. This is explained by the fact that the cleaning rod, like the pump piston, when entering upwards, is capable of drawing in all dust, crumbs or sand from the floor. That is why you need to put something on the floor, for example, an unnecessary magazine or newspaper.

If fresh rust has appeared, then it is worth removing it with the end of a wooden stick or an ordinary cloth, which is moistened in RJ or alkaline oil. To soften rust, soak a cloth in oil, then place the cloth on the affected area and leave for about 10 hours.

If you went hunting in frosty weather, then you first need to give the weapon time to warm up after the frost at room temperature, and only then start cleaning.