- January 5, 2021

- Weapons and ammunition

- Lolita Milyavskaya

Currently, this arsenal is very often used in our country. This ammunition was invented in 1943 by Soviet designers N.M. Elizarov and B.V. Semin. And they began to produce it in 1947. All over the world this cartridge was known as ammunition for the famous Kalashnikov assault rifle.

Only later, on the basis of this ammunition, they began to produce bullets for sport hunting - 5.6x39 and the American cartridge 5.56x45. The list is actually not complete yet.

It is worth noting that this cartridge is mainly used for hunting and for training in military units.

The main purpose of this ammunition

In order to decide which 7.62x39 cartridges are better, you first need to understand what this ammunition is and what its most important purpose is.

This arsenal was originally created as a cross between a rifle cartridge - 7.62x54 - and a pistol cartridge - 7.62x25. This ammunition is ideal for combat with a person whose average weight is no more than 70 kg, as well as for firing from light machine guns and machine guns.

Many hunters prefer to use this ammunition for shooting from carbines, such as the SKS. Such ammunition can be fired mainly at a distance of 200 meters, no more.

Main characteristics of this cartridge

Before deciding which 7.62x39 cartridges are better, it is recommended that you familiarize yourself with the basic characteristics of this cartridge.

These characteristics include the following:

- The bullet energy is about 2200 J. Ideal for use in military service. But experts do not recommend hunting animals due to the fact that one bullet cannot finish off the animal (that is, it is necessary to shoot at it several times).

- This cartridge is produced with SP, FMJ, HP bullets.

- The weight of the cartridge can vary from 16.2 to 20 g, and its length is 55.5 mm.

- The weight of the bullet can be 6.6 g, or even 12.6 g.

- The initial bullet speed varies from 293 to 760 m/s.

- This cartridge is ideal for conversion weapons.

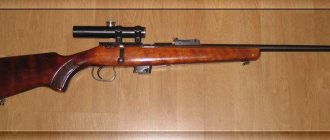

- In addition, the arsenal is suitable for rifles that have a bolt action.

Due to the fact that this ammunition has a fairly wide penetration effect, it is capable of penetrating body armor, a steel helmet, dry pine beams, brickwork and even high-strength steel armor.

The main advantages and disadvantages of this ammunition

Very often, many hunters are interested in the question, which 7.62x39 cartridges are better? In order to answer this question, it is very important to familiarize yourself with the main advantages of this ammunition.

Thanks to the following qualities, this arsenal is very familiar to many Russian hunters:

- Relatively low price. That is, it is easy and simple to find in many stores.

- Ideal for training. Quite often this arsenal is used for sports shooting.

- Slight cartridge recoil.

- This ammunition has a fairly stable flight through various obstacles. For example, through bushes.

But, despite the fact that this arsenal is in demand, it also has disadvantages. These include the following:

- The arsenal's ballistics are noticeably poor.

- This cartridge is not particularly effective against large animals.

- It happens that the quality of the cartridge can fail at the most inopportune moment.

However, there are situations when hunters still managed to kill large animals, such as a bear, with one arsenal. But, as experts note, this is just a matter of luck. If we consider this cartridge as a whole, then this ammunition is good, but in its own way.

Features of the penetrating action of the 7.62x39 mm cartridge

The bullet of this cartridge is capable of having the following penetrating effect.

1. You can easily and simply pierce a steel helmet SSh-40 as follows:

- At a distance of more than 1100 m using an armor-piercing incendiary bullet, the probability will be about 80–90%.

- At a distance of 900 m with a steel core bullet there is an 80-90% probability.

2. You can penetrate the 6B1 body armor as follows:

- At a distance of 600 m with a steel core bullet there is an 80-90% chance of success.

- At a distance of 1000 m with an armor-piercing incendiary bullet with a probability of 80–90%.

3. High-hardness steel armor, the thickness of which is about 7 mm, and the angle of contact is 90 degrees, can be pierced using an armor-piercing incendiary bullet as follows:

- With a probability of 50%, but at a distance of 300 m.

- With a probability of 90%, but at a distance of 200 m.

4. You can break through a parapet from tightly compacted snow as follows:

- At a distance of 500 m to a depth of 25–30 cm.

5. And you can pierce dry pine beams, the dimensions of which are 20x20:

- At a distance of 150 m and to a depth of 30–40 cm.

- At a distance of 500 m and to a depth of 25 cm.

7.62 mm rifle and machine gun cartridges of the 20th century

SPECIAL COMBINED ACTION BULLETS

Small arms cartridges with special bullets appeared in the arsenal of all warring states during the First World War. Their appearance was due to the development of weapons and military equipment, against which ordinary bullets with a lead core were ineffective. Special combined action bullets are bullets that have two or more types of combat action. Their main purpose is to disable military equipment. Combined combat bullets appeared in service with the Red Army in the early 1930s.

Armor-piercing bullet B-30

The appearance of German tanks and armored vehicles on the battlefield during the First World War created an urgent need to equip the Russian infantryman with weapons capable of resisting an armored enemy.

At the end of the 1920s, large-scale research and development work began in the Soviet Union to create a promising armor-piercing rifle bullet.

7.62 mm rifle and machine gun cartridges: with armor-piercing bullet B-30 mod.

1930 (left), with a T-30 tracer bullet mod. 1930 (right) Already in 1930, an armor-piercing bullet with a tool steel core was adopted into service with the Red Army under the designation “7.62 mm armor-piercing bullet model 1930 (B-30).” The cartridge with the B-30 armor-piercing bullet and brass sleeve received the designation “7.62 B-30 hl” (GAU index - 57-B-222). The B-30 bullet weighing 11.0 g consisted of a steel, tombak-clad (bimetallic) shell, a lead jacket and a steel hardened pointed core with a length of 29.7 mm, a diameter of 6.1 mm and a weight of 5.36 g. The core was made of cold-drawn heat-treated tool steel grade U10; U12; U12 HA. The lead jacket was intended to ensure tight mounting of the bullet, soften the load on the barrel when the bullet cuts into the rifling and protect the bore from excessive wear. The length of the bullet with a conical rear part was 36.2 mm. The B-30 armor-piercing bullet penetrated armor with a thickness of 2 to 4 mm - at a distance of 1200 m; armor 7 mm thick - up to 400 m. Cartridges with the B-30 bullet were produced only with a brass sleeve. The tip of the bullet was painted black. When hitting an armored barrier, the bullet core destroyed the lead jacket and the bullet casing, and then pierced the barrier, hitting the crew of the armored vehicle, as well as its instruments and equipment. Possessing significant armor penetration, the B-30 armor-piercing bullet had at the same time a significant drawback, which was its weak armor-protecting effect. With the start of production of rifle and machine gun cartridges with the more universal armor-piercing incendiary bullet B-32, the production of cartridges with the B-30 bullet was discontinued. During the Great Patriotic War, rifle and machine-gun cartridges with B-30 armor-piercing bullets had limited use, and were gradually forced out of use by cartridges with more universal B-32 armor-piercing incendiary bullets.

ARMORS-PIECING INCHENTION BULLETS B-32/BS-40

The adoption of an armor-piercing bullet, however, did not completely solve all the problems. The B-30 armor-piercing bullet penetrated the barrier only due to its kinetic energy, and after it penetrated, it hit fragments of the deformed core, heated as a result of the impact, and fragments of pierced armor, but this was clearly not enough to reliably destroy technical targets. It was required that the armor-piercing bullet also have an incendiary effect.

In 1932, the Red Army's small arms ammunition system was supplemented by a new 7.62 mm rifle-machine-gun cartridge with an armor-piercing incendiary bullet B-32. The cartridge with the B-32 armor-piercing incendiary bullet and bimetallic sleeve received the designation “7.62 B-32 gzh” (GAU index - 57-BZ-323); with a brass sleeve “7.62 B-32 gl” (index - 57-BZ-322), and a cartridge with a B-32 bullet and a steel sleeve “7.62 B-32 gs” (index - 7-BZ-3– 01). The B-32 bullet model 1932 was intended for firing at lightly armored vehicles with gasoline engines; ignition of flammable materials in thick-walled containers not protected by armor (railway tanks with fuel, gas stations, gas storage facilities), as well as to destroy enemy personnel located behind light armored cover at ranges of up to 500 m.

7.62-mm rifle-machine-gun cartridges (from left to right): with armor-piercing incendiary bullet BS-40 mod.

1940, with an armor-piercing incendiary bullet B-32 mod. 1954, a special ShKAS rifle-machine-gun cartridge with a light bullet L. According to the design and type of materials used for the manufacture, the B-32 bullet was identical to the B-30 bullet, with the only difference that inside the head part of the shell in front of the top of the armor-piercing core, instead of lead, it was placed incendiary composition. The B-32 bullet is ogival in shape (36.8 mm long and weighing 9.5–10.0 g) with a conical tail and a belt. The bullet had a bimetallic jacket with a lead base; a mixture of aluminum and phosphorus was used as an incendiary composition, in the head part there was a steel core made of high-carbon tool steel U12 A or U12 XA with an ogival head part and a rear cone, in a lead jacket. The core of the B-32 bullet was made from a steel rod by machining by cutting on metal-cutting machines, followed by heat treatment. The bullet was fastened to the cartridge case by compressing the barrel into an annular groove (flute) on the bullet. When hitting a solid barrier, the movement of the bullet was sharply slowed down, while the armor-piercing core, moving forward by inertia inside the bullet shell, compressed the incendiary composition in front of it at high speed, igniting it. The head part of the bullet shell was destroyed, and part of the burning incendiary composition was drawn into the hole made by the armor-piercing core. This achieved the armor-piercing effect of the bullet, as well as the ignition of flammable liquids and materials behind the barrier (armor). The top of the armor-piercing incendiary bullets was painted black with a red belt.

The B-32 armor-piercing incendiary bullet pierced a 10-mm sheet of armor steel grade 2 P at a distance of 200 m; 7-mm armor - at a range of up to 700 m and bullet-resistant body armor at a distance of 700-745 m, and after such penetration they ensured 75% ignition of gasoline.

In 1940, a new modification of the armor-piercing incendiary bullet appeared with enhanced armor-piercing effect, significantly exceeding the armor-piercing effect of bullets with ordinary armor-piercing cores, especially when hitting armor normal to the surface. The new bullet with a cylindrical bottom, designated “BS-40”, unlike the B-32 bullet, had an armor-piercing core made of RE-6 hard alloy based on tungsten carbide, containing 86–87% tungsten and up to 6. 0% nickel. The length of the armor-piercing core of the BS-40 bullet was 22.5 mm. In terms of design, the bullet of this cartridge was similar to the B-32 bullet, not only the materials used in the manufacture of the BS-40 bullet (with the exception of the core), but also the incendiary composition. The BS-40 differed from the B-32 bullet only in that it was 6 mm shorter without a conical bottom. With a bullet mass of 12.1–12.5 g and an initial speed of 800–815 m/s, the armor-piercing incendiary bullet mod. 1940 was superior to the B-32 bullet in armor penetration by almost one and a half times. Thanks to the hard alloy core, the BS-40 bullet had a significantly stronger penetrating effect than the B-32 bullet - from a distance of 200 m it penetrated armor up to 17 mm thick! Metal-ceramic cores have better armor penetration, in addition to greater hardness, also because they are 30–40% shorter, have a greater lateral load and a closer center of gravity to the head of the bullet. However, the cost of the BS-40 bullet turned out to be significantly higher than all other rifle bullets, primarily due to the use of a carbide core. The top of the BS-40 armor-piercing incendiary bullets was painted black, the side surface of the bullet and the edge of the cartridge case were painted red, and the bottom of the cartridge case was painted black.

After the end of the Great Patriotic War, the B-32 rifle-machine-gun cartridge with an armor-piercing incendiary bullet underwent a deep modernization at NII-61. This work, carried out by the design team consisting of B.V. Semin, N.V. Smekaev and V.V. Trunov under the leadership of N.M. Elizarov, was completed only by 1954. The designation of the modernized cartridge remained the same, but the GRAU index was changed to 7 BZ-3.

The B-32 armor-piercing incendiary bullet model 1954, when fired from a single PK/PKM machine gun, provided 80% of through holes in a 2 P armor plate with a thickness of 10 mm, installed at an angle of 900 at a distance of 200 m. Currently, 7 BZ3 cartridges are produced Novosibirsk Low-Voltage Equipment Plant and Barnaul Machine Tool Plant with bimetallic and varnished steel sleeves, respectively.

At the beginning of the 21st century, the B-32 armor-piercing incendiary bullet (index 7 BZ-3) fully complies with the requirements for it and allows it to hit any infantry personal protective equipment (body armor, helmets) at maximum firing ranges, enemy manpower in field-type shelters at medium and short ranges, as well as cars, tanks and other lightly armored targets. In the foreseeable future, a replacement for the armor-piercing incendiary bullet is not expected.

Armor-piercing tracer bullets BT/BT-90

In the early 1930s, 7.62 mm rifle-machine-gun cartridges with armor-piercing tracer bullets were developed and tested in the Soviet Union, which were intended to destroy lightly armored targets, as well as for target designation and fire correction.

In fact, the design of the first armor-piercing tracer bullets was similar to tracer bullets, in which a short armor-piercing core was built into it. Based on the results of tests in 1932, a 7.62-mm rifle-machine-gun cartridge with an armor-piercing tracer bullet was adopted into service with the Red Army. The cartridge with an armor-piercing tracer bullet and a brass sleeve received the designation “7.62 BT gl” (GAU index - 57-BT-322).

The BT armor-piercing tracer bullet (weighing 9.9 g) with a cylindrical rear part consisted of: a bimetallic (in early samples - nickel silver) shell; armor-piercing pointed core made of U10 steel (diameter 6.8 mm and length 14.5 mm); a lead core pressed into the head of the shell; a cup with a tracer composition (20.0 mm long), as well as a ring - for the expiration of combustion products of the tracer composition.

In terms of armor penetration, the BT bullet was slightly inferior to the B-30 and B-32 bullets (at a distance of 800 m it penetrated aircraft armor 3-4 mm thick, at 300 m - 7 mm), but significantly surpassed the T-30 tracer bullet in this characteristic. Thus, one of the disadvantages of tracer bullets was eliminated - their weak effect on a protected target. The BT bullet tracer included the following components: magnesium (23%), barium nitrate (67%), shellac (10%). The tracing range of the BT bullet was 1000 m, the color of the trace was light green. Cartridges with the BT armor-piercing tracer bullet were produced with a brass sleeve for the ground forces and with a ShKAS bimetallic sleeve for the Air Force. The tip of the bullet was painted purple

However, the BT bullet had one, but very significant drawback - it did not have a lead jacket around the armor-piercing core, which significantly increased the wear rate of the weapon bore when firing these bullets. In addition, it had a weak armor effect. Rifle and machine gun cartridges with the BT bullet were in mass production in 1935–1937. They were replaced by a new rifle-machine-gun cartridge with a universal armor-piercing incendiary bullet BZT.

The issue of an armor-piercing tracer bullet was returned to again in Russia only at the end of the twentieth century. The development of a modern armor-piercing tracer bullet began in the late 1980s - early 1990s at the Klimovsky TsNIITOCHMASH, which carried out this work together with the Tula Automatic Lines Design Bureau and the Novosibirsk Low-Voltage Equipment Plant. In parallel, work on an armor-piercing tracer bullet was carried out by the Research Institute No. 3 of the GRAU of the Ministry of Defense. The result of the work was the creation by the designers of the Novosibirsk plant N. Ya. Ulyanin and I. O. Nekrasov of a new armor-piercing tracer bullet for the 7.62 mm rifle-machine-gun cartridge, adopted by the Russian army in 1999 and designated “7.62 -mm BT-90" (GRAU index - 7 BT 1).

The BT-90 bullet is intended for target designation, destruction of living targets protected by personal armor protection, lightly armored and unarmored vehicles alone or in conjunction with other types of bullets. The BT-90 bullet is an ogive with a rear cone, a belt and ledges towards the head and tail parts. The bullet consists of main parts: a bimetallic shell; armor-piercing pointed hardened core made of tool steel U12 A (length 20.04 mm); a tracer-cup, placed with the bottom facing out, with a tracer composition and a concentrator hole. Reducing the leading part of the bullet due to ledges reduces friction in the barrel bore when cutting the bullet into the rifling, and therefore the core is located in a shell without a lead jacket. The BT-90 bullet is equipped with a slow-burning 5 M type tracer, the design, components used and action are similar to the tracer of the T-46 M1 bullet, and ensures that the tracing start point is moved 50–120 m from the muzzle of the weapon. The burning time of the composition with the start of tracing at a distance of 50–120 m is at least 2.9 seconds. Tracing range is up to 1300 m. The color of the track is red. The top of the bullet is painted with green varnish.

The BT-90 bullet has the same dispersion characteristics as the T-46 M1 tracer bullet. The BT-90 bullet provides 80% of through holes when firing at a steel sheet made of grade 3 steel, 5 mm thick, installed at an angle of 900 to the horizontal at a distance of 500 m and 100% of through holes when fired at a steel sheet of grade 2 P steel, 5 mm thick. at a distance of 200 m. Rifle cartridges with the BT-90 bullet are produced at the Novosibirsk Low-Voltage Equipment Plant.

At the moment, the 7.62-mm rifle-machine-gun cartridge 7 BT1 with the BT-90 armor-piercing tracer bullet is the most modern small arms ammunition of this class in the world and in the near foreseeable future it can completely displace rifle-machine-gun cartridges with an ordinary tracer bullet from circulation.

ARMORS-PIECING INCENTION-TRACER BULLETS BZT/ZB-46

In 1936, the BT armor-piercing tracer bullet was replaced initially in production, and subsequently in supplying the Red Army, with its modernized version - the BZT armor-piercing incendiary tracer bullet, which was also intended for firing from rifles, infantry and aircraft machine guns at manpower, lightly armored targets, as well as for target designation and fire adjustment. 7.62-mm rifle-machine-gun cartridges with an armor-piercing incendiary tracer bullet BZT and a brass sleeve, which entered service with the Red Army, received the designation “7.62 BZT gl” (GAU index - 57-BZT-322).

The designers, having given the armor-piercing tracer bullet incendiary properties, eliminated the main drawback of the BT bullet - its weak armor-protecting effect, which was extremely important when shooting at military equipment. In addition, the incendiary effect of the BZT bullet, provided by a special composition in the head of the bullet, was enhanced by the flame of the burning tracer, which penetrated the barrier after the armor-piercing core.

Diagram of bullets for 7.62 mm rifle and machine gun cartridges (from left to right): with a steel core LPS, armor-piercing incendiary B-32, modernized tracer T-46M, armor-piercing incendiary tracer ZB-46, armor-piercing incendiary tracer BZT , sighting-incendiary PZ

The armor-piercing incendiary-tracer bullet BZT with a cylindrical rear part (weighing 9.0–9.2 g) was a slightly modified BT bullet, in which in front of the head of the armor-piercing core, instead of lead, there was an incendiary composition weighing 0, 2 g. Behind the short steel core there was a cup with a pressed tracer compound. The lead jacket around the core, like the BT bullet, was missing. The general design of the elements, the composition of the tracer, the tracing range and the armor penetration characteristics of the BZT bullet remained the same as that of the BT bullet. Reducing the volume of the tracer composition reduced the length of the green trace to 700 m. The top of the BZT bullet was painted purple with a red rim.

The presence of an incendiary composition in the BZT bullet sharply increased its effectiveness compared to the BT bullet. An armor-piercing incendiary tracer bullet ignited both armored gasoline, due to the incendiary composition, and unprotected gasoline, due to the combustion of the tracer. But in terms of incendiary action when firing at unarmored targets, the BZT bullet was significantly inferior to special incendiary bullets. Just like the B-32 bullet, the BZT bullet ignited gasoline in fuel tanks hidden behind the armor, but due to the lower mass of the core, the thickness of the armor penetrated was reduced to 7 mm when fired at 200 m.

Cartridges with the BZT bullet were produced in two versions: with a brass case for ground forces and with a bimetallic case ShKAS for aircraft machine guns of the Air Force.

With the start of production of 7.62-mm rifle-machine-gun cartridges with the ZB-46 armor-piercing incendiary-tracer bullet, the production of cartridges with the BZT bullet, both in the version for weapons of the ground forces and in the ShKAS version, was discontinued. Rifle-machine-gun cartridges with ZB-46 bullets were in production until the very end of the Great Patriotic War and were supplied mainly to the Air Force. The production of rifle-machine-gun cartridges with the ZB-46 armor-piercing incendiary-tracer bullet was discontinued simultaneously with the discontinuation of production of cartridges for the ShKAS aircraft machine gun with all bullet ranges.

TRACER BULLET T-46 M1

In the early 1990s, the T-46 M bullet, among tracer bullets for other domestic small arms cartridges, underwent its last modernization to date. The modernization of the bullet was carried out at TsNIITOCHMASH by a team of designers led by L. I. Novozhilova and T. P. Vasilyeva on the basis of peroxide-free tracer and ignition compounds. During the modernization, the T-46 M1 tracer bullet received a tracer composition with the tracing start point moved beyond the muzzle of the weapon to a distance of 50–120 m. This solution made it possible to reduce the illumination of night optical-electronic sights and reduce the probability of detection of a shooting position by the enemy by 1.5 -3.5 times, while the tracing range increased by 5–10%. In general, the combat effectiveness of firing cartridges with a modernized tracer bullet has increased by 1.1–1.3 times.

In the modernized T-46 M1 tracer pool, tracer No. 5 M contained three types of burning pyrotechnic compositions: ignition-retardant VZSF-9 M, transitional and tracer MGS-91.

The tracer composition MGS-91 consisted of the following main components: strontium nitrate (51%), magnesium powder MGF-3 (18%), aluminum-magnesium powder PAM-2 (8%), as well as graphite, magnesium carbonate, polyvinyl chloride, carbon dioxide strontium and SF-022 A resin. The new tracer composition was highly resistant to decomposition during storage, which ensured that cartridges were stored in a hermetically sealed container without bleeders for at least 25 years. The main components of the ignition composition VZSF-9 M: red lead (54.5%) and ferrosilicon (27%), as well as iron, technical boron and graphite. In production and technological terms, in the process of developing a highly sensitive igniter composition for the bullet, it was possible to mechanize the process of its preparation.

After the bullet left the barrel, combustion from the ignition composition was transferred to a transition composition weighing 0.07–0.11 g, consisting of a mixture of tracer and ignition compositions in a 50/50 ratio, and then to the tracer composition. Tracing time is at least 3 seconds, tracing range is up to 1300 m, the color of the trace is red. An additional pyrotechnic retarder ensured that the beginning of the tracing was moved 50–120 m to camouflage the shooter.

During long-term storage, gases released by the pyrotechnic composition cause swelling of zinc (metal) boxes. In this case, the lids of the boxes are pierced with a special punch and, after the gases have escaped, they are sealed in the simplest way - with a piece of waxed paper with gun-type lubricant.

A rifle-machine-gun cartridge with a new tracer bullet was adopted by the Russian Army in 2002 and received the designation “T-46 M1” (GRAU index - 7 T2 M1). The production of cartridges with T-46 M1 tracer bullets with bimetallic sleeves was launched by the Novosibirsk Low-Voltage Equipment Plant.

CARTRIDGES FOR AIRCRAFT MACHINE GUN ShKAS

In 1932, the Soviet Air Force adopted a fundamentally new 7.62-mm rapid-firing aircraft machine gun designed by Shpitalny-Komaritsky (ShKAS) with a unique rate of fire at that time - 1800-2000 rounds per minute (or in other words - 30-50 rounds per minute). second), which required unprecedented acceleration when moving the moving parts of the automation. Not designed for such high inertial loads, standard rifle-machine-gun cartridges, getting into the feed mechanism of the weapon, were deformed, cases of dismantling of conventional cartridges were observed, and, due to the reduced reloading cycle time, even rupture of cartridges, which led to difficult delays in firing. Therefore, specially for ShKAS aircraft machine guns, under the leadership of N. M. Elizarov, cartridges were developed that had tracer, incendiary and combined action armor-piercing incendiary bullets capable of igniting gasoline tanks protected by armor. Cartridges for aircraft machine guns were manufactured with tighter tolerances (increased accuracy) and more durable assembly, which was necessary to ensure an increased rate of fire and synchronized firing through the propeller. In these cartridges, to prevent the cartridge from being dismantled (dismantled) at a very high rate of fire, the walls of the cartridge case were thickened, the fastening of the primer in the socket was strengthened, and a double ring crimp of the bullet was introduced in the barrel of the cartridge case. The bullet was secured in the case with two folds. Cases for special cartridges for ShKAS aircraft machine guns were produced only as bimetallic ones.

For 7.62 mm ShKAS aircraft machine guns mod. 1932, SN (Savina - Norova) arr. 1937, Ultra-ShKAS arr. In 1939, special rifle-machine-gun cartridges with bullets were used: L (index 57-N-425); T-30 and T-46 (index 57-T-425); B-32 (index 57-BZ-425); B-32 (index 57-BZ-425); BZT (index 57-BZT-425); Z (index 57-З-425); PZ (index 57-ZP-425). They had the following device features:

- thickened sleeve walls for strength;

- varnish coating of bimetallic cartridges to avoid tight extraction (except for cartridges with a capsule painted with red varnish);

- deeper seating of the capsule with a cap of reduced height;

- fastening the capsule with a circular bead. In addition, cartridges with an L bullet have a deeper (2 mm) bullet seating and double rolling of the case muzzle wall.

At the bottom of the cartridge case for ShKAS machine guns, in addition to the standard designations of the date of manufacture (the last two digits of the year of manufacture and the manufacturer's number, the letter "Ш" was placed. The capsule was painted with red varnish. Otherwise, the coloring remained standard for the corresponding types of bullets. Cartridges intended for infantry weapons, ShKAS machine guns could not be used, and ShKAS cartridges with a varnished bimetallic sleeve, with a red primer, were prohibited from being used for firing from rifles and carbines, since they could misfire (due to the deep seating of the primer) and tight extraction .

Sergey Monetchikov Photo from the author’s archive

Feature of ammunition with an ordinary bullet 7.62 PS (57-N-231)

This ammunition is ideal for defeating manpower. The 7.62 mm cartridge of the 1943 model has a steel core. Since 1984, spherical grained gunpowder began to be used. Previously, they used rifle pyroxylin powder.

The ammunition mass is 7.9 g. They are capable of penetrating a steel helmet at a distance of 900 m.

Since 1989, they began to use a heat-strengthened core of increased hardness specifically in order to increase the penetrating effect of the bullet. And it is worth noting that the manufacturers managed to do this; the penetrating effect of ammunition with the new core on solid obstacles increased by about 1.5, or even 2 times.

This ammunition does not have any distinctive coloring, that is, to distinguish it, you need to pay attention to the year of manufacture.

Russian cartridges

The experience of World War II showed the need to create, instead of rifles and submachine guns, a fundamentally new type of hand-held individual automatic infantry weapon chambered for an intermediate power cartridge. In the USSR, the development of a new cartridge began in 1943 at OKB-44, subsequently FSUE TsNIITOCHMASH. Development of various cartridges for new weapons continued until 1948. In 1949, simultaneously with the 7.62-mm Kalashnikov assault rifle of the 1947 model (AK), they were put into service cartridges with ordinary, armor-piercing incendiary, incendiary and tracer bullets are accepted. At the same time, blank and training cartridges were adopted for service. Subsequently, the production of cartridges with armor-piercing incendiary and incendiary bullets was abandoned. In the early 1960s, a cartridge with a subsonic muzzle velocity was created for firing from a machine gun with a PBS-1 silencer.

Improvement of the 7.62 mm cartridge mod. 1943 was carried out in the 1980-90s in the direction of increasing the penetrating effect (for a bullet with a steel core), as well as increasing the tracing range and slowing down the ignition of the tracer (for tracer cartridges). Until 1984 for 7.62 mm cartridges mod. In 1943, tubular nitroglycerin powder was used, and since 1984, nitroglycerin powder with spherical graining was used. Initially, the cartridge was produced only with a bimetallic sleeve - steel clad with tombak. In the early 1960s, a number of enterprises began producing varnished steel sleeves, and in the early 2000s, the production of polymer-coated steel sleeves was mastered.

Cartridges with ordinary bullets - 7.62 PS (57-N-231)

Cartridges with ordinary bullets - 7.62 PS (57-N-231)

The 7.62 mm cartridge, model 1943, with a steel core bullet (7.62 PS) is designed to destroy manpower. Since 1984, when spherical grain gunpowder began to be used instead of rifle gunpowder, a ledge was made on the rear of the bullet to facilitate cartridgeing. These bullets, weighing 7.9 g, pierce a steel helmet at a distance of 900 m. They do not have a distinctive color.

Since 1989, to increase the penetrating effect of bullets, a heat-strengthened core of increased hardness began to be used. The penetrating effect of bullets with a new core on solid obstacles has increased by 1.5-2 times. It does not have a distinctive color and the new cartridge can be distinguished from cartridges with a non-heat-strengthened core only by the year of manufacture. Bullet cartridge 7.62 PS (57-N-231)

Main characteristics of the 7.62 PS cartridge

Cartridge mass, g16.3 Bullet mass, g.7.9 Cartridge length, mm56 Initial bullet speed, m/s.725

Cartridges with a tracer bullet - 7.62 T-45 and 7.62 T-45M (57-T-231P and 57-T231PM1)

Cartridge with tracer bullet - 7.62 T-45 (57-T-231P)

The 7.62-mm cartridge of the 1943 model with a T-45 tracer bullet (7t62 T-45) is designed for target designation and fire adjustment at firing ranges of up to 800 m, as well as for hitting manpower. The cartridge is available with bimetallic or varnished steel sleeves.

The tracer produces a bright glowing red trace, clearly visible day and night. When hitting flammable objects, the bullet can ignite them.

In the late 1990s, the FSUE TsNIITOCHMASH modernized the tracer. A new cartridge with a modernized T-45M tracer bullet was put into service in 2002. The modernization made it possible to increase the tracing range to 850 m and ensured the ignition of the tracer composition at 50-120 m from the muzzle. This delay in ignition of the tracer makes it possible to better camouflage the shooter’s firing position and ensures continuous observation of the battlefield through night sights with electro-optical converters.

The bullet heads of all tracer cartridges are painted green.

Bullet cartridge 7.62 T-45 (57-T-231P)

Main characteristics of the 7.62 T-45 cartridge

Cartridge weight, g16.1 Bullet weight, g.7.6 Cartridge length, mm56 Initial bullet velocity, m/s.725 Tracing range, m800

Cartridges with armor-piercing incendiary and incendiary bullets - 7.62 BZ and 7.62 3 (57-B3-231 and 57-3-231)

Cartridge with armor-piercing incendiary bullet - 7.62 BZ (57-B3-231)

Cartridge with incendiary bullet - 7.62 3 (57-3-231)

7.62-mm cartridges of the 1943 model with armor-piercing incendiary (7.62 BZ) and incendiary (7.62 3) bullets were produced until the early 1960s. They were intended to destroy lightly armored targets, ignite fuel located behind armor or in thick-walled containers, and to destroy personnel located behind light armored cover.

Armor-piercing incendiary bullet - 7.62 BZ (57-B3-231)

Cartridge with a bullet with reduced velocity - 7.62 US (57-N-231U)

Cartridge with a bullet with reduced velocity - 7.62 US (57-N-231U)

A 7.62-mm cartridge with a reduced bullet speed (7.62 US) was put into service in 1962 simultaneously with a muzzle silencer for the Kalashnikov assault rifle, called the “Silent and Flameless Firing Device (PBS-1).” The cartridge and muffler were developed at FSUE TsNIITOCHMASH. PBS-1 with a 7.62 US cartridge ensures silent aimed shooting from an AKM assault rifle at a range of up to 400 m.

Compared to ordinary bullets, a bullet with reduced velocity has greater mass and length.

To ensure the necessary penetrating effect, the bullet core is made of durable steel.

The cartridge is available with bimetallic or varnished steel sleeves.

The bullet has a subsonic initial speed and does not create a ballistic wave along the trajectory, and the muffler (PBS-1) reduces the speed of gas flow from the muzzle of the barrel to subsonic. The US bullet is capable of penetrating a steel helmet at a range of up to 400 m and anti-fragmentation vest at a range of 75 m.

The head of the bullet is black with a green belt.

Reduced velocity bullet, cartridge 7.62 US (57-N-231U)

Main characteristics of the 7.62 US cartridge

Cartridge mass, g20 Bullet mass, g.12.6 Cartridge length, mm56 Initial bullet speed, m/s.300

Cartridge with armor-piercing bullet - 7.62 BP (7N23)

Cartridge with armor-piercing bullet - 7.62 BP (7N23)

The creation in the 1980-1990s of relatively lightweight bulletproof vests with a high level of security and the saturation of ground forces units of many armies of the world with them led to the need to improve the cartridge with an ordinary bullet. In the late 1990s, such modernization was carried out at the Barnaul Cartridge Plant. During the modernization, the shape, material and heat treatment process of the core underwent changes.

As a result, the bullet became armor-piercing. The 7.62 mm 1943 model cartridge with an armor-piercing bullet (7.62 BP) was adopted for service in 2002.

An armor-piercing bullet ensures the destruction of living targets in personal armor protection, located openly or behind light shelters, various fire weapons and unarmored vehicles.

The new cartridge is more than three times superior in penetration of solid barriers to a cartridge with an ordinary bullet. At the same time, the trajectory of the bullet of the new cartridge is ensured to match the bullet with a steel core.

The head of the bullet is black.

Armor-piercing bullet cartridge 7.62 BP (7N23)

Main characteristics of the 7.62 BP cartridge

Cartridge mass, g16.3 Bullet mass, g.7.9 Cartridge length, mm56 Initial bullet speed, m/s.740

Cartridge with a bullet with reduced ricocheting ability - 7.62 PRS

Cartridge with a bullet with reduced ricocheting ability - 7.62 PRS

In 2002-2003, a number of cartridges with bullets with reduced ricocheting ability (PRS) were developed for units of the Ministry of Internal Affairs of the Russian Federation. Unlike ordinary bullets, PRS-type bullets do not have a steel core. The need to create special cartridges of this type is associated with the peculiarities of the tactics of using special units of the Ministry of Internal Affairs, most of the combat operations or special operations of which are carried out in populated areas. In this case, small arms fire is conducted at short ranges. In such situations, the high initial velocity of ordinary bullets with a steel core leads to a large number of ricochets from the walls of buildings, concrete fences, road surfaces, etc. This creates a real threat of defeat for its personnel. Bullets of the PRS type, when they hit solid obstacles, are crushed, quickly lose speed and do not produce as many dangerous ricochets as bullets with a steel core.

In the early 2000s, by order of the Russian Ministry of Internal Affairs, through the joint efforts of specialists from JSC Barnaul Cartridge, a 7.62 mm cartridge of the 1943 model was created with a bullet with reduced ricocheting ability (7.62 PRS model 1943).

The cartridge is designed for firing from AKM, AK-103 and AK-104 assault rifles. Due to the absence of a steel core, this cartridge is superior in accuracy to the 7.62 PS cartridge, while ensuring complete alignment with the trajectories of the cartridge with an ordinary bullet. The bullet does not have a distinctive color, but on the bottom of the cartridge case, along with the factory number and year of manufacture, there is a “PRS” stamp.

Bullet with reduced ricocheting ability of the 7.62 PRS cartridge

Main characteristics of the 7.62 PRS cartridge

Cartridge mass, g16.9 Bullet mass, g.8.0 Cartridge length, mm56 Initial bullet speed, m/s.725

Blank cartridges - 7.62 blank. 43 g. (57-X-231) and PHS 19

Blank cartridge - 7.62 blank sample. 43 (57-X-231)

Blank cartridge - PHS 19

To simulate the sound of a shot from machine guns and light machine guns, during the training of shooters, as well as for firing fireworks, a 7.62-mm blank cartridge mod. 1943. Together with a bushing for blank firing, which is screwed onto the muzzle of the barrel of an assault rifle or light machine gun and allows for the creation of the necessary pressure of powder gases in the barrel bore, the blank cartridge ensures the operation of the moving parts of the weapon's automation. The shot is accompanied by sound, a flash of flame and smoke.

A blank cartridge differs from a combat cartridge in the absence of a bullet and an elongated cartridge case. The case muzzle is crimped with a star and covered with a layer of sealing varnish. The blank cartridge of the 1943 model is shorter than the live cartridge, its length is 48.2 mm. Blank cartridges are available with bimetallic or varnished steel sleeves.

For throwing grenades from a 30-mm silent underbarrel grenade launcher of the "Silence" rifle-grenade launcher complex based on the cartridge case mod. In 1943, a special blank cartridge PHS 19 was used (special blank cartridge). The case muzzle of this cartridge is compressed with a star. It is shorter than a blank cartridge.

Training cartridge - 7.62 UC mod. 43 (57-N-231 UC)

Training cartridge - 7.62 UC mod. 43 (57-N-231UCH)

Training cartridges are used to teach how to load a weapon, fire a shot, and load magazines. The training cartridge is made using the main parts of a cartridge with an ordinary bullet with a 7.62 PS steel core, but does not contain a powder charge and has a cooled igniter primer. The cartridge is available with a bimetallic or varnished steel sleeve.

Increasing the strength of the bullet fastening in the cartridge case, in order to prevent it from falling out during training for loading weapons, is ensured by additional crimping of the barrel onto the bullet. The training cartridge bullet does not have a distinctive color, but the cartridge case has four symmetrically located longitudinal embossments.

« back | menu | forward "

Features of the 7.62×39-9.7 cartridge with a semi-jacketed bullet

Quite often, many people, especially novice hunters, wonder which 7.62x39 cartridges are better? In order to answer this question, it is very important to familiarize yourself with all the varieties of these cartridges.

These bullets are produced by the Barnaul Machine Tool Plant and the Tula Cartridge Plant. The weight of the ammunition is about 9.7 g. The bullet consists of a tombak shell and lead in the head. The cartridge case is made of lacquered steel with a groove, and the gunpowder has a mass of 1.5 g.

Main characteristics of the ammunition:

- The total mass of the cartridge is about 18 g.

- The length of the ammunition is 56 mm.

- The bullet speed at the muzzle is 660 m/s.

- Muzzle energy – from 216 to 222 kgf m.

- The maximum pressure of powder gases is 300 MPa.

- The maximum shelf life of the cartridge is up to 10 years.

- This cartridge can be fired at a distance of 200 m.

- The range of destruction of this ammunition is 100 m.

This cartridge has the most important drawback - it is unreliable chambering of a semi-jacketed bullet due to its very soft nose.

If, for example, we compare the ballistic characteristics of ammunition, 7.62x39-9.7 is worse than military and hunting cartridges 7.62x39-8. The initial speed indicators, as well as the possible range of use for the latter, are much higher than for the former.

The flight trajectories of the semi-shell ammunition and the shell ammunition do not coincide at all.

To achieve defeat of the animal, it is best to work with such a cartridge at distances from 100 to 120 m. At long distances, you can also use this ammunition, but you must first zero the carbine. This is necessary so that the aiming correction can be identified.

For example, if you aim at a distance of 100 m, then you need to clearly understand that at a distance of 50 m the trajectory of the bullet relative to the aiming line will rise by about 2 cm. Then, having reached 100 m, it will cross it, that is, it will reach the aiming point. Then, at about 150 m, the trajectory of the ammunition decreases by about 9 cm. Then at a distance of 200 m it decreases by 25 cm, and at a distance of 300 m - to 90 cm.

Encyclopedia of weapons

Cartridge 7.62x39 mm, 1943, Russia

Performance characteristics 7.62x39 mm (57-H-231C, with steel core)

Caliber, mm — 7.62 Bullet diameter, mm — 7.9 Bullet weight, g — 7.9 Powder weight, g — 3.0 Initial bullet speed, m/s — 710–725 Muzzle energy, J — 1990–2080

The 7.62×39 mm cartridge appeared in 1943. An intermediate cartridge designed by N. M. Elizarov and B. V. Semin. It was created in response to the Germans creating an intermediate cartridge, which was used in the StG-44 assault rifle. Final development was completed by 1949. The final cartridge design was very different from the initial 1943 design.

Work on creating an intermediate cartridge in the USSR began back in 1939, although the question of this was raised much earlier. To study the issue, a 5.45 mm caliber cartridge was developed, and the task was given to design a self-loading rifle for this cartridge. However, due to the outbreak of the Great Patriotic War, the designers were switched to more relevant work.

Soviet 7.62 mm cartridges mod. 1943:

- with a bullet with a lead core and a 41 mm sleeve (left) - with a bullet with a lead and steel core and a 39 mm sleeve.

The development of an intermediate cartridge was started again in 1943, after the participants of the Technical Council of the People's Commissariat of Armaments (NKV) were familiarized with captured samples captured at the front from the Nazis, as well as with the American M1 self-loading carbine, which was made available to the USSR for review.

Intermediate cartridges from the Second World War:

7.62×33 (USA) 7.92×33 (Germany) 7.62×41 (USSR) left - right

Particular attention of specialists was attracted by the new German cartridge of 7.92 mm caliber with a sleeve length of 33 mm and the MKV 42 [N] carbine developed for it, which was tested in the active army. This cartridge, 48 mm long, had a mass of 16.2 g. With a bullet mass of 8.2 g and an initial speed of 700 m/s, it provided targeted shooting at a range of 800 m.

At the meeting, it was decided that it was necessary to develop a cartridge of reduced power to replace the rifle cartridge in such types of weapons as self-loading (automatic) rifles and light machine guns, as well as new types of small arms for it.

Based on the new intermediate cartridge, it was possible to create a lightweight individual automatic weapon with a greater effective firing range than a submachine gun. OKB-44 was appointed responsible for the development of the new cartridge (later NII-44, which in 1949 became part of NII-61 and was reorganized in 1966 into TsNIITOCHMASH).

To determine the optimal characteristics of the cartridge, calculations were carried out to select the bullet speed and its mass for calibers 5.6 mm, 6.5 mm, and 7.62 mm. These calibers were chosen as the most frequently encountered in practice.

The following requirements were imposed on the new 7.62 mm cartridge: the cartridge case must be of a modern shape - without a flange; smaller weight and dimensions than a rifle cartridge; cartridge power reduced to 20% (compared to a rifle); the bullet energy at a distance of 1000 m should have been at least 25 kgm.

The intermediate cartridge was to be used for firing from an automatic carbine-machine gun, a self-loading rifle and a light machine gun. The weapon chambered for the new cartridge had to be lightweight, including by reducing the barrel length.

For the same purpose, it was considered possible to use thin rifle barrels for submachine gun carbines (machine guns) without fear of overheating, because They were supposed to be fired mainly with single shots and only occasionally, at the most critical moments of the battle, with automatic fire.

Considering the flatness of the trajectory to be one of the main characteristics of the cartridge, OKB-44 decided from the very beginning that our cartridge should be better than the German one. For the 7.92×33 cartridge, the direct shot range (DPV) was 300 m; for ours, the DPV was taken to be 325 m.

And already on September 3, 1943, the NKV Technical Council reviewed the first two versions of the cartridge, and one of them was chosen (later called the 7.62 mm cartridge of the 1943 model). After the September meeting, all weapons design bureaus and the research site for small arms and mortar weapons of the GAU (NIPSMVO) began developing weapons for a promising machine gun cartridge.

In December 1943, the first batch of cartridges with a bullet with a lead core (this cartridge was assigned the index 57-N-231) was tested at the test site. After some modifications, in March 1944 the production of an experimental batch of 7.62 mm cartridges began. 1943. The original version of the cartridge had a 41 mm long sleeve and a bullet with a lead core without a rear cone and with a short head.

The weapons being developed at that time for a new cartridge - a self-loading carbine and an automatic carbine (automatic) - were intended primarily for firing single shots. It was assumed that automatic fire when firing from a machine gun was to be used only in close combat (at a range of 100-200 m).

Based on this, during the development of the cartridge mod. In 1943, the main attention was paid to ensuring the necessary accuracy of firing with single shots, the range of a direct shot and the penetrating effect of the bullet.

High accuracy of fire with automatic fire was not required from the new cartridge. However, later, after the adoption of the AK (Kalashnikov assault rifle), the main type of shooting from a machine gun, in order to increase the density of fire (fire density - the number of bullets per linear meter per minute), they began to consider firing in bursts, regardless of the distance to the target. At the same time, in fairness, it should be noted that the probability of hitting the target when firing in bursts increased, but only slightly, while the consumption of cartridges increased in proportion to the length of the burst.

In 1944, after receiving the first test results, work began on improving the cartridge in order to increase its accuracy and penetration. The head (ogive) part of the bullet was lengthened, which made it possible to improve the ballistic coefficient while maintaining the mass of the bullet. The bullet had a rear cone introduced, which reduced air resistance to the bullet’s flight, not only, as was then believed, at subsonic speeds (i.e. when firing at long range), but also at supersonic bullet flight speeds.

To maintain the overall length of the cartridge, the cartridge case neck was shortened by 2 mm and the depth of the bullet in the case was increased. The sleeve received a final length of 38.7 mm (when designating a 7.62×39 cartridge, the length of the sleeve is indicated in round numbers).

Cartridge 7.62×39 mm

After this, work began to replace the lead core with a steel one. The bullet with a steel core received the name “surrogated”. Its length increased from 22.8 mm in the first version to 26.8 mm. The main argument for using low-carbon steel for the core was not so much an increase in the bullet's penetration effect, but rather the saving of scarce lead (up to 50%) and the manufacturability of stamping the core.

By the way, the technology for its manufacture was borrowed from the cartridge. It should be noted here that at that time the main measure of the penetrating effect of a bullet was the assessment of the possibility of penetrating a steel army helmet at a distance of 800 - 1000 m.

By mid-1947, all the shortcomings noted during testing in the cartridge mod. 1943 with an ordinary bullet were eliminated, and the GAU decided to produce a series of cartridges and prototype weapons for military testing.

Cartridges arr. 1943 with different types of cartridges:

— brass, — bimetal, — varnished steel — with polymer coating.

In order to increase the tactical capabilities of promising weapons, as well as based on the experience of creating 7.62 mm rifle cartridges for various purposes, along with a cartridge with an ordinary bullet, the development of cartridges mod. 1943 with special bullets: armor-piercing incendiary (developed in 1944), incendiary and tracer (developed in 1948).

In 1949, simultaneously with the Kalashnikov assault rifle, 7.62-mm cartridges mod. 1943 with the bullet types listed. Subsequently, the improvement of the cartridge mod. 1943 with an ordinary bullet with a steel core was carried out in the direction of increasing the penetrating effect of the bullet (to ensure the destruction of manpower in personal armor), and the tracer, in the direction of increasing the burning time of the tracer and slowing down the time of the start of its burning.

In the improvement of cartridges, the use of new spherical grained powders as charges was of great importance. As is known, the priority for the creation of spherical grained gunpowder belongs to the United States. Its main advantage is its high gravimetric density (filling density of the cartridge case) - about 0.85 g/cm3, increased progressiveness of combustion and high manufacturability. This allows, with an equal charging chamber, to provide greater muzzle energy to the bullet or, with equal muzzle energy, to reduce the dimensions of the cartridge case.

Initially, the 7.62×39 cartridge was produced only with a bimetallic sleeve - steel clad with tombak. But in 1948, due to difficulties in obtaining bimetal, the main part of which was previously supplied from the USA under Lend-Lease, the cartridge case of an automatic cartridge began to be made from brass-plated steel. The brass plating process, borrowed from German industry, involved the use of highly toxic substances.

Therefore, with the development of bimetal production in the USSR in 1952, automatic cartridge cases again began to be made from this material. Subsequently, in the early 1960s, a number of enterprises began producing varnished steel sleeves (coated with green varnish), which ensured significant savings in tombac. Already in our time, the production of steel sleeves with a polymer coating (water-polymer solution) has been mastered, which has significantly reduced the harmfulness of production.

Live ammunition:

Tactical and technical characteristics of 7.62x39 mm PS (57-H-231, steel core bullet)

Caliber, mm - 7.62 Bullet diameter, mm - 7.9 Bullet length, mm - 26.8 Bullet weight, g - 7.9 Powder weight, g 3.0 Cartridge weight, g - 16.3 Initial bullet velocity, m/s — 710–725 Muzzle energy, J — 1990–2080

Cartridges with an ordinary bullet “7.62 mm cartridge mod. 1943 with a bullet with a steel core PS" (PS is a “surrogated” bullet; later the term “bullet with a steel core” began to be used), code name - “7.62 PS”, is intended to hit living targets located openly or behind light cover, fire weapons and non-armored vehicles.

Initially, this cartridge with a bimetallic sleeve had the index 57-N-231S. The cartridge with a varnished steel sleeve, which appeared in the early 1960s, received the index 57-N-231SL. But over time, it was considered inappropriate to indicate the case material in the cartridge index, and all cartridges with a steel core bullet received a single index - 57-N-231.

An ordinary bullet consists of a steel shell clad on both sides with a layer of tombac, a stamped steel core made of mild steel grade 10 and a lead jacket. In the middle part of the bullet there is an annular knurling into which the cartridge case neck is pressed when assembling the cartridge. In the 1960s, a pilot batch of cartridges with PS bullets was manufactured and tested, the steel casing of which was coated with green varnish instead of tombac.

Since 1962, the muzzle of the cartridge case at the junction with the bullet and the edge of the primer have been coated with sealant varnish to increase moisture resistance. In 1962-1963 the color of the varnish was purple, and since 1964 the varnish on cartridges with any type of bullet became red.

Since 1984, when spherical grained powder began to be used instead of rifle gunpowder, a ledge was made on the back of the bullet to facilitate cartridgeing. The ledge prevented small particles from getting between the muzzle walls and the bullet. The bullet of these cartridges also does not have a distinctive color.

For a long time, the issue of manufacturability in the production of cartridges prevailed over the possible increase in the penetrating effect of a bullet - as is known, it is provided mainly by the material and shape of the core. In particular, hardening of the core was not allowed, and its shape was determined by the labor intensity of stamping.

However, the widespread use of personal armor, which provided protection against low-carbon steel-core bullets, required improvements to the cartridges. Since 1989, to increase the penetrating effect of bullets, a heat-strengthened core of increased hardness began to be used.

Performance characteristics of 7.62x39 mm PS (with heat-strengthened core)

Caliber, mm - 7.62 Bullet diameter, mm - 7.9 Bullet length, mm - 26.8 Bullet weight, g - 7.9 Powder weight, g 3.0 Cartridge weight, g - 16.4 Initial bullet velocity, m/s — 710–725 Muzzle energy, J — 1990–208

It is made from high-carbon spring steel grades 65G, 70, 75 with subsequent heat treatment. The penetrating effect of bullets with a new core on solid obstacles has increased by 1.5-2 times.

A bullet with a heat-strengthened core ensures penetration of a steel helmet at a distance of 1000 m; anti-fragmentation bulletproof vest at a range of 700 m and bulletproof vest protecting against machine gun bullets with a non-heat-strengthened core at a range of 100 m.

The bullet of this cartridge also does not have a distinctive color. A new cartridge can be distinguished from cartridges with a non-heat-strengthened core only by the year of manufacture.

Cartridges with tracer bullet:

Tactical and technical characteristics of 7.62x39 mm T-45 (57-T-231P with a tracer bullet)

Caliber, mm — 7.62 Bullet length, mm — 28.0 Bullet weight, g — 7.6 Initial bullet speed, m/s — 710–725

Cartridge 7.62 mm mod. 1943 with a T-45 tracer bullet, code name -7.62 T-45, index - 57-T-231P, designed for target designation and fire adjustment at firing ranges up to 800 m, as well as for hitting manpower. The cartridge is available with bimetallic or varnished steel sleeves. In the period from 1949 to 1951. inclusive, the cartridge was made with a brass-plated sleeve.

A core made of lead-antimony alloy is pressed into the bimetallic shell of the tracer bullet, in its head part. Behind the core there is a tombac-clad steel cup with a pyrotechnic composition pressed into it (ignition, transition and tracer).

To avoid damage to the tracer composition, the T-45 bullet does not have knurling. A ring is attached to the bottom of the bullet; it acts as a nozzle and ensures uniform flow of combustion products of the tracer composition.

When fired, combustion from the powder charge is transferred to the igniter composition. After the bullet leaves the barrel, combustion from the ignition composition is transferred to the transition and then to the tracer composition. When burned, the tracer produces a bright glowing red trace, clearly visible day and night.

When hitting flammable objects, the bullet can ignite them. In 1973, the tracer cartridge was modernized. Changing the design of the bullet made it possible to increase the volume of the charging chamber, which made it easier to select a charge for different batches of gunpowder, ensure the stability of ballistic characteristics and obtain trouble-free operation of the weapon.

This modernization of the tracer cartridge was carried out by employees of TsNIITOCHMASH - V.M. Sabelnikov (leader), P.S. Korolev and A.T. Khomyakova. In the late 1990s, TsNIITOCHMASH engineers L.I. Novozhilova and T.P. Vasilyeva modernized the T-45 bullet tracer. The new cartridge received its full name - “7.62 mm cartridge mod. 1943 with a modernized T-45M tracer bullet."

It was put into service in 2002 under the designation 57-T-231PM1. The modernization made it possible to increase the tracing range to 850 m and ensured that the tracer composition began burning at 50 - 120 m from the muzzle.

This delay in the tracer’s burning allows for better masking of the shooter’s firing position and ensures continuous observation of the battlefield through night sights with electro-optical converters.

The tip of the bullets of all tracer cartridges is painted green. There are cartridges with a tracer bullet, manufactured in the early 1960s, that are unpainted, but with a green sealant at the muzzle of the case and along the edge of the primer.

Cartridge with armor-piercing incendiary bullet:

Tactical and technical characteristics of 7.62x39 BZ (57-BZ-231 with an armor-piercing incendiary bullet)

Caliber, mm — 7.62 Bullet length, mm — 27.7 Bullet weight, g — 7.7 Cartridge weight, g — 16.1 Initial bullet speed, m/s — 720-740

7.62 mm cartridge mod. 1943 with an armor-piercing incendiary bullet BZ, code name - 7.62 BZ, index - 57-BZ-231, designed to destroy lightly armored targets, ignite fuel located behind armor or in thick-walled containers; and to defeat personnel located behind light armored cover at a range of up to 300 m.

The cartridge was produced with a brass or bimetallic sleeve. An armor-piercing incendiary bullet consists of a steel shell clad with tombak with a tombak tip, a heat-treated steel core with a lead jacket and an incendiary composition located in a lead pan.

When a bullet hits the armor, the lead pan, moving forward by inertia, compresses the incendiary composition and thereby ignites it. The flame, through a hole punched by the steel core, penetrates into the armored space and is capable of igniting the fuel.

An armor-piercing incendiary bullet pierces a steel helmet at a range of 1100 m and anti-fragmentation bulletproof vest at a range of 1000 m. A 7 mm thick armor plate pierces at a range of 200 m. The tip of the bullet is painted black with a red belt. On cardboard packs, metal boxes and wooden boxes with BZ cartridges, an inclined black and red stripe is applied.

Incendiary bullet cartridge:

Tactical and technical characteristics 7.62x39 Z (57-3-231 with incendiary bullet)

Caliber, mm — 7.62 Bullet length, mm — 27.9 Bullet weight, g — 6.6 Cartridge weight, g — 15.2 Initial bullet speed, m/s — 740-755

7.62 mm cartridge mod. 1943 g with an incendiary bullet Z, code name - 7.62 Z, index - 57-3-231, designed to ignite flammable liquids (gasoline, kerosene) in steel tanks with walls up to 3 mm thick, as well as easily flammable materials (dry grass, straw, etc.) at ranges up to 700 m.

By its design and action, the “7.62 Z” bullet belongs to the type of incendiary bullets with a pyrotechnic incendiary composition and is an incendiary tracer, providing observation of the results of firing along a clearly visible (up to 700 m day and night) red track.

The cartridge was produced with a brass or bimetallic sleeve. The bullet consists of a steel clad with tombak, a shell with a tombak tip, an incendiary composition located in the head of the bullet, a low-carbon steel core, a jacket made of a lead-antimony alloy, a bimetallic cup with a pyrotechnic composition (ignition, transition and tracer) and a ring (its the purpose is the same as in other tracer cartridges).

When a bullet hits a solid obstacle, a sharp dynamic compression and heating of the incendiary composition occurs, the steel core moving forward, as a result of which the incendiary composition ignites. The bullet tip is crushed, the jacket is deployed, and the flame from the incendiary composition ignites the target. When encountering low-density obstacles, due to the low sensitivity of the bullet, the incendiary composition may not ignite.

There are two modifications of the bullet with different ogive radius. The sharper ones, which appeared later, deviate to a lesser extent from the trajectory of the PS bullet. The tip of the bullet of the “7.62 Z” cartridge is painted red. Cardboard packages, metal boxes and wooden boxes containing incendiary cartridges are marked with a slanted red stripe.

Cartridges with armor-piercing incendiary and incendiary bullets were assembled by hand and had a high cost. It was planned to use them only during hostilities. These cartridges, as a rule, were not used for target practice. After sufficient stocks of cartridges with the BZ and Z bullets had been accumulated, their production was discontinued. Currently, cartridges with armor-piercing incendiary and incendiary bullets have been discontinued, but can be found in army stocks.

Reduced velocity bullet cartridge:

Tactical and technical characteristics of 7.62x39 US (57-3-231U with reduced bullet speed)

Caliber, mm — 7.62 Bullet length, mm — 33.62 Bullet weight, g — 12.5 Cartridge weight, g — 19.9 Initial bullet speed, m/s — 285-300

In the mid-1950s, to equip reconnaissance and reconnaissance-sabotage units and ensure the covert destruction of unprotected living targets at a range of up to 400 m, a 7.62-mm cartridge with a reduced bullet speed US, code name, was developed and put into service in 1962 - 7.62 US, index - 57-N-231U.

This cartridge is intended for firing from AK assault rifles (AKS, AKM, AKMS, AK-103 and AK-104) with silent and flameless shooting devices PBS or PBS-1. The cartridge with the US bullet, together with the PBS and PBS-1 devices, was developed at NII-61 by engineers N.M. Elizarov (chief designer of the department, designer of the complex), B.V. Semin (patron), K.V. Smekaev (cartridge), L.I. Golubev (muffler), M.E. Fedorov and M.A. Kuzmina.

The cartridge is available with bimetallic or varnished steel sleeves. An increase in the mass of the bullet (it is 12.5 g) in order to conserve energy was achieved by increasing its length - 33.62 mm (bullet length of the 7.62 PS cartridge is 26.8 mm). Providing the necessary penetrating effect was achieved by using a core made of U12A tool steel, located in the head of the bullet.

The lead core located behind it provides not only the necessary mass, but also acts as a shirt. The selected bullet diameter is -7.94 mm (all other bullets have a diameter of 7.92 mm) - ensures that the bullet fits tightly into the rifling and the necessary pressure of the powder gases in the barrel. A bullet receiving a subsonic initial velocity does not create a ballistic wave along the trajectory, and the silencer (PBS) reduces the rate of gas flow from the muzzle of the barrel.

The US bullet is capable of penetrating a steel helmet at a distance of up to 400 m and anti-fragmentation vest at a distance of 75 m. The bullet is painted black with a green belt. On cardboard packs, metal boxes and wooden boxes with US cartridges, an inclined black and green stripe is applied.

Cartridge with armor-piercing bullet:

Tactical and technical characteristics of 7.62x39 BP (7N23 with an armor-piercing bullet)

Caliber, mm — 7.62 Bullet length, mm — 27.4 Bullet weight, g — 7.9 Cartridge weight, g — 16.3 Initial bullet speed, m/s — 725-740

The creation in the 1980-1990s of relatively lightweight bulletproof vests with a high level of protection and the saturation of ground forces units of many armies of the world with them led to the need to improve the cartridge with an ordinary bullet.

In the late 1990s, such modernization was carried out at the Barnaul machine tool plant D.I. Veronsky and V.V. Zakharyashchev. During the modernization, the shape, material (instead of low-carbon steel, they began to use U12A tool steel) and the heat treatment process of the core underwent changes.

As a result, the bullet became armor-piercing. The new cartridge was put into service in 2002 and received the name - 7.62 mm cartridge of the 1943 model with an armor-piercing BP bullet, code name - 7.62 BP, index - 7N23.

The new cartridge is designed to destroy living targets wearing personal armor protection (located openly or behind light cover), fire weapons and non-armored vehicles. The design of the 7N23 cartridge bullet is similar (except for the core) to a cartridge with a 7.62 PS steel core bullet. The cartridge case is varnished steel.

The new cartridge is more than three times superior in penetration of solid barriers to the cartridge with the PS bullet. At a distance of 200 m, the armor-piercing core of the new cartridge bullet penetrates a 5-mm armor plate of the 2P brand, and at 250 m, a bulletproof vest of the 6B5 type. At the same time, the trajectory of the bullet of the new cartridge is ensured to match the bullet with a steel core. The color of the bullet is black on the tip.

Cartridge with a bullet with reduced ricocheting ability:

Cartridge 7.62×39 PRS - with a bullet with reduced ricocheting ability

In 2002 - 2003 For units of the Ministry of Internal Affairs of the Russian Federation, a number of cartridges (9x18, 9x19, 5.45x39, 7.62x39 and 7.62x54R) equipped with bullets with reduced ricocheting ability (RPS) were developed. Unlike ordinary PS type bullets (PST, LPS), PRS type bullets do not have a steel core.

The need to create special cartridges of this type is associated with the peculiarities of the tactics of using special units of the Ministry of Internal Affairs, most of the combat operations or special operations of which are carried out in populated areas. In this case, small arms fire is conducted at short ranges.

In such situations, the high initial velocity of ordinary bullets with a steel core leads to a large number of ricochets from the walls of buildings, concrete fences, road surfaces, etc. This creates a real threat of defeat for its personnel. Bullets of the PRS type, when they hit solid obstacles, are crushed, quickly lose speed and do not produce as many dangerous ricochets as bullets with a steel core.

Blank cartridge:

Performance characteristics of 7.62x39 blank cartridge (57-X-231 blank cartridge)

Cartridge length, mm — 48.2 Cartridge weight, g — 8.2 Powder weight, g — 0.73

To simulate the sound of a shot during shooter training, as well as for firing fireworks, a blank cartridge is used. Together with the blank firing bushing, which is screwed onto the muzzle of the barrel of an assault rifle or light machine gun and allows you to create the necessary pressure of powder gases in the barrel, the blank cartridge ensures the operation of the moving parts of the weapon's automation.

The blank cartridge and muzzle device (bushing for blank firing) were developed by NII-61 designer E.T. Rozanov in 1949. The cartridge received its full name - 7.62 mm blank cartridge mod. 1943, code name - 7.62 blank model. 43 and index - 57-X-231.

Blank cartridges are available with bimetallic or varnished steel sleeves. Blank cartridges manufactured in 1949 -1951 have a brass-plated steel sleeve. A blank cartridge differs from a combat cartridge in the absence of a bullet and an elongated cartridge case. The case muzzle is crimped with an asterisk and covered with a layer of violet or red sealing varnish. The powder charge consists of 0.73 g of P-125 porous pistol powder.

Blank cartridge arr. 1943 is shorter than the combat ones, its length is 48.2 mm. When fired from the igniter primer, the powder charge ignites and the pressure created causes the sprocket of the compressed barrel to open. The shot is accompanied by a characteristic sound, a flash of flame and smoke.

Training cartridge:

Tactical and technical characteristics of 7.62x39 UC (57-N-231uch - training cartridge)

Cartridge length, mm — 56.0 Cartridge weight, g — 14.8

A training cartridge is used to teach how to load a weapon, fire a shot, and load magazines. Its full name is 7.62 mm training cartridge mod. 1943, conditional - 7.62 UCH model 43 and index - 57-N-231uch.

The cartridge is made using the main parts of a cartridge with an ordinary bullet with a steel core of 7.62 PS, but does not contain a powder charge and has a cooled igniter primer or a brass igniter cap. The cartridge is available with a bimetallic or varnished steel sleeve.

Increasing the strength of the bullet fastening in the cartridge case, in order to prevent it from falling out during training for loading weapons, is ensured by additional crimping of the barrel onto the bullet. The training cartridge bullet does not have a distinctive color, but the cartridge case has four symmetrically located longitudinal embossments.

High pressure cartridge:

Performance characteristics of 7.62x39 VD (57-N-231 V high-pressure cartridge)

Caliber, mm — 7.62 Bullet length, mm — 28.25 Cartridge length, mm — 61.5 Bullet weight, g — 9.2 Cartridge weight, g — 17.7

High pressure cartridge, full name - 7.62 mm cartridge mod. 1943 high pressure", conditional - 7.62 HP sample. 43" and index - 57-N-231 V, was developed at NII-61 (lead designer K.V. Smekaev).

The VD cartridge is designed to test the strength of barrel blanks and is used only in weapons manufacturing plants. A larger powder charge and a special bullet design provide a higher pressure of powder gases than when firing a conventional cartridge. The same pressure is provided by live cartridges at temperatures of - 60°C and + 70°C. This cartridge is available with a bimetallic or varnished steel sleeve.

The bullet of this cartridge consists of a bimetallic shell and a lead core. It differs sharply in shape and design from live ammunition bullets. The bullet has a short ogive and a flat tip.

There is a conical recess in the bottom of the bullet to ensure that the leading part of the bullet is tightly pressed against the inner surface of the barrel bore. The leading part of the bullet at a distance of about 14 mm from the bottom has a stepwise transition from a diameter of 7.92 mm to 7.58 mm. Due to the longer bullet, the cartridge has a greater overall length of 5.5 mm, which eliminates the possibility of loading it into standard weapon magazines.

The bullet has no distinctive coloring. Cartridges from early years of production may have a yellow color to the entire surface of the bullet. The packaging boxes and crates are marked "High Pressure".

Cartridge with enhanced charge:

Tactical and technical characteristics of 7.62x39 UZ (57Shch6 - cartridge with enhanced charge)

Caliber, mm — 7.62 Bullet length, mm — 26.8 Cartridge length, mm — 56.0 Bullet weight, g — 7.9 Cartridge weight, g — 15.6

7.62 mm cartridge mod. 1943 with a reinforced UZ charge, code name - 7.62 Z obr.43 UZ, index - 7Shch6 is intended to test the strength of the weapon's locking mechanism and is used in the manufacture of weapons and their overhaul.

It creates the same pressure in the barrel as when firing live ammunition at a temperature of + 70°C. UZ cartridges are loaded with smokeless pyroxylin powder of the P-45 or P-125 grades and an ordinary bullet with a steel core.

To distinguish it from military cartridges, the UZ cartridge bullet is painted with black varnish along most of the length of the bullet or up to the point where the cartridge case is crimped. The packaging boxes and crates bear the inscription “reinforced charge.”

Their use during shooting is strictly prohibited. 7.62 UZ cartridges are available with bimetallic and varnished steel sleeves.

Model cartridge:

Exemplary cartridge of the 1943 model.

To control measuring instruments (during ballistic tests) and ballistic weapons, as well as to certify these weapons, standard cartridges are developed.

They are similar in design to a cartridge with an ordinary steel core bullet, but all their parts are manufactured with greater precision (with half tolerances). This provides more stable ballistic characteristics in terms of bullet speed and powder gas pressure.

The tip of the bullet of the standard cartridge mod. 1943 is painted white. The packaging of exemplary cartridges bears the inscription “Exemplary”.

Cartridges for throwing grenades:

Special blank cartridge PHS-19

Based on the 7.62 mm cartridge case of the 1943 model, special auxiliary cartridges for throwing grenades and a cartridge for a special pistol complex were created. In 1950, the VG-45 rifle grenade launcher (attached to the muzzle of the SKS carbine) was adopted by the Soviet army.

The grenade launcher was fired with VPG-1 rifle anti-tank grenades and VOG-1 rifle fragmentation grenades. They were thrown from a grenade launcher using special blank cartridges PHS-45 (special blank cartridge).

For throwing grenades from a 30-mm silent underbarrel grenade launcher of the "Silence" rifle-grenade launcher complex based on the cartridge case mod. 1943 by designer TsNIITOMASH M.I. Lysenko created a special expelling cartridge PHS-19 (special blank cartridge).

The case muzzle of this cartridge is crimped with a star. It is shorter than a blank cartridge. Silence of firing from the grenade launcher system was ensured by a piston placed inside the grenade launcher barrel. During the firing process, the powder gases pressed on the piston, which, in turn, pushed the grenade out of the barrel.

After giving the necessary impulse to the grenade, gas-dynamic braking of the piston occurred. As a result, the piston came to the forward position with minimal speed. Powder gases were cut off by a piston in the grenade launcher barrel and gradually released into the atmosphere.

The grenade received an initial speed of about 100 m/s, which provided an effective firing range of about 300 m.

Cartridge for a special pistol complex:

7.94 mm special cartridge PS1

The specific tasks solved by underwater saboteurs required the creation of a special installation tool in the 1970s. Based on cartridge case mod. In 1943, TsNIITOCHMASH created a 7.94-mm special cartridge PS1 with a dowel for attaching special devices to structures made of various materials - for example, steel, concrete, wood.

The institute also developed a firing device for this cartridge. The use of the special pistol complex SPK-1 is possible not only on land, but also under water. The complex was developed by a group of specialists including V.I. Abramova, V.I. Zubachev and P.I. Serdyukov. In 1979, it was accepted for supply to the Navy.

Despite the fact that the 5.45x39 mm cartridge and weapons for it are now officially in service in the Russian army, the troops have a significant number of Kalashnikov assault rifles and light machine guns of 7.62x39 mm caliber.