Want to make your own switchblade? Then take a closer look at these instructions. Such a knife will be very useful in your pocket, especially if you go hiking or just walk in nature. You never know who you will meet along the way? Also, with a knife you can always cut something, cut it, pick it up, or even unscrew some screws if necessary. In this instruction we will look at how to make just such a knife.

The author used N690 steel as the material for making the blade. It is well suited for making knives, it is easily hardened and knives made from it hold an edge well. Assembling the knife is not difficult, but the author uses a belt sander, which greatly simplifies this process.

Materials and tools used by the author:

List of materials:

— steel N690 or similar; - spring; - bolt; — aluminum foliage for making handles; — textolite or something similar (used to finish the internal parts of the handle); - epoxy adhesive; - pins (nails will do); - screws.

List of tools:

— belt sander; - vice; - drilling machine; — welding inverter; - Bulgarian; - files; - marker; — “Dremel” with grinding and polishing attachments; - keys, pliers, etc.

Knife making process:

Step one. Let's start with making the blade

The first thing you need to do is develop a blade design for your knife. There is nothing complicated about this; the blade should have two grooves, thanks to which the blade will be held closed, as well as open. First draw the desired profile on paper and then cut it out.

Now we process the blade on a belt sander, bringing the profile to perfection. Finally, you will need to carve grooves in the blade; this design provides two pieces. First we cut them out using a grinder, and then we finish them using a flat file.

Don't forget to also drill a hole in the blade into which the axle will be installed.

Step two. Making a locking lever

The locking lever must also be made of durable steel, since with prolonged use the retaining hook may wear out. The lever locks the blade in two positions, first closed and then open.

We apply the profile to the metal and cut it out, finishing it with files and a hand saw. Finally, drill a hole for the axle.

Using the template, cut out two parts of the handle, and you will also need to cut out two similar parts from PCB. Glue the parts together using epoxy glue. When the parts are ready, glue them with epoxy glue to the final layer. Once the glue has dried, cut them out.

Finally, sand the parts using a belt sander.

Step five. Final preparation of all parts

You need to drill holes and tap threads in the handle; it will be assembled with screws. You also need to bend the holding lever at a certain angle; to do this, the author heats it red-hot with a burner and then bends it.

The handle also has another spring that supports the lever. For this spring you will need to machine and install a stop. We fasten the stop using pins. Ordinary nails can serve as pins.

Step six. Steel hardening

Let's start hardening, thanks to this the knife will not become dull for a long time. For N690 steel, the hardening temperature is 1071 degrees Celsius. Visually, this temperature is determined by a yellow glow. You can also determine the required temperature with a magnet; if it is not attracted to the hot steel, it means that it has been heated to the required temperature. Cool the blade in mineral or vegetable oil. As for the lever, it is also highly desirable to harden it. The author heats the metal using a torch and a special stove.

The first folding knives appeared before our era. The oldest finds date back to 600-500 BC. They were found during excavations of ancient Roman cities. It is possible that they were invented back in ancient Greece, but since the knives were used until they were completely worn out, only a few copies of Roman folding knives have reached us.

In the sixteenth century, Navaja knives using a folding mechanism appeared in Spain. Their popularity increased due to the adoption of a law prohibiting persons of ignoble origin from possessing weapons. The size of the Navaja when unfolded reached 45 centimeters, so it was quite a serious weapon.

Between 1650 and 1700, folding knives became widespread among the peasants of Western Europe. So-called “penny knives” appeared, which were of very low quality. They also produced piece products from the best steel and careful hand assembly. Naturally, a high-quality folding knife at that time was a rarity, accessible to few. The famous French knives of the Opinel brand trace their ancestry precisely from this elite group.

During the American Revolutionary War (1775-1783), folding knives acquired a locking blade made of good quality steel. Spring mechanisms began to be used everywhere, and various rings and gate-shaped designs appeared.

After the Vietnam campaign of the 20th century. folding knives have received a new impetus for development. The appearance of tactical folding knives dates back to this time.

Types of folding knives

There are a huge number of types of folding knives. They can be roughly divided into several categories:

- Folding knives made of plain steel without blade lock. Typical representatives of this category are folding knives from the USSR and similar Chinese knives. Here you can also include an unnamed Chinese-made switchblade, with which all markets and kiosks used to be littered. Knives in this category are highly not recommended for purchase, since they are made of low-quality steel, often break, can fold on the fingers and do not cut, no matter how much you sharpen them. A person who first became acquainted with folding knives through the example of these models may consider folding knives to be complete nonsense for the rest of his life;

- Multifunctional folding knives. This group is the most famous and includes inexpensive knives made in Russia, Chinese knives (usually counterfeits of well-known brands) and Swiss knives from the Victorinox brand. Of these options, Victorinox is the undisputed leader and is recommended as the first knife for every day;

- Chinese branded knives. They are, as a rule, copies of expensive American models. They are sold under their own brand, with minor design changes to avoid litigation from the original manufacturer. Sufficiently high-quality copies of knives made of good steel;

- Expensive folding knives from famous American brands. The cost of serial copies is on average about 12-18 thousand. The best grades of knife steel are used for their production.

In addition to this classification, the best folding knives differ in their blade locking mechanisms:

- Liner lock is the most popular system, which is a metal plate that secures the blade in the open state;

- Axis lock is a more reliable system, in which a spring-loaded pin serves as a lock;

- Virolok is the simplest system used on Opinel knives. It is a regular ring with a slot for folding the blade. If the ring is turned, the blade is locked in the open position.

There are many more different blade fixation systems, but they are much less common.

Should you buy switchblades?

If you examine the rating of folding knives, automatic knives will confidently take a leading position. It’s hard to imagine a street hooligan without a switchblade, although, as a rule, he only has a stupid Chinese knockoff knife. A high-quality switchblade is expensive and will always be inferior in reliability to its non-automatic counterparts.

The automatic switchblade is always activated by pressing a button. The button activates a spring, which ejects the blade, fixing it. Such knives are the most impressive, as the blade appears in a split second with a characteristic click. Switchblade knives come in two types, each with a different blade ejection pattern:

- Switchblade with vertical blade ejection;

- Front ejection switchblade.

The first category includes inexpensive automatic knives, since the vertical blade ejection system is simpler to implement (by the way, unnamed Chinese automatic knives also belong to this group). A switchblade with frontal ejection is a more technically complex system; even Chinese copies cost from 3 thousand.

Some fans of quality folding knives order handmade switchblades for themselves. As a rule, these are deep reworkings of serial models, with the complete replacement of all buttons and springs with higher quality ones.

Operating principle

In front-facing knives, the blade is not removed from the side, as in traditional mechanical knives, but is pulled forward from the end along the center line of the handle . The release button or bracket on the handle of the knife is pressed; in automatic models, opening and folding is carried out automatically. A switchblade with a frontal ejection blade is available with a single-sided blade or uses the principle of a dagger blade, in which the tip is sharpened on both sides.

Automatic folding weapons are prohibited weapons by Russian law depending on the length of the blade, but this restriction does not apply to semi-automatic models. The miscarriages are equipped with safety locks to avoid accidental injuries during transportation and storage.

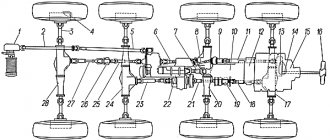

Popular mechanisms that eject the blade when the spring is stretched include samples from Microtech and Ultratech. The Benchmade, Pagan and Infidel models are prototypes with a coil compression opening. The opening mechanism in both cases is located parallel to the blade shaft inside the handle. The blade has a lock in the shank area, which, when the tip moves, moves back and forth along the grooves inside the handle.

A special flag is provided in the chassis structure for attaching the slider. The frame has two locking locks that lock the blade in the closed and open position. Knives are available with a lever on the side or front end of the handle. The helix of the frame expands or contracts as the slider moves forward, contributing to a straight-line force in the blade tang area. Further movement of the lever leads to the opening of the spring-loaded lock mechanism, and the lever moves to the free position.

A spring transmits forward movement to the blade through a pin, and the blade is ejected from the handle of the knife under the influence of inertia. The lock comes into operation and fixes the tip in the working position. The knife is closed in the reverse order using locks. First, the spring is compressed or stretched, which leads to a force in the shank area. The open-lock lock opens, the blade is pulled into the handle and secured with a closed-lock fastening lock. For the flawless operation of a complex mechanism, the quality and thoroughness of the processing of internal surfaces is an important condition.

Advantages and disadvantages

The weapon can be quickly brought into working position with one hand. Quality is valued in knife fighting, and this is also important for those who have one hand free while working.

The disadvantages of the design include the following points:

- The width of the blade cannot be greater than the size of the handle, and in the open position there is a faintly visible play. Weapons companies produce tools that do not have this drawback, but the products are highly expensive.

- The opening mechanism becomes dirty, and cleaning is difficult due to the complexity of the design. In some models, preventive cleansing is performed only by a specialist. Semi-automatic and automatic options require additional protection in the field.

There are no disadvantages in knives that open under the influence of gravity (inertial weapons). The folding model of the German paratroopers is a famous representative of this series, the weapon is modified and produced in our time. The knife is reliable, its structure is simplified, and a non-specialist can easily disassemble the structure for cleaning.

Types of locks

The frontal automatic switchblade is produced by gunsmiths with a reliable blade lock in the working position. There are several types of fastening locks:

- liner-lock - a linear lock, in which a spring fixes and presses the blade, while being part of the handle;

- back-lock - a spiral in the handle holds a special part on the side of the butt to fix the blade in the required position;

- clasp-knife - to secure the tip, a ring-shaped coupling is provided, which rotates when fixed;

- axis-lock - pin type lock;

- Balison-lock - provided in butterfly-type knives;

- ultralock - a linear and frame lock is assembled.

USSR folding knives

The industry of the USSR produced many folding knives for hunters, travelers, gardeners and summer residents. As a rule, these were the same type of model, differing only in the number of tools. It is worth noting that knives from the 60s and 70s were of higher quality than knives released in subsequent years. In the 90s, with the advent of better quality foreign knives, the popularity of Soviet knives gradually faded away.

The most famous knife in the USSR is the Belka. This knife was the dream of all the boys of that era. Among the monotony of knife products, it was “Belka” that stood out favorably with its design. These knives were distinguished by their unpretentiousness and reliability.

The best models of folding knives

The Ontario RAT is considered the most popular folding knife in the world. This model is considered a survival knife, although it gained its popularity as a knife for every day. The popularity of this device lies in its attractive price-quality ratio. For less than 3 thousand rubles, the buyer receives an excellent cutting blade with bevels from the butt. This knife has become the best-selling folding knife in the world.

The Victorinox Classic keychain knife is the most popular knife in the Victorinox line and one of the most popular knives in the world. Mainly used for nail care. Small scissors and a nail file, despite their miniature size, work flawlessly. Swiss quality, as they say, obliges.

The Opinel No. 8 knife is a bearer of the traditions of the first European knives. Despite its outdated appearance, it has an amazing cut. Can be used in the kitchen, where its wooden handle will fit perfectly into any interior. Recommended for lovers of classic knives.

Types of front cameras

Front switchblades are divided into categories depending on their design features. Some models provide only automatic opening of the blade, others also close by moving the slider.

Types of mechanisms:

- In single-operation systems, the blade is automatically ejected, and for the next use the knife is charged for extension. A lever on the handle moves from one position to another to compress the spring. Historically, the famous McGovern weapon belongs to a variety of single-operation knives, despite the fact that for many users this design seems outdated and inconvenient. Modern analogues are models from the Microtech HALO line, the only drawback of which is the impossibility of automatically bringing them to the non-working position.

- Two-operation systems are popular types - about 90% of front-facing knife models belong to this segment. The internal mechanism of Out The Front Double Auto is adjusted by moving the outer lever on the handle to the desired position. The design is a steel frame chassis with two springs, which, when compressed and stretched, work to fold or eject.

DIY folding knife

Making a folding knife with your own hands is quite a difficult task. To solve it you will definitely need a drawing. The process of creating a blade is no different from making a blade for a fixed knife; there will be no problems with the handle either, but assembling the locking mechanism will require pinpoint precision.

There is one secret that masters usually do not disclose. To make a flawlessly working designer folding knife, you need a high-quality Chinese donor with the necessary fixation system for 1,200 rubles. It is completely disassembled, the springs are changed, the blade is made of powder steel, the original material is put on the linings and the designer knife is ready! No one will even suspect him of being a former Chinese model.

Features of operation

Knives with frontal blade ejection are produced with blades that are made in the shape of a rectangular regular prism. The blade is narrower than a small-sized handle; it is limited by its width. Front blades are used for cutting and piercing operations, but are rarely used in harsh extreme conditions, because there is a gap and slight vibration of the blade.

Automatic mechanisms require careful and periodic maintenance. Knives are not used when working with abrasive materials, the dust from which penetrates into the smallest crevices of the tool and, in combination with moisture, contributes to rapid wear. After such use, the knife is disassembled, cleaned and lubricated. There is an erroneous theory that frontal devices are disposable and cannot be disassembled.

High-quality Russian-made knives are complex, but collapsible designs with a long service life. The owner of the knife can independently process the internal surfaces if he has accuracy, patience and special tools.

Tips for disassembly and cleaning:

- Before work, prepare all the required tools. For the fastening screws on the handle, appropriate cue balls are selected in shape and diameter.

- Pay attention to removing springs that may fly out to the side. Miniature parts are difficult to find; if lost, you will need to place an order with the manufacturer.

- High-quality compounds manufactured in the factory are used for lubrication. Homemade recipes will be harmful; unprofessional ingredients may leave an unpleasant taste on the tongue after cutting the food.

- When assembling, the blade is placed in the middle position, that is, it extends halfway from the handle. The mechanism will start correctly and there will be no problems with operation.

The history of the creation of a folding knife

Over their long history, folding knives have gone through a difficult path of improvement.

Presumably, they were made by masters of ancient Greece. Although they did not look very aesthetically pleasing and were not entirely safe, they are considered a real breakthrough of that time.

The production of knives with a folding mechanism began in the 16th century in Spain. They were, as a rule, made by persons of ignoble origin, who were prohibited from owning bladed weapons.

The design of such knives was far from ideal. She assumed that the blade should rotate around the attachment point. Such a knife was difficult to control, since it could fold or unfold at any time.

Design of the first folding knives

Over time, the quality of the metal improved, production conditions and materials improved, which could not but affect the strength and reliability of the switchblade designs (front and side discharge).

Innovative models of automatic switchblades with a non-standard blade shape, additional design elements, and ergonomic handles have appeared on sale. These innovations have significantly improved the ease of use and safety of knives.

Mechanism for transforming the sofa “Italian folding bed”

This transformation mechanism belongs to the double-folding mechanisms, just like the American clamshell. A double-folding mechanism is a mechanism that is brought into working position in two steps.

The principle of operation of the mechanism

To unfold the Italian folding bed from the sofa to the bed, you need to pull the upper part of the back of the sofa towards you (usually the back has a special loop for this purpose).

- In the first step of unfolding, the back of the sofa, together with the pillows, tilts forward and then lies down and rests on the seat of the sofa.

- At the second stage, the inner part of the sofa structure rotates around its axis, this is reminiscent of the unwinding of a rolled mattress. After this reversal, the support legs are revealed; the previously hidden ones were hidden and folded inside the structure, and the resulting sleeping area of the sofa rests on them.

Due to reinforced springs, the mechanism can be folded and unfolded without significant effort.

Advantages of the Italian folding bed: this mechanism is the most reliable and durable of folding beds, this became possible thanks to the use of reinforced metal pipes in the frame of the mechanism, the sofa when folded has a compact size, when unfolding there is no need to remove the pillows from the seat of the sofa, Italian folding beds have the most a thick and comfortable mattress for sleeping; in addition, the frame uses slats and belts that create an orthopedic effect.

Disadvantages: lack of storage space for linen, high price

In terms of ease of use and orthopedic properties, this type of mechanism is most suitable for a sleeping sofa for daily use.

How to choose the best

Before you start choosing and purchasing a knife, decide for what purpose it will be used.

- It should be remembered that the traveling version of the knife is not always convenient to use in urban environments, and vice versa;

- when buying a folding knife, make sure that it fits comfortably in your hand and is comfortable for you to use;

- A prerequisite for a reliable branded knife is high cost. A modern high-quality representative of knife products is made from expensive materials using special techniques, so it cannot be cheap;

- for those who value brand rather than quality, there are many different fakes assembled in China.

All of the above factors will help you make the right choice.

Preparatory stage

To make an automatic switchblade yourself, you need to take a strip of metal and transfer a sketch of the intended product onto it. Then, using sandpaper or a special machine, you will need to process the future blade.

If there is no suitable device, then you shouldn’t even start manufacturing quite complex products. Alternatively, you can use a needle file, a file or a hand drill for finishing. In addition, old kitchen knives are sometimes used as points.

After processing the blade and giving it the required shape, the part is clamped into a yew and grinding begins. Initially, rough finishing is done with a diamond file, then finishing is done using a fine-grained stone. The excess metal is sawed off, a hole is drilled in the center in the prepared part, and the end of the product is also sanded.

USSR folding knives

The Soviet Union produced many types of folding knives. They were not distinguished by their skillful design or great strength, but were in demand among tourists, hunters, summer residents and even gardeners.

The most reliable knives are those made in the 60-70s. last century. One of these is the world famous Belka model. Almost all teenagers of that time dreamed of it.

In subsequent years, the quality of Soviet knife products gradually declined, so they were replaced by more popular foreign knives. Modern Russian copies are also not in great demand in the world. They were forced out of the market by knives made in the USA, France, and Japan.

The Soviet knife “Belka” is the dream of many teenagers in the USSR

Rules of care

A spring-loaded switchblade requires more frequent and meticulous care than a regular one. Let us outline the main points in this matter:

- knife sharpening. It depends on factors such as the thickness and geometry of the blade, and the general purpose of the knife. The most effective sharpening is carried out by moving the blade against the whetstone at a certain angle. It is important to remember that the sharper the knife, the more carefully you need to handle it;

- cleaning the knife. One of the most important processes. If you do not clean the knife in time, the switchblade mechanism may become clogged with dirt and jam at the most inopportune moment. This is especially true for multifunctional knives. In case of contamination, it is necessary to disassemble the mechanism, clean, lubricate and reassemble. In order for knives of this type to serve for many years, timely cleaning is very important for them;

- knife lubrication. It is best to lubricate the knife with high-quality gun oil using a toothpick. There should not be too much lubricant to prevent dust and dirt from accumulating in the holes. Blades are usually treated with wax paste.

Varieties

For many years, knives have been considered an indispensable attribute in various sectors of our lives. The most common classification is based on their application.

Combat knives

They are used exclusively in military practice and are rightfully considered edged weapons. Front-end switchblades are not sold in regular stores, and owning them without identification is illegal.

Travel knives

Convenient and easy to use tools that are easy to sharpen and very rarely break. With their help, you can make a path in the forest thickets, cut wood for a fire, or make a primitive table on a camping trip.

Sports knives

This type of knife is part of sports equipment and is used only for throwing in special competitions. They are usually made without cutting edges and overhead handles.

Hunter knives

Sufficiently durable products that can not only remove the skin of an animal or butcher a carcass, but even kill the animal at point-blank range. They hold an edge well and have a high degree of wear resistance.

Rating of popular products

| Photo | Model | № | Description |

| Ontario RAT Folder Model 1. | 1 | In almost all surveys, experts give first place to a Taiwan-made copy called Ontario RAT Folder Model 1. It is distinguished by a reliable monolithic design, fits well in the hand, and confidently leads in terms of price-quality | |

| Victorinox | 2 | If we take into account European manufacturers, the most popular here are Swiss knives from Victorinox. |

This is a world-famous brand with a hundred-year history, which is famous for its high quality, safety and extraordinary product design.

Their main advantage is versatility. Such knives are usually equipped with a file, a corkscrew, a screwdriver and other “tricks” for use in everyday life.

Victorinox products are very easy to recognize thanks to the emblem in the form of a national flag

Spyderco Paramilitary–2

This is a fairly massive specimen, the length of which in working condition is 242 mm.

The ten-centimeter blade is distinguished by unsurpassed proprietary sharpening, a high level of strength and reliability. The proprietary Liner Lock mechanism allows you to safely open and lock the blade.

The special G-10 material with a rough surface contributes to ease of use. Many users note the versatility and unusual design of the blade.

Another Spyderco product called Paramilitary-2 often falls into different ratings for reliability and popularity.

The demand for it is explained by the fact that the knife blade, due to special materials, has increased strength, hardness, and wear resistance. It is non-corrosive and insensitive to infrared radiation

Opinel knives are easily recognizable thanks to their unique wooden handle. It is usually made from expensive species - beech or boxwood.

The blades are made of high-carbon stainless steel. The client can choose from 11 standard product sizes with different handle and blade lengths

At first the company produced balisong knives, but gradually reoriented itself to the production of folding knives. They are equipped with reliable Axis-lock locks with a smooth lock.

Distinctive features of this model are also perfect sharpening and complete absence of play. These qualities allow you to use the knife in various everyday situations without breaking or quickly becoming dull.

Brass and natural wood are used to make the handle. It is important to note that when purchasing this model of knife, the client is provided with a lifetime warranty on the product, which means that the company is completely confident in the quality of its products

The knife handle is made of titanium alloy, the blade is made of S35VN stainless steel. The total length of the knife is 212 mm, the length of the blade is 92 mm.

All copies of this model are made by hand using a reliable Integral Lock.

It has a wavy blade shape, which looks very impressive, but makes it difficult to sharpen. The knife is well suited for both straight and reverse grip lovers.

The handle impresses not only with its beautiful design, but also with its ease of use. The weight of this model is 134 grams

Assembly

Homemade switchblades at this stage acquire the desired shape and appearance. Elements for riveting are cut from nails or suitable wire. After their installation, it is necessary to grind off the edges to obtain a uniform surface.

Then, using a diamond file, a rectangular hole is made in the blade, and an axle is made using a lathe. Alternatively, you can do it with a file, but this process will take much longer. The clamp and the working part are adjusted to each other by cutting out rectangular sockets. A U-shaped fixing element is inserted into the handle of the product.

A spring cut out of steel is secured with a bolt. If the entire procedure is performed correctly, when you press the latch, the spring will act as a pusher. As this element, you can use a similar spare part from a car starter. At the end of the process, the device is polished with a special paste to a mirror shine.

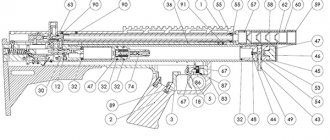

Drawing "Miscarriage"

A drawing of a folding knife is usually used for mounting it at home. The materials for a homemade folding knife of good quality will be needed: Damascus steel, which is durable and reliable; wood or plastic.

Before you start working, you need to draw a switchblade assembly diagram and always keep it at hand.

Front ejection switchblade diagram

Practice shows that before assembling a knife with a button, carefully study the locking mechanism - this is the most difficult process. If you master it well, you can make high-quality folding knives with your own hands.

| Spyderco Military | |||

| 3 — 4 | Another popular model is the folding knife of the American company Spyderco Military. | ||

| Opinel | 5 | Folding knives from the French company Opinel are the embodiment of true quality, practicality and strict design, which has been maintained for over a hundred years. | |

| Benchmade Griptilian 550 | |||

| A sample from Benchmade called Griptilian 550 has earned a place among the best blades in the world due to its low cost and excellent ergonomics. | |||

| Buck 110 | |||

| True connoisseurs of knife products often note the Buck 110 model. Its blade is made of high-quality steel, which holds an edge perfectly. | |||

| Chris Reeve Sebenza large 21 | 8 | Lovers of elegance and beautiful design can be advised to pay attention to the products of Chris Reeve. The Sebenza large 21 model especially stands out here. | |

| Benchmade 710 | 9 | The ranking is completed by another American-made knife – Benchmade 710. |