Jumping up one and a half meters, the mine wreaks chaos and destruction around itself. Small metal balls scatter with a chilling whistle, penetrating through everything living and inanimate within a radius of 30 meters.

The enemy is hiding, not understanding whether artillery is targeting him, or whether their unit has run into a well-organized ambush. The enemy signalmen, in turmoil, are trying to request help from the headquarters from the medical detachment. All this was done by just one engineering munition. Frog mines are a terrible anti-personnel weapon that we will talk about today.

How it all began

More than 500 years ago, the first mines appeared and they looked like gunpowder charges that soldiers placed under the enemy’s stone fortifications.

Sappers of those times dug tunnels and were responsible for trench systems and the durability of defensive structures. It got to the point that if, during defensive actions, one or another structure did not withstand the enemy’s onslaught, the sapper was considered guilty, and his head flew from his shoulders.

The Englishman Bickford significantly expanded the capabilities of demolition masters by inventing the fire cord at the end of the 19th century.

The first land mines began to be used during the American Civil War (1861-1865) and Russian-Turkish battles (1877-1878)

Man discovered TNT and dynamite, and successfully began to use them in subversive operations at the turn of the 19th and 20th centuries.

At the beginning of the twentieth century, mine production became widespread. During the Russian-Japanese clashes of 1904-05, this weapon was already produced in a factory.

With the appearance of tanks on the battlefield, the filling of the mine becomes noticeably heavier and now this type of charge is used not only against infantry, but also against armored tracked vehicles. After the end of the Great Patriotic War, the commanders of leading countries came to a common opinion on the need to gradually reduce the number of anti-personnel ammunition of this type.

Types of anti-personnel mines

The most famous domestic mine is the pressure anti-personnel mine, or PMN for short. Few would have thought that this type of engineering weapon would become one of the most powerful high-explosive mines in the world when it was adopted by the USSR in 1950. It can be cleared, but it would be more advisable to detonate it at the installation site by trawling or by throwing a sapper “cat”, because it is hypersensitive to pressure.

If an enemy soldier steps on the pressure surface of a mine cover, then within a second he will need urgent hospitalization. The soldiers dubbed the mine the “black widow” because of the black surface of the rubberized cover.

The power of the mine was enough for the person who stepped on the PMN to have his foot torn off at the cut of his boot in almost 100% of cases.

During the war in Afghanistan, Soviet special forces laced their sneakers or combat boots very tightly when they knew that when carrying out a mission there would be an area mined with such mines. In exceptional cases, this could save the damaged limb from amputation.

Almost two decades later, at the end of the 60s, the PMN-2 mine was developed, similar in principle to the PMN. This mine was also guaranteed to incapacitate the enemy by tearing off a limb. Only, unlike the “black widow,” she also caused serious damage to the other leg. Although the mass of explosive in the filling of the mine was half that of the PMN.

There are frequent cases when an enemy soldier who stepped on PMN-2 lost both feet at once. The shock wave of the mine is so strong that in some cases the victims lost consciousness. In addition, enemy soldiers died from pain shock and heavy blood loss long before the arrival of field orderlies.

After 10 years, there is a need to install a self-destruct timer on new generation mines. This happened due to the fact that many offensive operations under limited time conditions failed when the troops encountered their own minefields that had not been dismantled.

In the 70s, the PMN-3 was put into service, and an electronic sensor was installed in it, which made it possible to automatically detonate the mine after a certain period of time.

It was also very difficult to clear the mine, because during enemy counter-sapper actions it immediately went off if the angle of inclination was exceeded by more than 90 degrees.

Performance characteristics of PMN mines

| Characteristic | PMN | PMN2 | PMN3 |

| Weight, kg | 0.55 | 0.4 | 0.6 |

| Explosive | TNT | A mixture of hexogen and TNT | TNT with hexogen |

| Explosive mass, kg | 0.2 | 0.1 | 0.08 |

| Pressure plate radius, mm | 55 | 60 | 61 |

| Pressure sensitivity, kg | 8-25 | 15-25 | 5-25 |

| Height, mm | 50 | 54 | 54 |

| Self-liquidator time range | — | — | 12 hours, 1, 2, 4 or 8 days. |

If the detonation of a high-explosive mine is aimed at disabling one enemy infantry combat unit, then the principle of operation of fragmentation ammunition is based on the defeat of several soldiers. When the guy wires of the POMZ-2 circular mine are touched, the fuse pin is pulled out and the projectile detonates.

The bodies of such mines are made so that when they explode, their components are also parts of the destructive elements.

Performance characteristics of POMZ-2

| Weight, kg | 1.6 |

| Explosive | TNT |

| Explosive mass, kg | 0,075 |

| Radius of cast iron body, mm | 30 |

| Tension sensitivity, kg | 1-2 |

| Height, mm | 130 |

| Length of guy wires, m | 4 |

Directional mine MON-50. Its detonation occurs after the sapper gives a command to the control panel.

It is also equipped with a mechanical trigger sensor in the form of a tension wire. It is one of the most powerful anti-personnel mines and the only one that causes significant damage not only to infantry, but also to enemy light equipment.

Performance characteristics of MON-50

| Weight, kg | 2 |

| Explosive | PVV-5A |

| Explosive mass, kg | 0.7 |

| Damaging elements, pcs. | 550 metal balls |

| Destructive range, m | 30 |

| Height, mm | 160 |

| Length, mm | 220 |

| Width, mm | 60 |

Mines of the Red Army

Mines of the Red Army

In the USSR in the period 1922–1928, due to the difficult economic situation of the country, the development of mine weapons did not go beyond the development of prototype mines and the development of tactics for their use. For example, in 1924, the “Manual of the Red Army on underground mine work” and “Manual on subversive work” were published.

By 1928, the military leadership of the USSR had already developed certain ideas about the place and role of mine weapons in modern warfare, on the basis of which tactical and technical requirements for types of engineering ammunition were formulated.

Military engineers I. V. Volkov, D. M. Karbyshev, A. I. Kulichikhin, A. D. Podshivalkin, B. M. Ulyanov, D. V. Chernyshev, I. A. Shipilov, B. A. Epov, V.P. Yastrebov developed modular components for mines, which were used until the end of World War II, and some of them are still in use. These are detonator cap No. 8 TAT, detonating cord DSh-27, blasting machines PM-1 and PM-2.

PM-1 demolition machine and DSh-27 detonating cord

Back in 1924, military engineer Dmitry Mikhailovich Karbyshev (1880–1945) proposed the first sample of a fuse with an arc-shaped target sensor for an anti-tank mine. The mine itself was supposed to represent an explosive charge into which this fuse was inserted, which included a 200-gram TNT block as an intermediate detonator. This kit was adopted by the Red Army as the first example of a service anti-tank mine.

Fuze with an arc-shaped target sensor designed by D. M. Karbyshev for an anti-tank mine

Mine T-4 designed by N. N. Simonov

One of the first Soviet anti-tank mines, which were supposed to be produced on an industrial scale, was the T-4 mine with an explosive charge of 2.8 kg, proposed in 1932 by N. N. Simonov. It was not possible to organize mass production of these mines in factories due to problems with production capacity, but a certain number of them were produced in military workshops. This mine served as a prototype for the development of other Soviet anti-tank mines.

Anti-tank mine TM-35

However, military tests revealed a number of significant shortcomings of both the Karbyshev fuse and the T-4 mine. In 1935, it was removed from service and replaced with the TM-35 metal anti-tank mine.

The new mine had a steel rectangular body with a push-on cover and a universal multi-purpose mine fuse MUV. The total weight of the mine is 5.3 kg, the weight of the explosive charge (pressed TNT) is 2.8 kg.

Author's note

A number of foreign sources mention the TM-38 mine. However, such a mine did not exist. The authors of both public and official publications were misled by the number 38 embossed on the cover of the mine and some differences in the appearance of the TM-35 mine produced in 1935 from those produced in 1936 and later. In any case, there is no mention of the TM-38 mine in any of the Soviet official publications, while the mine that many call TM-38 is called TM-35 there. And the numbers on the cover indicate the year of manufacture of this particular mine. The author has encountered mines with the numbers 36, 37, 38, 39, 40.

In 1932, a prototype of the subsequently widely known MUV fuse appeared - the “simplified CF fuse”, which could be used as a fuse with both tension and pressure action. For many years, this fuse became the main mine fuse of the Red Army, and its modifications MUV-2, MUV-3 and MUV-4 are still in service today.

Fuzes MUV (top) and UV

In 1998, production of the MUV fuse with a plastic body was resumed in Russia.

In 1942, the Germans copied it and produced it under the symbol ZZ 42. In the post-war period in Czechoslovakia it was produced under the symbol RO-1.

Dynamoelectric blasting machine PM-2

It was copied under various names in Bulgaria, Israel, China, Poland, Yugoslavia and 29 other countries!

In 1932, the Red Army received the PM-2 dynamoelectric blasting machine, which could explode up to 25 electric detonators connected in series.

In 1933, a high-explosive anti-personnel mine PPM mod. 1933.

Anti-personnel mine PPM arr. 1933

By 1936, the MED-35 delayed-action fuse with a deceleration period from 12 hours to 35 days was adopted into service with the engineering units of the Red Army to assemble target mines.

In 1934, the DP-1 road-infantry land mine was put into service, intended to destroy combat and transport vehicles on the roads. In fact, it became one of the first anti-vehicle mines.

In 1939, the TM-35 mine was modernized and began to be produced under the designation TM-35M. Next, the following were developed and put into service: the elongated metal anti-tank anti-track mine TM-39, its wooden version TMD-40, the metal anti-tank anti-track mine PMZ-40, the EZ-1 anti-tank mine (activated using an electric contactor).

However, the capabilities of the then Soviet industry and the raw material base were very limited, especially in relation to metal. Therefore, the search began for alternative materials for mine bodies, which led to the appearance of two samples of cellulose mines - the anti-tank TMB and the anti-personnel PMK-40.

With regard to anti-personnel mines, the command of the Red Army first decided to limit itself to the use of universal mine fuses of the UV type (later MUV), as well as the VPF fuse, which could work in two ways: as a tension and inclined action fuse. And the mines themselves were supposed to be collected by the troops on the spot as needed, from improvised means.

However, during the Soviet-Finnish War (November 28, 1939 - March 12, 1940), the command of the Red Army was faced with the fact that Finnish rifle units on skis easily penetrate the rear of the Red troops through the gaps between units, and it is impossible to tightly close the entire front line with infantry.

Universal mine fuses MUV (above) and VPF

In this regard, in December 1939, a wooden anti-ski mine was urgently developed and put into production, and in January 1940, a metal anti-personnel high-explosive fragmentation mine PMM-5 (and its wooden version PMD-5), which was intended for the first time. a line against skiers, and the design of which used a target sensor in the form of a push metal bow.

Then the powerful fragmentation jumping anti-personnel guided mine OZM-152 entered service with the Red Army. By this time, the Red Army had already developed a division of mines into controlled and automatic.

Metal anti-personnel mine PMM-5 (top) and wooden anti-ski loop mine

OZM-152 was a guided mine. To control the explosions of such mines, there were BIS and KRAB-A switches, which made it possible to connect up to 12 mines to them. This made it possible to create controlled minefields.

As mentioned above, by the middle of 1940, the PMK-40 high-explosive pressure-action anti-personnel mine, which was successful in design but unsatisfactory in body material, entered service.

Mine PMK-40

Soviet designers returned to the idea of this mine only in 1949, creating the PMN plastic mine, which became as popular in the world as the Kalashnikov assault rifle.

Bouncing anti-personnel guided mine OZM-152

By the spring of 1941, the PMD-6 wooden anti-personnel high-explosive pressure mine was developed, but it appeared in the army much later.

In 1940, the MV-5 pressure fuse, which was very successful in design, reliable and extremely simply designed, was developed and put into service. It consisted of only five parts and could be manufactured in any metalworking workshop. Although it had absolutely no safety devices, the rather large trigger force (10–30 kg) and easy-to-use design virtually eliminated accidental triggering. Suffice it to say that this design was used in all Soviet anti-tank mine fuses up to and including fuses for post-war mines of the TM-62 series.

TMB mines

Metal anti-tank anti-track mine TM-39 (left), its wooden version TMD-40 and metal anti-tank anti-track mine PMZ-40 (right)

Initially it was used only in the TMB mine. But in 1941, the most advanced of all Soviet anti-tank mines of that time, TM-41, was created for this fuse.

This mine is an anti-track push-type mine. It had a sealed housing and was very easy to use. When installing it, you only had to unscrew the plug, insert the MV-5 fuse with the MD-2 fuse into the socket and screw the plug back on.

In the pre-war years, the F-10 object mine, exploded by radio using a coded radio signal, was adopted by the Red Army. The range of reliable operation of the radio mine was up to 600 km. Radiomins made a huge impression on the Soviet senior military leadership. It was ordered to immediately take it into service.

Anti-tank mine TM-41

But at the same time, the mine was so classified that even in secret documents it was called not a mine, but a “technique of special secrecy” (TOS).

It got to the point that the “Manual” for this mine was drawn up in such a way that a specialist, who was not verbally explained the essence of its mine design, could not understand what was what.

According to the staff of the RKKA rifle divisions No. 4/400-416 dated April 5, 1941, a separate sapper battalion of the division provided for a platoon of the “Block” device (1 officer, 5 sergeants, 28 soldiers, 4 trucks). This platoon was intended to install radio mines.

To be fair, it must be said that in fact these mines were nothing special. An ordinary object-controlled mine, only the control (explosion) was carried out not by wire, but through a command radio line. In addition, the method of explosion by radio had a number of significant disadvantages.[6]

Firstly, the power supply for the F-10 radio mine was only enough for 40 days, while a wired mine can be detonated even several years after it was laid.

Secondly, the radio mine needed an antenna 30 meters long, directed to the east, and the depth of the antenna could not exceed 1 meter. But the control cable of a wired mine can be buried to any depth and led in any direction.

Thirdly, the enemy, having learned about the use of radio-detonated mines, could intercept the radio signal and jam it.

That's exactly what happened. At first, the use of radiomin gave some results. Thus, in Vyborg, occupied by the Finns, in August 1941, out of 25 installed F-10 mines, they managed to detonate 17 (68%). But already in Kharkov in October-November of the same year, out of 26 installed F-10 mines, only 6 (23%) were activated. And that was thanks to the fact that the miners used a powerful radio broadcasting station in Voronezh. German field radio jamming stations simply did not have enough power to jam it.

Fourthly, without intelligence information about how the enemy uses a mined object, and whether he uses it at all, one cannot hope for serious damage from the use of mines.

Suffice it to say that of the six F-10 mines detonated in Kharkov, only one exploded in a building occupied by the enemy for official purposes. The five remaining mines destroyed apartment buildings, burying their residents under the rubble, who for various reasons remained in the city after the Red Army units left it.

By June 1941, the Red Army had the following mines in service:

Anti-tank:

a) anti-track TM-35, TM-39, PMZ-40, TMD-40, TM-41, TMB; b) anti-bottom AKS.

Anti-personnel:

PMM-6, PPM, DP-1, OZM-152, PMC-40, PMD-6. F-10 radio-controlled object mine.

In addition, there was a whole set of standard means of explosion: delayed action fuses, push and pull fuses, blasting caps, electric detonators, fire and detonating cords. They made it possible to improvise mines of any purpose and power on the spot.

Separately, it is necessary to mention the LMG anti-aircraft cumulative mine designed by Major General Galitsky. It was installed on the side of the road, at a distance of about 30 meters, and a tension wire was stretched from it across the road. When the tank touched the wire, the powder rocket engine was fired and the grenade flew into the side of the tank. The explosion of a powerful shaped charge penetrated the side armor of any tank.

Anti-aircraft cumulative mine LMG designed by Major General Galitsky

Author's note

It is generally accepted that the Germans invented cumulative shells, and that these shells were one of the secret weapons of the Wehrmacht. They say that Hitler allowed their use only when he learned that German anti-tank artillery was powerless against Soviet T-34 and KV tanks. They say this was a heavy blow for Stalin, and he ordered all reconnaissance forces to be deployed to discover the secret of shells burning through armor. Allegedly, only by the spring of 1942, with great difficulty, was it possible to obtain one shell, and before that, many Soviet tanks burned out due to the short-sighted technical policy of Soviet leaders in the pre-war period.

Indeed, since October 1941, German artillery began to use cumulative shells. But these were over-caliber shells for 37-mm anti-tank guns and their range did not exceed 150 meters. And to shoot at a tank directly from such a distance, you have to be an artilleryman of exceptional courage!

Meanwhile, back in the summer of 1941 (!), Soviet LMG cumulative mines burned German tanks, and by October of the same year, the Red Army had a VPGS-41 rifle cumulative grenade designed by Serdyuk. And in general, the Soviet anti-tank artillery, until the appearance of the Tiger and Panther tanks at the front (1943), did not experience any particular need for cumulative shells. Conventional armor-piercing shells coped well with German tanks of all types, which had to put more and more armor on themselves every month. For example, the thickness of the frontal armor of the PzKpfw IV increased from 50 mm in 1939 to 80 mm in 1944!

So the question of priority in the creation of cumulative ammunition is not as simple as it seems at first glance. Let us recall that the cumulative effect itself was discovered by a Russian military engineer, General M. M. Boreskov back in 1863! It is likely that the development of cumulative ammunition in Germany and the USSR proceeded almost simultaneously.

* * *

The Germans were the first in the world to create an aircraft remote mining system. For Ju-87k dive bombers in 1939, universal miniature fragmentation bombs “Spreng Dickenwend-2” (SD-2) “Schmetterling” were developed. They were equipped with three types of fuses: a) ensuring the bomb explodes in the air or when it touches the ground; b) slow action (5-30 minutes); c) triggered when the position of the bomb lying on the ground changed.

These bombs weighed 2 kg and were placed in discardable cassettes - Mk-500 (6 pieces), AV-23 (23 pieces SD-2), AB-24t (24 pieces), AV-250 (96 pieces), AV-250- 2 (144 pieces). The Germans first used cluster bombs with great success in the Polish campaign (September 1939), and then used them throughout the war.

Actually, the dropped cassettes were used to bomb infantry columns and infantry positions on the ground, and the use of SD-2 mini-bombs in a mine version was intended only to hinder the enemy’s use of the area and the work of the orderlies.

Typically, some of the bombs in the cassette had delayed-action fuses and shear-sensitive fuses, the majority had conventional fuses.

Universal fragmentation mine - aerial bomb "Spreng Dickenwend-2" (SD-2) "Schmetterling"

Drop cassettes were not used to lay minefields, since remote mining tactics did not exist then, and no one thought of developing it. However, this is how German authors (Nowarra N. “Luftwaffen-Einsatz “Barbarossa”; Bekker S. “AngifT-shoehe 4000”) explain the reasons why SD-2 bomb-mines have not found widespread use either as bombs or as min remote:

“Unexpectedly for the Soviet command, on June 22, 1941, the enemy used small fragmentation bombs on a large scale for the first time. According to the Luftwaffe leadership, the effect could only be achieved with the massive use of new ammunition. Therefore, by the beginning of summer, the German logistics services had prepared stocks of 2,298,500 2-kilogram SD-2..., while previously they were used only in isolated cases.

In the bomb bays of many twin-engine bombers, cassettes were installed into which 360 SD-2 were loaded... Another option for using small bombs was the AB-250 containers, which were suspended under the wings of the Ju-87, Bf-109, Bf-110 and other aircraft that did not have internal bomb bays . The AB-250 container held 96 SD-2s... and opened before reaching the ground.

The bombs exploded both when the impact mechanism was activated and without it, exploding at a height of up to half a meter from the ground. Without the use of cassettes, the optimal bombing altitude was about 500 m, and with containers it was slightly higher. Tiny fragments from each bomb were scattered within a radius of up to 12 m... A kind of carpet paths were formed on the ground, which probably hit stationary aircraft, vehicles, and troops not hidden in shelters. In the figurative expression of G. Novarra, “a whole shower of these satanic eggs passed over Russian airfields.”

But he also noted that SD-2 bombs exploded at the slightest vibration, and due to design flaws, they were pinched in the cassette grids. After one Ju-88A and one Do-17Z exploded in the air without enemy influence, and in other cases the bombs that fell during landing “mined” their airfield, the commander of the air fleet, Field Marshal A. Kesselring, further limited the use of small fragmentation bombs externally suspended containers.

Engineer General E. Marquard, who led the development of aerial bombs in the Technical Directorate of the German Ministry of Aviation, subsequently spoke about the “satanic eggs” as follows:

“Despite the success of its use in the first days of the Russian campaign, the SD-2 remained “one-day butterflies.” Soviet air defense systems soon proved to be very effective in the fight against low-flying bombers, forcing our planes to climb higher and higher. This decided the fate of the SD-2 - no new special devices were developed for their use.” /Cm. in the book by D. Khazanov “1941. Bitter lessons. War in the air"/

And yet, aviation cassettes with SD-2 mine bombs can be considered a full-fledged aviation remote mining system.

After World War II, the Americans adopted the Schmetterling system as an aircraft mining system called “The Butterfly”, and the SD-2 bomb was given the name AN-M83.

For conventional high-explosive bombs (100 kg, 250 kg, 500 kg), the Germans developed delayed-action fuses with deceleration times of up to 2–3 days. They actually turned aerial bombs into object mines, which excluded the possibility of carrying out rescue and restoration work at the bombing site.

* * *

When describing mines of the first half of the 20th century, surprise mines, chemical mines and fire mines should also be mentioned.

The British were the first to use chemical mines in 1917. The Germans also created and used mustard gas mines in 1918. They were delayed-action demolition charges containing mustard gas to prevent the enemy from using underground structures left behind by retreating German troops.

The first and probably the only standard example of a chemical mine (not counting the post-war American chemical mines Ml and M23) should be considered the German “Spruhbuchse 37”, which was developed by 1937 and was produced in Germany during the Second World War.

American chemical mine XM-1 (1953)

But none of these mines discovered by the Allies in warehouses were filled with mustard gas.

It has been documented that no one used chemical mines during the war.

Author's note

There is still ongoing debate about why neither the Germans nor the Allies used chemical weapons during the Second World War.

The prevailing opinion is that this was prevented by the fear of the Germans (allies, Russians) that the opposing side would respond by flooding Germany (England, the USSR) with thousands of tons of toxic substances.

In the author’s opinion, the reasons here are different: 1) the difficulty of subsequent actions of friendly troops in the contaminated territory; 2) the absolute dependence of chemical weapons on weather conditions, therefore, the unpredictability of the consequences of their use, including for friendly troops and the population; 3) the ineffectiveness of such weapons in operational terms.

The most noticeable result, and then only tactical (!), is the exhaustion of the enemy’s forces and friendly troops, forced to act in defensive means. Obviously, the military leadership of all the warring countries understood this.

Let's now touch on fire mines and mines. In the initial period of the Great Patriotic War, the Red Army used an improvised fire mine: up to 20 Molotov cocktails placed around an anti-tank mine in a radius. The burning liquid after the explosion affected an area of up to 300 square meters. m.

Soviet flamethrower HE FOG

Also, Soviet troops used wire-controlled stationary flamethrower bombs from the FOG.

This is a cylindrical container (25 l) filled with liquid or thickened fire mixture. Either a short metal fire hose was screwed onto it, which threw the mixture in one direction, or a four-beam head, which threw the mixture in four directions at once, but at a shorter distance. The maximum flamethrowing range was 100 meters. The pressure in the container was created by burning the powder charge.

These devices were quickly copied by the Germans and used in 1944 in the defense of the Atlantic Wall on the French coast. The British used improvised fire mines during the First Battle of El Alamein in 1942.

However, fire mines mainly use petroleum products or phosphorus compounds, which are an acutely scarce strategic material in wartime. Therefore, they are resorted to quite rarely when there are liquid petroleum products that are unsuitable for their intended use. But then the fire mines are usually just improvised.

Surprise mines were used to a very limited extent during World War II. They are not capable of having any noticeable impact on the course of the battle, deterring the enemy, or causing him significant losses. Usually, when using them, after several explosions, the enemy quickly identified the types used and subsequently avoided being hit by such mines. At most, surprise mines can make it difficult to use local items, equipment, abandoned weapons, and premises. And although there is a lot of talk about surprise mines, they are usually not worth the effort required to make and use them.

Frog mines

Why did frog mines get such a nickname? This is because the principle of operation of such frog mines is based on the jump of a projectile with explosives at a distance of 1-1.5 meters above the ground, followed by detonation. One of the brightest representatives of jumping mines is OZM-72. Today, more than 40 years after its adoption, it remains the most effective and lethal all-round mine.

The enemy touches the tension cable, which activates the expelling charge. He throws a frog mine up to 140 cm above the ground. When the charge reaches its highest point, the detonator is triggered and the frog mine explodes. It scatters 2,400 balls and fragments of a cast-iron body around itself at a distance of up to 25 meters.

Clearing the OZM-72 frog mine is possible only in one case - if it is used in remote mining conditions. In other cases, the sensitivity of the fuse does not give the enemy sapper a chance to make a second mistake, so he prefers to act with a “cat”.

A group of several OZM-72 frog mines with NVU-P applied to them represents a terrible force.

This is a special explosive device, which is an electronic unit with a seismic sensor built into it. This unit connects to OZM-72 located around the perimeter and reads vibrations of the earth’s surface from the enemy’s steps. In this case, trip wires will not be needed, as required by a single installation of an anti-personnel mine.

The sensor gives a signal that an enemy is approaching it, and it is triggered at the most favorable moment for detonation. The enemy has no chance at all to get out of such a minefield alive and unharmed. The seismic device reacts only to the movement of enemy infantry; it is not interested in tanks and other equipment.

But which mine became the prototype of the deadly OZM-72? It all started during the fighting on the fronts of the First World War. German engineers invented the S-mine - a 500 gram cast iron can filled with explosives. The shrapnel in the frog mines was placed between the sides of the can and the explosive, and the whole thing was filled with cement.

The fuse was screwed onto a tube passing through the longitudinal axis of the can. At the bottom of the structure, on the wooden bottom, there was a striking mechanism, and a metal chain up to 1.5 meters long was mounted to the bottom of the can, in the center. Its second end was attached to the bottom of the connecting tube passing through the body of the frog mine. Also at the bottom of the mine, on the outside, there was a bag of black powder, which also contained an electric igniter.

S-mine began to be used during the active phase of “trench warfare”. They were buried right in front of the wire fences, and the wires were fed into the trench. The sapper connected the wires to a galvanic battery, after which the powder charge was triggered, throwing the frog mine 150 cm. As soon as the chain was sufficiently stretched, it pulled the ignition tube along with it. The fuse hit the striker, striking a spark, thereby provoking an explosion and hitting the enemy with fragments.

In those days, the first frog mine was not particularly effective.

Firstly, this happened due to the visual difficulty of determining whether the enemy was in the affected area of the projectile - this was very difficult to do from a trench. In addition, the frog mine came with very long wires of at least 50 meters, and they were not particularly strong.

The wires were easily deformed by enemy shell explosions, and their insulation was very far from perfect. Sometimes, even an accidentally ricocheted enemy bullet could easily lead to failure of the detonation mechanism.

After the smoke on the battlefields of the First World War cleared, the commanders of the leading countries immediately began to invest huge amounts of money from state budgets on the development of the main, in their opinion, areas of weapons development. They believed that aircraft, tanks and chemical weapons would “rule the roost” in future battles.

Everyone forgot about the mines except the Germans. Although they had no other choice, because the Treaty of Versailles, which followed the end of the First World Conflict, prohibited the German army from having airplanes, chemical weapons and tanks.

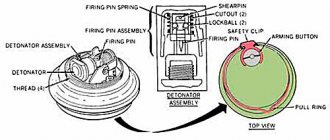

In 1935, a new model of the frog mine Sprengmine 35 (Springmine 35) entered service with Germany. Its name literally translates as “jumping mine.” German sappers also called this deadly mine Schueltzenmine 35 and Schrapnell-Mine 35. The design of the S-mine was taken as the basis, but now the frog mine did not need to be controlled by peering into the horizon, trying to see the approaching enemy.

The basic operating principle of the Sprengmine 35 mine was based on the autonomous operation of the mine without the participation of a sapper in detonating it.

An enemy soldier touched one of the four trip wires, running crosswise from the body of the frog mine at a distance of 4 meters. The tripwires pulled the pin and cocked the mine's igniter primer into the firing position. After 3.5 seconds, the frog mine jumped up with a deafening whistle and exploded into many deadly pieces of wire and body fragments. Sometimes the Germans used balls from bearings as destructive elements.

The frog mine could be installed on almost any surface and at any angle. The main rule of a sapper of those times was considered to be proper camouflage of a frog mine. To do this, it was enough to dig a shallow hole of 20 cm, and then carefully install Springmine into it. The trip wires of the frog mine were made of a strong metal cable, and they also had to be camouflaged, because they could not be called invisible to the enemy.

The frog mine could also be installed without the use of trip wires. When installing a frog mine, it was enough to use an S.Mi.Z 35 fuse, the tendrils of which extended beyond the diameter of the mine body by 5-10 cm. But Wehrmacht sappers used this method of laying a mine only under conditions of severe time constraints.

In other cases, when the situation permitted, an ANZ 29 fuse was screwed onto the frog mine, to which trip wires were connected. This fuse could also be used to remotely detonate a mine. As in the case of the predecessor S-mine, the sapper shorted the ends of the wires to the galvanic battery, bringing the ANZ into a firing position and after a few seconds the frog mine soared upward. Also S.Mi. 35 easily mated with the following fuses: MiZ 40, DZ 35, SMiZ 44, ZZ 35 and ESMiZ 40.

The use of fuses on the German Sprengmine 35 frog mine did not involve dismantling the device.

There was only one way to clear a section of terrain filled with frog mines - by detonation.

Tactical and technical characteristics of S.Mi. 35

| Weight, kg | 4.2-5.1 |

| Explosive | TNT |

| Explosive mass, kg | 0.2-0.5. |

| Damaging elements, pcs. | 340 |

| Destructive range, m | 30 |

| Height, mm | 130 |

| Length of guy wires, m | 4 |

| Sensitivity, kg | 2-5 |

Soviet-made anti-tank mines TM-35 and TM-35M

The TM-35 mine

is the first standard anti-tank mine of the Red Army, and before its appearance, soldiers used a set of TNT blocks selected by weight, on top of which a metal bracket was attached, connected to a fuse.

In addition, it is indicated that by 1935, the development of a new metal anti-tank mine with the index TM-35 was completed, which is written about in the 1934 edition of the Manual for Engineering Troops in the paragraph “Demolition work.” The later model of this mine TM-35M

is a copy of the earlier model and is different from the mine there is a slightly higher height of the ammunition body itself (it was 11.5 cm instead of 8.5 cm) and a correspondingly greater total weight, which was 7 kg, which is 1.2 more than the previous mine, and a correspondingly larger TNT charge (4 kg instead 2.8 kg.). the difference was that the TM-35M was filled with TNT, and was not filled with checkers and was equipped with an additional 200 gram checker that served as an intermediate detonator.

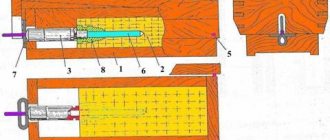

The mine consisted of an iron body with a removable lid on the canopies. In the middle of the box there was a thin-walled iron box with dimensions of 10x5x2.5 cm. It also had a hole for placing a fuse in the end wall, which should go inside the body. To place the MUV fuse in this box, there was a special hole in the body of the mine body, closed by a small flap. In the middle of the box there was a double-armed lever that could easily swing in a vertical plane. When the fuse was inserted into the mine, the pointed part of the lever fell into the P-shaped hole of the fuse pins. The other end of the lever was placed strictly under the pressure bolt. The empty space was filled with melinite or TNT, the newer TM-35M anti-tank mine was filled with ammatol, TNT, ammonite or the “French mixture”. The mine that the troops were supplied with was not equipped and, accordingly, not ready for use. Filling with explosives and equipping with a fuse, and this was a universal mine fuse ( MUV

equipped with a special T-shaped combat pin) was done in the sapper company immediately before mining. The body of the mine contained 6 checkers of melinite or TNT, 400 grams each, which were made up of 2 checkers of 200 grams each. (total 2 kg. 800 gr.), and if the mine was filled with crumbly explosives, then almost 2.4 kg were placed in the mine. explosives. Immediately before installing the mine, it is loaded with explosives, and during installation itself, you need to check the alignment of the fuse seat, for which a special template was used, which was inserted into the hole located on the front wall of this ammunition. In terms of its design, it was an ordinary wooden stick replicating the fuse with an MUV fuse equipped with an MD-2 fuse, but a little longer to make sure that the place for the fuse would fit freely and without load into the mounting hole of the TNT block. Next, it was necessary to fold back the mine cover, after which, using another plate template, verify the correct position of the pressure bolt, which consisted of checking the lowering of the cover so that the plate would not press on the lever, remove the safety pin from the fuse and, without force, insert the fuse into the standard hole, visually observing the pointed end of the lever falls into the special loop of the P-shaped pin, then put the damper in place and carefully, without allowing an impact, lower the pressure cover into its normal place and close it with box locks. There were pressure corrugations on the cover and when a tank, car or other equipment collided with the mine cover, the latter, being compressed under the weight of the passing equipment, pressed the pressure bolt, which accordingly pressed on the end of the lever and at the same time the second end of the lever rose slightly upward and with this movement pulled out A P-shaped pin from a mine fuse, after which an explosion occurred.

In the figure above, the lever is indicated in blue, and the P-shaped pin is highlighted in green.

Look closely at the driving device for the mine explosion, namely the box with the lever and the fuse. The same mechanism was used in the TM-39 and TMD-40

, but they had a pair of them and they stood at the end parts of the ammunition. Such boxes were mounted in TM-39 and TMD-40 mines and closed with flaps. This was already a step forward, for the reason that it was possible to prepare the box for detonation and install the fuse correctly in it, and all this could be checked in advance, at any convenient time, and the boxes themselves could be placed in mines directly at the mining site. The TM-35 mine, due to the lack of an alternative, was used by the Red Army in the difficult years 1941-42 for the country, and during the first battles with the German army, the weakness of the mine charge, which was less than 3 kg, was revealed. and therefore, in a hurry, stronger metal mines were designed and put into production, such as the elongated TM-39 and TM-41, while the latter was round in shape with a tola or ammonite weight of 3.6 kg, but they could not equal German for 5 kg of TNT. But an acute shortage of metal and wartime difficulties forced the industry to abandon the production of TM-41 metal mines and quickly reorient itself to the production of primitive wooden mines of the TMD-40 class.

Anti-tank mine of the Soviet army TM-35 anti-track and anti-wheel pressure action. The explosion occurs with a force of 120-260 kg, which is ensured by the collision of a car wheel, tank caterpillar or other equipment on the upper part of the mine, which has structural metal corrugations on both sides; when removed, the P-shaped combat pin is removed from the fuse and an explosion occurs. The mine can be installed on the ground, in the ground, in the snow, and all this is done manually. Moreover, the leakage of the mine seriously limits its tactical capabilities in damp, swampy soils, especially if a non-moisture-resistant explosive is used or the minefield is planned to be installed for a long time. The duration of action of the mine itself is not limited and fully depends on the safety of the explosive and therefore TNT, which has practically no explosive properties, is considered the best for it). The destruction of the mine body, which occurs from corrosion, makes the mine dangerous for humans, and not just equipment, since the MUV fuse can be triggered by its low weight. The mine is generally considered to be retrievable, but due to the high sensitivity of the fuse, the difficulty of removing it gives every reason to consider this ammunition practically irretrievable. The first days of the war showed that the TM-35 was very difficult to install

, and if mining needs to be done at the front line, under enemy fire or at night, then this task is practically impossible and fatal for the miners, and the mine was weak and the detonation did not always produce the desired result. For this reason, the production of TM-35 mines was completely curtailed during the Soviet Union’s attack on Finland in 1939-40, and the reserves were depleted in the summer and autumn of 1941 and in 1942 it was impossible to meet the TM-35 in combat units and it was replaced by a mine TM-35M.

Combat use

One of the first “baptisms of fire” of the Sprengmine 35 frog mine occurred in the midst of fierce fighting between the French and Germans during World War II. Then, on September 13, 1940, the Germans had to retreat and take up defense in the Palatinate Forest area. The French command decided to send numerous reconnaissance groups to find out the location of the enemy's defensive positions.

Under the cover of darkness, the scouts set out to carry out a combat mission. But almost none of them made it back alive, and the few soldiers who were lucky enough to survive spoke confusedly of “ambushes out of nowhere” and “aimed fire from German guns.” In fact, the French ran into well-placed Sprengmine 35. Frog mines, exploding at a height of one and a half meters, destroyed almost the entire personnel of the reconnaissance group.

Invented during the First World War, the S-mine laid the foundation for the discovery of new deadly projectiles - frog mines.

New samples of frogs are very difficult to detect, because if a sapper uses a mine detector, he will certainly hit the trip wires connected to the fuse. And when using a probe, there is a risk of explosion. And with skillful camouflage, a frog mine can become an insurmountable obstacle for enemy infantry.