Booby trap MS-3. Mines and traps

Details Category: Sniper Date of publication 12/24/2013 20:21 Author: Super User Booby-trap (or surprise mine) MS-3 is intended for setting up various kinds of traps (surprises), as well as installing anti-tank mines in a non-retrievable position. It is in service with the Russian army and a number of other countries.

Booby trap MS-3

Main tactical and technical characteristics of the MS-3 booby trap

| Type: | high explosive, unloading action |

| Diameter, mm: | 110 |

| Height, mm: | 65 |

| Weight, g: | 660 |

| Case material: | plastic |

| Target sensor diameter, cm: | 5 |

| Target sensor type: | unloading action |

| Time to bring into combat position: | 5 minutes—15 hours (depending on air temperature) |

| Mass of explosive (explosive), g: | 340 |

| Explosive: | TNT |

| Minimum holding weight, kg: | 5 |

| Temperature range, °C | ± 40 |

| Service life in combat deployment: | indefinitely |

ML-7 booby trap (Soviet and Russian mines)

The mine is intended for use as an anti-personnel mine device for anti-personnel mines that do not have their own such device.

In addition, the mine can be used as a mine-trap with unloading action.

When used as an anti-personnel mine anti-personnel mine device, the ML-7 mine is installed under the bottom of a push-action anti-personnel mine such as PMN, PMN-2, PMD-6m, or similar, and when attempting to remove the anti-personnel mine from the installation site, the ML-7 mine explodes, damaging enemy deminer. In this case, detonation or destruction of the anti-personnel mine occurs.

When used as a booby trap, the ML-7 is installed on the ground so that it is not visible (for example, in an open hole), and an object is placed on it that will certainly arouse the enemy’s interest and encourage him to pick up or use it (weapons, objects everyday life, etc.). In this case, personnel are damaged due to the force of the explosion (high explosive impact).

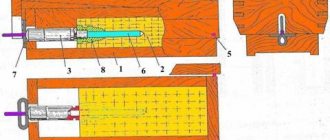

The mine consists of a body (1), an explosive charge (2) and two additional detonators (3).

The body of the mine is rectangular in shape and is made of plastic and serves to house a fuse, a target unloading sensor (spring-loaded cover), two additional detonators and an explosive charge.

The explosive charge consists of two plastic boxes filled with explosives of the PVV-5 type. These boxes are attached to the sides of the body with spring latches and can be removed from the mine if necessary.

Additional detonators are placed in housings on both sides of the fuse and are 5 gram tetryl blocks. mass each and serve to transfer detonation from the fuse to the explosive charge.

The fuse is a safety type of unloading action and consists of the following main systems - a safety system, a long-range cocking mechanism, a safety-detonating device and an actuating mechanism.

The safety system is designed to ensure safe handling of the mine in the transport position and transfer of the fuse to the firing position.

The long-range cocking mechanism ensures that the fuse is brought into firing position after 45 seconds. - 20 minutes. after the safety pin of the safety system is removed.

The safety-detonating device ensures that the mine cannot explode in the transport position and, at the same time, the reliable transfer of detonation from the fuse through additional detonators to the explosive charge in the firing position.

The actuator ensures that the fuse is triggered when the load is removed from the mine.

In the photograph of the mine at the beginning of the article, two boxes with an explosive charge, a target sensor (pressure cap), a safety pin ring and a red ribbon on the pressure cap pin are clearly visible.

The mine can only be installed manually on the surface or in the ground or snow. The mine is not intended for use underwater.

The operational life of the mine has not been determined. The mine is not equipped with a self-destructor. The mine cannot be removed or neutralized.

The mine has a fuse that is part of the mine design.

Tactical and technical characteristics of the ML-7 mine

Type of mine…………………………………………………… high-explosive trap with unloading action Weight of mine…………………………………………………………… 100 gr. Weight of explosive charge (PVV-5+ tetryl)…………………… 40 g. (30 g. - PVV-5, 10 g. - tetryl) Length……………………………………………………………… 7.2 cm. Width…………………… ……………………………………. 6.9 cm. Height……………………………………………………….. 3 cm. Minimum load weight……………………………300 g. Type of target sensor…………………………………….. mechanical unloading Dimensions of target sensor……………………………………. 5.5 x 5.5 cm. Time to transfer to firing position………………… from 45 sec. at temp.+50 deg. up to 20 minutes at temp. -40 gr. Temperature range of application……………….. -40 - +50 degrees Type of long-range cocking mechanism………………….. hydromechanical Fuze……………………………………………… ….. own, mechanical Neutralization……………………………………….. non-neutralizable Retrievability………………………………………………………………. non-retrievable Self-neutralization/self-destruction…………………. no/no Duration of combat work……………………………………….. not determined Guaranteed shelf life……………………………… 10 years Combination with mines/items……… ……………….. anti-personnel pressure action / any weighing more than 0.3 kg. Restrictions on electrical networks and electrical interference……….. no Detectability………………………………………….. metal detectors - less than 4 cm, RF detectors - less than 5 cm, odorant detectors - 25-40 cm. Time and calculation for installing a mine……………………… 4 min. 1 person

Planting a mine is quite safe. From the moment the combat pin and pin of the mine cover are pulled out until the fuse is armed, depending on the ambient temperature, it takes 45 seconds. (at +40 degrees) up to 20 minutes (at -40 degrees).

After completing all the steps of bringing the installed anti-personnel mine into firing position, the cover pin and the combat pin are removed from the ML-7, after which the mines are masked. From the moment the pin is pulled out of the ML-7, its return to a safe position is impossible. After the deceleration time has expired, the ML-7 will definitely go into combat mode. If by this moment there is no load on it, then ML-7 will explode.

The minimum mass of the cargo must be at least 300 g. The ML-7 explosion occurs when the cargo moves upward by 3-5 mm.

Mines are packed in boxes of 72 sets (gross weight 24 kg) not fully equipped. Box dimensions 65.8x59.8x20.6cm. Additional detonators are stored in the same box, separate from the mines.

The color of the mines is grayish-blue. It can be olive, sandy yellow, yellowish-gray. The marking is applied mechanically (extruded) on the mine cover and is standard (mine code, manufacturer code, batch number and year of manufacture. Some batches of mines are not marked.

The mine was adopted by the Soviet Army in 1984 and was used quite widely during the war in Afghanistan (1979-89) in the period 1985-86. and during both Chechen wars (1995-96, 1999-02). Quite significant quantities of these mines remained in the former Soviet republics (Tajikistan, Kazakhstan, Kyrgyzstan, Turkmenistan, Ukraine, Belarus). Therefore, it is possible that these mines may appear in regions of local conflicts.

The reason for the adoption of the ML-7 mines was that by 1983, the dushmans began to remove significant quantities of anti-personnel mines of the PMN and PMN-2 type installed by the Soviet troops and actively use them in battles against Soviet units. It was impossible to use MS-3 mines as an anti-removal device due to the low weight of anti-personnel mines such as PMD-6m, PMN, PMN-2, and MS-4 mines were too expensive.

The installation by Soviet sappers of anti-personnel mines with homemade anti-removal devices repeatedly led to accidents, and the time for mining sharply increased, while the quality of the improvised anti-removal elements was low.

All this caused the appearance of ML-7 mines, and very few of them were used, about 1-2 thousand over a period of 9-11 months of 85-86, after which the dushmans almost universally abandoned the removal of Soviet anti-personnel mines and returned to the proven simple and an effective method of demining - driving large flocks of sheep through suspicious areas.

Veremeev Yu.G.

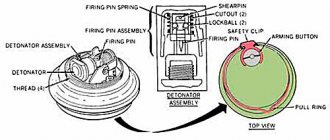

Operating principle

When the load is removed from the mine, the rod rises under the action of the spring, and the combat protrusion disengages from the firing pin. It should be remembered that the MS-3 explosion occurs when the load moves upward by only 3-5 mm.

The firing pin is released, under the action of the mainspring it passes through the rod window and pierces the M-1 detonator cap, which explodes and causes an explosion of the tetryl block and explosive charge.

If an MS-3 mine is installed under an anti-tank mine, the detonation is transferred to the anti-tank mine charge.

Installation procedure

The MS-3 mine is used as an anti-removal element when installing anti-tank mines, as well as for mining military and household items that the enemy can use. These items are used as cargo installed on the MS-3 mine and must have a mass of at least 5 kg.

Examples of installing an MS-3 booby trap:

Examples of installing an MS-3 booby trap.

A - under an anti-tank mine when installing it in a non-removable position;

B - under the box;

B - between boxes in a stack. 1 — MS-3 mine; 2 - anti-tank mine; 3 - boxes.

To install the MS-3 mine you need:

1. Prepare a hole for installing the MS-3 mine (when installing the MS-3 mine under an anti-tank mine, the hole comes off at the bottom of the hole for the anti-tank mine).

2. Unscrew the cap of the impact mechanism and check the serviceability of the cutter and the presence of a metal element; if necessary, replace it (the metal element for installation at temperatures above 0°C has red ends, the metal element for installation at temperatures below 0°C has white ends).

3. Screw on the cap.

4. Unscrew the plug, install the MD-9 fuse into the mine and screw the plug all the way.

5. Install the MS-3 mine in the hole so that the protrusion on the cover rises above the level of the top of the hole; if necessary, install the rod head on the protrusion of the cover.

6. Hook the hook onto the ring of the safety pin.

7. Place a load (anti-tank mine) on the MS-3 mine so that the load (anti-tank mine) presses on the head of the rod or the protrusion of the cover and closes the MS-3 mine.

8. Holding the anti-tank mine (load) from moving with your left hand, pull out the safety pin with a hook.

9. Conceal the MS-3 mine and anti-tank mine.

When mining various objects, the MS-3 mine is installed in the ground under the object or can be clamped between objects, for example, between boxes with military equipment (ammunition, food) stacked.

MS-3 mines installed in thawed ground under anti-tank mines and under various objects can spontaneously detonate when the ground freezes as a result of soil heaving, leading to the removal of the load from the mine.

Surprise mines

The MS-3 mine is intended for installing anti-tank mines in a non-retrievable position and for setting various kinds of traps (surprises). High-explosive mine with unloading action. Mina is very similar in appearance to PMN. It is distinguished by the presence of a protruding vertical mine fuse rod, covered with a rubber cover in the shape of a truncated cone.

Tactical and technical characteristics of the SM mine:

- mine weight - 660 g;

- explosive mass – 340 g (TNT);

- mine diameter – PO mm;

- mine height - 65 mm;

- minimum load weight – 5 kg.

The MS-4 mine is intended for mining business, personal or household items in order to destroy manpower. It can be used as an anti-train fuse when mining railways and as an object mine fuse when destroying various structures.

The body of the mine is rectangular in shape. There are no inscriptions on the body. MS-4 can be set to trigger from:

- vibrations, removal from place;

- changes in the angle of the mine (tilt by 20 degrees);

- after the set deceleration time has elapsed. Tactical and technical characteristics of the MS-4 mine:

- mine weight - 410 g;

- explosive mass – 120 g (TNT);

- mine length – 155 mm;

- mine width – 92 mm;

- mine height – 31 mm;

- minimum load weight – 5 kg.

The ML-7 booby trap is designed to place anti-personnel pressure mines in a non-retrievable position. The mine consists of a rectangular plastic body, an explosive charge (2 rectangular PVV-5A bombs weighing 15 g each), a discharge fuse and two additional detonators.

Explosive checkers are placed in plastic cases and can be removed from the mine if necessary. Additional detonators are explosive (PETN) blocks weighing 5 g, which are attached to the mine body using spring latches (shown in the photo on the pressure sensor of the mine target).

Tactical and technical characteristics of the ML-7 mine:

- mine weight - 0.1 kg;

- explosive mass – 40g;

- mine length - 72 mm;

- mine width – 69 mm;

- mine height - 30 mm;

- minimum load weight - 300 g.

The ML-8 booby trap is designed for installing anti-personnel, anti-tank mines and explosive charges in a non-retrievable position, as well as for constructing booby traps when mining various objects. The body of the mine is plastic, rectangular in brown color with a white metal target sensor cover. Mine fuse is safety type, unloading action.

When the metal nut of the mine trigger (fuse cap) is unscrewed and the nylon thread hidden underneath is tensioned, the igniter primer is pierced (with a characteristic loud click) and the mine is transferred to the firing position after 120 - 150 seconds.

Tactical and technical characteristics of the ML-8 mine:

- mine weight - 370 g;

- explosive mass – 80 g (PVV-5 A);

- mine length - 114 mm;

- mine width - 60 mm;

- mine height – 40 mm;

- minimum load weight – 250 g.