Anti-tank mine TM-57 (Soviet and Russian mines)

Anti-tank anti-track mine. Designed to disable enemy tracked and wheeled vehicles. Enemy vehicles are defeated due to the destruction of their chassis when a mine charge explodes at the moment the wheel (roller) hits the pressure cover of the mine.

The photo shows a mine with an MVZ-57 fuse in firing position. On the side wall there is a clearly visible socket for an additional non-removable fuse, closed with a screw plug.

The mine can be installed both on the ground and in the ground, in the snow, under water, manually or by means of mechanization (trailed mine spreaders PMR-1, PMR-2, trailed minelayers PMZ-3, PMZ-4, tracked minelayer GMZ, helicopter mining system VMR-2).

The combat life of the mine is not limited. When the metal body of a mine is destroyed by corrosion, the sensitivity of the mine increases from 200-500 kg. up to 3-5 kg. The mine is not equipped with a self-destructor.

The TM-57 mine was the first anti-tank mine in the Soviet Army designed to meet the requirements of a mechanized installation. Thus, the carrying handle is placed on the bottom of the mine and secured with a pin to prevent spontaneous rotation so as not to jam the minelayer feeding mechanism. To use the mine by means of mechanization, an MVZ-57 fuse was developed for it, which has a mechanism for slowing arming. At the moment the mine passed through the minelayer’s conveyor, a special mechanism pressed a button on the fuse body, causing the clock mechanism to work, which transferred the fuse to the firing position in 2-3 minutes.

The mine can be used with fuses MV-57, MVSh-57, MZK, MVZ-57. The first three fuses are intended exclusively for manual installation. MVZ-57 can be used for both mechanized and manual installation. To set the mine to be non-removable, there is an additional point on the side of the mine body for screwing in an MUV fuse with an MD-5M fuse. The point is clearly visible in the picture to the right of the marking.

Tactical and technical characteristics of the mine

Mine type………………………………………………………………anti-track Housing……………………………………………………… ……………metal. Weight…………………………………………………………………………………9 kg. Weight of the adult substance (TNT or TGA)…………………6.5 kg. Diameter………………………………………………………………………………32 cm. Height with MV-57……………………………………………………… ………………11.1 cm. Height with MVSh-57……………………………………………………27.2 cm. Target sensor diameter……………… …………………22cm. Sensitivity……………………………………………………200-500 kg. Temperature range of application………………-60 —+60 degrees.

The mine was intended to replace the obsolete TM-46 mine. Although the explosive charge itself did not increase so significantly (by only 800g), however, if the explosion of the TM-46 broke 3-4 track tracks, somewhat damaging the roller, then the explosion of the TM-57 and the roller rendered it completely unusable. The balancer was often damaged, or rather its bearing was broken.

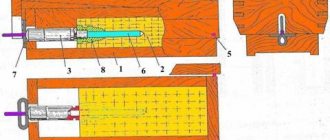

In the figure on the left, conventional colors show the target sensor (pressure cap) in brown, the fuse itself in yellow, and the additional point for the non-removable fuse in red. A mine explodes when the caterpillar hits the fuse or pressure cap. The MVSh-57 fuse is similar to the MVSh-46 fuse. The only difference is the size of the thread for screwing the fuse into the socket of the mine screwed into the point (the thread of the MVSh-57 is larger than that of the MVSh-46-46).

In the picture on the right is a mine with an MVSh-57 fuse.

The TM-57 mine turned out to be very successful, strong, and its fuses were simple and reliable. Therefore, even after the development and adoption of the TM-62 family of mines, the TM-57 mine continues to be used. It's still in production. It is often preferred by the troops due to its lighter weight than the TM-62, larger target sensor area, and, therefore, the likelihood of hitting the tank. An additional socket for non-removable installation distinguishes it favorably from the TM-62, which does not have this socket. The point here is not only that in order to install the TM-62 for non-detachment, it is necessary to install an MS-3 surprise mine under it; and the TM-57 can be installed using a simple MUV fuse with an MD-5M fuse. This additional socket also allows you to screw an EDPr electric detonator or another fuse using an MD-5M fuse into a mine, and use the TM-57 both as a conventional demolition charge and as a controlled mine.

A cross-section of the mine clearly shows the socket for an additional non-removable fuse on the side of the mine and its intermediate detonator. The main fuse of the MVZ-57 is in firing position.

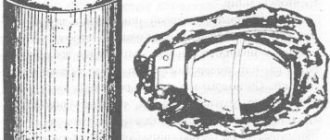

The figure shows the MVZ-57 fuse.

On the left, the fuze is shown upside down in a safe position. It is clearly visible that the detonator assembly with the trigger mechanism (analogous to the MV-5 fuse) is located horizontally, i.e. the fuse is in a safe position and no matter how hard you press on the mine, the trigger mechanism will not work and there will be no explosion. The trigger mechanism itself is shown in the center. On the right is the fuse in top view. The release button is shown in gray, held in place by a red safety bracket (the color is relative!) with a red ring. covering the fuse body.

Veremeev Yu.G.

Anti-tank mine TM-57 with MVZ-57 fuse

⇐ PreviousPage 10 of 12Next ⇒

The TM-57 anti-tank mine is designed to destroy enemy tanks, self-propelled guns, armored personnel carriers and other mobile equipment.

Design of a TM-57 anti-tank mine with an MVZ-57 fuse: 1 – body; 2 – shield; 3 – MVZ-57 fuse; 4 – diaphragm; 5 – charge; 6 – bottom; 7 – central additional detonator; 8 – side additional detonator; 9 – plug

The TM-57 mine consists of a body with a pressure part, which plays the role of a target sensor, a charge with two additional detonators and fuses MVZ-57, MV-57 or MVSh-57.

The body of 1 mine is made of steel and has a pressure part. At the bottom center of the lid there is a hole for screwing in the fuse. Diaphragm 4 separates the charging chamber from the lid. On the side there is an ignition socket with a thread for an electric detonator (ZTP ignition tube, MD-5M fuse). This socket is used when installing a mine in a non-removable position with a MUV-2 (MUV-3 or MUV-4) fuse. At the bottom of the 6th mine there is a folding handle for carrying. Charge 5 has two additional detonators: 7 and side 8.

How the mine works

When hitting an installed mine, its cover is deformed; the impact mechanism of the fuse, lowers down, is baked by a sleeve with a KD-MV detonator capsule into the mine diaphragm; with further pressing, the pin is cut off, the balls release the striker; under the action of the mainspring, the firing pin pierces the detonator cap, causing it to explode and the mine to explode.

Anti-tank cumulative mine TMK-2

The TMK-2 anti-tank cumulative mine explodes under the bottom of a tank, armored personnel carrier and other equipment.

Design of the TMK-2 anti-tank cumulative mine: 1 - extension; 2 - screw; 3 - fuse; 4 - fuse; 5 - cap; 6 - short circuit lining;

7-body; 8 - charge; 9 — lens; 10 — additional detonator; 11 - bottom; 12 — detonating device DUM-2; 13 — paws; 14 – bracket; 15 – glass.

Operating principle of the mine:

When hitting a mine fuse, the tube bends, the coils rotate, the rod pulls the cap out of the sleeve, as a result of which the balls release the firing pin, which, under the action of the mainspring, pierces the primer-igniter of the fuse, and from it the moderator ignites. After 0.3-0.45 s, i.e. when the middle part of the tank (vehicle) is above the mine, the detonator cap explodes from the moderator flame, and from it the tetryl bomb explodes. Its explosion is transmitted to the upper tip of the mine's detonating device (DUM-2), then to the detonating cord and then to the lower tip of the DUM-2, which detonates the additional detonator and the shaped charge of the mine.

Anti-tank mine TM-83

The TM-83 mine is an anti-tank, anti-aircraft, cumulative mine based on the principle of an impact core.

Main performance characteristics:

- Mine weight - 20.4 kg.

- Charge weight - 9.6 kg.

- Damage range - up to 50m.

- Cocking time - 1-30 minutes.

- Damaging effect - hole? 80 mm, in armor 100 mm thick.

- Fuse type - non-contact two-channel with seismic and infrared target sensors.

Set contents:

- Incompletely equipped mine - 1 pc.

- Optical target sensor (ODS) - 1 pc.

- Seismic target sensor (STS) - 1 pc.

- Safety actuator mechanism (PIM) - 1 pc.

- Closing mechanism - 1 pc.

- Bracket - 1 pc.

- Current source - 3 pcs.

- Pin - 1 pc.

- MZU control panel (for 10 fuses) – 1 pc.

- Packing box - 1 pc.

Anti-tank mine TM-89

The TM-89 mine is an anti-tank, cumulative high-explosive mine.

Main performance characteristics:

- The fuse type is non-contact magnetic with a built-in ampoule current source.

- Overall dimensions of the mine: height - 132 mm; diameter - 320 mm.

- Weight: mines - 11.5 kg; explosive charge (TG-40/60) - 6.7 kg; packages with mines - 63.5 kg.

- Long-range cocking time - 20-700 s.

- Installation method: manually, minelayer GMZ-3, equipment VMR-2.

- Set composition: Mine with fuse – 1 pc. Detonator – 1 pc.; Trigger mechanism – 1 pc.; Key - 1 for 4 mines

The mine consists of a warhead (mine body, explosive charge and built-in fuse) and an additional detonator.

Mines can be equipped with an A-332 type power source (in the absence of an MTs-0.7A ampoule current source).

The warhead of the mine has an explosive charge with a cumulative notch, a non-contact fuse of a magnetic operating principle, an overburden charge, and a pyrotechnic moderator

Operating principle of the mine:

After the cover of the remote mechanism is torn off and its thread is pulled out, or after the cover of the trigger mechanism is torn off after 20-700 s. The hydraulic retarder rod moves upward, releasing the HB engine. Under the action of the spring, the slider rotates, closing the contact, which ensures the connection of the current source to the electrical circuit. By turning the engine, the central CD is installed under the PIM cover, and the side CD is brought to the wall of the fuse casing. When a tank passes over a mine, the magnetic field changes. This change is sensed by the target sensor.

The target sensor produces a signal, which, after processing by the electronic circuit, is sent to the actuator, causing the activation of the electronic device, ignition of the pyrotechnic amplifier and initiation of both CDs. Triggering of the side CD causes the PIM cover to be cut off, the tip of which pierces the CD. At the same time, the PIM engine is released, which moves under the action of the spring, and the PIM CD is installed in line with the retarder and PZ. The igniter capsule ignites the moderator, triggering the CD, PZ, and detonator of the fuse of the main explosive charge of the mine.

Anti-personnel mines

Anti-personnel mines are designed to destroy enemy personnel. They are divided into: high-explosive, fragmentation, special.

Anti-personnel mines very often pop out of the ground with the help of a knockout charge and hit with fragments from above; “finger”, containing one pistol cartridge and striking a fighter with a shot in the foot at the moment when he steps on it.

High-explosive mines and bullet mines hit one person when they explode. When they explode, fragmentation mines can hit several people at the same time.

According to the principle of actuation, anti-personnel mines are divided into automatic and wire-controlled.

Mines that operate automatically have drive devices that are triggered by:

- from pressing a mine (in push-action mines);

- from tension (in tension mines).

Depending on the combat situation, terrain conditions and design features, anti-personnel mines are installed in the ground or on its surface; If the snow cover is deep, mines can also be laid in the snow. When installing mines in the ground, they are installed in holes dug according to the size of the mine so that the installed mine or its fuse rises slightly above the ground surface (mine by 1–2 cm, MUV-2 or MUV fuse by approximately half its length) and easily disguised as the surrounding background.

Mines are installed on the ground in the presence of vegetation (tall grass, bushes, crops), which well camouflages the installed mine.

If there is snow, mines are installed:

- with a snow depth of up to 10 cm - on the ground;

- at greater depths - on compacted snow with a masking layer of snow up to 5 cm.

Installation of anti-personnel mines on the ground is carried out only manually.

Mines installed with a MUV-2 fuse, as well as PMD-6 and PMN mines, are not subject to seasonal rearrangement and neutralization; they are destroyed at the installation site.

Anti-personnel mine PMD-6M

Anti-personnel mine PMD-6M: 1 - cover; 2 - fuse; 3 — rubber cap; 4 - metal element; 5 - cutter; 6 — safety pin; 7 - combat check; 8 - drummer; 9 — combat check;

10 - the body explodes; 11 — fuse MD-5M; 12 - metal plate;

13 — mine body; 14 - explosive charge; 15 - masking layer

⇐ Previous10Next ⇒

Recommended pages:

Ministry of Defense of the USSR - Anti-tank mine TM-57

3

— move the MV-57 or MVZ-57 fuse to a safe (transport) position and screw it into the mine, and unscrew the MD-10 fuse from the MVSh-57 fuse;

— place MVSh-57 fuses and MD-10 fuses in appropriate packaging;

- remove the mine from the installation site.

To transfer the MV-57 fuse from the combat to the safe (transport) position, you must:

— insert the pin with the bracket into the screw hole;

— by pressing your thumb, move the rotary bracket with the impact mechanism to a horizontal position;

— without releasing your finger, turn the screw a quarter turn to the left (counterclockwise);

— insert the bracket into the cap of the plug.

To transfer the MVZ-57 fuse from the combat to the safe (transport) position, it is necessary:

— take the fuse in your left hand with axis 20 (Fig. 3) of the mainspring towards the thumb;

— put the key on the end of the axis 20 of the mainspring;

— turn the axis to the right (clockwise) so that the tooth of the sector stop 37 moves away from the rotary bracket of the impact mechanism;

— press the thrust nut 38 with your right hand and turn the impact mechanism to a horizontal position;

— holding the hammer mechanism in a horizontal position with the thumb of your left hand, insert the blade of a screwdriver key with your right hand between the fuse body and the thrust pawl 34;

— place the pawl under the rotating bracket 8 of the impact mechanism; in this case, the starter button will rise, and the switch 26 will engage with the balancer of the deceleration mechanism;

- use a screwdriver to wind the mainspring until the tooth touches the sector stop of the rotary bracket;

— insert the safety pin under the starter button so that its legs cover the rod and are firmly held on the button, and secure the pin ring to the body.

1.6. STORAGE AND TRANSPORTATION

TM-57 mines are stored and transported in wooden boxes or cylindrical packaging made of plywood or paper casting, 5 pieces each.

In the military, TM-57 mines can be transported and carried equipped with MV-57 or MVZ-57 fuses if they have safety checks.

Transportation of mines with MV-57 and MVZ-57 fuses in bulk (without packaging) is prohibited.

Storage and transportation of mines equipped with MVSh-57 fuses is prohibited.

Fuzes MV-57 and MV3-57, when stored separately from mines, are placed in metal boxes - MV-57, 15 pcs., MVZ-57, 10 pcs. A winding screwdriver key is placed in each box with MVZ-57 fuses.

The pins in the MV-57 and MVZ-57 fuses are screwed in.

MVSh-57 fuses are stored and transported in wooden boxes of 20 pieces. in everyone. MD-10 fuses for them are stored and transported separately from fuses in wooden boxes. Each box contains 54 metal boxes containing 20 fuses. There are a total of 1080 fuses in the box.

2. INSTRUCTIONS FOR USE

Anti-tank mines are designed to mine terrain against enemy tanks, self-propelled artillery units and armored personnel carriers.

Anti-tank mines, as a rule, are installed in the ground with camouflage with a layer of soil by means of mechanization or manually.

Mechanization means ensure the installation of mines in the ground with camouflage with turf (Fig. 6) and soil (Fig. 7).

When installing mines in the ground manually, the thickness of the masking layer of earth above the mines should be 5–8 cm. The mines are carefully camouflaged to match the background of the surrounding area.

When installing anti-tank mines in the ground, round or square holes are torn off for them in accordance with the size of the mines. If the ground has a grassy cover, then the turf is cut and rolled towards the enemy, as shown in Fig. 8.

In hard ground, anti-tank mines are installed in holes so that the mine cover rises 2–3 cm above the ground surface (Fig. 9), and in soft ground it is flush with the ground surface.

On roads, mines are installed in the same way as in hard soils, and are masked with a thin layer of road material (soil, crushed stone, gravel, etc.).

In swampy areas, boards, poles, branches and similar objects are placed under the mine, the dimensions of which are 2-3 times the diameter (width) of the mine (Fig. 10).

Placing mines in depressions and potholes, as well as next to stumps, boulders, hummocks, etc. is prohibited.

It is permitted to remove mines from their installation site if they were installed without anti-removal elements. Mines installed in a non-retrievable position, mines with damaged covers and bodies are subject to destruction at the installation site by an explosion of overhead explosive charges.

Rice. 6. Installing a mine in the ground with camouflage with turf

Rice. 7. Installation of a mine with camouflage with soil

Rice. 8. Installing a mine on grassy ground

Rice. 9. Installing a mine in hard ground

Rice. 10. Planting a mine in a swampy area

Mines, the retrievability of which has not been reliably established, are pulled from the place of their installation with cats, being at a safe distance or in shelter, after which unexploded mines are neutralized or destroyed.

3